Soft machining is a fundamental process in modern metal manufacturing. By machining materials in their soft or annealed state, manufacturers can remove bulk material efficiently, prepare parts for heat treatment, and ensure dimensional accuracy for downstream finishing. This guide covers everything from definitions, processes, methods, advantages, challenges, and supplier selection, to FAQs and case study insights.

Table of Contents

1. What Is Soft Machining?

Soft machining refers to the cutting and shaping of materials before heat treatment, when the material remains in an annealed or normalized state. Because the material hardness is still low, machining efficiency is higher, and tools experience significantly less wear. Soft machining is widely used for roughing and semi-finishing to prepare parts for subsequent heat treatment and hard machining.

2. Soft Machining Process Explained

Soft machining is a foundational stage in metal manufacturing, especially for parts that will undergo heat treatment later. A well-designed soft machining workflow ensures efficiency, precision, and stability throughout the entire production cycle. Below is a detailed breakdown of each step.

1. Material Preparation

Proper material preparation is the first step of a successful soft machining process. Before machining, most materials go through one or more treatments to obtain consistent hardness and structural stability.

Typical material preparation steps include:

- Annealing or Normalizing

This softens steel and ensures uniform grain structure, making cutting smoother and reducing tool load. - Cut-to-Length Operations

Materials are pre-cut via sawing, flame cutting, plasma cutting, or waterjet to create manageable blanks. - Stress Relief Treatment

Removes internal stresses from casting, forging, or rolling processes, preventing deformation during machining. - Surface Cleaning & Pre-Inspection

Rust removal, scale cleaning, and dimensional checks ensure stable fixturing and predictable machining performance.

2. Machine Setup & Fixturing

In soft machining, workholding stability determines cutting efficiency and part quality. Because feed rates and DOC are higher, poor fixturing can lead to vibration, chatter, and dimensional errors.

Common fixturing methods for soft machining include:

- Hydraulic or Pneumatic Chucks

Ideal for soft turning of shafts and rings, ensuring uniform clamping force. - Soft Jaws / Custom Machined Jaws

Provide precise support for irregular shapes or thin-walled components. - Modular Multi-Axis Clamps for Milling

Used in 3-axis, 4-axis, and 5-axis machining to ensure rigid positioning. - Fixture Plates for Large Castings or Blocks

Distribute clamping forces evenly to prevent warping during aggressive roughing.

3. Cutting Tools for Soft Machining

Tool selection plays a major role in achieving high efficiency during soft machining. Since the material is not hardened, more economical tools can be used while still delivering long tool life.

Typical tools used in soft machining:

- Carbide Inserts (Most Common)

Suitable for steel, stainless steel, and cast iron roughing and semi-finishing. - High-Speed Steel (HSS) Tools

Great for aluminum, copper, plastics, and low carbon steels. - Coated Carbide Tools (TiAlN, TiCN, DLC)

Improve heat resistance, reduce wear, and enhance chip control in soft milling and turning. - Indexable Milling Cutters

Ideal for high-volume roughing of large surfaces or castings.

4. Cutting Parameters in Soft Machining

One major advantage of soft machining is the ability to use aggressive cutting parameters. Because the material is soft and ductile, high material removal rates can be achieved without compromising tool life.

Typical soft machining parameter trends:

- Higher Spindle Speeds (RPM)

Works especially well with aluminum, copper, or annealed steel. - Higher Feed Rates

Enables faster cycle times while maintaining acceptable surface finishes. - Larger Depth of Cut (DOC)

Removes bulk material efficiently in early stages. - Coolant Use for Chip Flush & Heat Control

Water-soluble cutting fluids or high-pressure coolant systems improve chip evacuation and extend tool life.

5. Quality Control During Soft Machining

Even though soft machining is often a roughing or pre-shaping stage, quality control remains critical. Poor accuracy at this stage can lead to part distortion after heat treatment or insufficient machining allowances for finishing.

Common quality checks in soft machining:

- Dimensional Inspection

Calipers, micrometers, height gauges, and CMM for key dimensions. - Geometric Tolerances

Checks for flatness, perpendicularity, roundness, and concentricity. - Surface Roughness Evaluation

Ensures surfaces meet requirements before entering the hard machining or heat treatment stage. - Pre-Heat-Treatment Allowance Verification

Ensures enough material remains for finishing after heat treatment.

