How to Avoid Stress Deformation in Titanium Alloy Machining

Titanium thin plate parts often deform due to machining stress, causing scrap and poor accuracy. This article explains causes and proven solutions to control deformation.

Company News, Industry Information, and more.

Titanium thin plate parts often deform due to machining stress, causing scrap and poor accuracy. This article explains causes and proven solutions to control deformation.

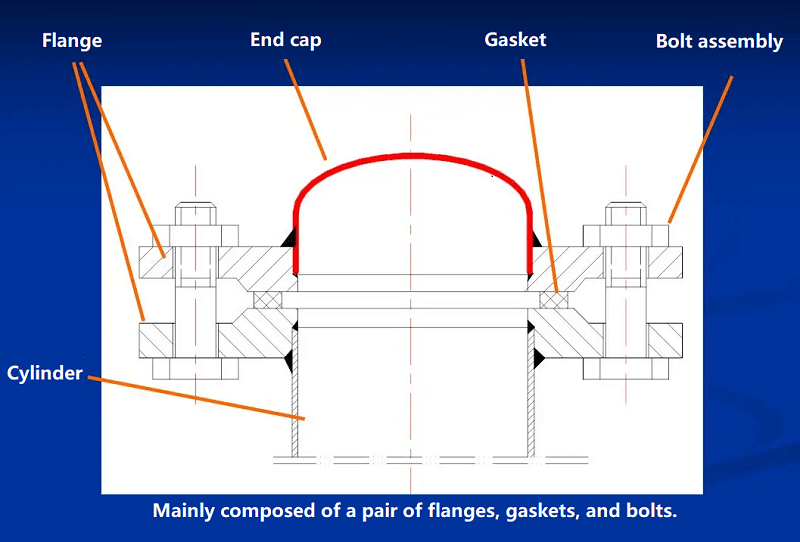

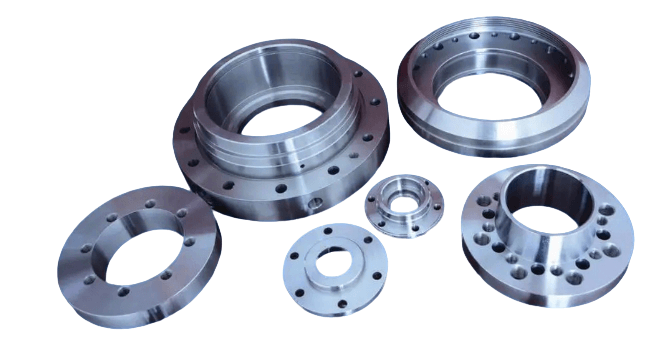

Comprehensive Analysis of Flange Structure and Working Principles Detailed Explanation of Application Differences Between Butt-Weld Flanges, Slip-On Flanges, Loose Flanges, and Threaded Flanges Introduction to Flange Sealing Surfaces, Gasket Performance, and Key Parameters like DN and PN Summary of Common Pressure Vessel and Pipe Flange Standards Assisting in More Accurate Engineering Selection

