CNC turning can create complex parts for the medical, military, electronics, automotive and aerospace industries. Learn about turning and the ten machining operations performed on a lathe.

Lathes are capable of performing many machining operations to create parts with desired characteristics. CNC turning is a common name for lathe operations. However, turning is only one of the lathe operations.

The changes in the cutting edge of the tool and the kinematic relationship between the tool and the workpiece result in different operations on a lathe. The most common lathe operations include turning, facing, grooving, parting off, threading, drilling, boring, knurling and tapping.

Table of Contents

1. CNC Turning

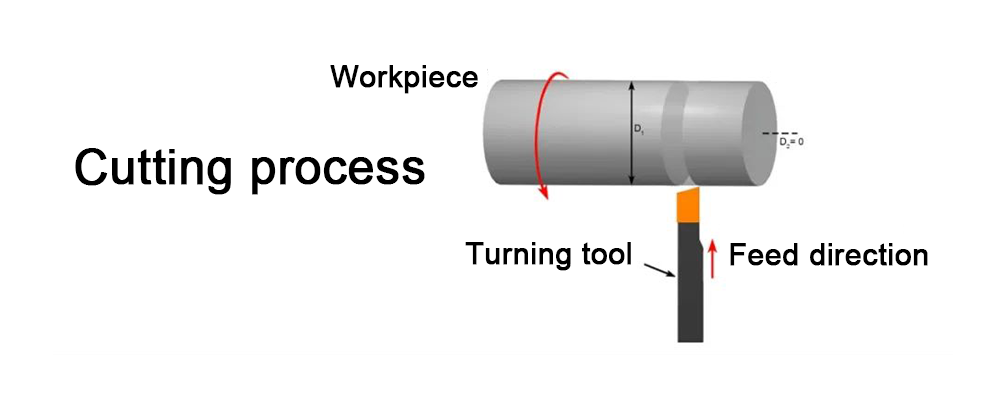

Turning is the most common lathe machining operation. During turning, the turning tool removes material from the outer diameter of the rotating workpiece. The main goal of turning is to reduce the workpiece diameter to the desired size. There are two types of turning operations: rough turning and finish turning.

The purpose of the rough turning operation is to machine the part to a predetermined thickness by removing the maximum amount of material in the shortest time, ignoring accuracy and surface finish. Finish turning produces a smooth surface finish and brings the workpiece to the final correct size.

Different parts of the turned part may have different outer diameters. The transition between two surfaces of different diameters may have several machining methods, namely steps, tapers, chamfers and contours. To produce these features, multiple radial cutting depths may be required.

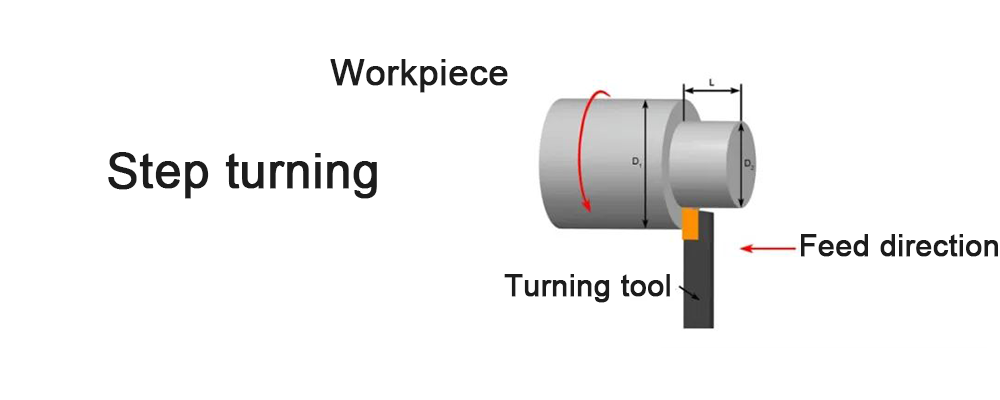

1.1 Step Turning

Step turning creates two surfaces of different diameters by a sudden change in diameter between the two surfaces. The final feature resembles a step.