3. Common Soft Machining Methods

Soft machining covers a wide range of machining operations performed before heat treatment, primarily aimed at roughing, shaping, and preparing components for hard machining or finishing. Below are the most commonly used soft machining methods, along with their typical applications and key advantages.

1. Turning (Soft Turning)

Soft turning is one of the most widely applied soft machining processes, especially for shafts, bushings, rings, flanges, and cylindrical components.

What soft turning involves:

- A cutting tool removes material while the workpiece rotates

- High feed rates and large depth of cut are possible

- Excellent for roundness, concentricity, and diameter control

Common applications:

- Automotive drive shafts

- Gear blanks

- Bearing housings

- Hydraulic cylinder tubes

Benefits of soft turning:

- High material removal efficiency

- Lower tooling cost due to reduced hardness

- Stable dimensional control before heat treatment

- Ability to generate near-net-shape profiles

Soft turning is often paired with hard turning after heat treatment to finalize tolerances and surface finish.

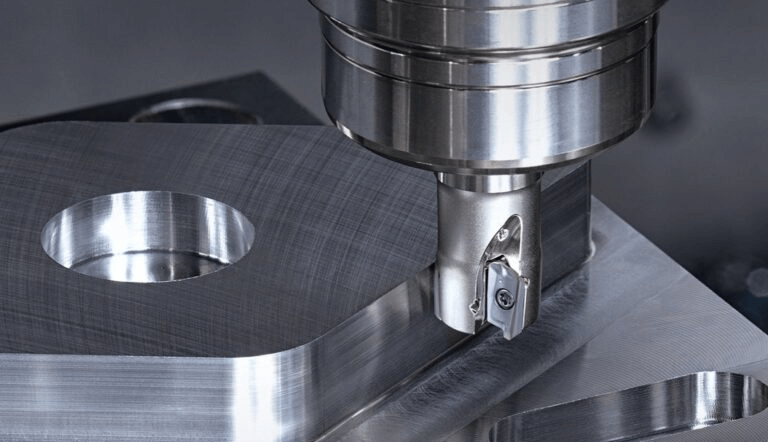

2. Milling (Soft Milling)

Soft milling is used to shape surfaces, slots, cavities, and complex geometries before final hardening. Since the material is soft, aggressive cutting strategies significantly reduce cycle times.

Typical soft milling operations:

- Face milling

- Slot and pocket milling

- Rough contouring

- 3-axis or 5-axis surfacing

- Milling of casting and forging stock

Typical applications:

- Gearbox housings

- Structural brackets

- Mold bases

- Engine blocks & large aluminum parts

Advantages:

- Fast roughing with large DOC

- Excellent flexibility for design changes

- Suitable for castings and large blocks

- Ensures adequate machining allowance pre-hardening

Soft milling is a critical step in preparing parts for finishing cuts or precision machining.

3. Drilling & Tapping

Drilling and tapping in the soft stage is essential for creating pilot holes, threaded holes, and pre-machined features that will later endure high loads after heat treatment.

Typical operations include:

- High-speed drilling

- Deep hole drilling

- Tapping and thread milling

- Counterboring and countersinking

Common applications:

- Bolt holes in castings

- Pilot holes for shafts

- Threaded holes in housings

- Cooling channels in molds

Key benefits:

- Much lower risk of tap breakage compared with hardened material

- High-speed drills increase productivity

- Threads formed before heat treatment maintain higher accuracy

- Reduced machining time in final stage

Drilling and tapping during the soft machining stage significantly lowers tooling risk and cost.

4. Grinding

While grinding is more typical after heat treatment, certain conditions require grinding during the soft stage especially for large castings, warped parts, or components that must achieve specific flatness before hard machining.

Soft grinding is used for:

- Flatness and parallelism correction

- Removing scale from castings

- Pre-finishing surfaces before nitriding or carburizing

Advantages:

- Precise geometric control

- Improved surface quality before hardening

- Less wear on grinding wheels compared with hard grinding

Soft grinding helps ensure that parts remain stable throughout the heat treatment cycle.