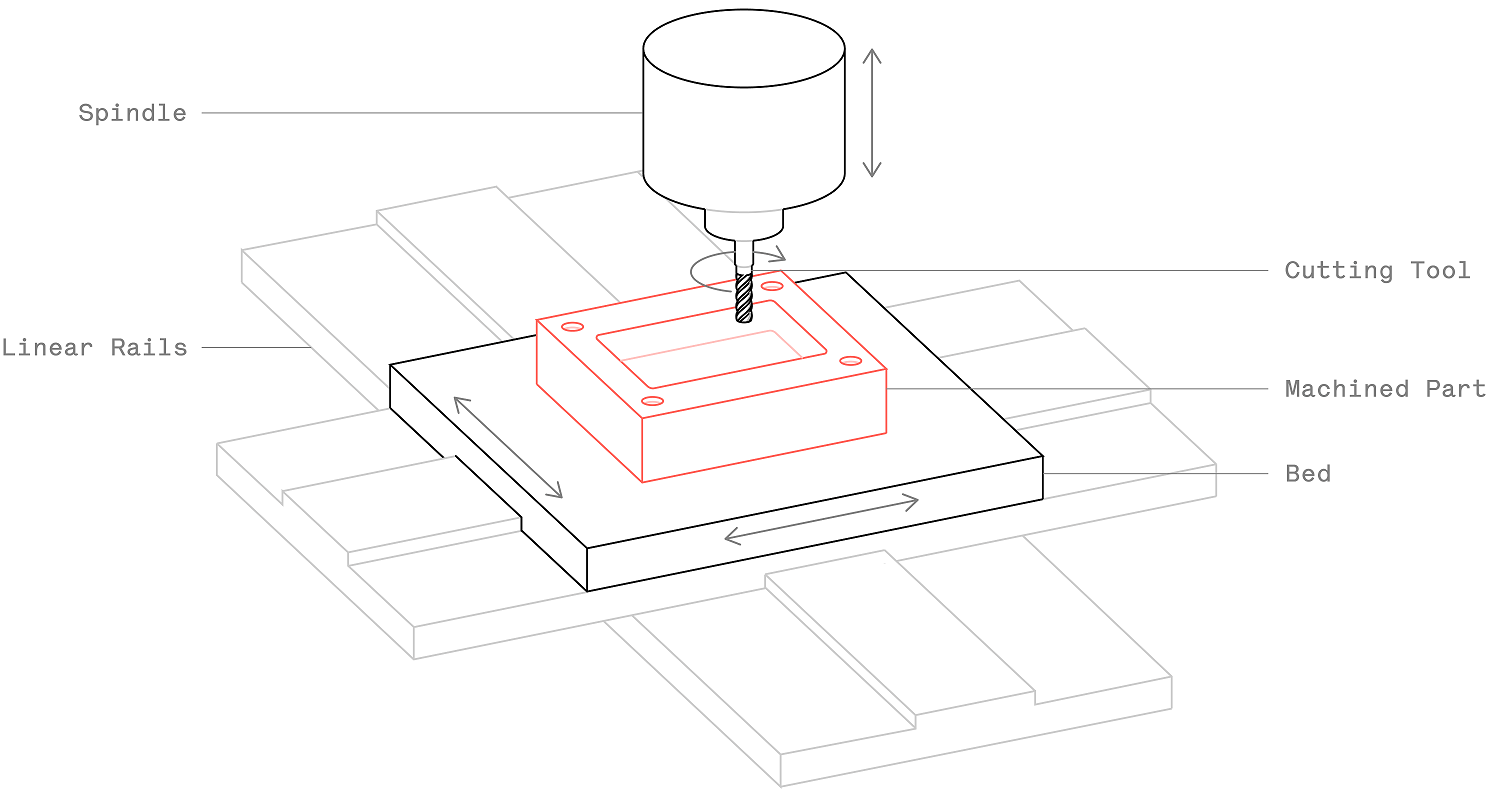

Practical CNC machining experience shared by a skilled machinist, covering roughing, corner clearing, semi-finishing, and finishing strategies, including tool selection, fixturing methods, toolpaths, and common mistakes to avoid.

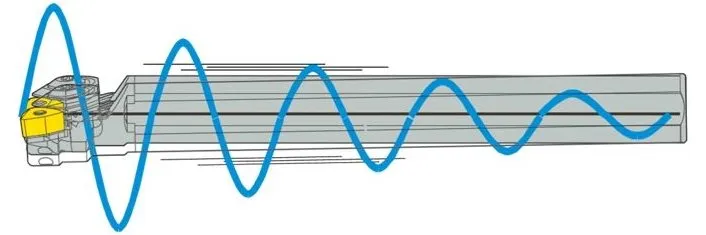

Excessive machining vibration causes scrap, rework, and tool failure. This guide explains vibration mechanisms and provides actionable tips to improve CNC milling, turning, and boring stability for consistent, high-quality results.

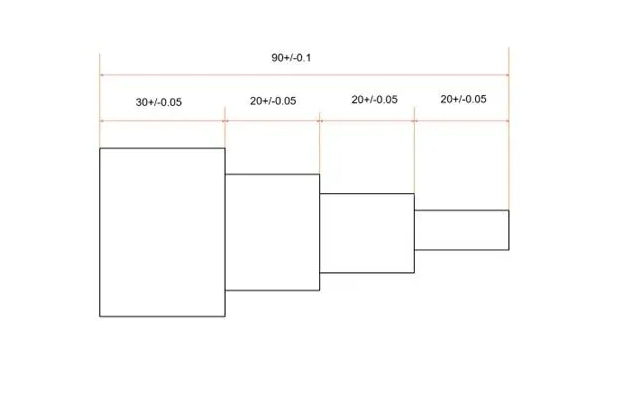

Tolerance stacking is a common but often overlooked issue in manufacturing and assembly. This article explains how tolerance stacking occurs, the risks it creates for machining and fit, and how GD&T, proper dimensioning, and automated assembly help control tolerance accumulation.

