I. Overview of Shaft Groove Machining

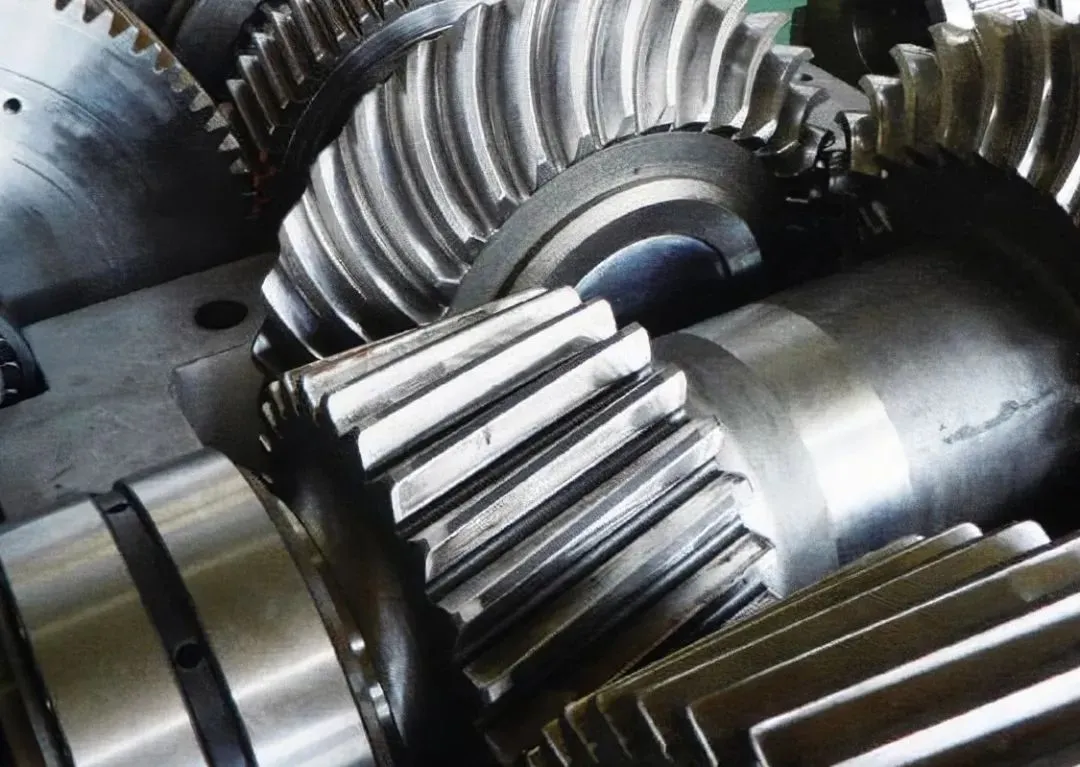

Shaft grooving is a common machining process, mainly used to create groove structures in various shafts, hubs, couplings, and other products, giving them better functional characteristics and performance. There are many methods for shaft grooving, including turning, milling, and drilling. The appropriate method should be selected based on the specific product requirements and the characteristics of the machining process.

II. Machining Methods for Shaft Groove Machining

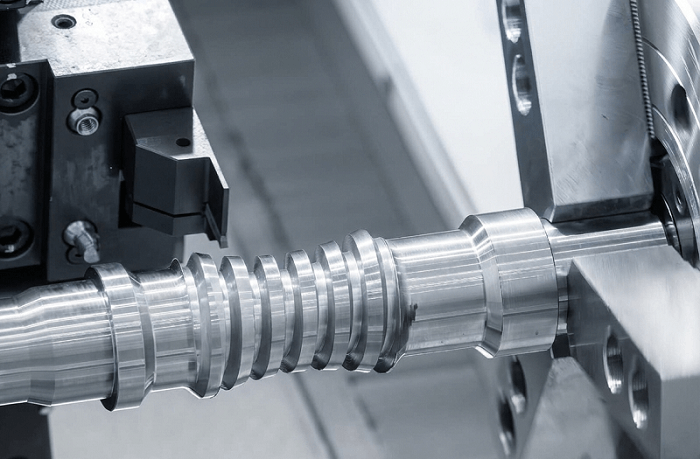

- Turning: Turning is a common method for machining shaft grooves. The process involves rough turning, then finish turning, and finally grinding. When turning grooves, appropriate cutting tools should be selected based on the diameter and depth, and cutting conditions such as feed rate and spindle speed should be controlled.

- Milling: Milling is suitable for machining shaft grooves with relatively large widths. The machining process involves segmented milling, first milling the depth, then the width. When selecting milling cutters, a reasonable ratio should be made based on the different shaft diameters, groove widths, and materials to achieve the best milling results.

- Drilling: Drilling is suitable for machining shaft grooves with relatively small depths. Small hole drills or deep hole drills can be used. During drilling, attention should be paid to maintaining drill bit cooling and lubrication, and controlling the feed rate to avoid poor drilling quality due to excessively fast or slow speeds.

III. Shaft Groove Machining Process

- Design the shaft groove drawings and process plan, and select appropriate machining methods and tools according to requirements.

- Select appropriate process parameters, such as feed rate and speed, based on the material’s hardness and physical properties.

- Perform pre-cutting treatments, such as clamping the workpiece, adjusting clamping force, and ensuring balance.

- Before rough machining, inspect and calibrate the milling machine and lathe to ensure tool fit and symmetry.

- Perform rough machining, finish machining, and regrinding steps to ensure the shaft groove meets quality and precision requirements.

IV. Precautions in Shaft Groove Machining

Select appropriate tools and process parameters to ensure cutting efficiency and quality.

Pay attention to the magnitude and balance of clamping force to ensure workpiece stability and precision.

Keep the machining equipment clean and maintain it to avoid damage to the equipment and engineers caused by cutting fluid and chips.

Pay attention to safety during machining to avoid accidents and malfunctions.

V. Conclusion

Grooving of shafts is an important process in machining. With the correct methods and procedures, ideal machining results and quality can be obtained. In actual operation, attention should be paid to selecting appropriate cutting tools and process parameters, and ensuring the normal operation and safety of the equipment.