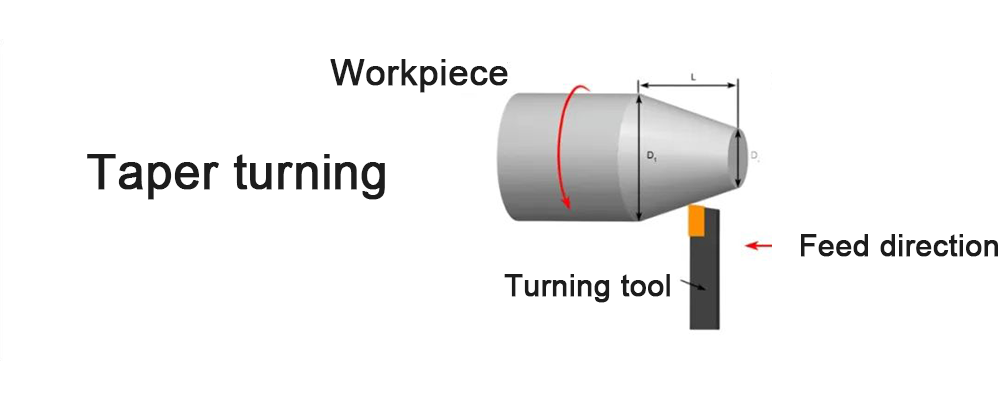

1.2 Taper turning

Taper turning is a process of producing a slope transition between two surfaces of different diameters by means of an inclined motion between the workpiece and the turning tool.

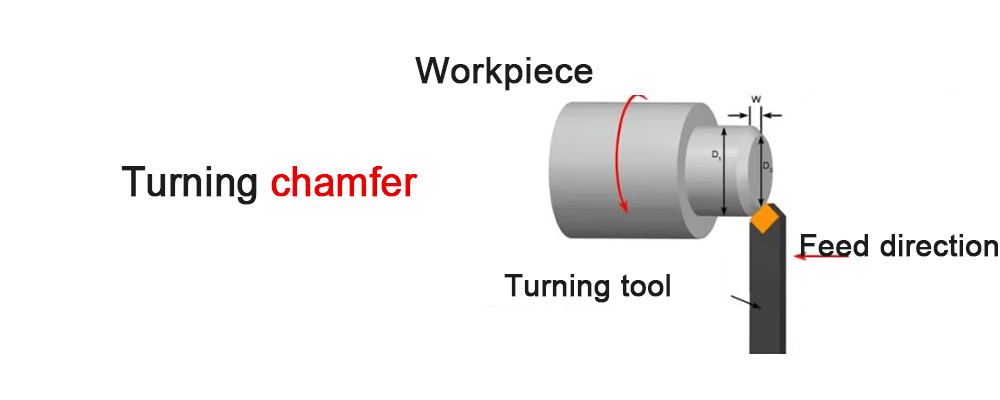

1.3 Turning chamfer

Similar to step turning, turning chamfer creates an angular transition between two surfaces with different turning diameters that were originally square edges.

