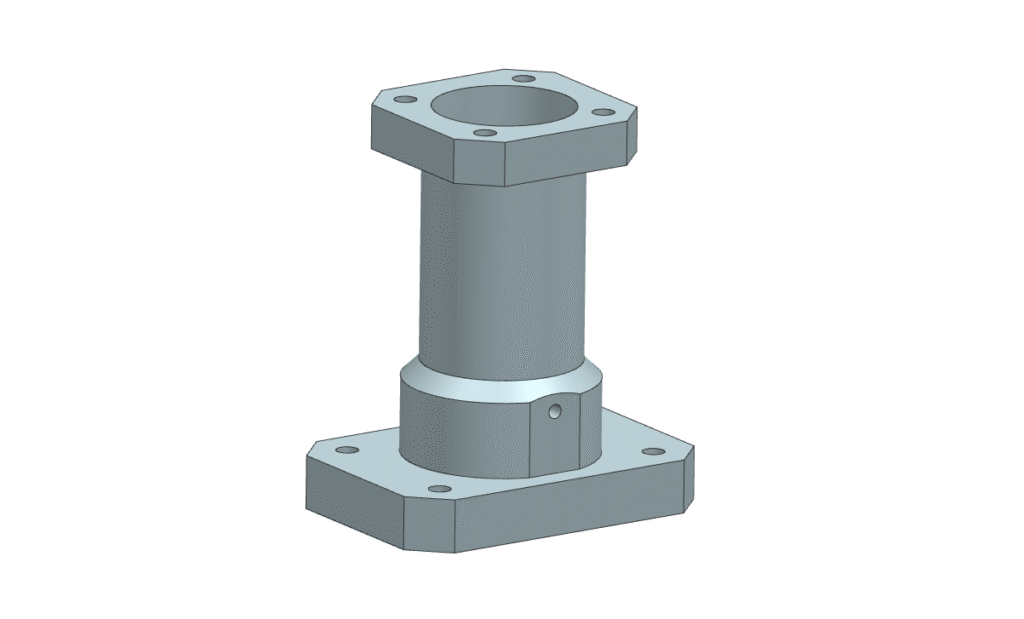

This CNC machining case features a custom non-standard square part, fully documented with 2D drawings and 3D models. The part is manufactured from aluminum alloy 6061 and finished with natural anodizing.

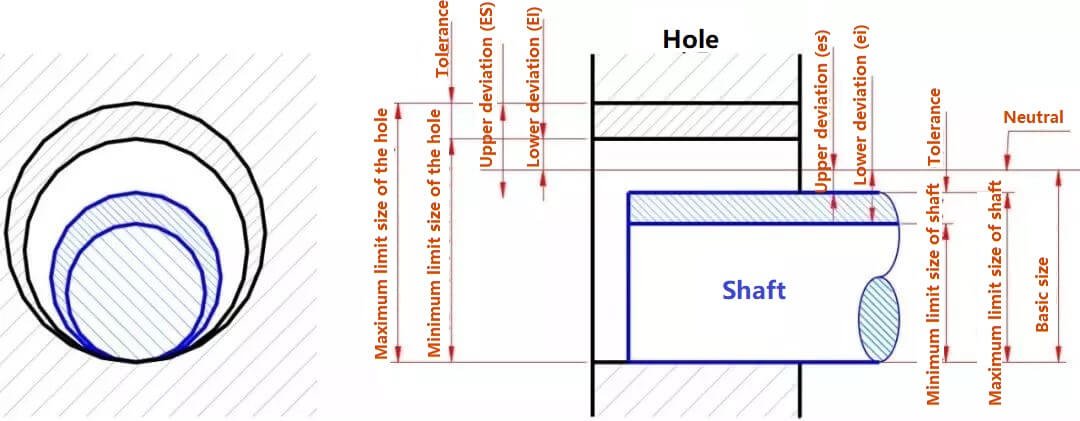

As a typical non-standard component, this part requires high dimensional accuracy, precise hole tolerances, and superior surface quality.

