Common Non-Standard Mechanical Design Errors and How to Prevent

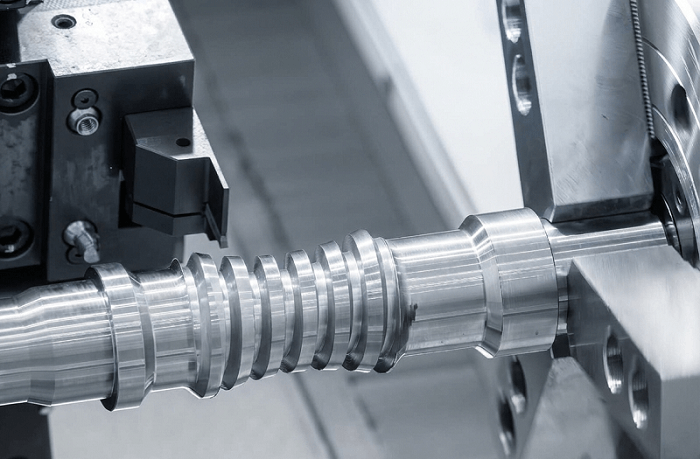

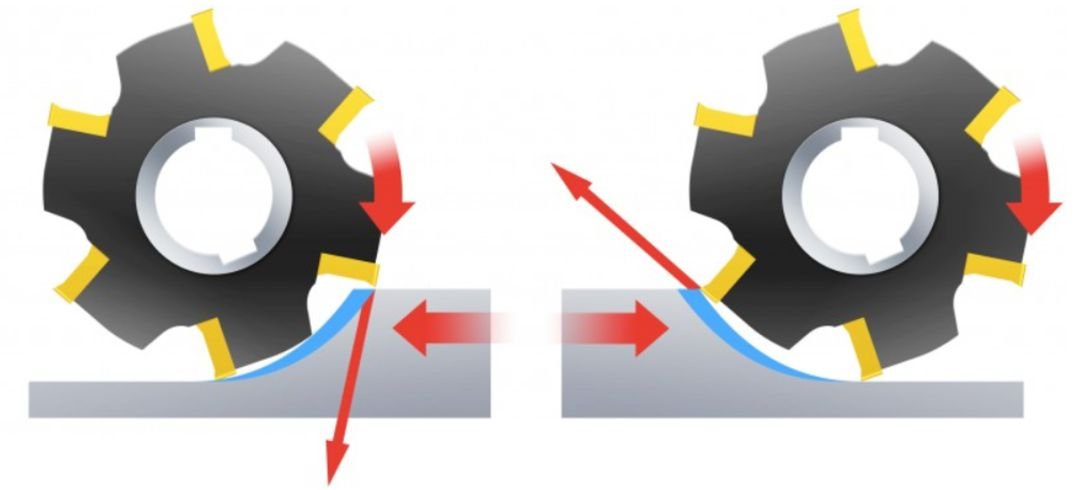

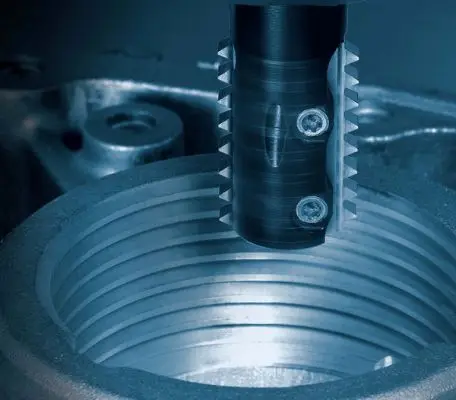

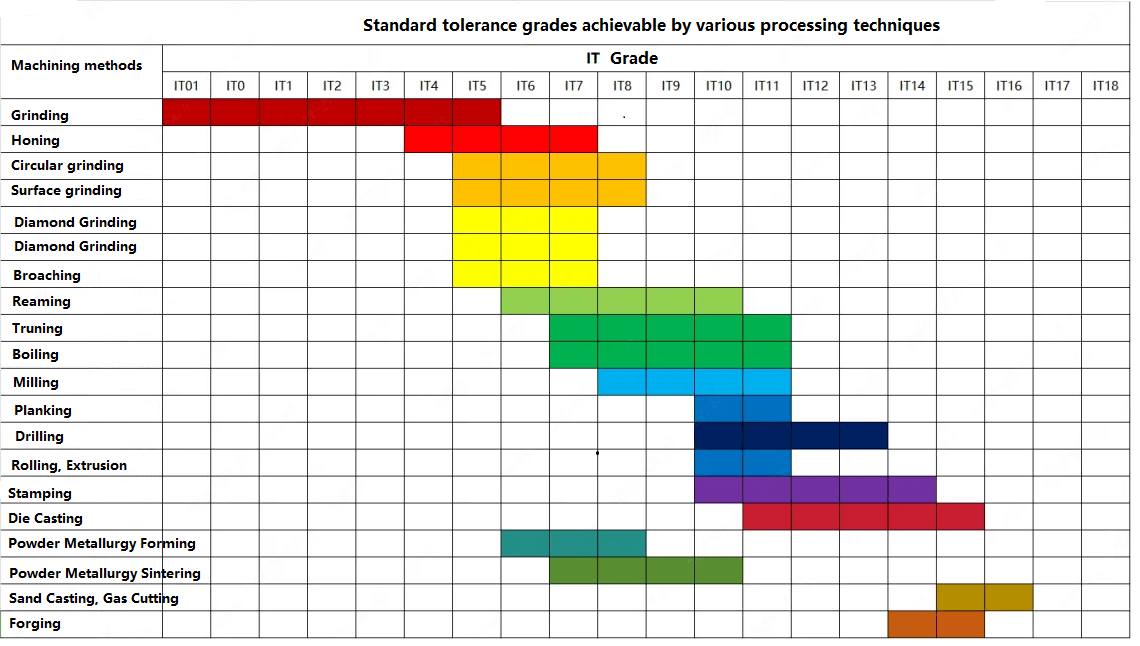

Common mechanical design mistakes in non-standard equipment development, including material selection errors, tolerance issues, structural interference, lubrication design, assembly problems and safety risks. Learn how to optimize design before CNC machining to reduce cost and prevent production failures.