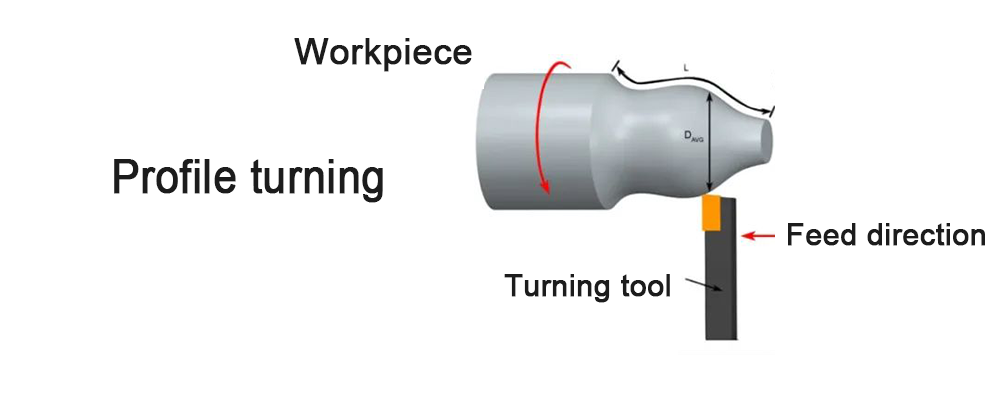

1.4 Profile Turning

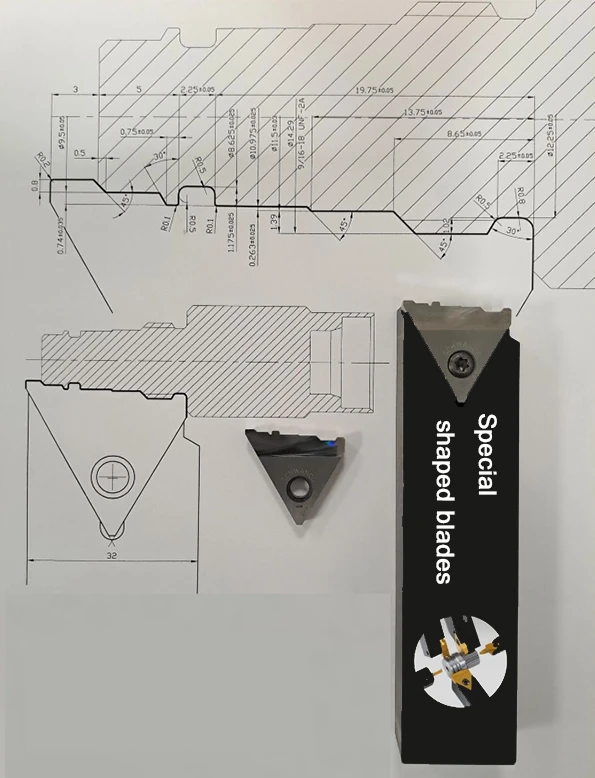

In the profile-cutting operation, the turning tool moves axially along a path of predefined geometry. Multiple passes of the profile turning tool are required to create the desired profile on the workpiece.

However, the forming tool ( a non-standard tool, customized tool, as shown in the figure) can achieve the contour shape in one go through the special structure of the tool.

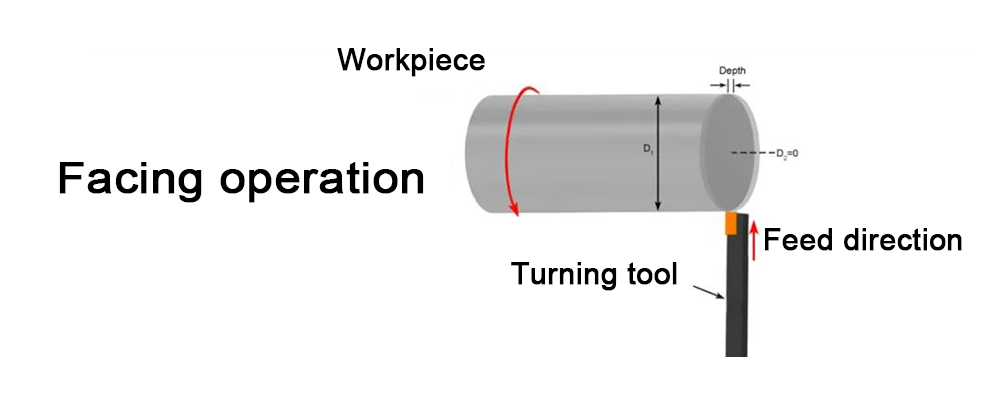

2. Facing

During machining, the length of the workpiece is slightly longer than the final part should be. Facing is a machining operation used to machine the end of a workpiece perpendicular to the axis of rotation. During turning, the turning tool moves along the radius of the workpiece, removing a thin layer of material to produce the desired part length and a smooth surface.

