Down-cut and up-cut milling represent two fundamental machining approaches. The direction of milling not only influences the distribution of cutting forces but also directly impacts machining efficiency, tool life, surface quality, and dimensional accuracy stability. This article systematically analyzes the differences and application strategies of these two methods from multiple dimensions, including definitions, cutting mechanisms, mechanical properties, suitable materials, and processing scenarios.

Table of Contents

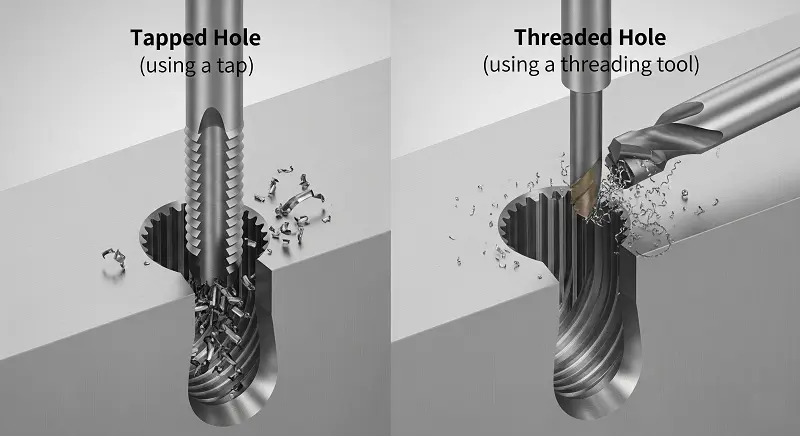

I. Basic Definitions and Distinguishing Methods

Climb milling refers to a milling operation where the cutter rotates in the same direction as the workpiece feed. In this process, the tool cuts from the exterior toward the interior of the workpiece, with the cutting depth gradually decreasing from maximum to zero, resulting in a “thick-in, thin-out” cutting effect.

Conventional milling refers to the milling cutter rotating in the opposite direction to the workpiece feed direction. Here, the tool cuts from the interior toward the exterior of the workpiece. At the initial contact between the cutter teeth and the workpiece surface, the cutting thickness is zero, gradually increasing to its maximum value as the cut progresses. The distinction can be determined by the machining contour direction:

When machining external contours: Clockwise feed direction is considered climb milling, while counterclockwise feed direction is considered conventional milling.

When machining internal contours: Counterclockwise feed direction is considered climb milling, while clockwise feed direction is considered conventional milling.

II. Working Principles of Climb Milling and Conventional Milling

1. Climb Milling

At the start of climb milling, the chip thickness is at its maximum. The cutting depth is small, resulting in minimal chip deformation, and the cutting force is directed toward the workpiece.

To achieve good surface quality, we typically employ climb milling. It offers advantages such as reduced rake face wear and stable machine operation, making it suitable for machining high-alloy steels under favorable cutting conditions.

Usage Notes:

Not suitable for machining workpieces with hard surface layers (e.g., castings’ outer surfaces), as the cutting edge must penetrate the workpiece’s hardened surface from the outside, causing significant wear. Backlash in the machine tool’s table lead screw and nut can cause table movement.

2. Conventional Milling

Conventional milling starts with a chip thickness of zero, increasing to its maximum value by the end of the cut. The milling process incorporates a polishing effect. The cutting force acts away from the workpiece (with a tendency to lift the workpiece).

Due to certain drawbacks associated with this method, such as accelerated wear on the rake face reducing tool life, surface hardening in high-alloy steels, and suboptimal surface quality, it is rarely employed.

Usage Instructions: The workpiece must be fully clamped to prevent the risk of lifting the worktable.

III. Comparison of Cutting Mechanisms and Mechanical Characteristics

1. Differences in Chip Formation Mechanisms

Climb milling starts at maximum chip thickness, gradually decreasing to zero as the tool moves forward. This instantaneous engagement avoids slippage of the cutting teeth on the workpiece surface, allowing chips to exit smoothly without friction on the machined surface.

