In the manufacturing industry, die casting and cnc machining are two of the most common yet fundamentally different processing methods. For design engineers or purchasing specialists, making an informed choice between the two directly impacts product cost, performance, and delivery schedule. This article provides an in-depth comparison of their principles, suitable applications, and economic efficiency, offering a scientific basis for your process selection.

Table of Contents

I. CNC Machining Vs Die Casting

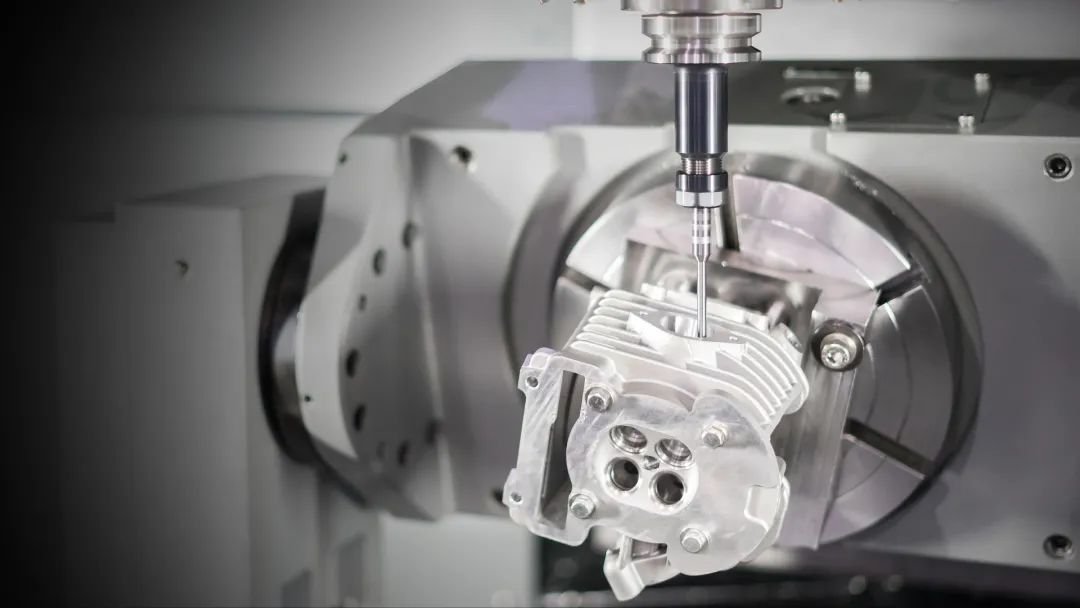

1. What is CNC Machining?

CNC machining is the process of removing material from a metal or plastic workpiece using cutting tools. With the aid of Computer Numerical Control (CNC) equipment, it enables high-precision manufacturing.

It is characterized by flexibility and accuracy, making it ideal for custom production of small batches, multiple varieties, and complex components.

Common Types of CNC Machining Processes

- CNC Milling: The cutting tool rotates at high speed and removes material through multi-axis motion, suitable for processing planes, slopes, grooves, holes, and complex surfaces.

- Turning: The workpiece rotates while the cutting tool advances, used for machining shafts, cylinders, cones, and threads.

- Drilling and Tapping: Used to create holes and threaded connections.

- 5-Axis Machining: The cutting tool moves simultaneously along five axes, allowing efficient processing of complex and irregularly shaped components, such as aerospace turbine blades and medical device parts.

2. What is Die Casting?

Die casting is a process in which molten metal is rapidly injected into a mold cavity under high pressure. It offers high efficiency, excellent consistency, and superior surface finish. It is especially suitable for mass production of metal parts with complex structures and moderate precision requirements.

Die Casting Process Flow

1. Melting: Heating metal materials (such as aluminum alloy or zinc alloy) until they become molten.

2. Injection: Using a high-pressure system to rapidly inject molten metal into the mold cavity.

3. Cooling: The metal quickly solidifies inside the mold to form the desired shape.

4. Ejection: The mold opens, and the finished part is pushed out.

5. Trimming & Finishing: Removing excess material and burrs, followed by optional surface treatments such as sandblasting, painting, or electroplating.

II. How to Choose? Four Core Decision Dimensions

1. Production Volume — Quantity Determines Cost Efficiency

In structural component manufacturing, production volume is the key factor influencing cost.

Die Casting:

Die casting is most suitable for large-scale production. Generally, when the production quantity is ≥ 5,000 pieces, its economic advantage becomes apparent.