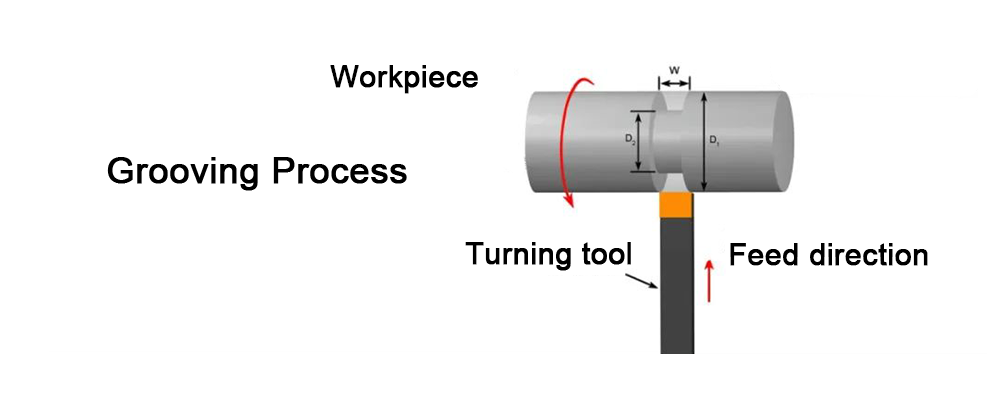

3. Grooving

Grooving is a turning operation used to create a narrow cut, or “notch,” in a workpiece. The size of the notch depends on the width of the tool. Larger grooves require multiple turns to complete. There are two types of grooving operations: radial grooving and face grooving. In radial grooving, the tool enters radially into the side of the workpiece and removes material in the direction of the cut. In face grooving, the tool cuts a face groove on the surface of the workpiece.

4. Cut-off Machining

Cut-off is a machining operation that results in the part being cut off at the end of the machining cycle. The process uses a tool with a specific shape to enter the workpiece vertically and make incremental cuts while the workpiece rotates. When the tip of the turning tool reaches the center of the workpiece, the workpiece slides off.

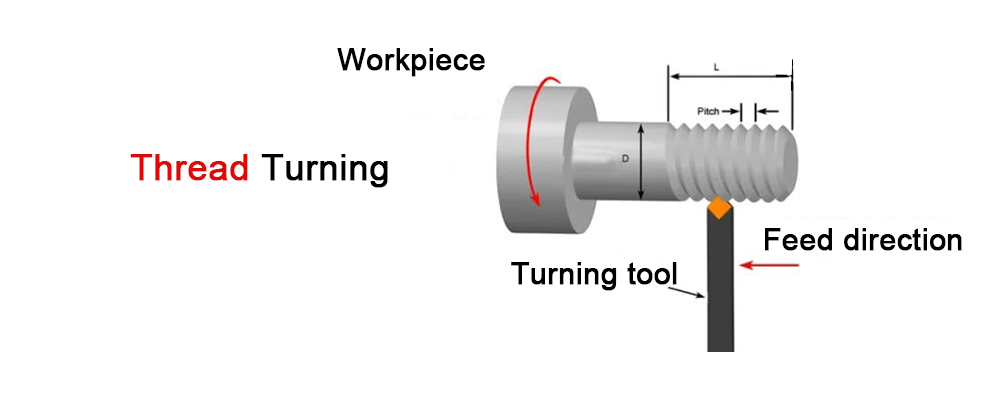

5. Thread Turning

Thread turning is a type of turning operation in which the tool moves along the side of the workpiece to cut external threads. A thread is a uniform helical groove with a specified length and pitch. Deeper threads require multiple passes of the cutting tool.

