The challenge posed by dispersed machining processes lies in precision control across multiple operations. The cumulative effects of repeated clamping, debugging, and inspection often lead to unstable workpiece dimensions and extended delivery times. Therefore, we present a case study approach that leverages the characteristics of turning-milling composite machining combined with optimized toolpaths to address these issues.

1. Part Structure and Design Requirements

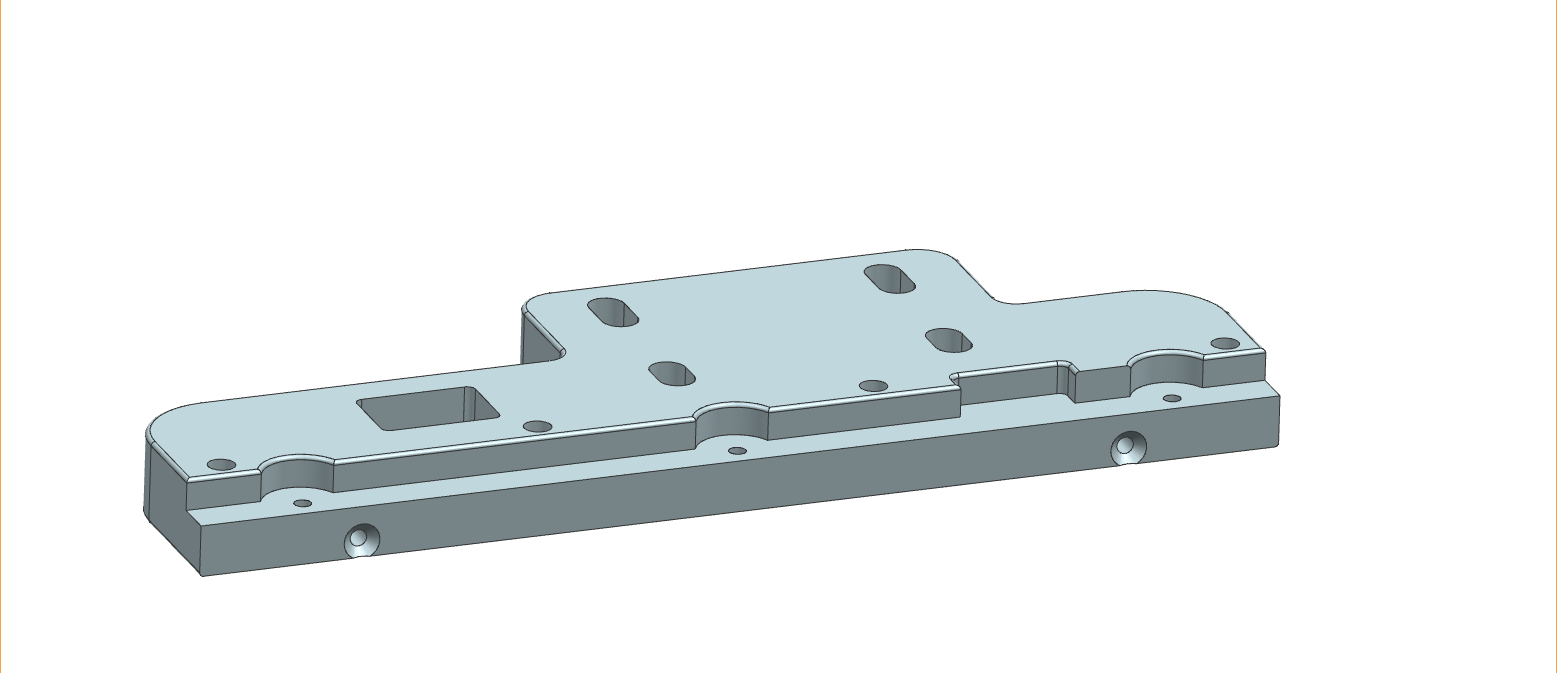

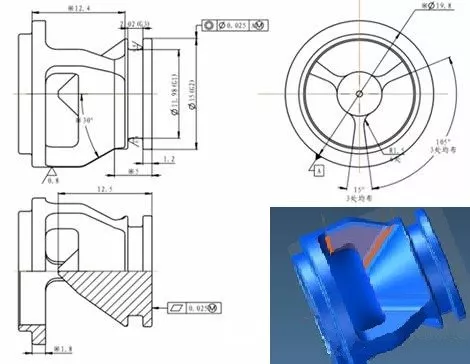

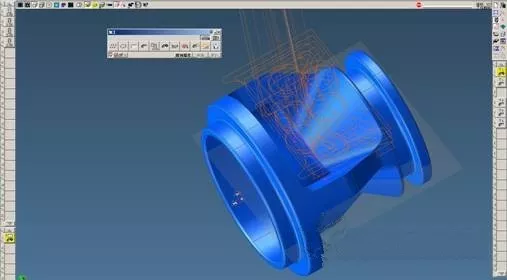

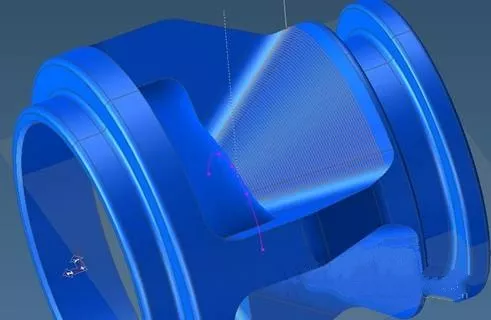

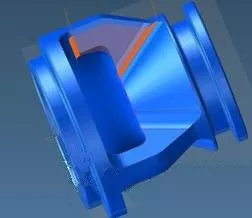

The structure of the liquid-cooled series seal block is shown in Figure 1. Materials include aluminum alloy and stainless steel. As the core component of the entire product, the seal block features precise dimensions and a compact structure. Nearly all dimensions are mating dimensions with other workpieces, with starred dimensions and dimensions marked with “G” being particularly critical and not allowing for any deviation. (Dimension tolerances are almost all within 0.03mm, tolerances for critical components are omitted.)

2. Original Fixture and Process Scheme Analysis

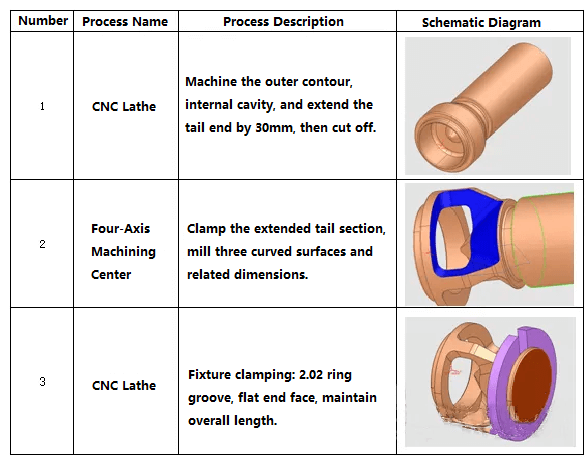

Given the part’s structural characteristics, the initial process scheme involved extending the tail end by 30mm to serve as the clamping area for a 4-axis machining center (vertical, A-axis rotary head). The 4-axis machining center processed three curved surfaces. Finally, a CNC lathe clamped the part to machine the 2.02mm ring groove, turning off the extended section while maintaining the overall length. The process arrangement is shown in Table 1.

3. Analysis of Issues with the Original Process Plan

Through actual machining verification, the original process plan exhibited the following shortcomings:

