Polypropylene (PP) CNC Machining Service

YPMFG Machining specializes in producing durable, lightweight, and chemically resistant PP parts for automotive, medical, and industrial applications. Achieve tight tolerances, smooth finishes, and cost-effective production with our advanced CNC machining capabilities.

Polypropylene (PP) CNC Machining Services

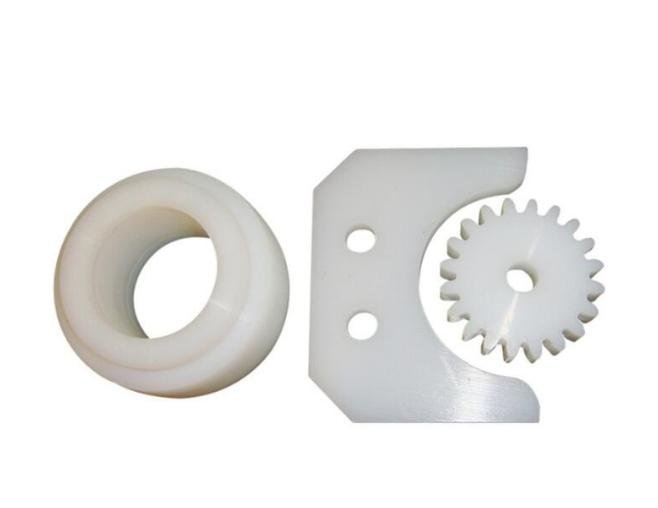

Polypropylene (PP) is a lightweight and durable thermoplastic widely valued for its strong chemical resistance and excellent mechanical properties. Its combination of toughness, flexibility, and low density makes it a popular material for CNC machining in industries such as automotive, medical, and consumer goods. Thanks to its good machinability, polypropylene enables the production of precise, complex components.

Polypropylene (PP) Machining Applications

Machinability:

PP is relatively easy to machine using sharp tools and controlled cutting speeds. However, it has a low melting point (~160°C), so heat buildup must be minimized to prevent deformation or surface melting.Strength and Toughness:

Offers good impact strength and fatigue resistance, making it suitable for parts exposed to repeated mechanical stress or flexing.

Surface Finish:

Produces a smooth, glossy surface after machining, thanks to its low friction and waxy texture. This property also makes PP parts naturally resistant to sticking and wear.Chemical Resistance:

Excellent resistance to acids, alkalis, and many solvents, enabling use in harsh chemical environments.Moisture Absorption:

Negligible moisture uptake, ensuring dimensional stability even in humid conditions.

Polypropylene (PP) Machining Applications

- Automotive Industry: Used for manufacturing fluid reservoirs, battery cases, and interior trim components that benefit from PP’s resistance to chemicals and low moisture absorption.

- Medical Devices: Ideal for producing laboratory containers, syringe components, and medical instrument housings, as it is non-toxic and easy to sterilize.

- Consumer Products: Frequently machined into durable everyday items like hinges, caps, handles, and protective housings due to its toughness and flexibility.

- Industrial Equipment: Applied in pump components, valves, and fittings that require resistance to corrosive substances and fatigue.

- Electrical Applications: Suitable for insulation parts and protective covers thanks to its excellent dielectric properties.

Material Properties for Machined Polypropylene (PP)

Material

Tensile Strength, Yield (MPa)

Heat Deflection Temperature (°C)

Hardness(Shore D)

Elongation at Break (%)

Melting Point (°C)

Generic Polypropylene Properties

25-40

100 @ 0.45 MPa

65-75

10%

160-170

CNC Machining Resources

Brass vs Copper vs Bronze: Differences, Properties, Machining Tips & Material Selection Guide

Differences between brass, bronze, and copper, including their properties, pros and cons, machining challenges, and how to select the best

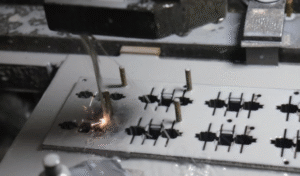

How to Avoid Stress Deformation in Titanium Alloy Machining

Titanium thin plate parts often deform due to machining stress, causing scrap and poor accuracy. This article explains causes and

Which Metal Resists Corrosion Best? Stainless Steel, Titanium, and Aluminum…

Which metal resists corrosion best in different environments? This guide compares stainless steel, titanium, and aluminum in terms of durability,