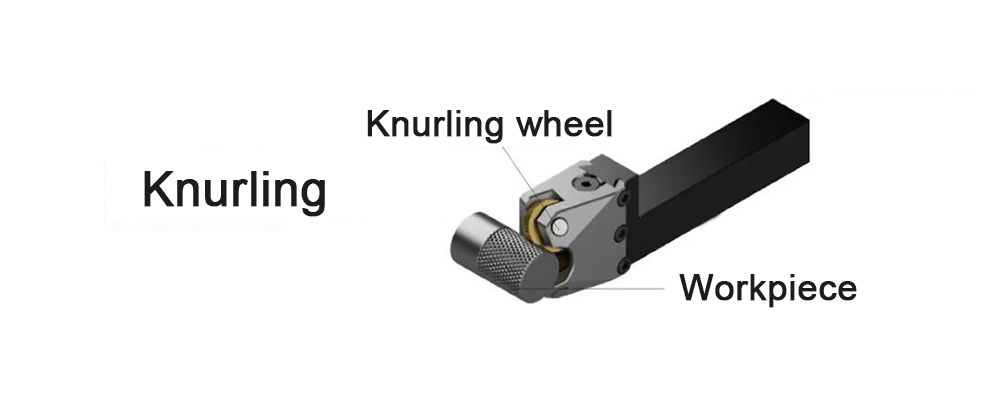

6. Knurling

Knurling is a machining operation that produces a reticulated pattern on the surface of a part. Knurling increases the grip friction and visual effect of the part. This process utilizes a unique knurling tool that contains one or more cylindrical knurled wheels (embossed wheels) that rotate within a knurling tool holder. The knurled wheels have teeth that roll over the surface of the workpiece to form a toothed pattern. The most common knurling pattern is a diamond pattern.

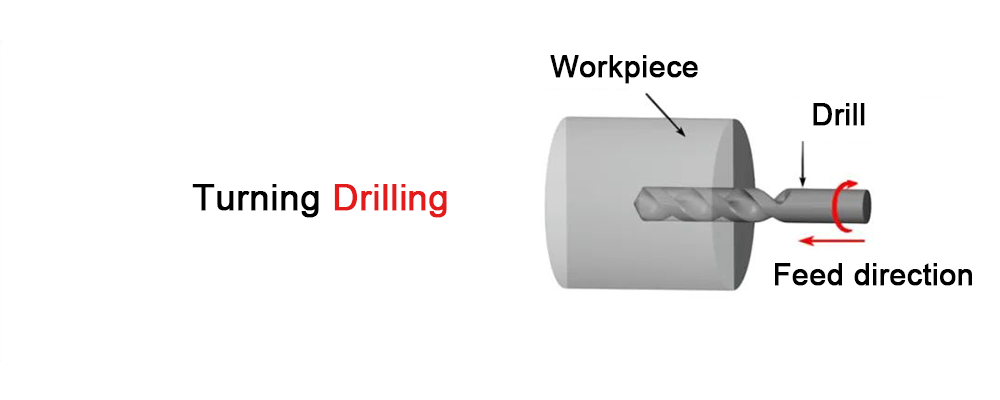

7. Turning Drilling

The drilling operation removes material from the inside of a workpiece. The result of drilling is a hole of the diameter determined by the drill. The drill is usually placed on the tailstock or lathe tool holder.

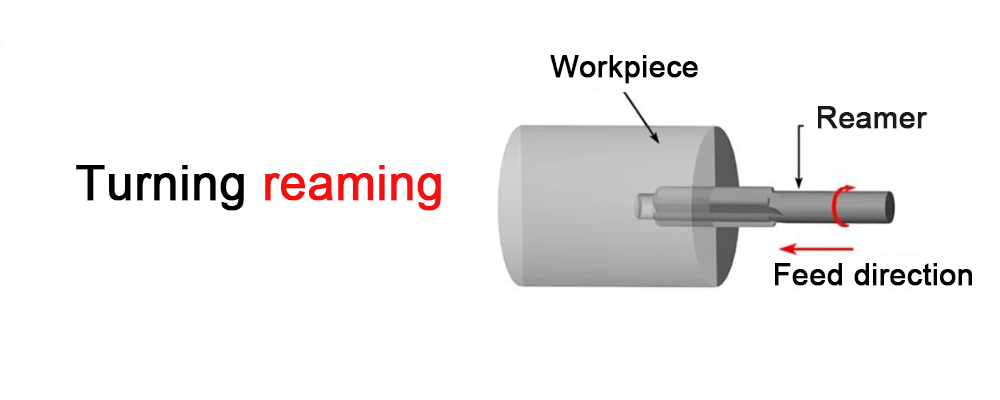

8. Turning Reaming

Reaming is a dimensional finishing operation used to finish a hole. In a reaming operation, the reamer enters the workpiece longitudinally through the end and machines the existing hole to the diameter of the drawing. Reaming removes a small amount of material and is usually performed after drilling to obtain a more accurate diameter and smoother internal surface.

