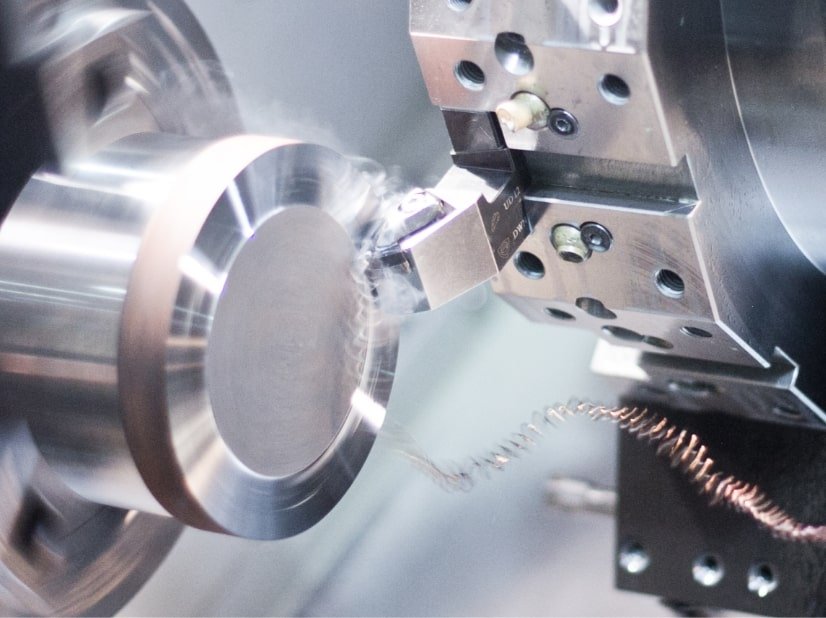

Case Study: Preventing Deformation in Sheet Metal Processing

This article presents machining solutions for simple thin plates, complex thin plates, and ultra-thin plates based on practical case studies, ensuring compliance with product precision requirements.