I. Project Background

In the marine and offshore engineering sectors, the reliability and environmental corrosion resistance of energy systems are paramount. The component featured in this case study is a critical mounting plate for shipboard energy storage systems (ESS) or battery boxes. Our client, a key player in the shipbuilding industry, challenged us to deliver high-precision, salt spray corrosion-resistant parts while simultaneously achieving cost efficiency (cost-down) for the structural components. Our provided custom machined parts solution was specifically designed to optimize the overall battery pack assembly structure and guarantee its long-term stability in harsh, humid, and high-salt-fog environments.

II. Component Specifications

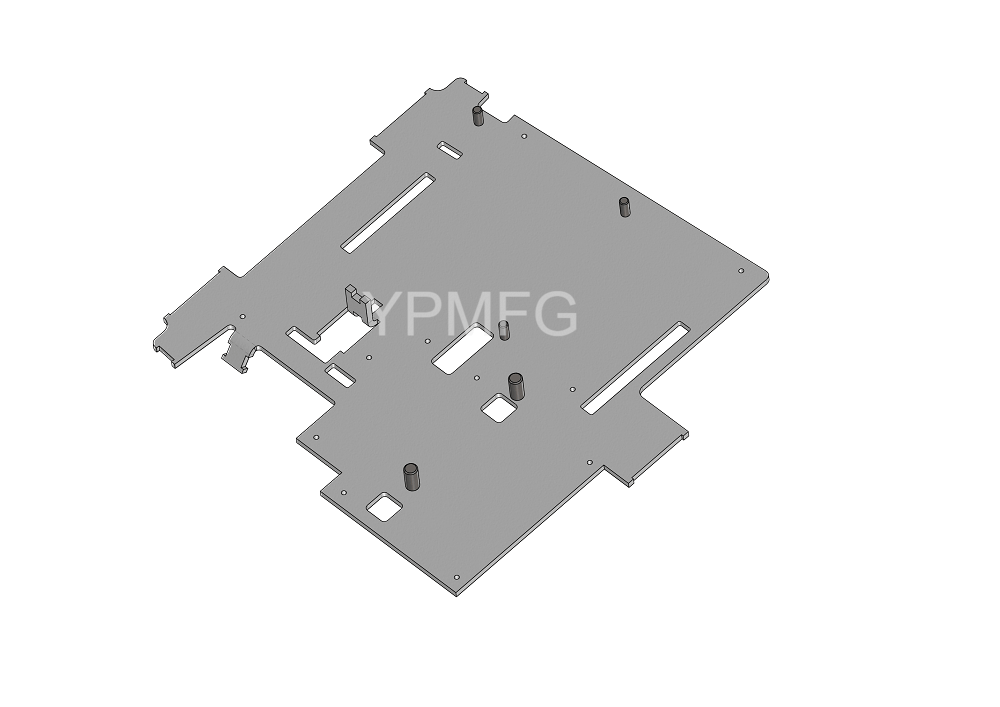

1. Component Use and Nomenclature

The part is designated as the Cost-Optimized Battery Box Mounting Plate. It functions as a critical supporting and connection element within the shipboard or offshore battery box, ensuring the stable mounting of internal components such as cell modules or the management system.

