Basic Introduction to Reamers

A reamer is a rotary cutting tool featuring one or more cutting teeth designed to remove a thin layer of metal from the surface of a machined hole. It is a precision finishing tool with straight or helical flutes, used for reaming or finishing holes. Due to its minimal material removal, reamers typically demand higher machining accuracy than drills. They can be operated manually or mounted on a drill press for operation.

Table of Contents

Primary Applications of Reamers

Holes processed with reamers achieve precise dimensions and shapes.

Reamers are used to ream holes that have been previously drilled (or reamed) on workpieces, primarily to enhance hole machining accuracy and reduce surface roughness. They serve as tools for finishing and semi-finishing operations, typically requiring minimal machining allowance.

Types of Reamers

Hand Reamer

As the name suggests, hand reamers are cutting tools used for manual reaming operations. They are employed to ream holes that have already been drilled (or reamed) on workpieces, primarily to enhance hole machining accuracy and reduce surface roughness. These tools are used for finishing and semi-finishing operations, typically with very small machining allowances.

Reaming Accuracy

Hand reamers achieve r eaming accuracy of H7, H8, and H9 for internal bores.

Precautions for Hand Reamers

Workpiece must be clamped squarely.

During reaming, apply balanced force with both hands.

When withdrawing the reamer, do not reverse it. Due to the reamer’s relief angle, reverse rotation may cause chips to jam between the reamer teeth and the hole wall, scratching the hole surface. This also accelerates reamer wear.

After use, clean the reamer thoroughly, coat it with machine oil, and store it in a box to prevent damage to the cutting edge.

Machine Reamer

A type of reamer specifically designed for use in machinery.

Machine Reamers Type

Concept of Straight Shank Machine Reamers:

Straight shank machine reamers are used for reaming holes to a specified precision on machine tools, performing semi-finishing and finishing operations on holes. They can also serve as pre-machining tools prior to grinding or lapping.

Applications of Straight Shank Machine Reamers:

Straight shank reamers are employed to ream holes that have been previously drilled (or reamed) on workpieces. Their primary purpose is to enhance hole machining accuracy and reduce surface roughness. These tools are used for finishing and semi-finishing operations, typically with very small machining allowances.

Carbide Taper Shank Machine Reamer:

Features and Precision: YT material is used for machining steel parts, and YG material is used for machining castings. Holes are priced at H7, H8, and H9, respectively.

Applications: Used for reaming matching holes in cast iron and steel parts.

Features: High number of teeth, stable operation, and good guidance.

Adjustable reamer

An adjustable reamer is one whose cutting edge diameter can be slightly adjusted multiple times for reuse, significantly reducing wear and tear and lowering processing costs.

Why design an adjustable reamer?

Because reamers are precision machining tools, they require extremely high dimensional accuracy. Even the slightest wear and tear can affect the dimensional tolerances of the workpiece. This is especially true in applications where reamers are used extensively, such as automotive engines. Since even the slightest wear and tear on the cutting edge can lead to scrapping, the reamer’s wear and tear is extremely high. To address this contradiction, adjustable reamers were developed.

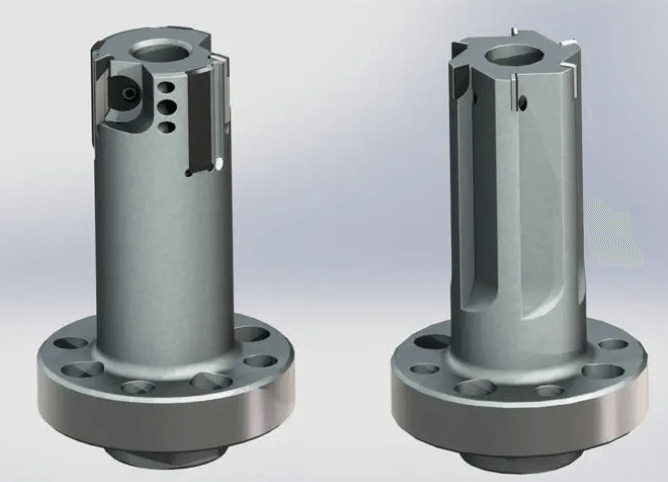

Modular Reamers

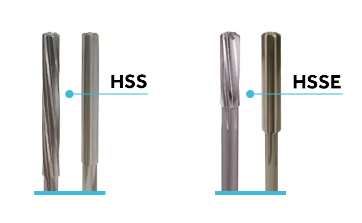

Modular reamers are reamers with separate cutting heads that can ream holes of different sizes. This makes them more precise than adjustable reamers, but they may also be more expensive. They are typically made of high-speed steel (HSS) or carbide. High-speed steel reamers are a good choice for general reaming, while carbide reamers are better suited for machining harder materials.

