In the industrial manufacturing sector, precision sheet metal enclosures have become the core carriers for products such as mechanical equipment, communication terminals, industrial control cabinets, and CNC machine tools due to their lightweight, high-strength, and high-adaptability characteristics. Their manufacturing processes demand stringent precision and process coordination, making them susceptible to various quality issues influenced by factors like material properties, equipment accuracy, and process parameters. Drawing on frontline production experience, this article identifies common process challenges in precision sheet metal enclosure manufacturing and provides targeted solutions.

I. Difficulty in Controlling Bending Accuracy

Prone to dimensional deviations and angular errors

Bending is the core process for shaping precision sheet metal enclosures and also the stage most susceptible to errors. Common issues include actual post-bending dimensions exceeding drawing tolerances, inaccurate bending angles, and warping or distortion of the workpiece. These problems are largely related to material springback, improper selection of bending dies, and unreasonable settings of pressure and bending speed.

Solutions

- Accurately calculate springback and compensate in die design:

Different sheet metal materials and thicknesses have different springback rates. Data should be obtained through preliminary trial bends, and springback compensation should be reserved during die design. For example, stainless steel has a higher springback rate than ordinary cold-rolled steel, so the die angle must be adjusted accordingly. - Match dedicated dies and optimize bending parameters:

Select appropriate dies based on the length and thickness of the bending edge to avoid uneven stress caused by using small dies for large workpieces. At the same time, fine-tune bending pressure and speed through multiple trial bends to ensure uniform force distribution and stable deformation of the sheet. - Adopt CNC bending equipment to improve automated precision:

CNC press brakes can precisely control bending angles and stroke through programmed settings, significantly reducing human error. They are especially suitable for sheet metal enclosures with multiple bends and high-precision requirements.

II. Thin Sheet Processing Is Prone to Deformation

Affecting Assembly Fit

Precision sheet metal enclosures commonly use thin sheets with a thickness of 0.5–2 mm. Such materials have low rigidity and are highly susceptible to plastic deformation during shearing, stamping, and handling. This often results in uneven surfaces and warped edges, directly affecting subsequent assembly accuracy and overall appearance quality.

Solutions

- Optimize processing methods to reduce stress-induced damage:

Replace traditional shearing with laser cutting. Laser cutting has a small heat-affected zone and smooth cuts, which helps minimize deformation caused by mechanical stress during cutting. During stamping, add flattening dies to reduce sheet warping. - Increase tooling and fixtures, standardize handling procedures:

Use dedicated fixtures to secure sheets during processing to prevent deformation caused by improper clamping. During transportation, use vacuum suction cups or flexible lifting tools to reduce impacts and compression from manual handling. - Design reinforcing ribs to enhance sheet rigidity:

At the product design stage, incorporate reinforcing ribs according to enclosure structural requirements. This not only improves the load-bearing capacity of thin sheets but also effectively suppresses deformation during processing and use.

III. Welding Deformation and Weld Seam Defects

Reducing Sealing Performance and Aesthetic Quality

For precision sheet metal enclosures that require assembly from multiple parts, welding is a critical process. Common welding issues include welding deformation, porosity, slag inclusion, and incomplete penetration. These defects not only affect appearance but may also reduce sealing performance and structural strength.

Solutions

- Select appropriate welding methods and control heat input:

Choose welding processes based on material type and thickness. For thin sheets, prioritize low-heat-input methods such as TIG welding or laser welding to reduce thermal deformation. Use segmented welding and symmetrical welding techniques to disperse heat and avoid localized overheating. - Prepare thoroughly before welding and strictly control parameters:

Clean oil, contaminants, and oxide layers from welding areas beforehand to ensure tight joint fit-up. Adjust current, voltage, and welding speed according to the material to improve weld formation quality. - Post-weld correction to repair deformed workpieces:

For slight post-weld deformation, apply manual correction or specialized straightening fixtures. For weld defects, use grinding and repair welding to ensure smooth, strong, and reliable weld seams.

IV. Uneven Surface Treatment

Affecting Appearance and Corrosion Resistance

Surface treatment of precision sheet metal enclosures directly determines their appearance and corrosion resistance. Common problems include uneven coating thickness, noticeable color differences, and peeling or flaking of plated layers. These issues are often caused by insufficient pretreatment or unstable coating parameters.

Solutions

- Strengthen pretreatment processes to improve substrate adhesion:

Before coating, perform degreasing, rust removal, and phosphating to eliminate surface contaminants and oxide layers, enhancing coating adhesion. Before electroplating, conduct proper degreasing, pickling, and activation to ensure uniform plating. - Optimize surface treatment process parameters:

Use electrostatic spraying instead of traditional manual spraying. Electrostatic spraying allows coating particles to adhere evenly to the surface, ensuring consistent thickness. Control environmental temperature and humidity during spraying to avoid color variation caused by environmental factors. - Implement quality inspection and strict finished-product standards:

After surface treatment, measure coating thickness with a coating thickness gauge and verify color consistency using a colorimeter. Rework nonconforming products to ensure surface quality meets design requirements.

