In machining, terms such as “speed,” “cutting speed,” “SFM,” and “surface speed” all refer to the relative linear velocity between the cutting edge tip and the workpiece. This definition applies uniformly to all machining operations (turning, milling, etc.).

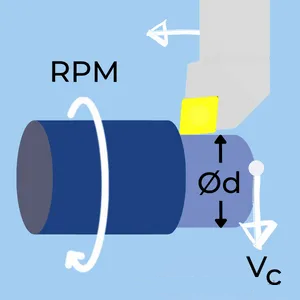

Cutting Speed (SFM) in Turning

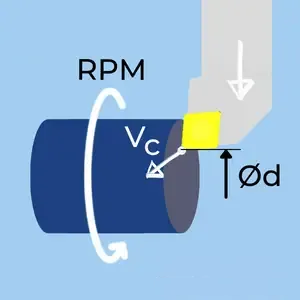

During turning operations, the workpiece rotates on the spindle (while the cutting tool remains stationary). The spindle speed (measured in RPM) converts to cutting speed at the point where the turning tool contacts the rotating workpiece’s diameter. Different diameters on the workpiece require different RPM values to achieve the same cutting speed.

Therefore, the CNC controller must continuously adjust the RPM to maintain a constant cutting speed. This is typically achieved using G96.

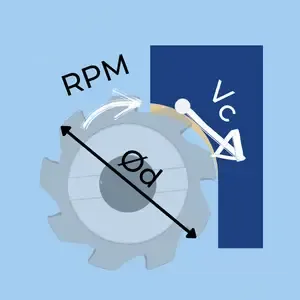

Cutting Speed in Milling (SFM)

During milling operations, the workpiece remains stationary while the spindle rotates the milling cutter. The spindle’s rotational speed (measured in RPM) translates into cutting speed at the point where the milling cutter contacts the workpiece’s diameter. Consequently, the RPM can remain constant throughout the entire operation. (This contrasts with turning, as you read above.)

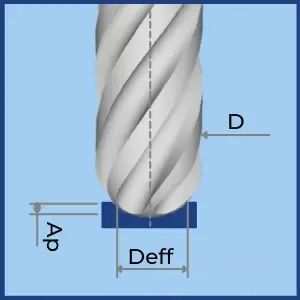

The simplified description above applies only to typical 90° end mills. For chamfering or ball-nose end mills, the point of engagement between the tool and material also depends on the radial and axial depth of cut. The diameter of this point is called the “effective diameter” (D eff), which should be used in the formula to calculate the cutting speed (SFM).

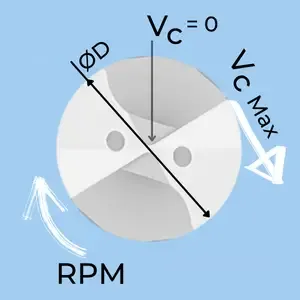

Cutting Speed During Drilling (SFM)

During drilling operations (and milling cuts), the entire surface of the cutting tool engages with the workpiece simultaneously. Since cutting speed depends on the engagement diameter (see formula), each position on the drill bit “experiences” a different cutting speed, with the center point always having zero cutting speed. Therefore, drill bits are manufactured from “all-purpose” carbide materials capable of operating at very low cutting speeds. Consequently, the cutting speed of a drill bit should always be maintained at a low level (relative to milling and turning).

Cutting Speed (SFM) for Face Turning and Cutting Off

During face machining and cutoff operations, the cutting tool moves from the outer diameter toward the centerline, often advancing all the way to the zero-diameter center. Spindle speed (RPM) increases as the tool approaches the center to maintain the required cutting speed. Since each machine has a maximum spindle speed limit, the spindle speed will eventually reach its maximum at some point during the operation.

Consequently, some machinists prefer using G97 mode (constant speed) for these operations. As with drilling, you should select an all-purpose carbide grade that performs well at both high and low cutting speeds.

This point is called the “clamping diameter” because the spindle speed is “clamped” to the maximum permissible RPM.

From the clamping diameter, the spindle speed remains constant while the cutting speed decreases, reaching zero when the cutting tool is positioned on the centerline.

Cutting Speed Units

SFM – Surface Feet per Minute

SFM stands for “Surface Feet per Minute.” It is a cutting speed measurement unit commonly used in the United States (but rarely used outside the U.S.). Speed is measured in feet per minute rather than meters per minute, the latter being the standard unit used in most countries.

m/min – meters per minute

In metric-using countries, the common unit for measuring cutting speed is “meters per minute.”

Conversion between SFM and meters per minute

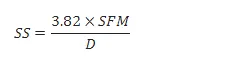

SS denotes spindle speed (revolutions per minute, RPM),

SFM represents surface speed (feet per minute), i.e., cutting speed,

D indicates the diameter of the tool or workpiece (inches).

What is the correct cutting speed for your machining application?

The correct cutting speed depends on a combination of the following factors:

Workpiece material machinability. (How resistant the material is to cutting)

Cutting tool carbide grade. (How wear-resistant the cutting tool material and coating are)

Overall program stability.