Summary of Soft Machining Methods

| Method | Best For | Advantages |

| Soft Turning | Shafts, rings, precision diameters | Fast, stable, cost-effective |

| Soft Milling | Complex shapes, castings | High MRR, flexible geometry |

| Drilling & Tapping | Holes & threads | Low tool risk, high accuracy |

| Soft Grinding | Flatness, surface prep | Better stability before heat treatment |

4. Advantages of Soft Machining

1. High Material Removal Rate (MRR)

In the soft stage, materials retain lower hardness and improved ductility, allowing cutting tools to engage with less resistance. This enables:

- Higher spindle speeds and feed rates

- Larger depth of cut (DOC)

- Aggressive roughing strategies such as high-feed milling, trochoidal machining, or dynamic milling

- Reduced overall machining time by 30–70% compared to hard machining

For manufacturers, this translates directly into:

- Shorter production cycles

- Higher machine utilization

- Increased throughput and capacity

This is especially valuable when removing large casting allowances or shaping heavy-duty structural components.

2. Lower Tool Wear & Cost

Because the material has not been hardened, cutting forces and temperatures are significantly lower. As a result:

- Carbide inserts maintain edge sharpness longer

- HSS tools become viable, reducing cost on drills and taps

- Tool changes are less frequent, reducing downtime

- Fewer chips are work-hardened, preventing premature chipping

For purchasing and business owners, this means:

- Lower tooling budget

- More predictable tool life

- Less risk of tool-related scrap

For engineers, stable tool performance also ensures higher process reliability.

3. Better Dimensional Stability

Machining in the soft state helps preserve geometric accuracy because:

- The material has minimal internal stress

- The cutting process generates less heat

- Deformation risk is lower during clamping or heavy roughing

- Dimensional drift over long cycles is reduced

This stability is crucial for:

- Maintaining straightness on shafts

- Ensuring flatness on large plates or molds

- Preparing accurate datums for CNC finishing after heat treatment

By controlling deformation early, manufacturers greatly reduce the risk of post-HT scrap.

4. Ideal for Roughing & Pre-Shaping

Soft machining is the most efficient stage for shaping parts close to their final geometry. Benefits include:

- Easily remove large-volume stock from forging, casting, or billet

- Create reference surfaces and datums for future hard machining

- Prepare critical features such as bores, pockets, and slots

- Leave controlled machining allowances for heat treatment and finishing

This pre-shaping step ensures that heat treatment has less impact on geometry, and final hard machining can focus purely on precision rather than heavy stock removal.

5. More Flexible Manufacturing

Because the material is easy to cut, soft machining allows manufacturers to adapt quickly:

- Design changes can be incorporated without high tooling cost

- Process adjustments (feed, toolpath, DOC) can be made easily

- Prototypes can be created rapidly for engineering validation

- Small batch production becomes economical and fast

For buyers and project managers, this flexibility is especially valuable in:

- Early product development

- Engineering trials

- Custom or low-volume production

- Projects requiring fast turnaround

Before a part is hardened, modifications are significantly cheaper and faster, reducing project risk and improving overall agility in production.

5. Soft Machining vs Other Manufacturing Methods

Soft machining is frequently compared with other manufacturing processes such as casting, hard machining, and heat-treatment-based workflows. Understanding these differences helps engineers and buyers make the right production decisions, reduce cost, and achieve better part performance.

1. Soft Machining vs Casting

Casting is often the first step in producing large or complex metal parts, while soft machining is used to refine the casted surface and prepare critical dimensions.

How They Differ

| Aspect | Soft Machining | Casting |

| Purpose | Shaping, roughing, pre-finishing | Producing raw material or near-net shapes |

| Precision | High (±0.05–0.2 mm typical) | Low to medium |

| Flexibility | High (easy to modify features) | Low (changes require new molds) |

| Surface Finish | Good (Ra 1.6–6.3 µm) | Poor to medium (Ra 6.3–25 µm) |

Key Insight

- Casting creates the shape. Soft machining creates the accuracy.

- Nearly all cast parts need soft machining for surfaces that interact with bearings, seals, gears, or precision fits.

When to choose soft machining over casting

- When design changes are frequent

- When tighter tolerances are required

- When flatness, concentricity, or surface finish matters

- When casting shrinkage must be corrected

Soft machining ensures the final component meets engineering-grade specifications.

2. Soft Machining vs Hard Machining

Soft machining is performed before heat treatment. Hard machining is performed after heat treatment, when the material hardness usually rises to HRC 45–65.