Conversely, conventional milling starts at zero chip thickness, gradually increasing to its maximum as the tool continues to rotate. This gradual engagement causes the cutting teeth to slide a distance on the workpiece surface before complete cutting, generating significant friction and heat, potentially leading to surface hardening.

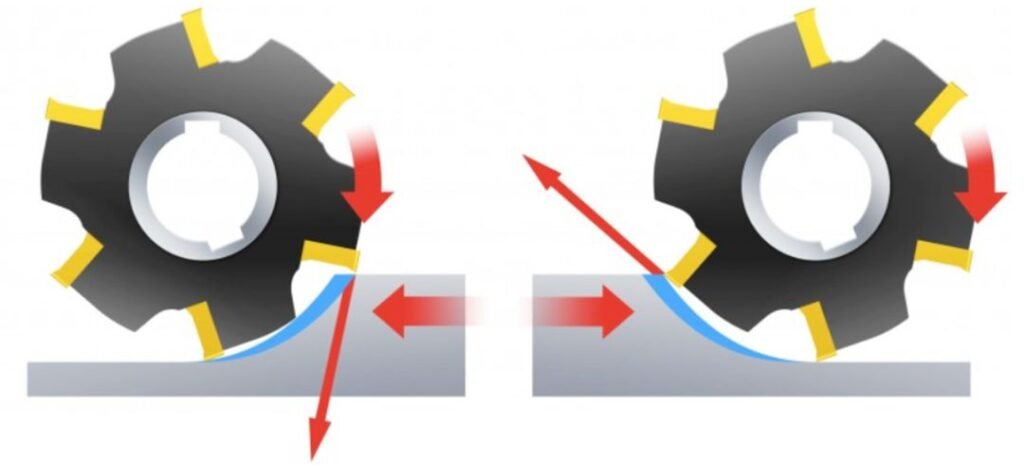

2. Analysis of Cutting Force Characteristics

Climb and conventional milling exhibit significant differences in cutting force distribution:

Climb Milling: The vertical cutting force is always downward, pressing the workpiece firmly against the worktable, which is beneficial for workpiece stability and positioning, but may cause the worktable to wobble in the presence of backlash.

Conventional Milling: The vertical cutting force is upward, tending to lift the workpiece, which can easily cause vibration, but effectively counteracts the backlash of the machine tool feed mechanism, maintaining a smooth cutting process.

These differences in cutting force distribution directly affect the stability of the machining process. Climb milling provides a more stable cutting force for workpiece fixation, while conventional milling can cause slight displacement of the workpiece position.

3. Comparison of Tool Wear and Life

Climb milling is generally more tool-friendly because the cutting thickness gradually decreases, resulting in more uniform tool wear and a 2-3 times longer tool life. Less friction during the cutting process reduces heat accumulation, thus lowering tool thermal fatigue and wear.

In conventional milling, the cutting teeth must forcefully penetrate the workpiece surface in the initial stage of cutting, generating a large impact load. During the cutting process, the friction between the cutting teeth and the machined surface intensifies, leading to surface hardening and further accelerating tool wear. The thick chips and high temperature generated when the tool exits conventional milling also cause high tensile stress, shortening tool life.