| Specification | Details |

| Material: | Aluminum Alloy 5052 |

| Thickness: | 3mm |

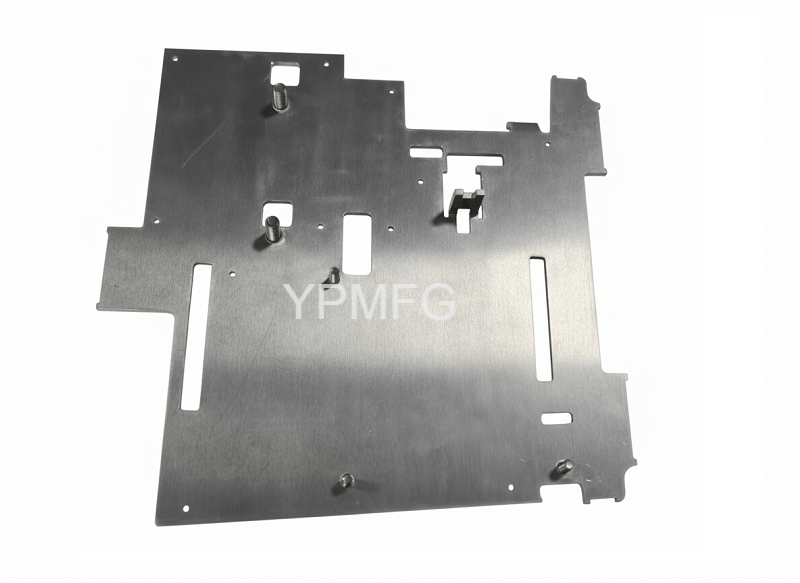

| Appearance: | Natural Color (Mill Finish) |

Aluminum Alloy 5052 belongs to the Al-Mg series and is renowned for its excellent seawater corrosion resistance, good weldability, and formability. This makes it an ideal choice for structural components in marine and offshore environments. The selection of this material was a critical engineering decision to meet the long-term usage requirements of the shipbuilding industry.

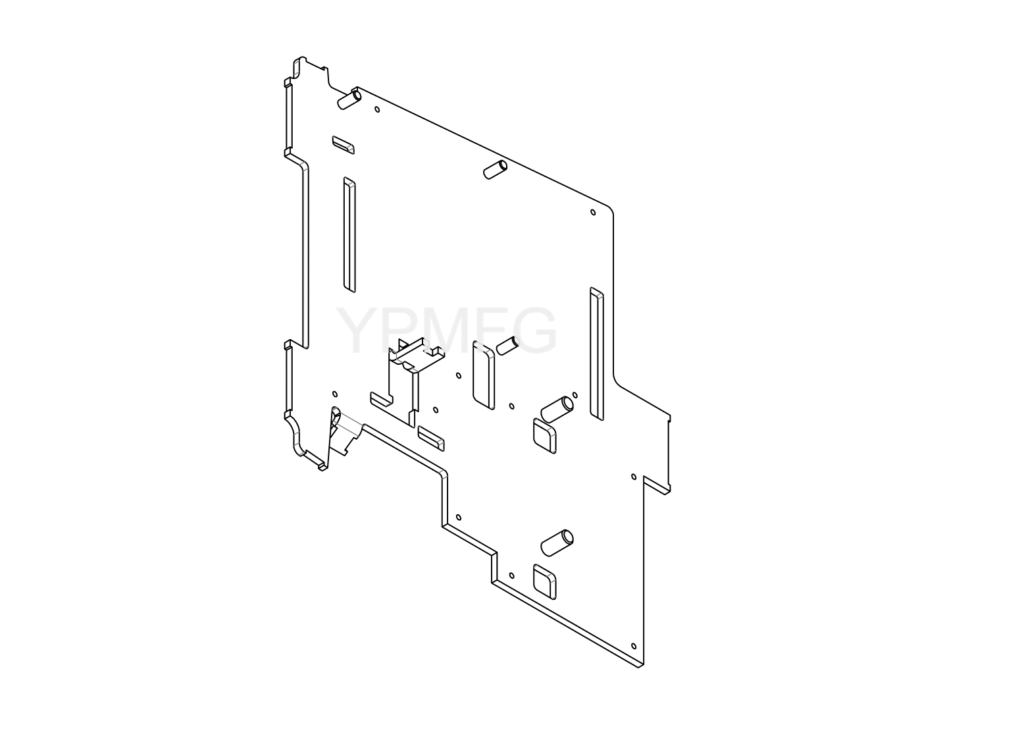

3. Key Geometric Features and Tolerances

This mounting plate is a complex component that combines sheet metal fabrication and CNC machining processes.

- Primary Structure: Includes pre-bending and final bending structures, along with multiple precision hole positions.

- Critical Dimensions: As per the blueprint, the design involves control over multiple dimensional tolerances.

- Angular Tolerance: The critical bending angles require a tolerance of ± 2.0°.

- Surface Finish: Requires deburring all edges treatment.

- Special Features: The components include self-locking studs and stud welding parts for mounting M4 and M6 threaded fasteners.