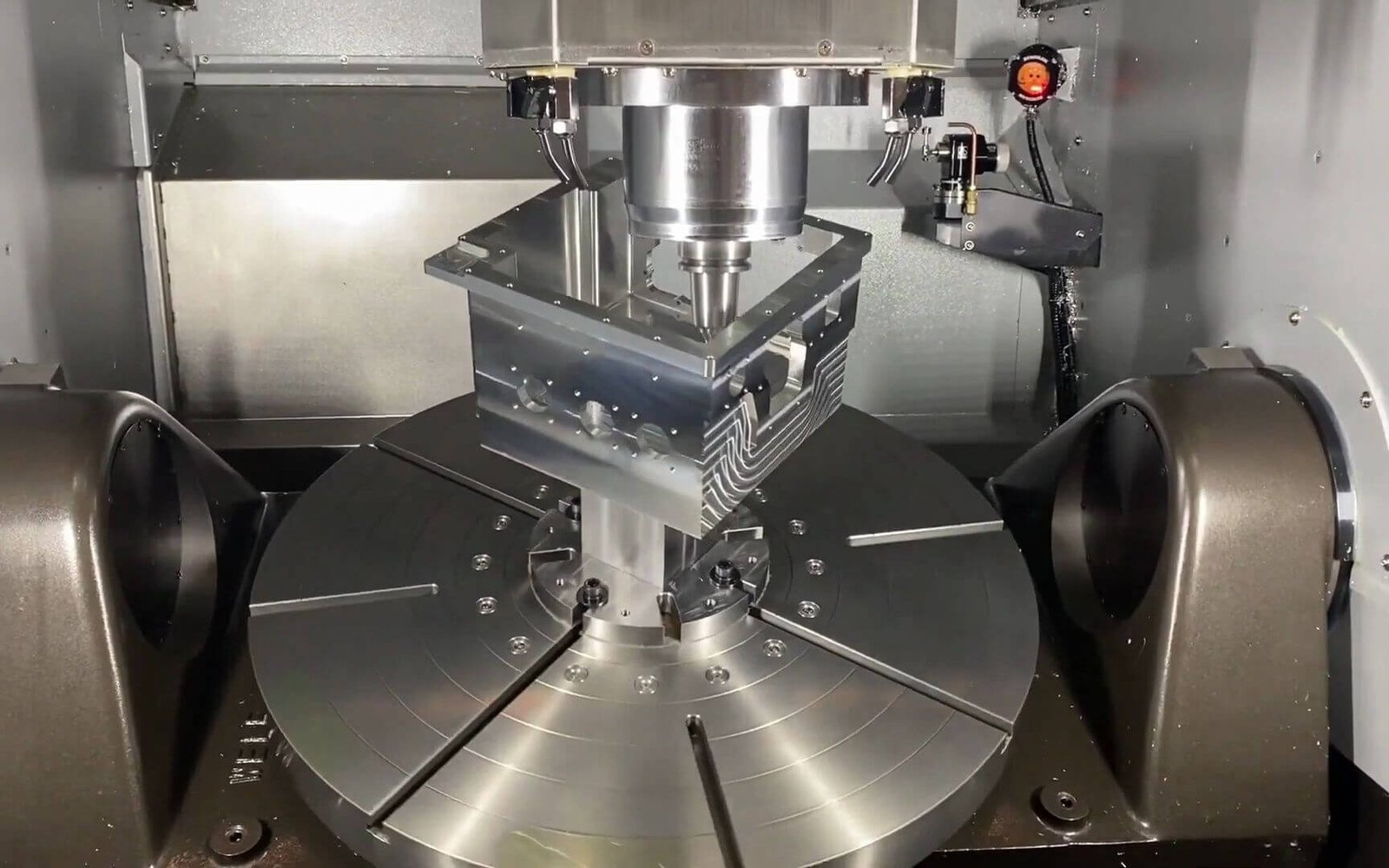

This study analyzes CNC machining solutions for medical device manufacturing , including orthopedic implants and surgical instruments, and explores CNC solutions such as 5-axis machining, mill-turn centers, and precision grinding.

A Comprehensive Guide to Fastener Classification: Understand the structural forms, application differences, and selection principles of 12 fastener categories for quick identification.

This compilation covers 12 essential simplified drawing methods for mechanical drafting, including standardized techniques for holes, slots, teeth, intersecting lines, and break-out methods. These techniques enhance drafting efficiency and are recommended for engineers and mechanical designers to bookmark for reference.

