CNC machining is a widely used manufacturing process and one of the common methods in the manufacturing industry, applied to produce various types of parts. Different types of parts require different processes to meet their specific requirements. There are many types of parts and corresponding machining processes. Below are some common types of machined parts and the typical processes used for each.

Table of Contents

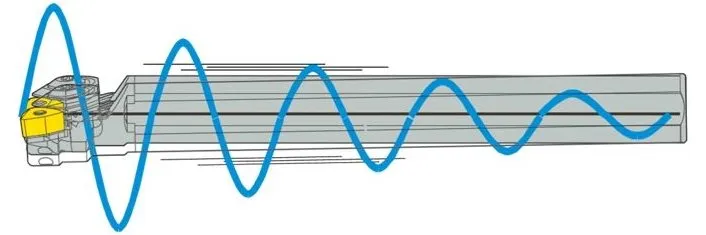

1. Shaft-type Parts

Shaft-type parts are usually cylindrical and are used for connection and rotation. Common shaft-type parts include bearing shafts, drive shafts, and spindles. Typical machining processes include turning, grinding, and threading. Turning is the most common method, where the workpiece rotates while a cutting tool removes material to achieve the desired dimensions and shape. For high-precision bearing shafts, grinding may also be applied. In addition, shaft-type parts may require drilling, reaming, tapping, and other processes.

Key Machining Points:

- Concentricity control: ≤ 0.01 mm

- High requirements for roundness and surface roughness

Common Materials: 45# steel, stainless steel, alloy steel

Surface Treatments: Chrome plating, nitriding, nickel plating

2. Gear-type Parts

Gear-type parts include various kinds of gears, such as spur gears, bevel gears, and more, usually with a circular shape. Gear machining typically involves processes such as milling, gear cutting, hobbing, shaping, shaving, grinding, and heat treatment. Milling is used to create the basic gear shape, while gear cutting is used to form the gear teeth. Grinding can improve gear accuracy and surface quality. Heat treatment is usually applied to enhance the hardness and wear resistance of gears.

Key Process Points:

- Gear accuracy must meet GB6–7 standards

- Heat treatment enhances hardness and wear resistance (e.g., carburizing and quenching, tempering)

- Surface polishing reduces friction and wear

3. Bolts and Nuts

Bolts and nuts are common components used for connecting parts. They are usually round or cylindrical and require turning, cutting, and threading processes. Turning is used to shape the main body of bolts and nuts, while cutting is applied to form the threads. Threading processes typically include single-point thread cutting and thread rolling.

Key Machining Points:

