One widely used method for achieving clean and properly conditioned surfaces is media blasting. By propelling abrasive particles at high speeds, this process removes rust, paint, scale, and other contaminants, while also smoothing or texturing surfaces as required. Its versatility has made it a standard practice across industries such as automotive, aerospace, marine, and construction.

This article provides a complete overview of media blasting—what it is, how it works, the types of media involved, its benefits and limitations, safety considerations, and best practices to ensure reliable results.

Table of Contents

What Is Media Blasting Surface Treatment?

Media blasting is a surface treatment process in which abrasive particles—known as “media”—are propelled at high speeds onto a workpiece using compressed air or water. The impact of the media cleans, smooths, or textures the surface by removing rust, paint, scale, or other contaminants. Depending on the type of media and pressure used, media blasting can also modify the surface’s microstructure, improve adhesion for coatings, enhance fatigue resistance, and create decorative or uniform finishes.

Basic Principles of Media Blasting

Power Source: Media blasting uses compressed air or water as the driving force to propel abrasive particles—called “media”—at high speeds toward the workpiece. The pressure can be adjusted depending on the type of media and the surface requirements, allowing for precise control of the process.

Surface Effects: The high-speed media particles impact the workpiece surface, acting like tiny cutting tools. Depending on the hardness and shape of the media, this impact can remove rust, paint, scale, or other contaminants while creating a desired surface texture. The resulting roughness improves coating adhesion, enhances fatigue resistance, and can leave a uniform, decorative, or functional finish.

Material Considerations: Different media types—such as glass beads, aluminum oxide, steel shot, walnut shells, or baking soda—affect the aggressiveness and finish of the process. Harder media remove material more aggressively, while softer or organic media provide gentle cleaning for delicate surfaces.

Process Control: Operators can adjust media type, particle size, pressure, and spray angle to achieve the desired surface finish without damaging the workpiece. This flexibility makes media blasting suitable for a wide range of materials, including metals, plastics, wood, and composites.

Media Blasting Operating Procedures

- Preparation: Ensure the work area is safe. Wear personal protective equipment as required, such as helmets, goggles, gloves, and protective clothing.

- Equipment Inspection: Check that the sandblasting machine is functioning properly, including the sandblasting gun, air compressor, abrasive storage container, and delivery system.

- Abrasive Selection: Choose appropriate abrasive based on material type and surface condition, such as quartz sand, steel grit, glass beads, or plastic pellets.

- Sandblasting Operation: Activate the machine to convey abrasive from the storage container through the delivery system to the gun. High-pressure air propels the abrasive at high velocity onto the object’s surface.

- Cleanup and Inspection: After blasting, remove residual abrasive and loose material from the surface. Inspect whether the surface achieves the desired treatment effect. Benefits of sandblasting include enhanced coating adhesion, improved surface finish and uniformity, and removal of surface defects that may cause corrosion or damage. However, the process may generate dust and noise, necessitating appropriate safety precautions and environmental protection measures.

Differences Between Media Blasting and Sandblasting

1. Media Blasting

- Definition: Media blasting is a general term for surface preparation or finishing processes where any type of abrasive material (“media”) is propelled at high speed to clean, smooth, or texture a surface.

- Abrasive Types: Can include glass beads, aluminum oxide, walnut shells, steel grit, plastic media, corn cob, ceramic beads, baking soda, and more.

- Applications: Versatile; used for delicate cleaning (e.g., aerospace parts), heavy-duty rust or paint removal, and surface texturing for coating adhesion.

- Advantages: Can be customized to the workpiece material and desired surface finish; gentler options are available for soft or sensitive parts.

2. Sandblasting

- Definition: Sandblasting is a type of media blasting that specifically uses sand (or sand-like abrasive alternatives such as garnet or olivine) to clean or prepare surfaces.

- Abrasive Types: Traditionally silica sand, though now often replaced with safer alternatives due to health concerns.

- Applications: Typically used for heavy-duty cleaning, rust and paint removal, or creating rough surface textures.

- Advantages: Very effective at removing coatings and corrosion quickly, but less gentle than other media options.

| Feature | Media Blasting | Sandblasting |

|---|---|---|

| Definition | Broad category of blasting with various abrasives | Specific type using sand or sand-like abrasives |

| Abrasive Variety | Multiple types: glass beads, walnut shells, aluminum oxide, steel grit, etc. | Sand or sand alternatives (garnet, olivine) |

| Surface Impact | Can be gentle or aggressive depending on media | Generally more aggressive; rougher surface finish |

| Versatility | High, suitable for delicate or precision work | Moderate, best for heavy-duty cleaning and roughening |

Types of Media Used in Media Blasting

The effectiveness of media blasting depends heavily on the type of abrasive chosen. Different media vary in hardness, shape, and aggressiveness, which directly affect the finish. Below are some commonly used materials:

- Sand: Traditionally used but now less common due to health risks from silica dust. Alternatives include garnet and olivine.

