CNC prototype machining enables engineers and designers to produce precise, functional prototypes quickly. Unlike traditional methods that require long setup times or costly molds, CNC machining can create small batches of prototypes with minimal delay.

Prototypes generally fall into two categories: appearance prototypes and functional prototypes. Appearance prototypes demonstrate a product’s visual and aesthetic qualities, helping stakeholders evaluate design and form. Functional prototypes focus on structural accuracy, mechanical performance, and durability, allowing real-world testing to ensure the design meets specifications.

CNC prototype machining provides a reliable, precise method for transforming design concepts into tangible, testable models, whether for medical devices, automotive parts, aerospace components, or military equipment.

In this guide, we explore how CNC prototype machining works, its advantages and limitations, key applications across industries, and practical tips for making prototypes that closely resemble the final product, helping you accelerate development, reduce risk, and bring better products to market faster.

Table of Contents

1. Applications of CNC Prototype Machining

CNC prototype machining is widely used in industries where accuracy, performance, and reliability are critical. Key applications include:

Medical Industry

Prototypes are essential in the medical sector, where device performance directly impacts patient safety. CNC-machined prototypes are used to produce implants, orthotic devices, enclosures, MRI machines, and research equipment. These prototypes must closely replicate the final product in form, function, and durability, as even minor errors can have serious consequences. Learn more about cnc medical machining.

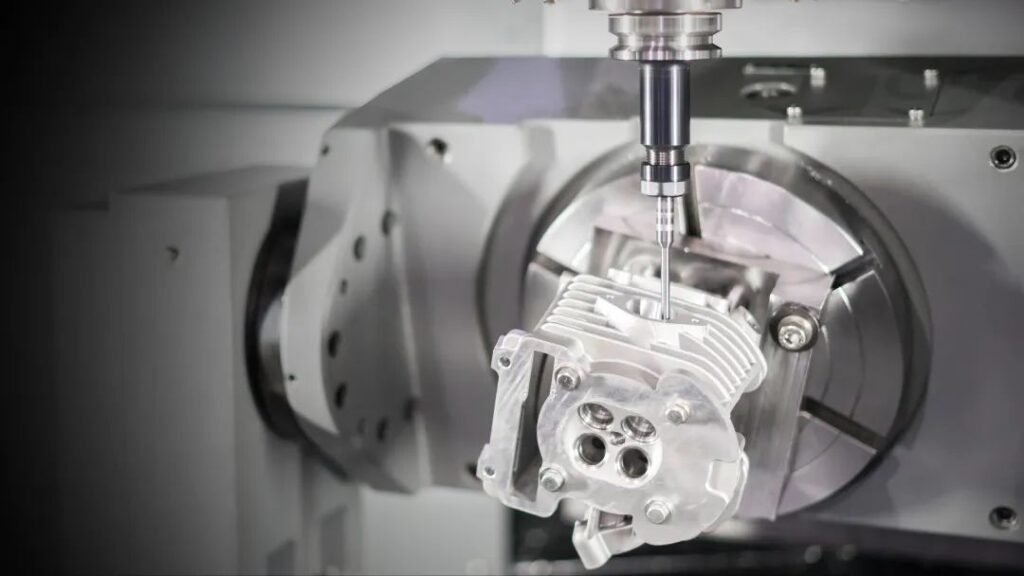

Automotive Industry

Automotive companies rely on CNC prototypes to validate designs, test components, and ensure proper integration with existing systems. CNC-machined prototypes are used for car parts, engine components, trucks, and shipping vessels. Producing prototypes to precise specifications allows engineers to detect potential design issues before full-scale production. Read more about automotive in cnc machining.