III. Analysis of Machining Challenges

1. Material and Thickness Challenges

Machining the 3mm thick 5052 aluminum alloy requires precise control over the springback phenomenon during stamping and bending operations. This precision is essential to ensure the final bending angle tolerance of ± 2.0° is consistently met.

2. Complex Multi-Process Integration

The component requires integrating multiple processes: Laser Cutting (Cut from DXF), Precision CNC Bending, Precision Drilling, Self-Clinching Stud Installation, and Stud Welding. A key challenge for marine applications is optimizing the process workflow and ensuring the corrosion resistance integrity of the material surface after welding and press-fitting.

3. Marine Application Environmental Requirements

In the shipbuilding industry, the installation of all fasteners (such as studs) must guarantee high reliability to prevent loosening or accelerated corrosion under ship vibration and high-humidity conditions. Consequently, the quality control standards (torque and pull-out force) for the self-clinching studs and welded studs are significantly higher than standard industrial requirements. Furthermore, the precision of critical dimensions, such as the precision hole positions, directly impacts the subsequent vibration isolation and thermal management performance of the battery modules.

IV. Detailed Manufacturing Solution

1. Manufacturing Process Route

The entire process route was meticulously defined to manage the multi-step nature of the 5052 aluminum battery mounting plate:

- Raw Material Preparation: Procurement and inspection of 3mm thick 5052 aluminum alloy sheets.

- Profile Cutting: Utilizing laser cutting or CNC punching equipment to precisely cut the outer profile and all hole positions according to the supplied DXF files.

- Precision CNC Bending: Using a high-precision CNC press brake to complete the pre-bending and final bending operations in sequence. We calculate and adjust the bending compensation factor based on the 5052 material characteristics to ensure the accuracy of the 90° and 125° angles.

- Deburring and Surface Treatment: Detailed deburring treatment is performed on all edges.

- Self-Clinching Stud Installation: Selecting corrosion-resistant grade self-clinching studs (e.g., FH-M4-12-21 and FH-M6-15-21 or equivalents). These are accurately pressed into place using specialized equipment. Critical Control Point: After clinching, local stress concentration is assessed, and the stud torque and pull-out performance are strictly tested to meet marine vibration requirements.

- Stud Welding: Performing arc stud welding at specified locations. Post-welding inspection is mandatory to ensure no spatter residue remains, which could otherwise lead to corrosion hazards.

- Final Inspection: Comprehensive dimensional and quality control check.

2. Quality Control (QC)

Our rigorous Quality Control protocol ensures that all aspects of the 5052 aluminum mounting plate meet the stringent requirements of marine applications:

- Dimensional Inspection: A comprehensive inspection of critical dimensions and geometric features is conducted using a Coordinate Measuring Machine (CMM).

- Functionality Testing (Critical Fasteners): We perform 100% spot-checking for torque and pull-out force on all installed self-clinching studs and welded studs. This guarantees that their mechanical performance complies with the shipbuilding industry standards for high-vibration and high-reliability structural components.

- Material and Surface Verification: We verify the certificate of the 3mm 5052 material and ensure that the surface is clean, free from any oxides or residues that could potentially compromise its corrosion resistance.

V. Final Results and Client Benefits

By successfully implementing the aforementioned custom machined parts solution, we delivered marine battery box mounting plates that meet the stringent environmental demands of our shipbuilding client.

1. Key Project Achievements

- Environmental Durability Assurance: The precise machining of 5052 aluminum alloy provided an essential foundation for excellent seawater corrosion resistance.

- High-Vibration Reliability: Strict quality control over the stud installation process ensured the structural integrity of critical fasteners under long-term ship operation and vibration conditions.

- Cost Optimization Target Met: As the “Cost-down” version, our highly efficient CNC machining processes and optimized workflow successfully helped the client achieve their target cost reduction goals while maintaining uncompromising quality.

2. Client Value Proposition

The client received custom precision machined parts perfectly suited for the marine environment, which significantly guarantees the long-term operational reliability of their shipboard energy storage systems—a factor critical to overall vessel safety. This project further solidifies our position as experts in precision machining and components for marine electrical systems.

We are committed to providing global marine and offshore engineering clients with a one-stop CNC machining solution, from design optimization to mass production. If you have similar needs for high-precision, corrosion-resistant, and high-reliability parts, contact our expert team today!