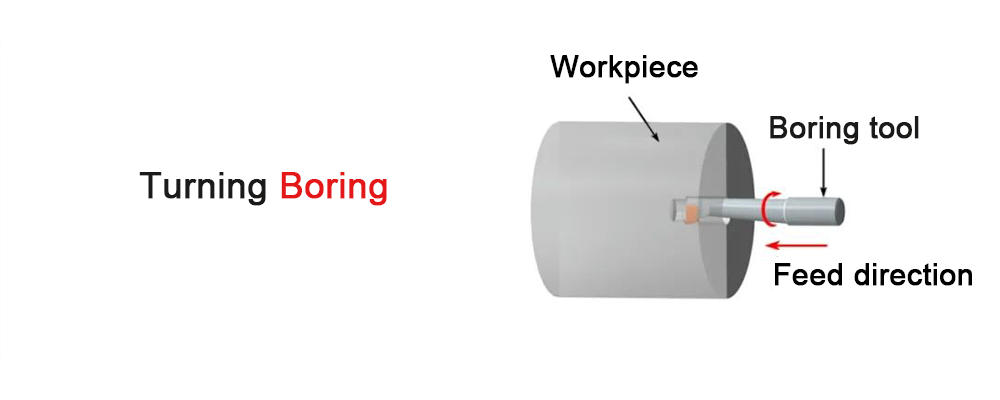

9. Turning Boring

In a boring operation, the boring tool enters the workpiece longitudinally and removes material along the inner surface to create a different shape or enlarge an existing hole.

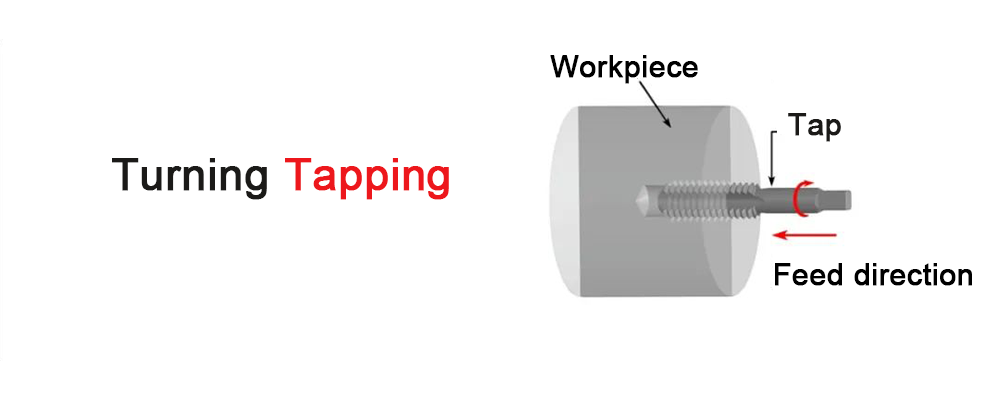

10. Turning Tapping

Tapping is a process in which a tap enters the workpiece longitudinally and machines threads in an existing hole. Before tapping, the bottom hole size of the machined hole diameter must have a corresponding size (if the bottom hole size is not right, tapping will easily cause the risk of tool breakage). Tapping is a finishing process for hole machining. Compared with CNC tapping, turning tapping has average stability but is more economical than CNC tapping.

Conclusion

This article only simply shares with you the traditional turning processing methods. If there is anything missing, you can leave us a message. Whether you encounter technical problems such as turning, face milling, slot milling, thread processing, pattern processing, boring and tapping, or want to find some cost-effective cutting products, please feel free to contact us.