- Tolerance grade: 6g/6H

- Thread rolling can improve strength and surface finish

- Materials: Stainless steel, carbon steel, titanium alloy

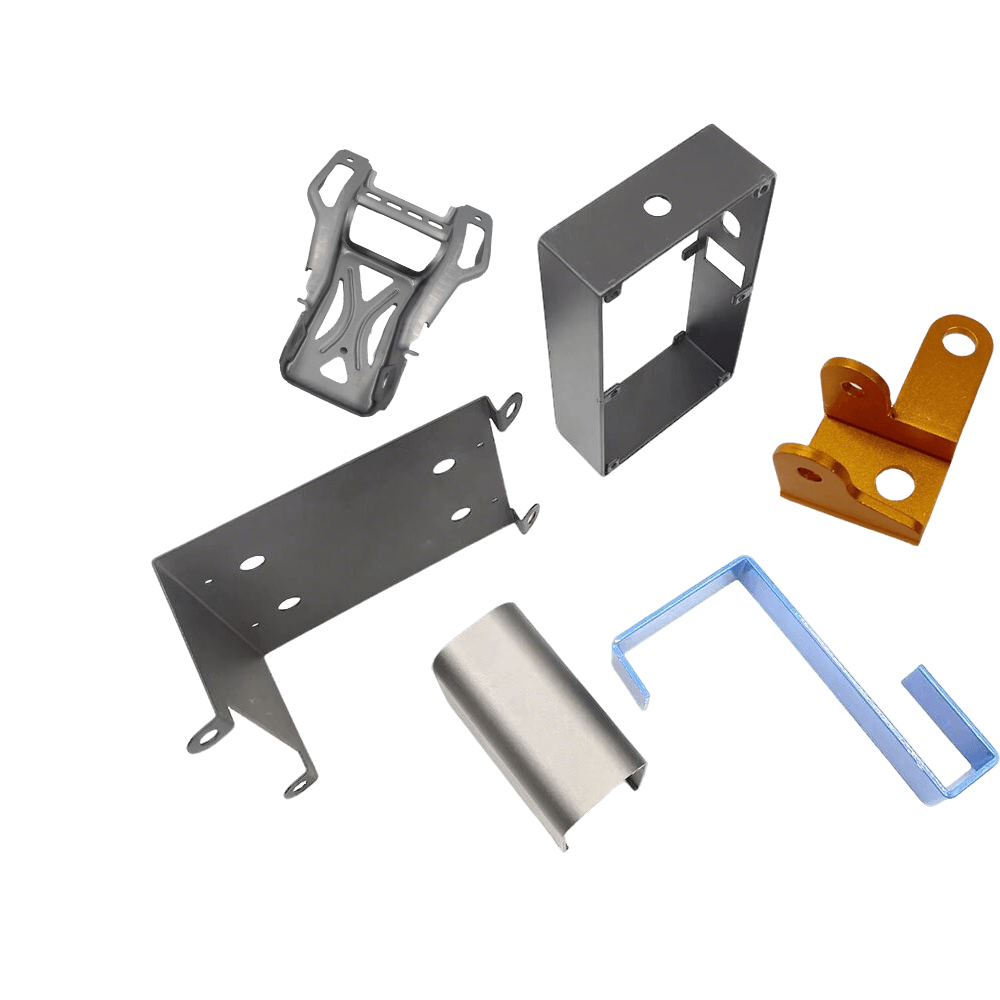

4. Sheet-type Parts

Sheet-type parts include various flat or thin components such as plates, metal sheets, chassis, brackets, and more. These parts are usually flat or bent. Common machining and fabrication processes include surface grinding, milling, shearing, bending, stamping, welding, and riveting. Shearing is used to cut the sheet to the desired shape, bending is for forming curves, stamping creates holes, depressions, or contours on the sheet, and welding or riveting joins different sheet components into an assembly.

Key Machining Points:

- Control sheet deformation and dimensional deviations

- Suitable for rapid prototyping and small-to-medium batch production

- Surface treatments: Anodizing, powder coating, electroplating

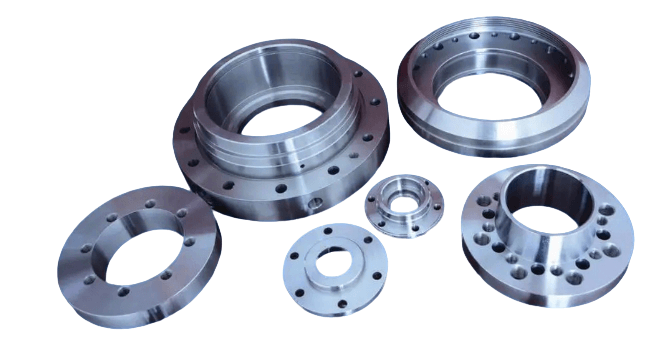

5. Sleeve-type Parts

Sleeve-type parts typically include bearings, bushings, flanges, and similar components. These parts usually require internal turning, internal grinding, and external grinding to achieve precise diameters and roundness. In addition, sleeve-type parts may require drilling, reaming, and tapping processes.

Key Machining Points:

- High requirements for roundness and concentricity

- Surface roughness can reach Ra 0.4

- Maintain proper fit and clearance (e.g., H7/g6)

6. Block-type Parts

Block-type parts include various types of blocks such as square blocks, rectangular blocks, cylinders, and more. These parts typically require surface grinding and milling to achieve precise flatness and contour. In addition, block-type parts may require drilling and tapping processes.

Key Machining Points:

- Control parallelism and flatness

- Suitable for CNC vertical machining centers

- Surface treatments such as anodizing or hard anodizing are possible

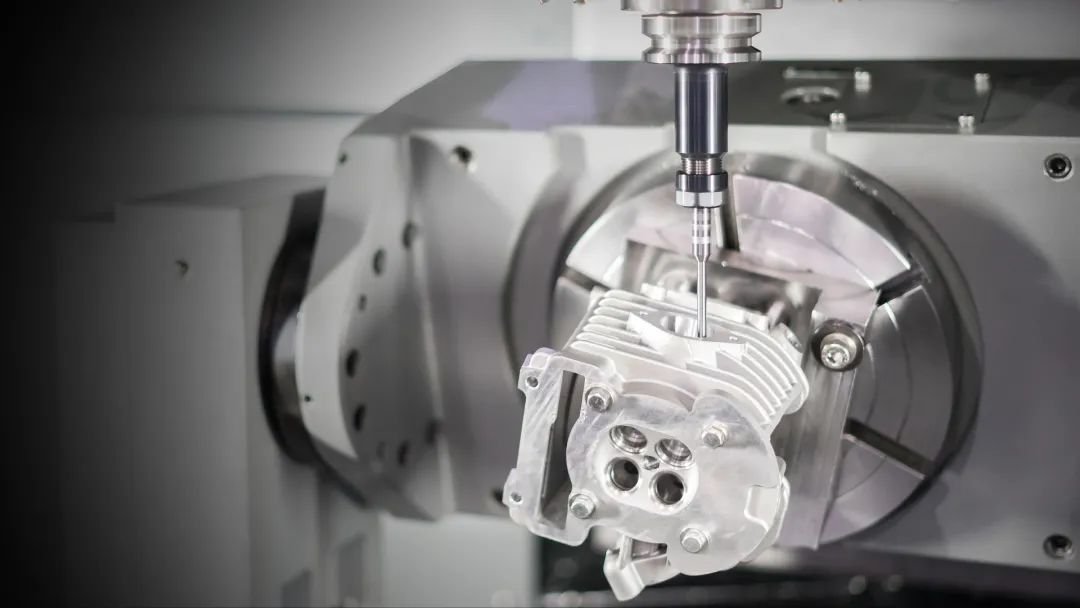

7. Casting-type Parts

Casting-type parts usually have complex 3D shapes, such as engine blocks, pump housings, and more. Machining processes include casting, grinding, turning, and heat treatment. Casting is the primary method to produce these parts, where molten metal is poured into a mold to form the part. Grinding, turning, and heat treatment are then applied to improve surface quality and dimensional accuracy.

Key Process Points:

- Mechanical machining is required after casting to ensure dimensional accuracy

- Heat treatment eliminates internal stress and improves stability

- Common materials: Cast iron, aluminum alloy, stainless steel

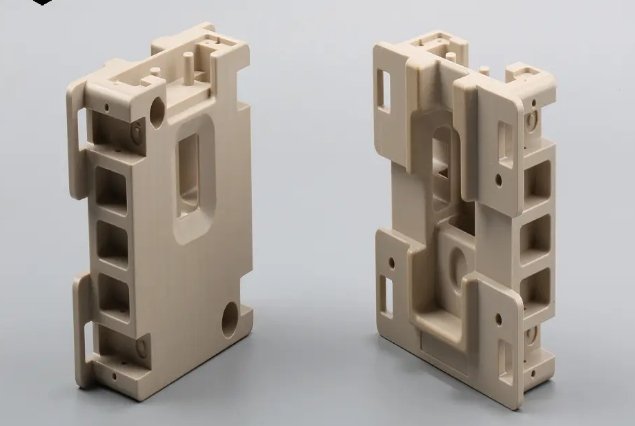

8. Housing-type Parts

Housing-type parts include various machine enclosures, machine tool beds, and similar components. These parts typically require surface grinding and milling to achieve precise flatness and contour. Additionally, housing parts may require drilling and tapping processes.

Key Controls:

- Ensure multi-surface parallelism and hole spacing accuracy

- Design dedicated fixtures to improve clamping precision

9. Electronic-type Parts

Electronic-type parts are usually small, such as circuit boards, connectors, and similar components. Machining processes include cutting, stamping, welding, and electroplating. Cutting and stamping create the shape and holes of the circuit board, welding connects electronic components, and electroplating protects and enhances surface performance.

Key Features:

- Small size, high precision

- Surface plating for conductivity and corrosion resistance

10. Plastic-type Parts

Plastic-type parts are used in various applications, including injection molding, extrusion, and compression molding. Injection molding involves injecting molten plastic into a mold, extrusion pushes plastic through a die to form the desired shape, and compression molding shapes heated plastic in a mold.

Key Process Points:

- Control mold temperature and shrinkage rate

- Secondary CNC machining can improve dimensional accuracy

Conclusion

Besides the common types of machined parts listed above, there are many other types, such as complex-shaped parts and freeform surface parts. Different machining processes can be selected to achieve the required shape, dimensional accuracy, and surface quality. For example, complex-shaped parts can be processed using multi-axis CNC machining, while freeform surfaces can be measured and machined using a coordinate measuring machine (CMM).

In summary, different types of parts require different machining processes to meet their specific requirements. Choosing the appropriate process and method is crucial to ensure part quality, precision, and performance. In practice, the machining process is usually selected based on the part’s shape, material, and requirements to achieve the best results.

YPMFG is equipped with advanced CNC lathes, 5-axis machining centers, and inspection equipment (CMM, surface roughness testers, etc.), offering full-process CNC machining solutions from prototyping to mass production.

Want to know which process is best for your part? Contact us for a free process evaluation and quote.