- Glass Beads: Provide a smooth, satin-like finish. Suitable for delicate cleaning and aesthetic purposes.

- Aluminum Oxide: Hard and durable, making it ideal for removing paint, rust, and corrosion.

- Walnut Shells: A natural, gentle option for cleaning softer materials without damage.

- Steel Grit and Steel Shot: Aggressive abrasives for heavy-duty removal of scale, coatings, or rust.

- Plastic Media: Softer abrasives, often used in aerospace and automotive industries for delicate parts.

- Corn Cob Grit: A mild option, good for cleaning wood and softer surfaces.

- Ceramic Beads: Durable and consistent, suitable for precision cleaning and deburring.

- Soda (Baking Soda): A gentle, eco-friendly option for removing contaminants without altering the substrate.

Each medium is chosen based on the material of the workpiece and the required surface finish. For example, steel grit might be used for preparing ship hulls, while soda blasting is more common for cleaning engines or delicate equipment.

Applications of Media Blasting

Pre-treatment for Coatings or Plating: Sandblasting removes contaminants such as dirt, grease, and oxides from part surfaces while creating a uniform textured finish. By switching abrasives, varying degrees of surface roughness can be achieved, enhancing adhesion between parts and coatings or plating.

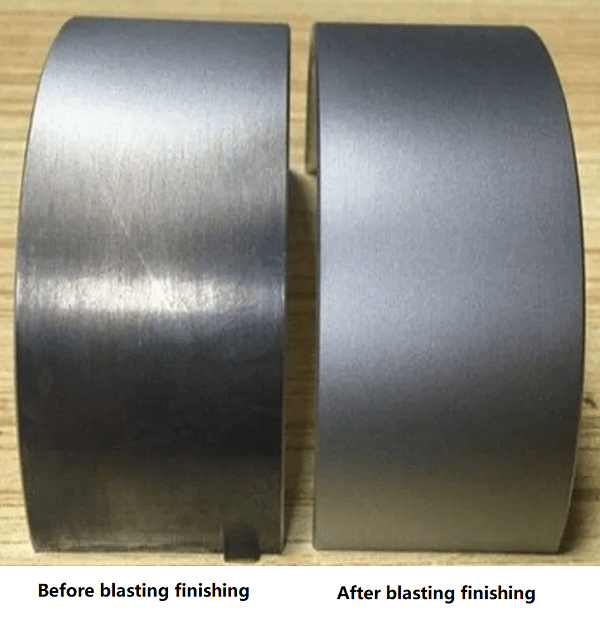

Cleaning and Polishing of Castings, Forgings, and Heat-Treated Parts: Sandblasting removes residual contaminants (such as scale and oil residues) from castings, forgings, and heat-treated components. It polishes surfaces to improve finish quality, effectively enhancing the aesthetic appeal of parts. By exposing a uniform, consistent metal base, sandblasting creates a visually appealing surface with decorative effects.

Media blasting + Anodizing Effect

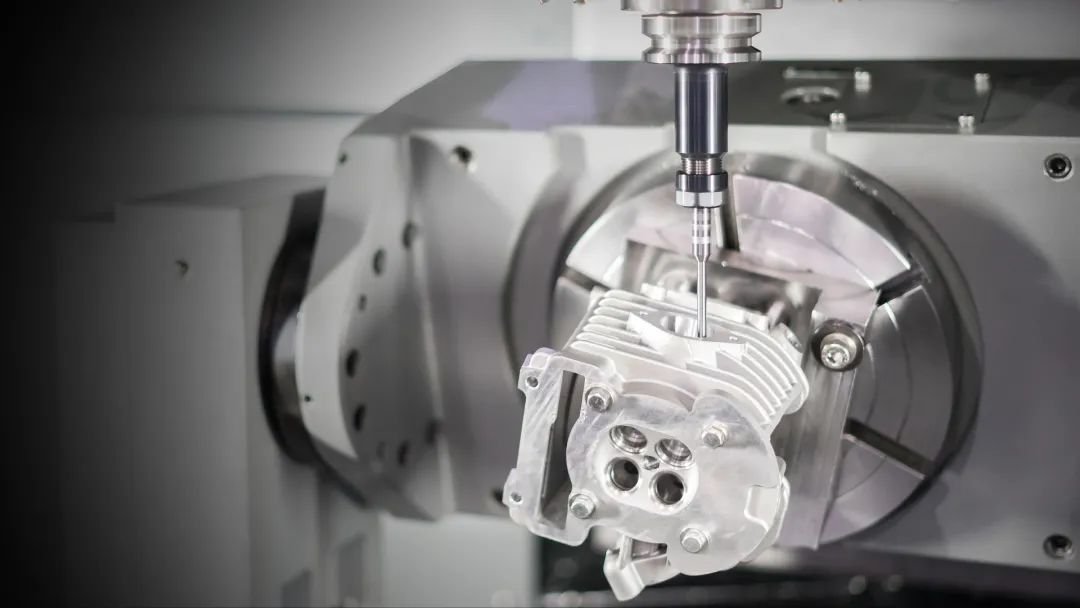

Deburring and Surface Enhancement for Machined Parts: Sandblasting removes minute burrs from workpiece surfaces, creating a smoother finish and eliminating potential hazards. It also produces very fine, rounded edges at surface junctions, enhancing the overall aesthetic appeal.

