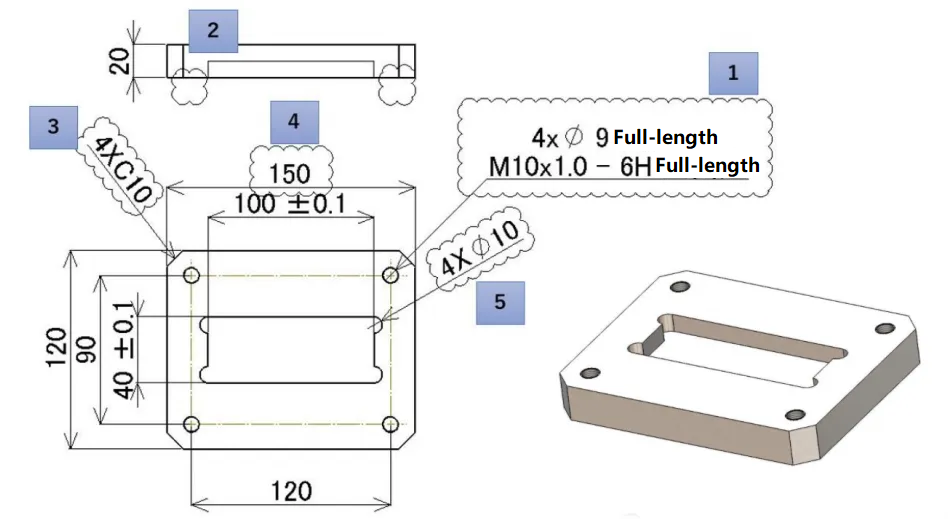

Case Study: High-Tolerance Aluminum Datum Block for Printer Equipment

Discover how our precision machining expertise solved the challenge of manufacturing an aluminum datum block with a ± 0.01 mm tolerance and complex geometric requirements.

Company News, Industry Information, and more.

Discover how our precision machining expertise solved the challenge of manufacturing an aluminum datum block with a ± 0.01 mm tolerance and complex geometric requirements.