Modular reamers typically feature a threaded shank with precise taper for exact positioning onto a modular adapter, allowing easy reamer replacement based on required dimensions or material being reamed. Introduced to address rising tooling cost pressures, modular reamers offer high flexibility and reduce tool replacement frequency over time.

Reamer Design

Number of Teeth

⑴ Reamers generally have 4-12 teeth.

⑵ Large-diameter reamers require a higher number of teeth.

⑶ Tough materials require a lower number of teeth, brittle materials require a higher number of teeth.

⑷ For ease of measurement, reamers generally use an even number of teeth.

① Straight Back Tooth

- Generally used for fine-tooth milling cutters for semi-finishing and finishing.

- Straight tooth grooves are easy to manufacture and are generally used for reamers with a diameter of 1-20 mm.

② Arc Back Tooth

- Arc tooth grooves provide greater chip space and tooth strength and are generally used for reamers with a diameter greater than 20 mm.

③ Broken Line Back Tooth

- Broken line tooth grooves are used for carbide reamers.

Slot Type

The flutes of reamers can be manufactured as either straight slots or spiral slots:

⑴ Straight-slot reamers are commonly used in production due to their ease of manufacturing, sharpening, and inspection.

⑵ Spiral-slot reamers offer advantages such as light and smooth cutting, stable operation, and efficient chip evacuation. They are primarily used for reaming deep holes and holes with interrupted surfaces.

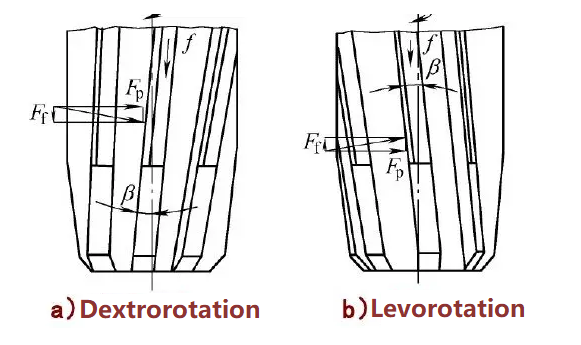

PS: Spiral directions include left-hand and right-hand.

① Right-hand reamers: Chips are ejected backward during cutting, suitable for blind holes. However, the cutting force Ff aligns with the feed direction, potentially causing “automatic feed” during operation.

② Left-hand reamers: Chips are ejected forward during cutting. The feed force Ff opposes the feed direction, ensuring secure clamping. Thus, they are suitable for through holes.

Common Reaming Methods

Preparation Phase:

Machine Lubrication Maintenance: Before reaming, thoroughly wipe away oil residue from the drill press. Run the machine idle for several minutes to lubricate and maintain it, then pause the power supply to install the workpiece.

Installation and Preparation:

Workpiece Mounting: Secure the workpiece onto the drill press according to machining requirements.

Tool Preparation: Prepare the drill sleeve, drill chuck, drill bit, and corresponding reamer sizes. For example, to drill a 16mm pin hole, install the drill sleeve and a 15.8mm drill bit for pre-drilling.

Reaming Operation:

Pre-drilling: Use an appropriate drill bit for pre-drilling to establish the foundation for subsequent reaming.

Reaming Bit Replacement: After pre-drilling, replace with a reaming bit of the corresponding size and apply an appropriate amount of lubricant to the hole.

Adjust Parameters: Modify the drill press’s speed and feed rate based on material hardness and machining requirements. For example, use 150 RPM and a 0.2mm feed rate for hard materials.

Drilling Operation: Start the drill press and slowly advance the reamer clockwise into the hole until the predetermined depth is reached. Note: Only clockwise rotation is permitted during reaming to prevent damage to the reamer teeth.