Enhancing Mechanical Component Performance: Sandblasting creates a uniform, fine surface texture (base pattern) that traps lubricating oil, improving lubrication conditions and extending mechanical service life.

Stress Relief: Impacting the workpiece surface removes residual stresses and increases surface strength. This treatment is commonly applied to springs, machining tools, and aircraft blades.

Advantages and Limitations of Media Blasting

Advantages:

Media blasting is widely used because it provides effective surface preparation, removing paint, rust, scale, and contaminants to create a clean base for coatings or bonding. Its versatility allows it to work on metals, plastics, wood, glass, and concrete, while operators can adjust pressure, angle, and media type to achieve anything from heavy stripping to delicate polishing. The process is also efficient, capable of treating large areas quickly or reaching complex geometries, and often proves more cost-effective than manual sanding, grinding, or chemical cleaning.

Limitations:

However, media blasting also comes with certain limitations. Fragile or soft materials can be damaged if the settings or abrasives are too aggressive, and the removal of material may affect tight tolerances or thin-walled parts. Surfaces that must remain untouched require masking, which adds time and cost, and some coatings or residues may still require chemical or thermal methods. In addition, professional blasting equipment represents a significant investment and requires skilled operation and ongoing maintenance.

Because of these trade-offs, it is important for engineers and manufacturers to weigh both the advantages and the limitations of media blasting when deciding whether it is the most suitable surface preparation method for their application.

Cost Factors in Media Blasting

The cost of media blasting varies depending on several factors, which makes it important to plan and budget effectively.

Key considerations include:

Type of Media: Harder or specialty abrasives (e.g., ceramic beads, aluminum oxide) tend to be more expensive than softer or organic media (e.g., walnut shells, corn cob).

Size and Complexity of the Part: Larger or more intricate parts require more time and media, raising costs.

Surface Condition: Surfaces with heavy rust, multiple paint layers, or tough coatings require more effort and longer blasting time.

Equipment and Labor: Costs vary between automated blasting systems and manual operations. Skilled labor also adds to the expense.

Waste Disposal and Recycling: Some media can be reused, lowering long-term costs, while others require careful disposal.

Compared to manual sanding, grinding, or chemical cleaning, media blasting is often more cost-effective in the long run, especially when dealing with large production volumes or frequent surface preparation needs.

Industries That Use Media Blasting

Media blasting is a versatile process that finds applications across many industries. Its adaptability makes it valuable for both heavy-duty and precision tasks. Some key industries include:

Automotive: Used for rust and paint removal, as well as surface preparation during both vehicle manufacturing and classic car restoration.

Construction: Effective in removing coatings, corrosion, or graffiti from concrete, metal structures, and building surfaces.

Marine: Shipyards rely on blasting to remove barnacles, rust, and old paint from ship hulls, preparing them for protective coatings.

Aerospace: Essential for cleaning and preparing aircraft components while preserving structural integrity. Plastic media and soda blasting are often chosen to avoid damaging sensitive parts.

Manufacturing: Applied in the production of metal components, tools, and machinery to ensure clean, uniform surfaces before coating, painting, or assembly.

These industries depend on media blasting for its ability to improve performance, extend service life, and ensure high-quality finishes.

FAQ: Common Questions About Media Blasting

1. Which materials are suitable for media blasting?

Most metals, ceramics, and even some plastics can be blasted. The choice of abrasive media ensures compatibility with the substrate.

2. Can media blasting damage parts?

If the wrong abrasive, pressure, or technique is used, parts may be overblasted or lose dimensional accuracy. Choosing the right media and settings prevents damage.

3. How does media blasting compare to chemical cleaning?

Unlike chemical treatments, media blasting is mechanical and does not involve harsh solvents. It offers faster results, less environmental risk, and more surface control.

4. Is media blasting environmentally friendly?

It depends on the media used. Natural abrasives like walnut shells, corn cob grit, and soda are more eco-friendly, while others require careful waste management.

5. Can I reuse blasting media?

Yes, many types—such as glass beads, steel shot, and ceramic beads—can be recycled multiple times, reducing cost and waste.

Conclusion

Media blasting is one of the most versatile and effective surface preparation methods available today. From removing rust and paint to producing precise finishes, it provides industries with a reliable way to improve product performance and longevity.

By understanding how the process works, choosing the right abrasive media, and following best practices, manufacturers and designers can achieve high-quality, consistent, and cost-effective results.

Whether in automotive, aerospace, marine, construction, or manufacturing, media blasting remains a trusted technique for achieving the clean, prepared surfaces that modern engineering demands.