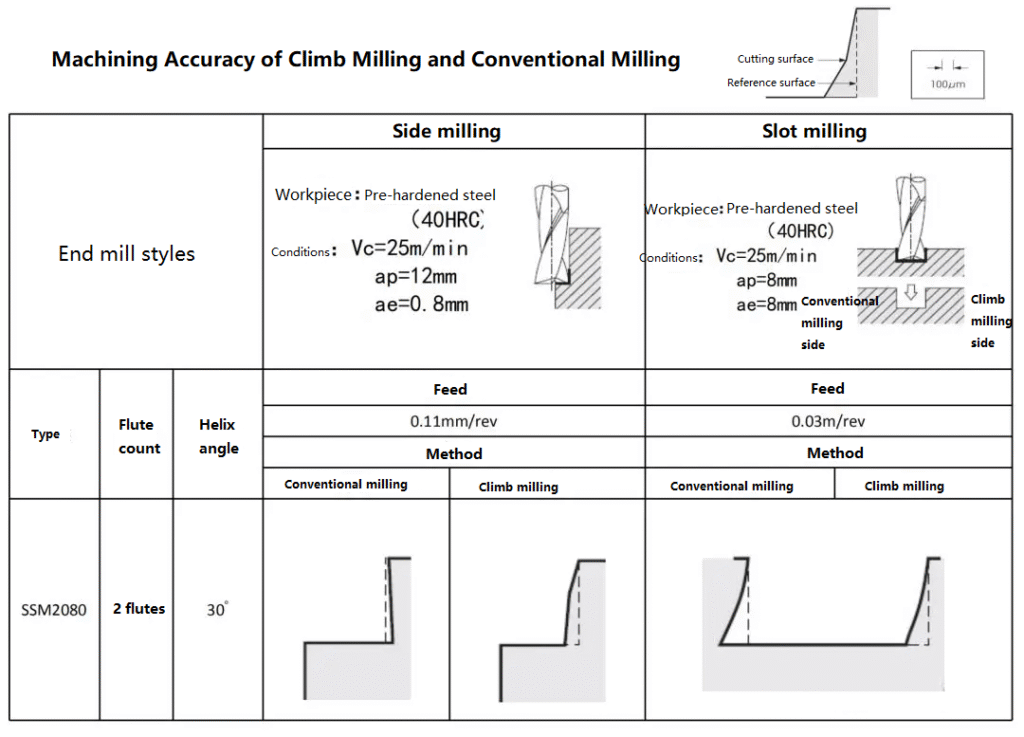

IV. Climb Milling and Conventional Milling Machining Accuracy

V. Applicability Analysis of Different Materials

1. Materials Suitable for Climb Milling

Soft materials such as aluminum alloys, copper alloys, plastics, and composite materials are generally recommended for climb milling:

Aluminum Alloys: Climb milling reduces burrs and deformation, provides better surface finish, and reduces frictional heat between the tool and the material.

Copper Alloys: Similar to aluminum alloys, climb milling reduces cutting forces and heat accumulation.

Stainless Steel: Climb milling reduces work hardening, especially suitable for machining thin-walled structures.

Non-metallic Materials: Such as plastics and glass fiber reinforced plastics, climb milling helps avoid material delamination or tearing.

2. Materials Suitable for Convention Milling

Hard materials or workpieces with a hardened surface layer are more suitable for convention milling:

Cast Iron: Contains a hard phase, convention milling better controls chip flow and prevents premature tool wear.

High Hardness

Steel: Convention milling reduces the initial impact on the tool, protecting the cutting edge.

Titanium Alloys: High strength and low thermal conductivity, convention milling reduces cutting temperature and delays tool wear.

Hardened Materials: Convention milling relieves pressure on the tool and improves durability.

Brittle Materials: Such as ceramics or certain glasses, convention milling reduces the risk of material fracture due to sudden loading.

VI. Applicable Strategies for Each Machining Stage

1. Roughing Stage

In the roughing stage, conventional milling is generally more suitable:

Conventional milling handles large allowances better and is more adaptable to uneven workpiece surfaces or the presence of hard skin.

Even with less than ideal workpiece fixation or insufficient machine tool power, conventional milling can provide relatively stable machining results.

The cutting force distribution of conventional milling is more uniform, which helps improve roughing efficiency.

2. Finishing Stage

In the finishing stage, climb milling is usually the preferred choice:

Climb milling provides better surface finish, reduces vibration and friction, and meets the requirements of high-precision machining.

The cutting force of climb milling is more stable, which is beneficial for maintaining machining accuracy and dimensional stability. When finishing thin-walled or flexible materials, climb milling can reduce compressive stress on the workpiece and prevent deformation.