Check fit: Periodically pause the operation during reaming to insert a pin of the corresponding size into the hole and verify the fit. If the hole is too loose, replace the reamer or adjust the machining parameters.

Cleaning debris: Regularly remove debris and chips from the hole during reaming to ensure hole accuracy and quality. Failure to promptly clear debris may result in an enlarged hole after reaming.

Characteristics of Reaming Process

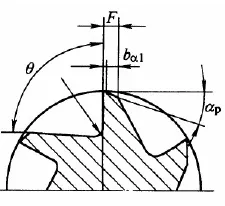

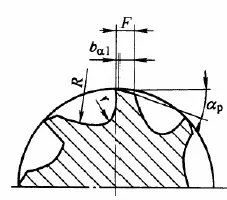

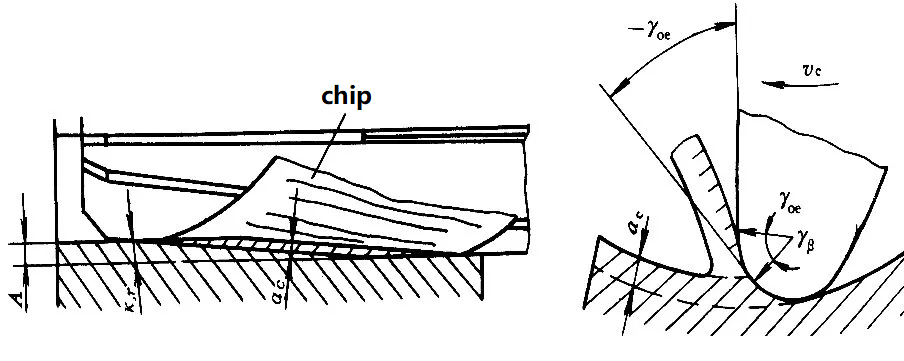

The reaming process involves a complex combination of cutting, extrusion, and friction.

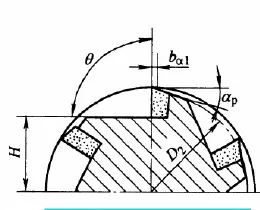

Cutting Depth in Reaming Operating Conditions of Reaming Cutting Edge Operating Conditions of Reaming

High machining quality with minimal allowances: Rough reaming allowance ranges from 0.15 to 0.25 mm, while finish reaming allowance ranges from 0.05 to 0.185 mm.

Fixed-diameter finishing tools: High production efficiency but limited adaptability. Each tool is designed for a single hole size.

Processing small to medium-diameter holes, typically less than 80 mm in diameter.

Precautions for Reaming

1. Requirements for Holes Before Reaming

The surface roughness of the hole must be less than 3.2 μm.

Reamers cannot correct straightness errors in holes.

For difficult-to-machine holes, the general procedure is:

Center drill positioning → Drilling → Reaming → Reaming

2. Adjust the coaxiality between the spindle and tailstock sleeve axes.

Coaxiality should ideally be within 0.02 mm.

Use a floating sleeve for the final reaming pass.

3. Selecting Appropriate Reaming Parameters

The depth of cut should be half the reaming allowance.

Lower cutting speeds yield finer surface roughness, speeds below 5 m/min are optimal.

Due to minimal material removal and the finishing section on the reamer, a higher feed rate is permissible.

When reaming steel, select a feed rate of 0.2–1 mm/rev.

4. Optimal Cutting Fluid Selection

When using a new reamer on steel, employ a 10%-15% emulsion as cutting fluid to prevent hole enlargement.

As the reamer wears, switch to an oil-soluble cutting fluid to allow slight hole expansion.

For castings: Kerosene

For bronze or aluminum alloys: L-FD-2 bearing oil or kerosene

Alternative to reamers

Reamers are primarily used for finishing holes, but if alternatives to reamers are needed, the following tools and methods can be considered based on specific machining requirements:

1. Drills

Twist Drill: Suitable for drilling holes in general materials, the most common drilling tool, ideal for rough machining.

Center Drill: Used to pre-drill holes in workpieces, ensuring accuracy for subsequent drilling.

Deep hole drill: Suitable for drilling deep holes, offering excellent chip removal and cooling performance.

2. Reamers

Used to enlarge the diameter of existing holes, typically removing more material than reamers but with slightly lower precision.