Since die casting requires the creation of molds—which are expensive—the cost per part decreases as production volume increases, as the mold cost is distributed across more units.

For example, an automotive engine bracket with an annual demand of 200,000 units costs 41% less per piece when produced via die casting compared to machining.

This clearly demonstrates die casting’s cost advantage in mass production.

CNC Machining:

CNC Machining, on the other hand, is better suited for small-batch production.

When the production quantity is ≤ 3,000 pieces, machining’s flexibility and cost-effectiveness stand out.

Since machining does not require costly molds, it avoids upfront investment and is ideal for small-batch or multi-variety production.

For instance, in the case of custom-shaped components for research equipment, where only 50 pieces are needed, the total cost of machining is 68% lower than die casting.

To more precisely determine which process is more economical under specific mold costs and unit prices, you can use the following decision formula:

Break-even Quantity=Mold Cost / (Machining Unit Price−Die Casting Unit Price)

If production quantity < break-even quantity, then machining is more cost-effective.

If production quantity > break-even quantity, then die casting is more economical.

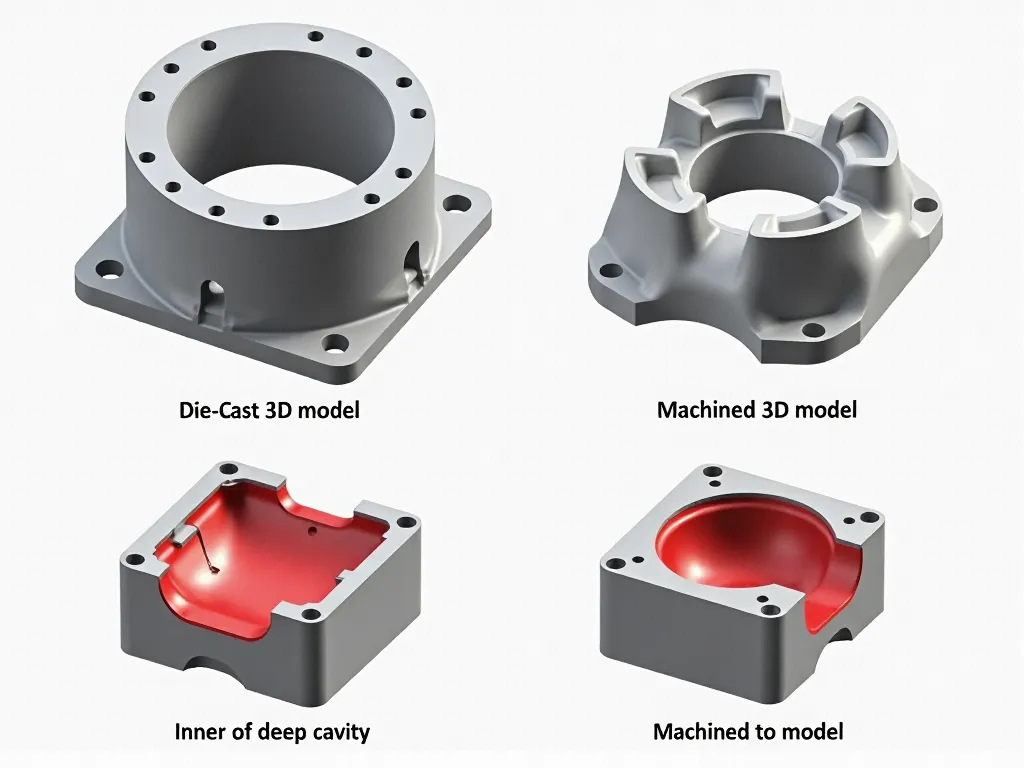

2. Shape Complexity — Geometry Defines Process Limits

The geometric complexity of structural components plays a crucial role in process selection.

Below is a general comparison of die casting and machining in handling different geometric features:

| Feature Type | Die Casting | Machining |

|---|---|---|

| Deep Cavities | Excellent – Formed in one shot with molds | Possible but time-consuming |

| Internal Recesses | Easy to mold, consistent results | Achievable but complex |

| Irregular Curved Surfaces | High efficiency with molds | Requires 5-axis CNC, costly |

| Thin Walls | Risk of incomplete filling | Excellent precision and control |

| Sharp Edges | Limited by mold wear | Easily achieved by CNC |

From the comparison above, we can see that die casting excels at forming deep cavities, recessed structures, and complex curved surfaces, achieving one-shot molding with high accuracy and consistency.