Discover how YPMFG delivered high-precision aluminum 6061 array hole plates within 6 days. This case study details part fabrication tailored to cutting tool industry requirements, ISO 2768-f tolerance control, anti-scratch processes, and gold anodizing solutions. It showcases our top-tier manufacturing capabilities in custom machined parts.

CNC machining applications in humanoid robot manufacturing, including joints, exoskeletons, transmission systems, and electronic components for high-precision, custom, and efficient production.

In the field of precision manufacturing, the surface quality of CNC machined parts directly affects both product performance and aesthetics. Scratches, a common surface defect, not only reduce the dimensional accuracy of workpieces but can also shorten their lifespan. So, how can scratches be effectively prevented in actual machining operations? This article provides an in-depth analysis from multiple perspectives.

This article provides a systematic technical guide to CNC machined part design, analyzing structural design, tolerance control, and five-axis machining features to help achieve high-precision manufacturing.

To overcome these influencing factors, CNC milling machine operators need to have a comprehensive understanding of the elements that affect machining accuracy. After gaining sufficient practical experience, they should analyze these factors and adopt effective solutions to minimize or eliminate their impact, thereby improving the precision of CNC milled parts.

how to choose the right machining methods and processes for different types of parts. Learn key process points for shafts, gears, housings, castings, and more with YP-MFG’s CNC machining expertise to improve part precision and manufacturing efficiency.

Learn about the core machining processes for precision medical device manufacturing. From cutting, lasers, and EDM to 3D printing, we offer an in-depth analysis of the applications and development trends of CNC precision machining in the medical industry. YPMFG provides professional medical device precision machining services.

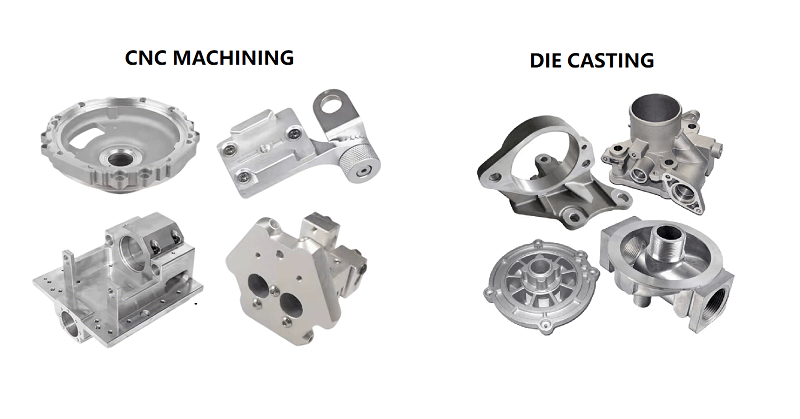

For design engineers or purchasing specialists, making an informed choice between the two directly impacts product cost, performance, and delivery schedule. This article provides an in-depth comparison of their principles, suitable applications, and economic efficiency, offering a scientific basis for your process selection.

This guide systematically introduces the fundamentals of threads, standard systems, machining methods, and key design considerations in CNC machining, aiming to help engineers and manufacturers achieve efficient and high-precision thread production.

Learn about the design and manufacturing of shaft components, from shaft types and force analysis to material selection and processing techniques.This article provides an authoritative shaft design reference, covering common types such as drive shafts, main shafts, and axle shafts, along with their technical requirements.

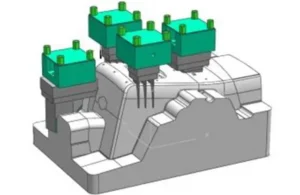

Tips for optimizing EDM electrode design to improve machining precision and efficiency. This guide shares expert insights and proven techniques used in electrical discharge machining.

Complete guide to forging processes, including key types, common methods, advantages and disadvantages, and real-world industrial applications. Perfect for engineers and manufacturing professionals.

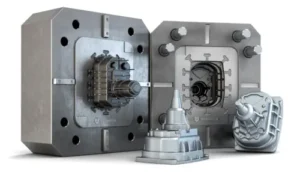

The metal die-casting molding process, or die-casting for short, is a casting method in which molten metal is rapidly injected into the cavity of a precision metal mold under high pressure and cooled and solidified under pressure to form a casting. This process, with its high speed and high pressure, is capable of producing metal parts with complex shapes and thin-walled cross-sections.

Titanium machining is tough due to heat and wear issues. Find out how to tackle these problems with the right tools, cutting fluids, and optimized techniques.