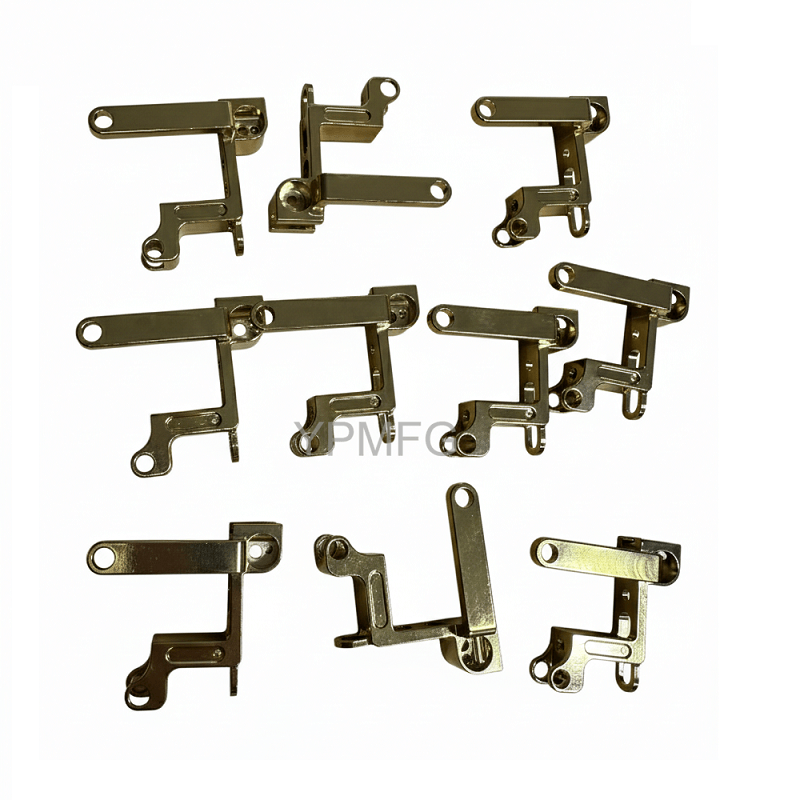

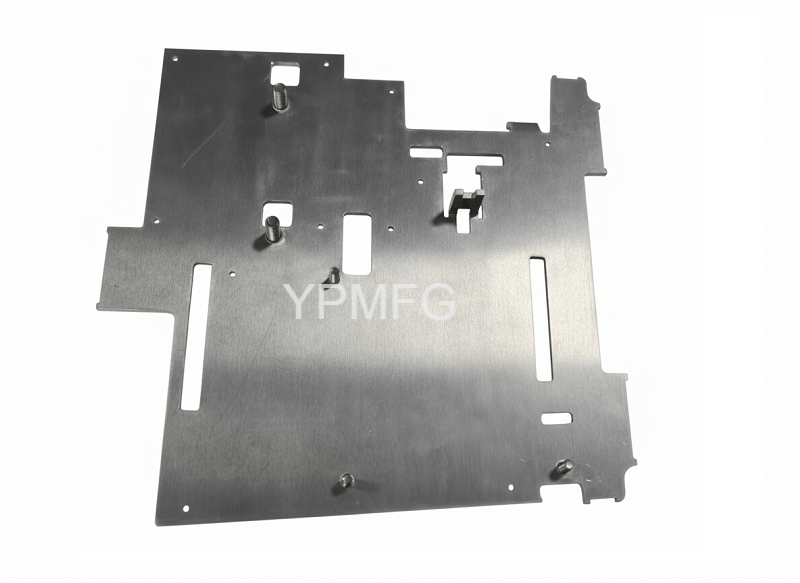

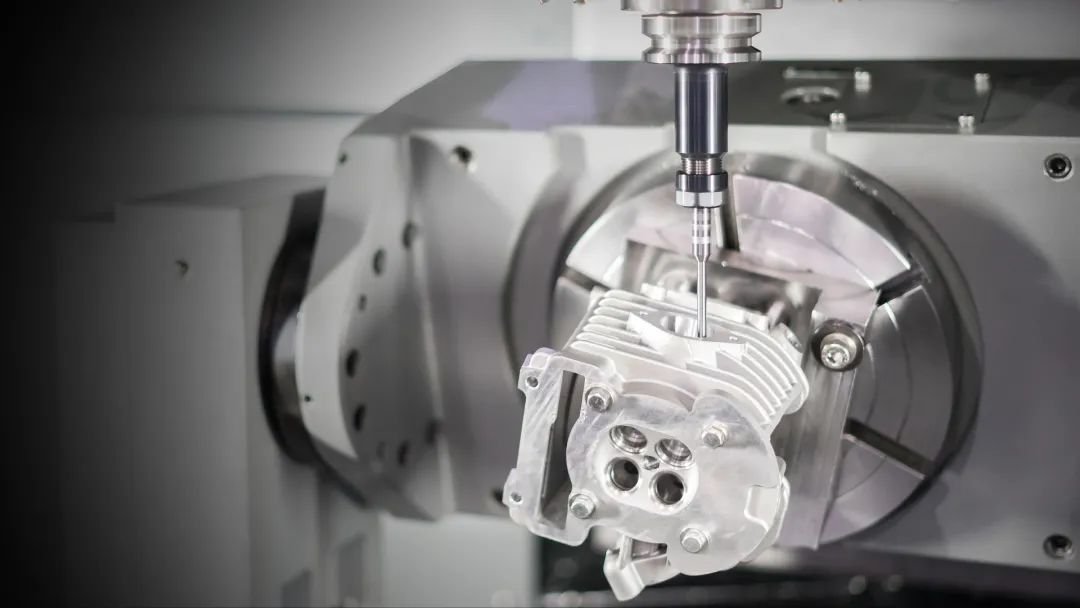

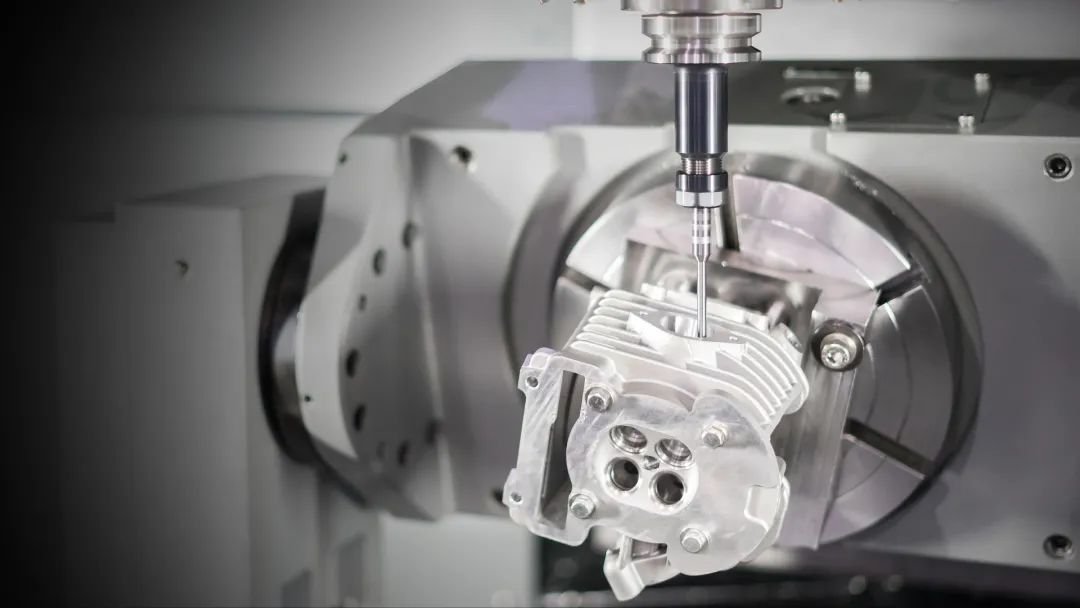

This project involved the custom CNC machining of precision mechanical components used in industrial machinery and equipment assemblies. The customer required stable dimensional accuracy, reliable assembly fit, and durable surface protection for parts operating in a mechanical environment with frequent installation and disassembly.

Common challenges in precision sheet metal enclosure manufacturing, including bending accuracy, deformation, welding defects, surface finishing, and hole positioning—with proven solutions to improve quality and assembly efficiency.

CNC machining case study of carbon steel tattoo machine components. Learn how precision machining ensures strength, consistency, and reliable assembly.

Simple-looking parts can receive surprisingly high CNC quotes. Learn which drawing details increase machining cost and how to optimize designs to reduce price.