However, thin-wall structures pose a challenge for die casting due to potential filling issues, while cnc machining allows precise control through fine milling.

Although machining can also produce irregular surfaces using 5-axis CNC Machining, the cost increases significantly.

3. Material — Physical Properties Determine Feasibility

The physical properties of materials are a critical factor in process selection, as different materials vary in their suitability for die casting and machining.

Materials Better Suited for Die Casting:

Alloys such as aluminum alloy (ADC12) and zinc alloy (Zamak) have excellent fluidity, making them ideal for die casting. These materials can rapidly fill mold cavities to form complex shapes while ensuring relatively long mold life.

However, stainless steel, due to its high melting point, can cause severe mold damage during die casting, making it unsuitable for this process.

Materials Better Suited for Machining:

Materials with high hardness, such as titanium alloys and quenched steels, lead to excessive mold wear in die casting and are therefore better processed via machining.

Machining allows for precise cutting of these high-strength materials using appropriate tools and parameters.

While copper alloys can technically be die cast, they require high-temperature-resistant molds, which significantly increase production costs and technical complexity.

A notable case involved a company attempting to die cast 304 stainless steel parts. The mold’s lifespan plummeted from the normal 100,000 cycles to just 3,000, and the unit cost was 220% higher than machining.

This case vividly illustrates the substantial impact of material selection on process cost — companies must thoroughly evaluate material properties to avoid costly missteps in choosing manufacturing methods.

4. Precision — The Lifeline of Critical Dimensions

In structural component production, precision requirements directly dictate process selection.

Die Casting Precision Limits:

Typical dimensional accuracy for die casting is around ±0.1 mm.

If tighter tolerances are required, secondary CNC machining is often necessary after die casting.

For example, an automotive transmission housing is usually first formed through die casting, and then key areas are milled to achieve the high precision necessary for assembly.

This hybrid approach — die casting followed by machining — effectively combines the efficiency of die casting with the precision of CNC, achieving both cost and quality balance.

CNC Machining Accuracy:

Five-axis CNC machining can achieve a high precision of ±0.02 mm. For structural components with extremely high accuracy requirements, such as aerospace hydraulic valve blocks, a full machining process can ensure both high precision and superior quality. CNC machining achieves this through precise tool path control and advanced measurement technologies, allowing strict control over critical dimensions.

A medical device company required die-cast parts to meet a full-size tolerance of ±0.05 mm, but the resulting 100% inspection rejection rate was as high as 37%. After revising the process, the company adopted a die-cast blank with a ±0.15 mm tolerance and then performed precision grinding on the critical surfaces. This effectively reduced the rejection rate and met the accuracy requirements. This case serves as a warning: when setting precision requirements, companies must fully consider the actual capabilities of the manufacturing process to avoid excessive costs and low production efficiency caused by overly tight tolerances.

Ⅲ. 3-Step Quick Decision Method

Step 1: Draw a Process Balance Diagram

To more intuitively compare the advantages of die casting and CNC machining across different dimensions, we introduce a process balance diagram (insert diagram: left side for volume/complexity, right side for precision/material). When production volume is high, shapes are complex, and materials are non-high-melting-point, the balance tips toward die casting. Conversely, for small volumes, simple shapes, and high-hardness materials, the balance favors CNC machining. This simple visual helps provide a quick initial judgment on process selection.

Step 2: Calculate Total Cost of Ownership (TCO)

Calculating total cost is crucial in process selection. The total cost can be calculated using the following formula:

Total Cost = (Unit Process Cost × Quantity) + Mold Cost + Post-processing Cost + Scrap Loss

To make cost calculation easier, we recommend using the Odoo Community Edition Cost Calculator. This free yet powerful tool can quickly and accurately calculate total costs under different processes, providing strong support for business decision-making.

Step 3: Conduct Validation Part Testing

Before full-scale production, validation part testing is essential to ensure process feasibility and product quality. For die casting, a simple trial mold can be used first, reducing costs by up to 60%, allowing the verification of process parameters and product design. For CNC machining, first articles should undergo full-size inspection to ensure machining accuracy meets requirements before proceeding with mass production. Validation testing helps identify potential issues early, preventing large-scale quality problems and reducing production costs and risks.