When machining curved surfaces on a four-axis machining center, workpiece circular runout caused by clamping errors and inherent A-axis errors is unavoidable. During workpiece clamping, each piece must be aligned using a dial indicator to control radial runout within 0.02mm. However, forces applied during machining and inherent clamping errors can cause milling damage to the profile or dimensional deviations, frequently resulting in inconsistent dimensions across the three curved surfaces.

During the final end-face machining operation, the small clamping area compromises stability, resulting in inconsistent step thickness behind the machined surface and causing end-face flatness to exceed dimensional tolerances.

Low machining efficiency. For the latter two processes, setup and alignment time significantly exceeds actual machining time. Due to unstable machining, both operators and inspectors spend considerable time measuring dimensions and sorting out nonconforming parts, resulting in extremely low production efficiency.

Material waste is substantial, as the extended length of raw material consistently exceeds the workpiece’s required length.

4. New Process Design

Based on a comprehensive analysis of the part’s structural characteristics and machining accuracy requirements, the various issues encountered in the original process design can be attributed to multiple setups and positioning errors. If this part could be machined in a single setup on a turning center, positioning errors would be eliminated. However, machining on a turning center presents two challenges.

(1) The machine tool must possess at least four-axis simultaneous control capability, with machining accuracy guaranteed within 0.005mm.

(2) Addressing programming challenges in turning-milling composite machining, particularly for surface machining and multi-axis simultaneous machining. Previously, the workshop primarily utilized three-axis power turret-type turning centers, where manual programming largely met requirements without involving specialized turning-milling software programming, especially for surface machining and multi-axis simultaneous operations.