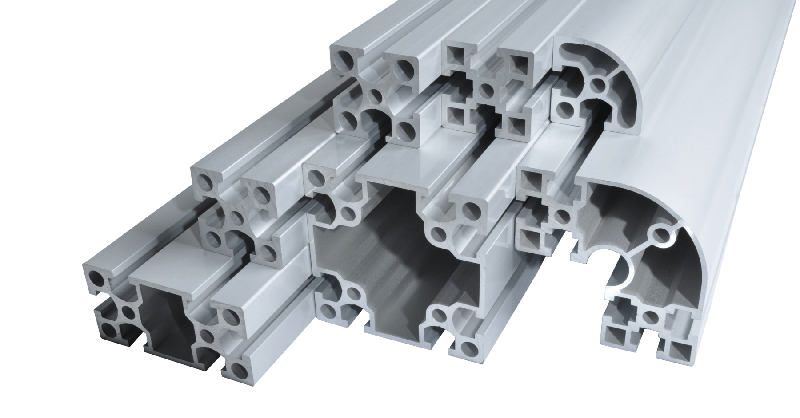

Aluminum and its alloys play a key role in many fields with their excellent properties, including low density, high strength, good conductivity, superior corrosion resistance and excellent forming performance. In addition, it maintains its performance at low temperatures, does not magnetize, does not spark on impact, and has sound absorption and nuclear radiation resistance.

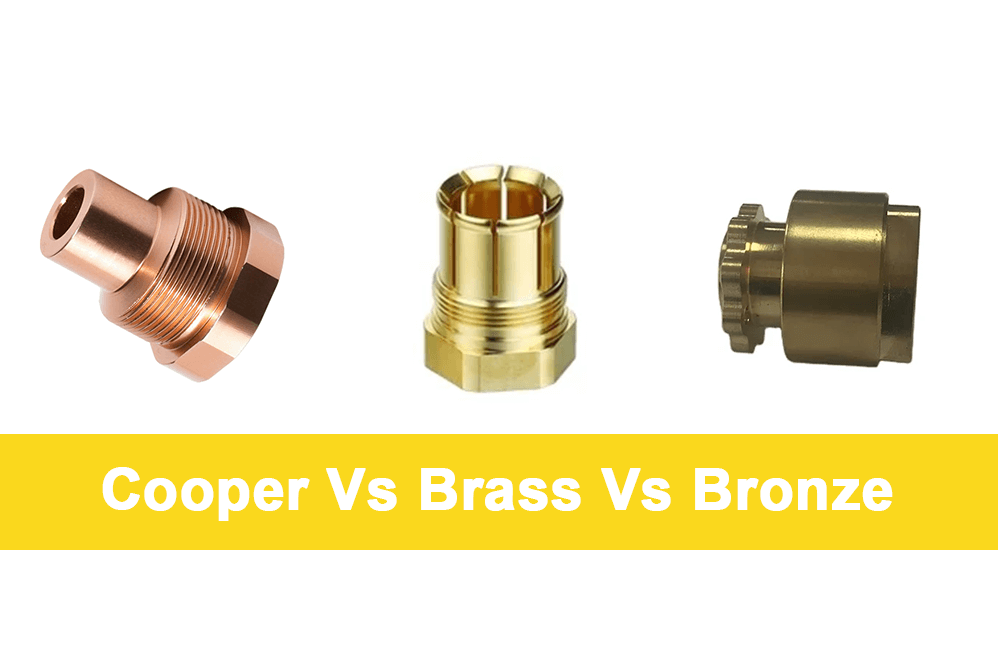

Differences between brass, bronze, and copper, including their properties, pros and cons, machining challenges, and how to select the best metal for your project. Get expert metal machining services with YP-MFG.

Professional analysis of aluminum alloy hard anodic oxidation technology: sulfuric acid process parameters, film properties, series alloys and solutions. Enhanced wear resistance for hydraulic components, aerospace parts.

YP-MFG is a leading manufacturer specializing in high-precision metal parts and CNC machining services.

Building A6, The Third Industrial Zone, Fenghuang Community, Fuyong Street, Bao’an District, Shenzhen

Copyright YP-MFG © 2026 All Rights Reserved

Click To Chat

I'm online now.

Hello, this is Judy from YPMFG. How can I assist you today? If you would like to get a free quote or have any questions, feel free to email us at sales@yp-mfg.com

WhatsApp Us

🟢 Online | Privacy policy

Chat with us