1.Project Background

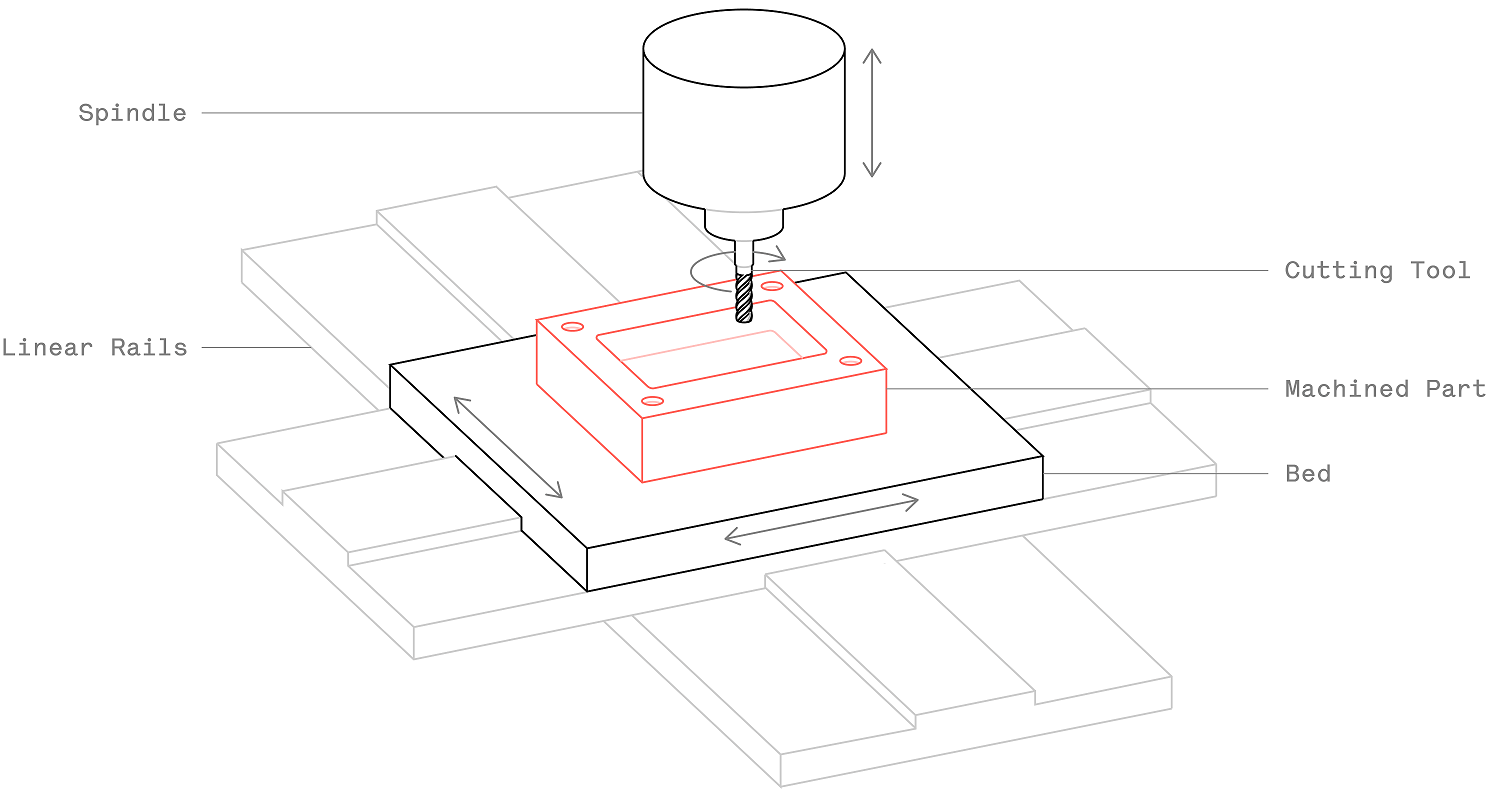

In modern industrial manufacturing, particularly within the high-precision cutting tools and automated tooling sectors, array hole plates serve as core components for workpiece positioning, pneumatic distribution, and precision assembly. The manufacturing challenge for such parts lies not in their geometric complexity, but in achieving consistent ultra-high-frequency features and stringent geometric positioning accuracy.