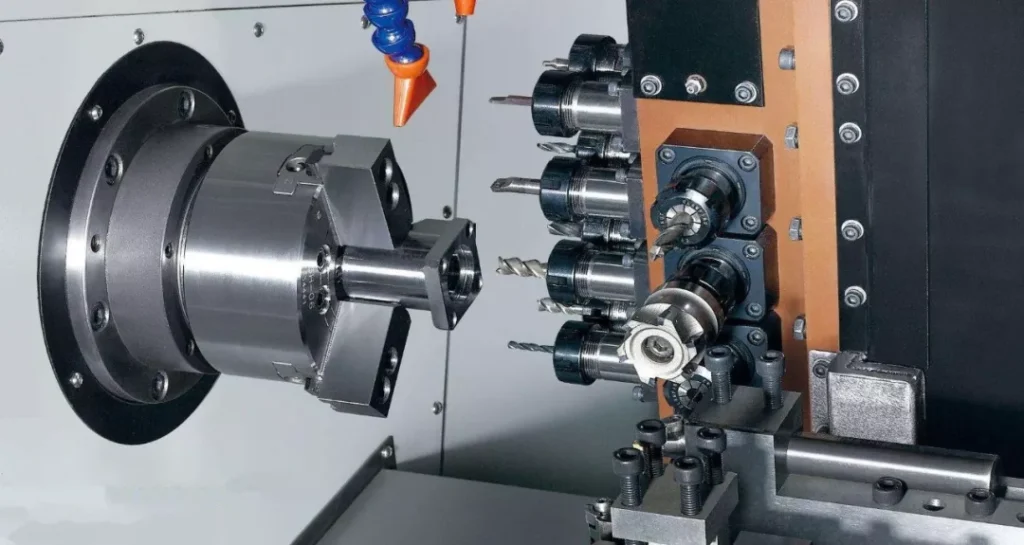

5. Implementation of the New Process Solution

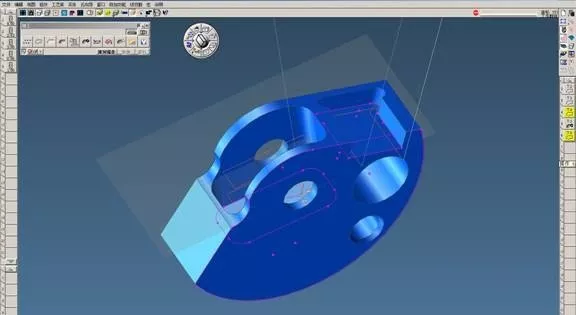

The new solution utilizes a turning-milling composite machine with a Y-axis to machine all workpiece contours and surfaces in one operation. This eliminates all clamping and positioning errors, ensures no tool marks on the workpiece surface, and meets dimensional requirements. Simultaneously, several core challenges in part programming require attention during machining.

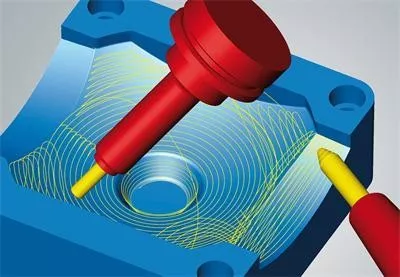

Challenge 1: Rough Milling for Stock Removal

Turning-milling composite machining intelligently identifies blank stock, automatically avoids interference, and ensures uniform post-machining stock removal to meet subsequent finishing requirements.

Challenge 2: Turning-Milling Surface Machining

Leveraging the multi-axis interpolation capability of turning-milling machines, tools can freely traverse complex surfaces to achieve high surface quality and dimensional consistency, fully meeting the machining requirements for part surfaces.

Challenge 3: Multi-Axis Milling in Turning-Milling Machines

For complex features like annular grooves and inclined surfaces, turning-milling machines enable multi-axis milling. This eliminates the need for multiple setups, reduces cumulative errors, and maintains both machining efficiency and precision.

Practical verification confirms the new approach’s feasibility: all workpiece contours are machined in a single turning-milling operation, meeting dimensional requirements while boosting efficiency by 40% and reducing material consumption by 50%. Figure 7 shows the post-machining result.

This new approach not only resolves precision and efficiency challenges in part machining but, most importantly, further expands the processing capabilities of Y-axis turning centers. When utilizing the Y-axis, the tool can traverse the entire surface laterally to generate a true surface finish equivalent to that of a CNC milling machine. Combined with software programming, this significantly broadens process capabilities. Many workpieces can now be processed on Y-axis turning centers, ensuring consistent quality while substantially boosting efficiency.

The above illustrates a typical workpiece. The original process required multiple machining operations on a machining center. Now, using a turning center combined with software programming, the part is machined in a single turning-milling operation. This not only reduces process steps and ensures better dimensional accuracy but also increases machining efficiency by over 20%. This fully demonstrates that expanding and enhancing process capabilities is the key to improving production efficiency and ensuring product quality.