Key Differences

| Attribute | Soft Machining | Hard Machining |

| Material Hardness | Below ~HRC 30 | HRC 45–65 |

| Cutting Load | Lower | Very high |

| Tooling Cost | Low | High (ceramics, CBN, PCD) |

| Material Removal Rate (MRR) | High | Low |

| Application | Roughing, semi-finishing | Finishing after hardening |

Why Soft Machining Is Still Necessary

- Hard machining alone cannot handle heavy stock removal

- Soft machining produces stable geometry before heat growth occurs

- It reduces part deformation during heat treatment

- It ensures sufficient machining allowance for final finishing

Soft machining and hard machining complement rather than replace each other.

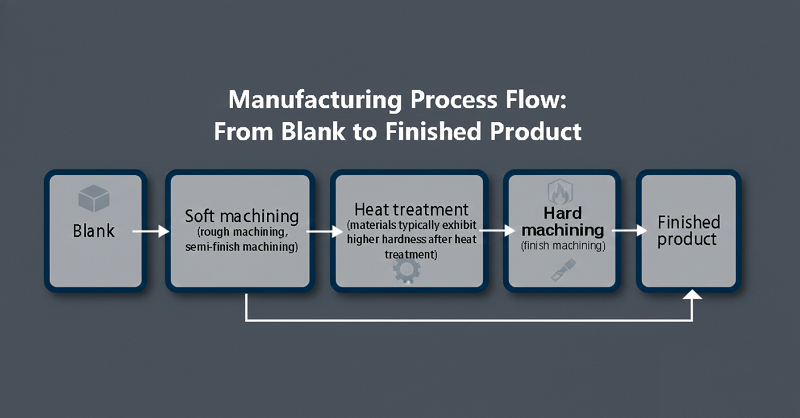

3. Soft Machining vs Heat Treatment Sequence

Heat treatment changes the internal structure of metals, impacting hardness, strength, and dimensional stability. Soft machining typically occurs before heat treatment for a reason.

Why Soft Machining Comes First

- Heat-treated materials deform or warp

- Cutting hardened material requires slower speed and expensive tools

- Removing large volumes post-hardening risks thermal cracks

- Pre-machining removes surface defects that could propagate during heat treatment

Typical Workflow

- Casting / forging / raw material cutting

- Soft machining → shaping + roughing

- Heat treatment → hardening, quenching, tempering

- Hard machining → finishing tolerance

- Grinding or polishing if required

Advantages of This Sequence

- Ensures dimensional accuracy after heat treatment

- Reduces overall manufacturing cost

- Improves part performance through controlled geometry and tolerances

- Minimizes scrap risk at the final stage

This sequence is the industry standard for shafts, gears, bearings, molds, aerospace components, automotive driveline parts, and many precision-machined items.

6. Industries Using Soft Machining

Soft machining plays a foundational role in many industries, particularly during initial manufacturing stages:

- Automotive (shaft, bushings, gear blanks, brackets)

- Aerospace (structural components, housings)

- Industrial machinery (frames, casings, blocks)

- Mold making (core blocks, cavity blocks before heat treatment)

- Oil & gas (valves, manifolds)

- Heavy equipment & construction machinery

Any part that requires heat treatment + precision finishing will typically undergo soft machining first.

Soft machining provides several strategic advantages that make it a critical stage in modern manufacturing, especially for components that require heat treatment and precision finishing. Below are the key benefits, expanded with deeper technical and business insights.

7. Conclusion

Soft machining is a critical step in modern manufacturing, especially for parts that will undergo heat treatment or hard machining. By machining metals in their soft or annealed state, manufacturers can achieve high material removal rates, lower tool costs, better dimensional stability, and more flexible production.

Throughout the soft machining process from material preparation, machine setup, fixturing, and cutting parameter optimization, to quality control, precision and efficiency are the keys to success. Common soft machining operations, including soft turning, soft milling, drilling, tapping, and optional pre-grinding, provide engineers and manufacturers with the flexibility to shape parts quickly while maintaining accuracy for downstream finishing.

Choosing a reliable soft machining supplier is essential. Suppliers with proper certifications, advanced CNC equipment, extensive experience with various materials, and robust quality assurance systems can help reduce risk, control costs, and ensure timely delivery.

Soft machining also complements other manufacturing methods:

- Casting provides near-net shapes, while soft machining ensures dimensional accuracy.

- Hard machining finalizes tolerances, with soft machining handling heavy stock removal efficiently.

- Heat treatment sequences rely on soft-machined reference surfaces to maintain geometry and stability.

By understanding the benefits, challenges, and best practices of soft machining, engineers, procurement managers, and company owners can make informed decisions that improve part quality, reduce production costs, and streamline manufacturing workflows.