3. Countersink drills

Used for countersinking, which involves machining a specific shaped flat surface or countersunk hole at the hole’s entrance.

4. CNC Machining Centers

Utilizes CNC machine tools for hole processing, achieving high precision and efficiency. Suitable for complex or precision hole machining tasks.

5. Rotary Tools

Reamers: Combines features of reamers and milling cutters, suitable for medium-precision hole machining.

Multi-Flute Reamers: Features multiple cutting edges to enhance machining efficiency and surface finish.

6. Specialized Machining Methods

Electrical Discharge Machining (EDM): Suitable for machining holes in hard materials or complex geometries.

Laser Machining: Utilizes high-energy laser beams for hole processing, ideal for high-precision and micro-hole applications.

7. Manual Tools

Hand Reamers: Suitable for finishing holes in small batches or maintenance work, offering flexibility but lower efficiency.

Combination tools: Such as drill-reamer combinations, enabling simultaneous drilling and reaming operations to boost efficiency.

8. Alternative Solutions

Broaching: Used for high-precision hole machining by removing material through broaching, suitable for mass production.

Grinding tools: Such as internal cylindrical grinders, suitable for ultra-high-precision hole machining, though equipment costs are high.

FAQs Reaming

Reaming Allowance?

Reaming allowance refers to the diameter-direction machining allowance left after the preceding process (drilling or reaming). Whether the reaming allowance is appropriate significantly impacts the surface roughness and precision of the reamed hole. The reaming allowance should not be excessively large or small. If the allowance is too large, it inevitably increases the cutting load on each tooth, compromises reaming stability, generates excessive cutting heat, causes the reamer diameter to expand, and consequently enlarges the hole diameter. Simultaneously, chips will tear, increasing surface roughness. This not only results in a rough hole finish but also accelerates reamer wear. Conversely, an excessively small reaming allowance makes it difficult to correct and remove residual deformation and machining marks from the preceding process. This prevents the elimination of prior tool marks and fails to achieve the required surface roughness, resulting in substandard reamed hole quality. Furthermore, the small allowance forces the reamer to cut in a scraping state, causing severe wear and reducing tool durability.

Regarding cutting parameters for reaming and boring in machining?

Reaming typically operates with the workpiece stationary while the reamer rotates and advances axially into the hole. On a lathe, the workpiece rotates while the reamer performs axial feed. During reaming, the cutting portion at the front end performs the cutting action, while the rear calibration section guides, dampens vibrations, finishes the surface, and ensures dimensional accuracy. The hole’s dimensional and geometric precision is directly determined by the reamer. Reaming can be categorized into rough reaming and finish reaming. It is typically performed on lathes, boring machines, or drilling machines, referred to as machine reaming, though manual reaming is also possible. Rough reaming achieves a cutting depth (single-side machining allowance) of 0.3–0.8 mm, with machining accuracy reaching IT10–9 and surface roughness of Ra10–1.25 µm. Finishing reaming employs a cutting depth of 0.06–0.3 mm, achieving machining accuracy of IT8–6 and surface roughness of Ra 1.25–0.08 µm. Cutting speeds for reaming are relatively low. For example, when reaming steel components with a carbide cylindrical multi-flute reamer, cutting speeds range from 6 to 12 m/min for hole diameters of 40 to 100 mm, with feed rates of 0.3 to 2 mm/r. Proper selection of cutting fluids such as kerosene, machine oil, or emulsions can enhance reaming quality and tool life while reducing vibration.

Conclusion

In summary, reamers play a vital role in machining by ensuring high accuracy, smooth finishes, and reliable hole dimensions. From hand reamers to machine and adjustable reamers, each type serves a unique purpose in achieving precise results across various industries. Selecting the right reamer, applying proper machining parameters, and following best practices are essential for maintaining efficiency and tool life.

At YPMFG, we specialize in precision CNC machining services, including custom hole finishing solutions with advanced inspection equipment. Whether you require high-precision reaming, prototyping, or mass production, our team delivers consistent quality and accuracy to meet your specific needs. With our expertise, your projects benefit from tighter tolerances, superior surface finishes, and reliable performance.

Contact YPMFG today to learn how our CNC machining solutions can support your next project with precision and efficiency.