Ⅳ. Revealing Industry “Hidden Rules”

Die Casting “Hidden Costs”:

When selecting a die casting supplier, companies need to be aware of certain hidden costs. Mold wear is inevitable during use, and mold maintenance fees typically account for about 15% of the mold cost per year, a cost that is often overlooked. In addition, residual release agents can cause subsequent plating defects, increasing rework costs. When working with die casting suppliers, companies should clarify how these costs are allocated and require suppliers to implement effective measures to minimize release agent residues, thereby reducing production costs.

CNC Machining “Gray Areas”:

The CNC machining industry also has some irregular practices. Delayed replacement of worn tools can lead to widespread dimensional errors, affecting product quality. Some unscrupulous suppliers may even machine aluminum instead of steel and then anodize it to disguise it as a high-end material. When selecting CNC machining suppliers, companies should strengthen quality control, regularly inspect tool conditions, and use material testing or other verification methods to ensure the supplied products meet specifications, avoiding these gray-area pitfalls.

Ⅴ. Conclusion: Make Best Decisions

In practice, a “Die casting + CNC Machining” hybrid process is often the optimal solution, balancing cost efficiency with precision requirements.

| Comparison Dimension | CNC Machining | Die Casting |

|---|---|---|

| Forming Principle | Material removal by cutting | High-pressure forming of molten metal |

| Mold Requirement | No mold needed | Requires precision mold |

| Suitable Volume | Small batch, diverse | Medium to large batch production |

| Accuracy | High (±0.01 mm) | Medium (±0.1 mm) |

| Material Range | Almost all metals and plastics | Low-melting-point metals (aluminum, zinc, magnesium) |

| Cost Structure | High unit cost, low upfront investment | Low unit cost, high upfront investment |

| Surface Quality | High surface finish achievable through machining | Excellent as-cast surface, ready to use |

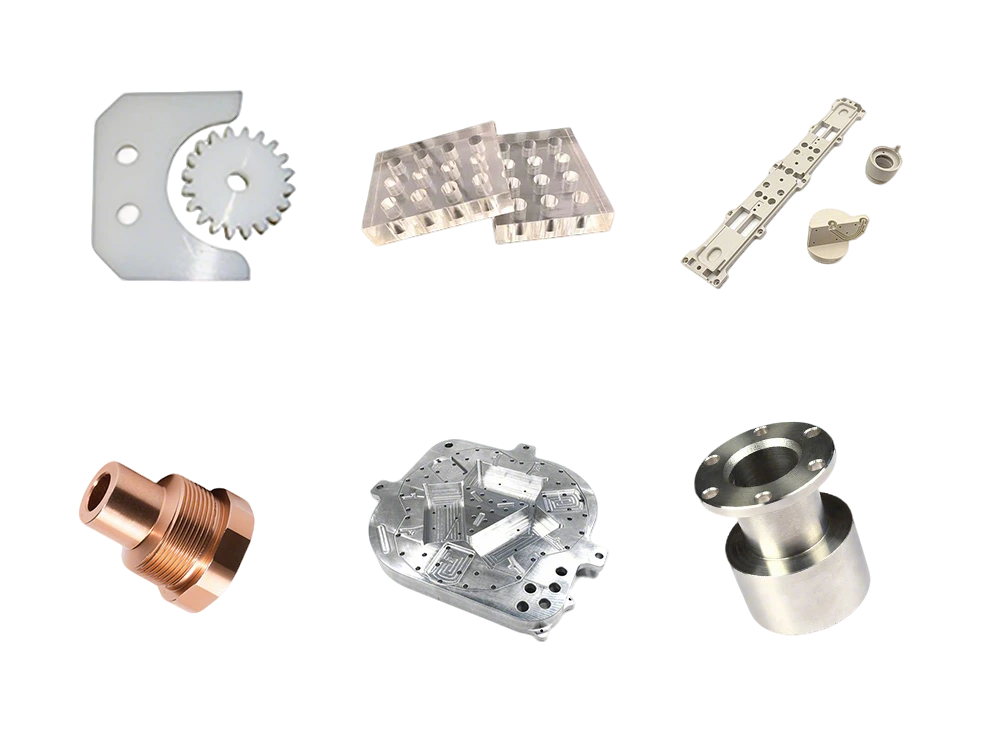

Find the Optimal Manufacturing Path with YPMFG Machining

At YPMFG Machining, we offer mature CNC precision machining service and die casting capabilities, supporting the full manufacturing process from small-batch validation parts to large-scale production.

Our engineering team can quickly provide cost analysis and process recommendations tailored to your project, helping you achieve the best balance between efficiency, cost, and quality. Contact Us Now!