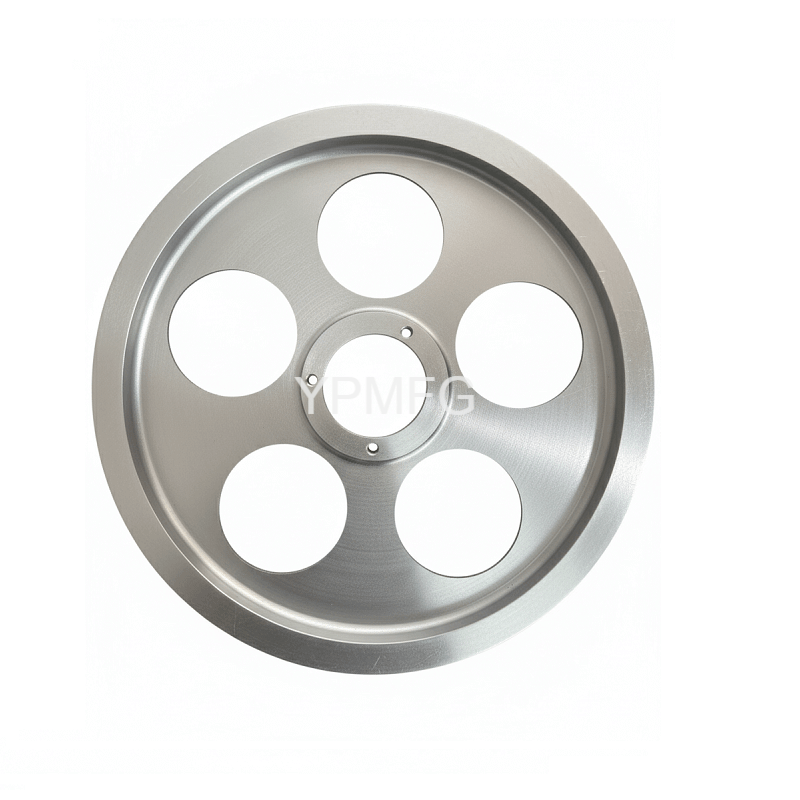

This case study highlights the successful CNC precision machining of a custom gearbox component featuring complex hole patterns, multiple bolt circle diameters, and critical positional tolerances. The part plays an important role within a gearbox and motor transmission system, where machining accuracy directly affects assembly alignment, operational stability, and service life.

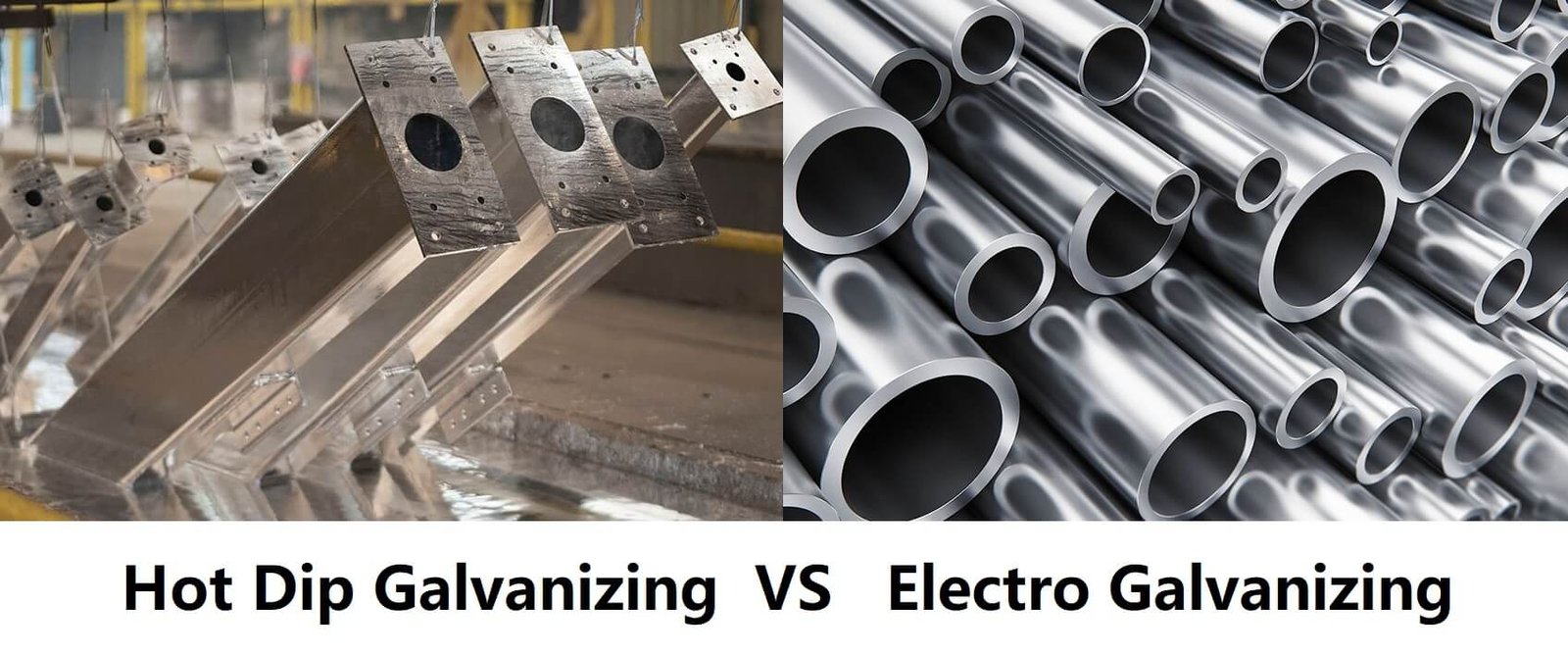

Hot Dip Galvanizing (HDG) and Electro-Galvanizing, though differing by only one word vary significantly in their process principles, anti-corrosion performance, and application scenarios. This article provides an in-depth analysis of both techniques from a materials science and engineering application perspective.

