In CNC milling, cutting vibration often referred to as chatter is one of the most common challenges affecting machining accuracy, surface finish, and tool life. Excessive vibration not only leaves visible chatter marks on the part surface but can also shorten spindle and tool life, leading to costly rework or scrap.

To help machinists and engineers improve stability and surface quality, we’ve summarized 12 effective methods to minimize CNC milling vibration.

1. Use Sharp Inserts to Lower Cutting Forces

Cutting force can be significantly reduced by using sharp inserts. Indexable inserts are either coated or uncoated and uncoated inserts are typically sharper because coating requires edge honing (ER treatment) to improve adhesion. However, this rounding slightly dulls the cutting edge. Use uncoated inserts when sharpness and light cutting are priorities.

2. Choose a Smaller Nose Radius

When cutting depth is fixed, a smaller nose radius helps reduce cutting forces, especially radial forces, which are the main cause of vibration in slender tools or workpieces. At the same depth of cut, a larger nose radius increases radial force and the tendency for tool shank vibration.

3. Avoid Cutting Depth Equal to the Nose Radius

If the cutting depth equals the insert nose radius, the tool experiences uneven cutting loads, which can easily trigger chatter. Always choose a depth of cut that’s slightly smaller or larger than the nose radius to maintain stability.

4. Use 90° Lead Angle Tools for Slender Workpieces

When cutting keyways with long, slender tools or turning long shafts, use tools with a 90° lead angle. This design minimizes radial cutting forces and helps suppress vibration. It also increases the axial cutting force, which is less likely to cause chatter.

5. Use Round Inserts or 45° Lead Angle Cutters

For deep-cavity milling, especially in mold machining, round-insert or 45° lead angle cutters are highly effective at reducing radial cutting forces. When the cutting depth is less than 1 mm, round or ball-nose end mills are ideal for achieving smooth, stable cutting.

6. Apply Plunge Milling for Deep Cavities

When machining deep cavities with long-reach end mills (tool overhang greater than 3× the shank diameter), plunge milling feeding axially like drilling is recommended. This method minimizes tool deflection and vibration. Always follow the tool manufacturer’s guidelines for the maximum allowable radial engagement during plunge milling.

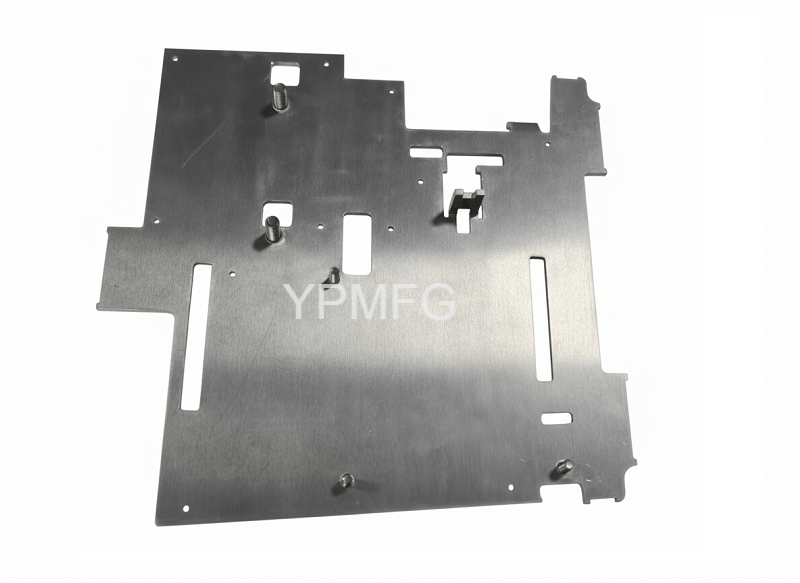

7. Improve Fixturing for Thin-Walled Parts

Vibration in thin-walled or box-type parts usually originates from the workpiece itself. To suppress it, focus on improving clamping rigidity. Use proper support structures, soft jaws, or temporary ribs to stiffen the workpiece during machining.

8. Use Inserts with Smaller Rake Angles for Boring

When boring internal holes, choose inserts with a smaller rake angle and a larger auxiliary clearance angle. This minimizes the contact area between the secondary cutting edge and the machined surface, reducing the chance of chatter and chip packing.

9. Use Unequal-Pitch Face Mills

Face mills with unequally spaced teeth (inserts) help break up the uniform cutting force pattern that causes resonance. For instance, a 100 mm face mill with five unevenly spaced inserts will produce less vibration than one with ten evenly spaced inserts under the same cutting conditions.

10. Use Inserts with Positive Rake and Large Clearance Angles

Positive rake and large relief angles reduce cutting resistance, allowing smoother and lighter cutting. Pair these inserts with an efficient chipbreaker design to improve chip evacuation and maintain stable cutting forces.

11. Adjust Cutting Parameters

Adjusting parameters can help when vibration is mild. Common methods include:

- Lowering spindle speed or workpiece rotation speed.

- Reducing depth of cut.

- Increasing feed rate per tooth or per revolution slightly.

In thread turning, if chatter occurs, try reducing the number of finishing passes by one or two to stabilize cutting.

12. Optimize Toolpath and Milling Direction

Strategic toolpath planning is key to reducing vibration. While traditional theory suggested that conventional milling helps suppress backlash vibration, modern CNC machines equipped with ball or roller screws can perform both climb and conventional milling effectively. The most important factor is ensuring the cutting force direction aligns with the workpiece’s clamping direction, improving overall rigidity and minimizing deflection.

Conclusion

Reducing cutting vibration on CNC milling machines requires a systematic approach optimizing tooling geometry, machining parameters, and fixturing conditions together. By applying these twelve methods, machinists can significantly enhance surface quality, extend tool life, and improve machining accuracy.

At YPMFG Machining, we specialize in precision CNC machining and process optimization to help manufacturers achieve better accuracy, quality, and efficiency.