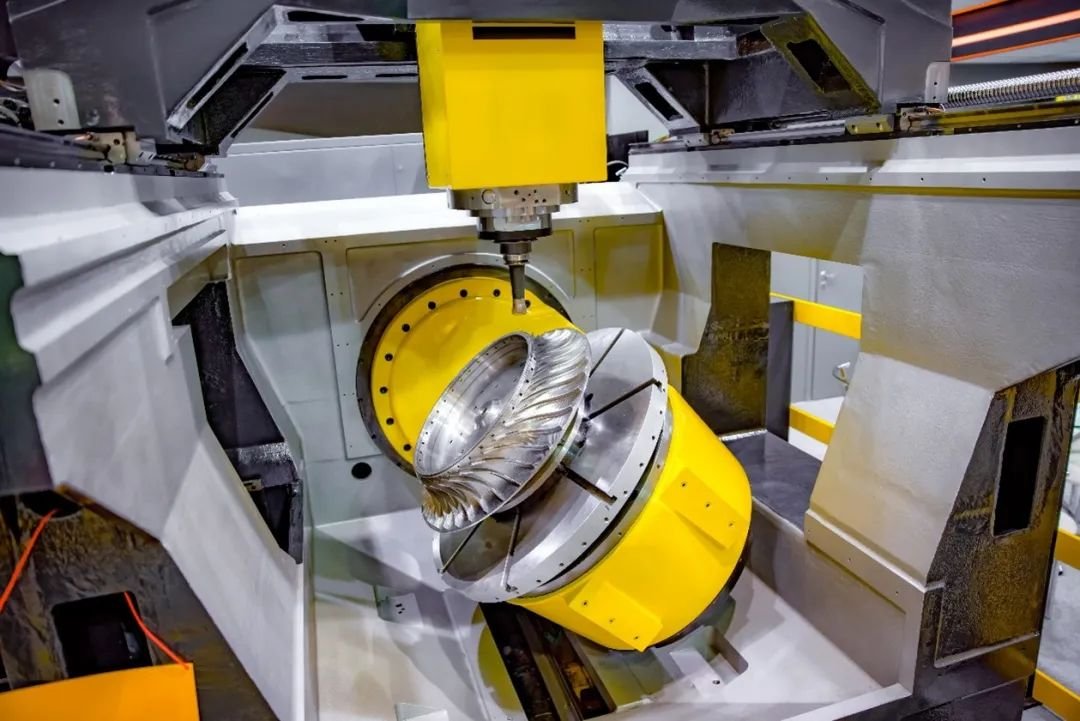

Aerospace Industry

Precision is crucial in aerospace. Even minor defects can affect aerodynamics, safety, or part lifespan. CNC prototype machining produces components such as landing gear parts, bushings, manifolds, and airfoils. These prototypes undergo rigorous testing to verify functionality under real-world conditions. With more information about aerospace machining you should know.

Military and Defense Industry

The defense sector requires highly complex and reliable equipment. CNC prototypes are used for vehicles, communication devices, ammunition, and other critical systems. Prototyping ensures operational reliability before committing to full production.

CNC prototype machining serves industries where precision, safety, and performance are essential. Its versatility accommodates both small-scale prototypes and complex functional models.

2. Advantages of CNC Prototype Machining

CNC prototype machining provides several advantages that make it a preferred method for engineers and designers:

Cost-Effective for Small Batches

For low-volume prototyping, CNC machining is often more economical than injection molding. Unlike molding, which requires expensive tooling and long lead times, CNC prototypes can be produced quickly once design blueprints are finalized.

High Tolerance and Precision

CNC machining produces prototypes with tight tolerances and fine details. This precision ensures that functional prototypes accurately reflect the performance and structural integrity of the final product, which is crucial for testing mechanical or load-bearing parts.

Speed and Efficiency

CNC prototyping accelerates development by allowing rapid testing and iteration of designs. This efficiency enables faster validation and refinement of products, reducing overall time to market.

Material and Process Flexibility

CNC machines can work with a wide range of materials, including metals such as aluminum, steel, and titanium, as well as engineering plastics. This flexibility allows prototypes to be made from the same or similar materials as the final product, ensuring realistic testing and performance evaluation.

High Similarity to the Final Product

Unlike some additive manufacturing methods, CNC prototypes closely resemble the final product in strength, appearance, and functionality. The machining process can also replicate other manufacturing techniques, such as sheet metal forming, providing an accurate representation of end-use components.

3. Disadvantages of CNC Prototype Machining

Despite its advantages, CNC prototype machining has limitations that engineers and designers should consider:

Higher Cost Compared to 3D Printing

While CNC machining is cost-effective for small batches relative to injection molding, it is generally more expensive than 3D printing. The process requires specialized equipment, skilled operators, and higher-cost raw materials, which can increase expenses for startups or early-stage projects.

Material Waste

CNC machining is a subtractive process, removing material from a solid block to create the final part. This can generate significant scrap, particularly with metal prototypes. Although much of this waste can be recycled, managing it adds complexity and potential cost.

Setup Complexity for Complex Geometries

Highly intricate parts may require multiple setups, specialized tooling, or multi-axis programming. These requirements can extend lead times and increase operator workload compared to simpler additive manufacturing methods.

Limited Design Flexibility for Certain Features

Some internal geometries or hollow features are challenging to produce with CNC machining alone. In such cases, hybrid approaches, combining CNC with casting or 3D printing, may be necessary.

Awareness of these limitations allows companies to determine whether CNC prototyping aligns with their project requirements, budget, and timeline.