Discover how we manufactured high-precision automotive bonnet hinge arms and strut mounts. Case study on controlling distortion in long machined parts and 5-axis solutions

Explore how we custom machine high-reliability, corrosion-resistant 5052 aluminum battery mounting plates for the marine industry. We focus on complex bending, precision riveting, and tight tolerance control for cost-effective marine components.

Learn how to reduce CNC machining costs with 13 practical design-for-manufacturability (DFM) tips. Discover how to optimize materials, tolerances, cavity depth, wall thickness, and part geometry to save time and cost without compromising quality.

When sourcing mechanical components, finding a reliable machining factory is essential to ensure product quality and on-time delivery. A good supplier not only delivers high-precision parts on schedule but also provides technical support and services that help customers reduce costs and improve competitiveness.

Here are 10 key points of a quality machining factory that procurement teams can use as a reference when evaluating potential suppliers.

This article systematically introduces cost control strategies throughout the entire process, from design to manufacturing, providing practical and comprehensive guidance.

As the wave of Industry 4.0 continues to deepen, the manufacturing industry is undergoing a profound transformation toward intelligence and digitalization. As a cornerstone of modern manufacturing, CNC machining must proactively embrace this trend, transitioning toward intelligent, digital, and networked production models.

Face milling is indispensable in the metalworking industry, which is undergoing significant transformation. Without face milling, the complexity of machining processes would be unimaginable. This technique achieves precision and surface quality improvements by generating flat surfaces to complete reference surfaces.

In this guide, we explore how CNC prototype machining works, its advantages and limitations, key applications across industries, and practical tips for making prototypes that closely resemble the final product, helping you accelerate development, reduce risk, and bring better products to market faster.

A reamer is a rotary cutting tool featuring one or more cutting teeth designed to remove a thin layer of metal from the surface of a machined hole. It is a precision finishing tool with straight or helical flutes, used for reaming or finishing holes.

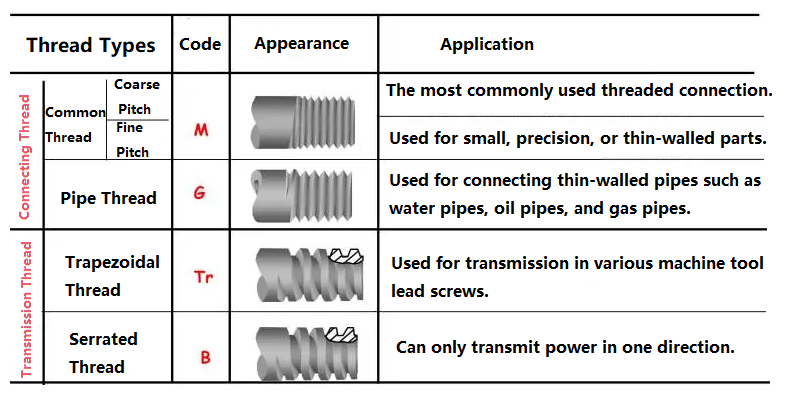

Threads are one of the most common structures in mechanical connections. This article systematically explains the basics of threads, including their classification, elements, marking methods, drawing techniques, and a common comparison table.

CNC precision machining has become an essential process for producing high-quality parts with extreme accuracy. From aerospace turbine blades to custom medical implants, industries increasingly rely on CNC precision machining to meet demanding requirements.

YP-MFG is a leading manufacturer specializing in high-precision metal parts and CNC machining services.

Building A6, The Third Industrial Zone, Fenghuang Community, Fuyong Street, Bao’an District, Shenzhen

Copyright YP-MFG © 2026 All Rights Reserved

Click To Chat

I'm online now.

Hello, this is Judy from YPMFG. How can I assist you today? If you would like to get a free quote or have any questions, feel free to email us at sales@yp-mfg.com

WhatsApp Us

🟢 Online | Privacy policy

Chat with us