PTFE (Teflon) CNC Machining Service

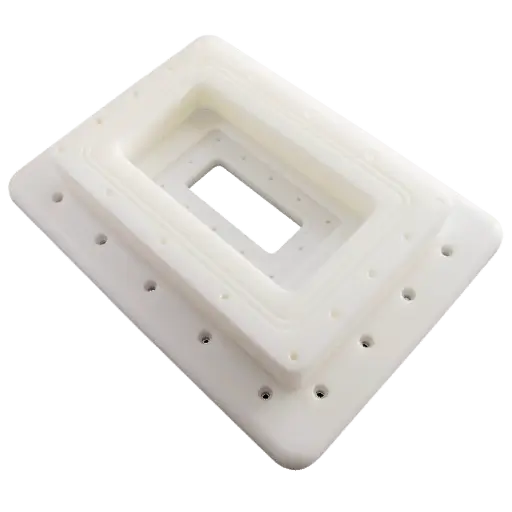

PTFE CNC machining services provide precision-engineered parts with excellent chemical resistance, high temperature tolerance, low friction, and non-stick properties.

PTFE (Teflon) CNC Machining Services

Polytetrafluoroethylene (PTFE) is a thermoplastic fluoropolymer consisting solely of carbon and fluorine atoms. Teflon stands out for its exceptional resistance to high temperatures and strong chemical corrosion resistance due to its fluoropolymer structure.

What makes PTFE (Teflon) unique compared to many other engineering plastics is its extremely high melting point, low coefficient of friction, and chemical inertness. These distinctive features have led to its widespread use not only in non-stick cookware but also in industries such as food and beverage, petrochemicals, medical devices, and electrical components.

Why Choose PTFE (Teflon) Machining?

- High Temperature Resistance – Works reliably in extreme heat without losing strength or stability.

- Outstanding Chemical Inertness – Withstands acids, bases, and solvents, making it ideal for harsh environments.

- Ultra-Low Friction – Naturally non-stick, reducing wear and improving efficiency in moving parts.

- Excellent Electrical Insulation – Safe for high-voltage and sensitive electronic applications.

- Dimensional Precision with CNC Machining – Custom parts can be manufactured to tight tolerances.

- Industry Versatility – Widely applied in food processing, medical, petrochemical, aerospace, and electronics sectors.

PTFE (Teflon) Machining Applications

PTFE (Teflon) is widely used in CNC machining thanks to its low friction, high temperature resistance, and chemical inertness. These properties make it ideal for demanding industries:

Food & Beverage: non-stick cookware, FDA-compliant seals, processing equipment parts

Chemical & Petrochemical: corrosion-resistant gaskets, valve seats, pump parts

Medical: sterilizable components, biocompatible instruments, device parts

Electrical: insulators, spacers, connectors, cable coatings

Aerospace & Automotive: lightweight seals, fuel system parts, wear-resistant components

Material Properties for Machined Stainless Steel

Material

Tensile Strength, Yield (MPa)

Elongation at Break (%)

Hardness (Shore D)

Heat Deflection Temperature (°C)

Melting Temperature (°C)

PTFE-Teflon

9-30

300-400

55-65

115

330

CNC Machining Resources

Which Metal Resists Corrosion Best? Stainless Steel, Titanium, and Aluminum…

Which metal resists corrosion best in different environments? This guide compares stainless steel, titanium, and aluminum in terms of durability,

Metallurgy and Heat Treatment Explained

Comprehensive insights into metallurgy and heat treatment in industrial applications: from crystal structures and iron-carbon phase diagrams to annealing, normalizing,

How to Tackle Titanium Machining Difficulties

Titanium machining is tough due to heat and wear issues. Find out how to tackle these problems with the right