Table of Contents

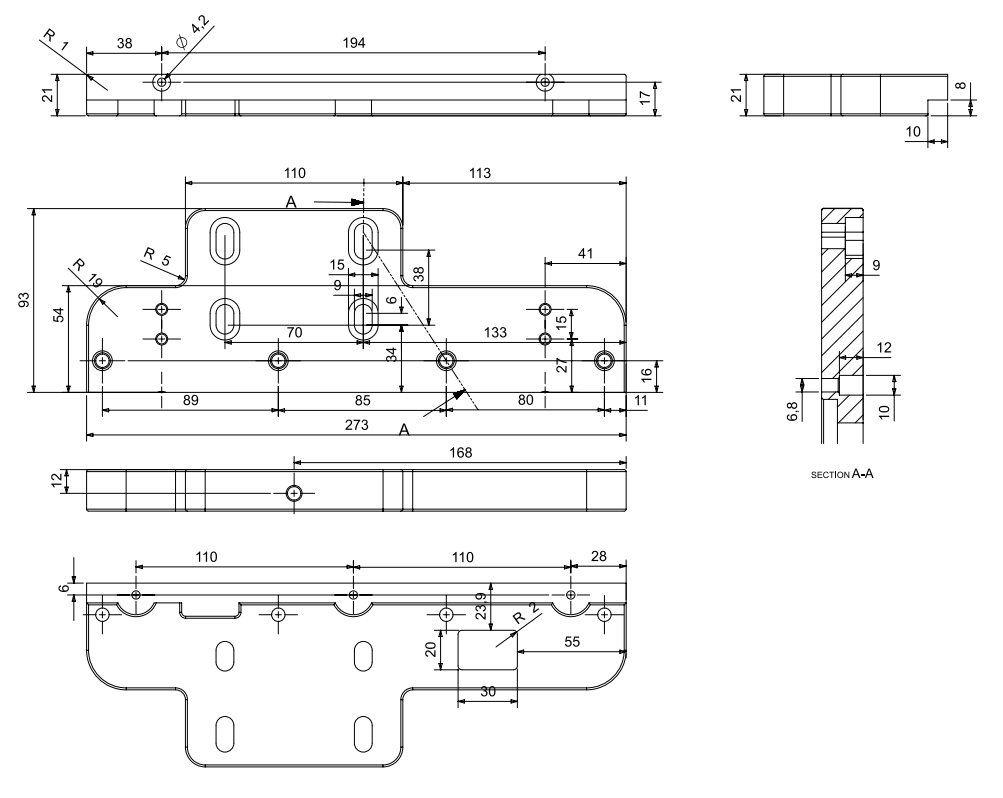

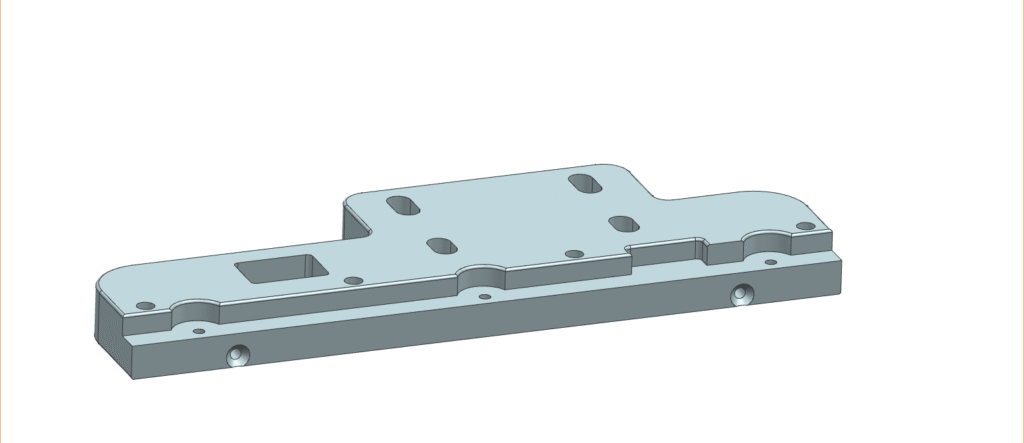

1. Product Drawing Display

2D Drawing:

3D Drawing:

2. Quote Analysis

In actual manufacturing, the quote for a part is influenced by many factors, including quantity, processing steps, materials, and surface treatment.

1)Processing parameters:

| Material | Surface Treatment | Quantity | Reference Price |

|---|---|---|---|

| Aluminum 6061 | Natural anodizing | 5 | Contact Us |

2)Price composition:

| Cost Item | Description |

| Material Cost | Calculated based on the market price of Aluminum 6061 and part dimensions |

| Surface Treatment | Natural anodizing cost calculated according to part surface area and process requirements |

| NC Machining Cost | Core cost covering CNC machining, milling, grinding, and labor for all processing steps |

| Milling Cost | Labor and machine cost for general milling operations |

| Manual Work Cost | Fixture setup, handling, and manual operations |

| Packaging | Part protection, packaging materials, and handling |

| Total | Total cost per piece (excluding tax) |

By breaking down the quote structure in detail, customers can clearly understand the cost contribution of each processing step, allowing them to make reasonable production decisions. Furthermore, as production batches increase, the cost per piece decreases significantly, as NC machining and labor costs are spread across more parts, making the overall unit price more cost-effective.

3. Machining Process

| Step | Operation | Description & Requirements |

|---|---|---|

| 1 | Material Cutting | Cut raw material to size 280×100×25mm (5 pieces) |

| 2 | CNC Rough Machining | Machine outer profile, U-slot, holes, and pre-precision holes (0.6mm allowance) |

| 3 | CNC Backside Machining | Leave 0.2mm thickness, perform one unclamped surface finishing, and precisely mill steps |

| 4 | CNC Finishing | Finish front surface to target thickness, machine D10 precision holes (tolerance 0–0.02mm), ensure hole centers are coaxial |

| 5 | General Milling | Machine side threaded holes |

| 6 | Thread Tapping | Complete internal thread machining |

| 7 | Deburring | Remove burrs generated during machining |

| 8 | Surface Treatment | Natural anodizing to enhance corrosion resistance and appearance |

4. Machining Challenges and Solutions

Precision Hole Control: Ø10 holes require a tolerance of 0 to +0.02mm. Multiple finishing passes and measurements are performed to ensure hole coaxiality.

Clamping Stability: For repeated backside machining, an optimized fixturing solution is used to prevent positional deviation.

Batch Consistency: Process optimization and tooling ensure consistent quality across pieces production batches.

5. Conclusion

This case study fully demonstrates our comprehensive capabilities in CNC machining of custom square parts. From process planning and precision control to cost optimization, we provide customers with reliable solutions. Whether for small-batch trial production or large-scale production, we guarantee consistent quality and delivery.

If you are looking for custom parts machining services, please contact us for a personalized quote and process recommendations!