4. Comparison with Other Prototyping Methods

To choose the most suitable prototyping method, it is helpful to compare CNC machining with alternatives such as 3D printing and injection molding:

| Feature | CNC Machining | 3D Printing | Injection Molding |

| Cost (low volume) | Moderate | Low | High (due to tooling costs) |

| Precision & Tolerance | Very high | Moderate | High |

| Material Options | Wide (metals, plastics) | Limited (mostly plastics) | Wide (plastics, metals with molds) |

| Strength & Durability | High | Low to moderate | High |

| Lead Time (prototype) | Fast (days to weeks) | Very fast (hours to days) | Slow (weeks to months for molds) |

| Realism to Final Product | Excellent | Moderate | Excellent |

| Complex Geometries | Good (multi-axis machining) | Excellent | Limited by mold design |

| Waste Generation | Moderate to high | Low | Low |

CNC vs. 3D Printing: CNC machining provides superior precision, material strength, and similarity to the final product, making it ideal for functional prototypes. 3D printing is faster and less expensive but may lack the structural integrity required for rigorous testing.

CNC vs. Injection Molding: CNC machining is more flexible and cost-effective for small batches, while injection molding is better suited for mass production but involves higher upfront tooling costs.

Understanding these differences allows engineers to select the prototyping method that best aligns with project goals, budget, and timeline.

5. Key Considerations for CNC Prototyping

Several factors influence the success, quality, and cost-effectiveness of CNC prototyping:

Material Selection

Selecting the appropriate material is essential. Metals such as aluminum, steel, and titanium are commonly used for functional prototypes, while engineering plastics may be suitable for appearance models. The material should match the prototype’s intended function to ensure accurate testing and performance evaluation.

Design for Manufacturability (DFM)

CNC machining has design constraints that must be addressed during planning:

Maintain proper wall thickness to prevent warping or breakage.

Avoid sharp internal corners unless specialized tooling is available.

Consider undercuts and complex geometries, which may require multi-axis machining.

Plan tolerances that align with functional requirements.

Lead Time and Production Planning

Although CNC prototypes can be produced faster than injection-molded parts, complex components may require multiple setups or specialized tooling. Accurate lead time estimation is crucial for scheduling testing, presentations, or product launches.

Cost Management

CNC prototyping is efficient for low-volume production, but costs can increase with complex designs or expensive materials. Careful planning, minimizing unnecessary features, and optimizing material usage can help control expenses.

Surface Finish and Post-Processing

Consider whether the prototype requires a specific surface finish, such as polishing, anodizing, or coating. Post-processing can affect both cost and production time and should be factored into planning.

6. From Prototype to Production

CNC prototyping plays a key role in bridging the gap between design and full-scale manufacturing:

Accelerated Development: CNC prototypes allow engineers to identify potential design issues early, reducing iterations during production and saving both time and resources.

Seamless Transition to Manufacturing: Since CNC machines can produce both prototypes and end-use parts, many components can transition directly to production with minimal adjustments. This ensures consistency and lowers setup costs.

Investor and Stakeholder Presentations: CNC prototypes provide tangible, functional models to demonstrate product feasibility, secure investor confidence, and gather stakeholder feedback. This is especially valuable for startups and new product launches.

Functional Validation: Prototypes enable real-world testing of mechanical performance, material behavior, and assembly processes. This ensures that the final product meets design specifications and operational requirements.

Leveraging CNC prototypes streamlines the path from concept to finished product, reduces risk, accelerates development, and improves overall quality.

7. Conclusion

CNC prototype machining is a versatile and efficient tool for product development, providing speed, precision, and realistic results that few other methods can match. From medical devices to automotive parts and aerospace components, CNC prototypes enable engineers to test, validate, and refine designs before committing to full-scale production.

Although CNC prototyping can be more expensive than 3D printing and may generate material waste, its advantages—high tolerance, functional accuracy, and close similarity to final products—make it an essential part of modern prototyping workflows. By carefully selecting materials, applying design-for-manufacturability principles, and planning production effectively, companies can maximize the benefits of CNC prototyping while minimizing its limitations.

Whether for a startup developing a first functional prototype or an established manufacturer refining complex components, contact us provides a reliable pathway from concept to production.

8. FAQs

Q1: Is CNC prototype machining the best option for prototyping?

It depends on project requirements. CNC machining is ideal for high-precision, functional prototypes made from the same materials as the final product. For purely visual models or low-strength prototypes, 3D printing may be sufficient.

Q2: How does CNC prototyping compare to 3D printing?

CNC prototypes are stronger, more precise, and closely resemble the final product. 3D printing is faster and less expensive for appearance models but may lack the structural integrity needed for functional testing.

Q3: How does CNC prototyping compare to injection molding?

CNC prototyping is more cost-effective and faster for small batches. Injection molding is better suited for mass production but requires significant upfront tooling costs and longer lead times.

Q4: What materials can be used for CNC prototyping?

CNC machines can work with metals, such as aluminum, steel, and titanium, as well as engineering plastics. Material selection should match the prototype’s intended function and testing requirements.

Q5: Can CNC prototypes be scaled to full production?

Yes. CNC prototypes can often transition directly to production, ensuring consistency and reducing setup costs.