VII. How to Choose between Climb Milling and Conventional Milling

| Material Type | Recommended Machining Method | Key Considerations | Machining Outcome |

|---|---|---|---|

| Aluminum Alloys, Copper Alloys | Climb Milling in Finishing Operations | Surface finish, tool life | High surface quality, high efficiency |

| Cast Iron, Hardened Steel | Conventional Milling in Roughing Operations | Prevent tool chipping, compensate for backlash | High stability, safe machining |

| Titanium Alloys, High-Temperature Alloys | Conventional Milling in Roughing Operations | Lower cutting temperature, reduce thermal stress | Extended tool life, reduced deformation |

| Plastics, Composite Materials | Climb Milling | Prevent delamination, improve surface quality | Reduced burrs, higher yield |

| Thin-Walled Parts | Climb Milling | Reduce compressive stress, prevent deformation | Maintained structural integrity, high accuracy |

- Material Hardness: For materials with high hardness, conventional milling is recommended because the larger cutting force during conventional milling improves tool stability.

- Surface Finish Requirements: If high surface finish is required, climb milling is recommended because it produces a higher surface finish.

- Tool Life: To extend tool life, climb milling is recommended because the smaller cutting force reduces tool wear.

- Machine Tool Rigidity: If the machine tool has good rigidity, climb milling can be used because the smaller cutting force improves machining accuracy.

VIII. Advantages and Disadvantages of Climb Milling and Conventional Milling

1. Advantages of Climb Milling

(1) High milling efficiency and fast machining speed.

(2) Heat and machining force are easily transferred to the milling cutter during milling.

(3) Larger cutting thickness can be milled, facilitating machining.

(4) Better milling results can be achieved for materials with lower hardness, such as some plastics and aluminum alloys.

2. Disadvantages of Climb Milling

(1) Milled surfaces are prone to cutting deformation and roughness.

(2) Larger cutting forces cause table vibration, easily generating cutting heat, leading to tool thermal imbalance and increasing milling difficulty.

(3) For some high-hardness, high-toughness steels, climb milling will reduce production efficiency and machining quality.

3. Advantages of Conventional Milling

(1) Good milled surface quality, less prone to thermal and cutting deformation.

(2) Can maintain tool straightness and accuracy, resulting in high milling precision.

(3) Milling speed can be relatively high, leading to higher production efficiency. (4) Climbing can be adapted to milling various materials.

4. Disadvantages of Climbing

(1) The cutting force is very small during milling, which can easily cause tool jamming.

(2) The tool is in a semi-suspended state during milling, requiring high operator skill, slight carelessness can easily affect milling accuracy.

(3) If the milling depth and speed are too fast, it may lead to severe tool wear or even fire.

IX. Conclusion

In actual machining, there is no absolute superiority or inferiority between climb milling and conventional milling, the key lies in whether they match the material properties, machining stage, and machine tool conditions. Generally, a combined strategy of “roughing with conventional milling and finishing with climb milling” can be adopted to ensure machining stability while balancing efficiency and surface quality. For complex parts, comprehensive optimization based on tool structure, cutting parameters, and fixture rigidity is also necessary.

With the increasing rigidity of CNC machine tools and advancements in tool materials and coating technologies, the application of climb milling in modern CNC machining is continuously increasing, and the usage scenarios of traditional conventional milling are also changing. In the future, with the development of intelligent machining and adaptive control technologies, milling methods are expected to automatically adjust according to real-time cutting conditions.

YPMFG: Your Trusted Partner for CNC Milling and Precision Machining

Achieving consistent, high-quality CNC machining results requires the right equipment, proven processes, and experienced engineers. For many small and medium-sized businesses, building these capabilities in-house can be costly and time-consuming. That’s where professional CNC machining services come in. YPMFG provides reliable CNC milling and precision machining solutions that help customers maintain accuracy, consistency, and production efficiency.

With advanced CNC equipment and a skilled engineering team, YPMFG is capable of handling a wide range of materials and complex part geometries. Whether your project requires climb milling or conventional milling, rough machining or high-precision finishing, we select the optimal machining strategy based on part design and functional requirements, balancing quality, lead time, and cost.

In addition, YPMFG offers an efficient and transparent quotation and project workflow. From design evaluation and process optimization to prototype and production runs, we support our customers at every stage. Simply submit your part details and technical requirements to receive a fast, reliable machining solution, making CNC manufacturing straightforward and dependable.