A Guide to Common Measurement Tools in Machining

Essential measurement tools used in machining, including calipers, micrometers, gauges, and more. Learn how each tool ensures precision and quality in manufacturing.

Company News, Industry Information, and more.

Essential measurement tools used in machining, including calipers, micrometers, gauges, and more. Learn how each tool ensures precision and quality in manufacturing.

The metal die-casting molding process, or die-casting for short, is a casting method in which molten metal is rapidly injected into the cavity of a precision metal mold under high pressure and cooled and solidified under pressure to form a casting. This process, with its high speed and high pressure, is capable of producing metal parts with complex shapes and thin-walled cross-sections.

Learn effective aluminum machining strategies to minimize deformation in aluminum alloy parts — from symmetric milling and tool selection to clamping techniques and optimized cutting parameters.

CNC Milling is an efficient, flexible and widely used processing method, suitable for everything from rough machining to precision parts molding. This article will systematically sort out the main methods, typical processing strategies, and commonly used calculation formulas of milling to provide a practical reference for your processing projects.

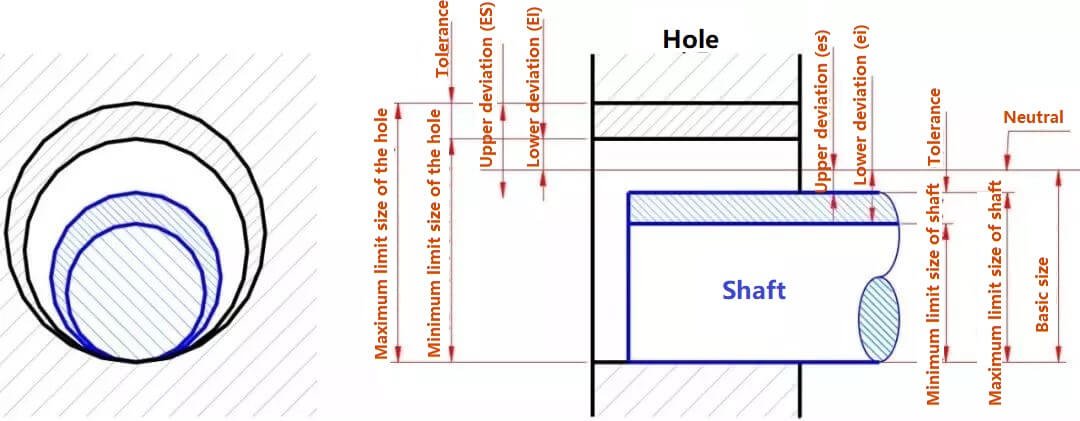

To ensure the interchangeability of parts—where any component from a batch can fit and function properly without selection or custom fitting—the dimensions must fall within an acceptable tolerance range. Well-defined tolerances and fits allow for efficient mass production while maintaining assembly performance, dimensional accuracy, and functionality.

Titanium machining is tough due to heat and wear issues. Find out how to tackle these problems with the right tools, cutting fluids, and optimized techniques.

This article changes the fine boring process from the tooling embracing radial clamping to the vertical clamping axial clamping. During the clamping process, the micrometer is used to measure the changes in the inner hole and the displacement of the generatrix on the outer circle side, and the deformation is monitored throughout the process.

10 types of CNC turning operations for high-precision manufacturing. Learn how to select the right process to meet your project requirements.

The 2025 latest comprehensive guide to gears covers gear principles, classifications, selection tips, and maintenance methods, helping mechanical engineers and procurement professionals choose more efficient and durable gear solutions.

YP-MFG is a leading manufacturer specializing in high-precision metal parts and CNC machining services.

Building A6, The Third Industrial Zone, Fenghuang Community, Fuyong Street, Bao’an District, Shenzhen

Copyright YP-MFG © 2026 All Rights Reserved

Click To Chat

I'm online now.

Hello, this is Judy from YPMFG. How can I assist you today? If you would like to get a free quote or have any questions, feel free to email us at sales@yp-mfg.com

WhatsApp Us

🟢 Online | Privacy policy

Chat with us