V. Insufficient Hole Position Accuracy

Restricting Assembly Efficiency

Mounting holes and locating holes on precision sheet metal enclosures require extremely high accuracy. Deviations in hole position or diameter can prevent component assembly or result in excessive assembly gaps. These issues are usually related to insufficient equipment precision or inaccurate fixture positioning.

Solutions

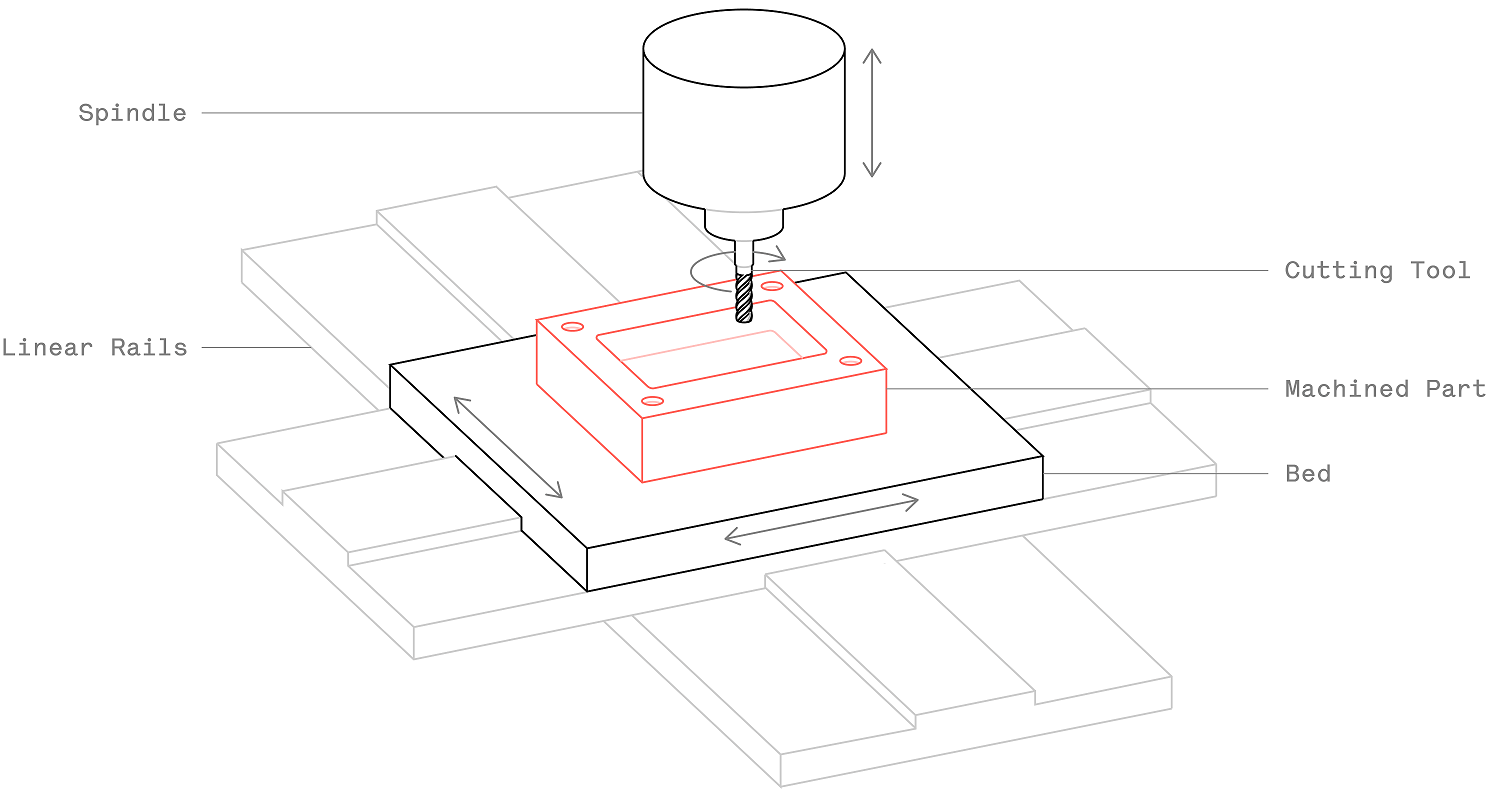

- Use high-precision processing equipment to ensure hole accuracy:

Employ CNC punching machines or laser cutting machines for hole machining. CNC equipment can achieve positioning accuracy of up to ±0.1 mm, meeting the requirements of precision sheet metal enclosures. - Design dedicated positioning fixtures to reduce alignment errors:

For mass production, create specialized positioning fixtures to ensure consistent sheet positioning in every operation, avoiding hole deviations caused by manual alignment. - Establish a first-article inspection system to correct deviations early:

Before batch production, process a first article and inspect hole coordinates and diameters using a coordinate measuring machine (CMM). Proceed with mass production only after confirmation of compliance, ensuring hole accuracy from the source.