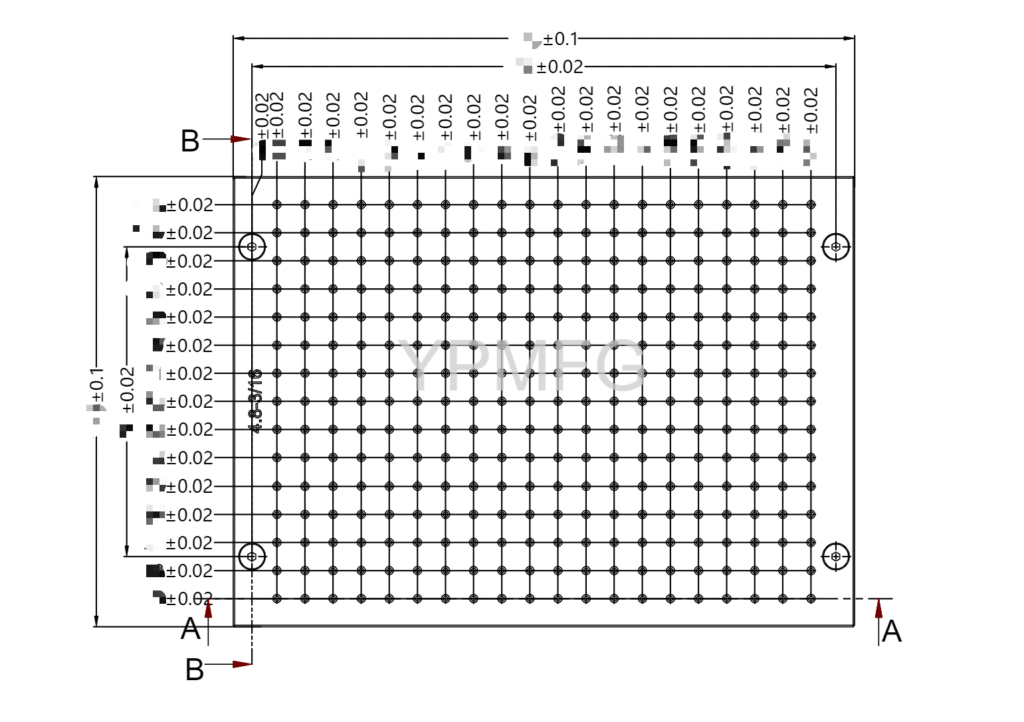

Recently, YPMFG undertook an exceptionally challenging project: machining a precision array hole plate (Part No.: 1.75 MM / 1.50 MM / 1 MM with 300 holes) for a high-end cutting tool supplier. The customer demanded completion of the entire process from raw material procurement, high-precision CNC drilling and milling, surface gold anodizing, to laser marking—within a tight 6-day total cycle time, while ensuring a 100% pass rate.

2. Part Specification

This component serves not only as a structural support for the mechanical assembly but also as the reference for subsequent precision assembly. Every design detail reflects the stringent requirements of Precision Machining. Core Function: This plate enables precise positioning and alignment of cutting tools, necessitating compliance with exacting physical conditions for assembly and fitting.

Material Specification: Aluminum 6061 (Aluminum 6061) is selected. This material is highly favored in the machining industry due to its excellent strength, corrosion resistance, and machining stability. It delivers exceptionally high-quality surface coloring effects, particularly when anodic oxidation dyeing is required.

Physical Specifications:

Overall Dimensions: 199±0.1 mm × 144±0.1 mm.

Thickness: 24.00 mm.

Hole Pattern Distribution: Includes 300 through/micro-deep holes with a diameter of φ1.50±0.05 mm.

Pitch Tolerance: Hole-to-hole spacing accuracy is locked at 9±0.02 mm.

Tolerance Standard: Linear dimensions and geometric features strictly adhere to ISO 2768-f (Fine) grade standards, meaning deviations for unmarked tolerances are strictly limited across spans up to 200mm.

3. Analysis of Machining Challenges

For any CNC machining facility, the difficulty of continuously machining 300 identical features while ensuring each falls within a ± 0.05 mm tolerance far exceeds that of producing a single ultra-precision hole.

3.1 Cumulative Tolerance and Thermal Expansion Compensation

When machining 300 holes with a 9 mm pitch on an aluminum alloy plate, inadequate thermal expansion compensation for the machine tool’s lead screw or workshop temperature fluctuations exceeding 3°C will cause linear material expansion. This leads to deviation of the outermost hole positions from their theoretical coordinates. The drawing’s specified span accuracy of 187±0.02 mm pushes the machine tool’s repeat positioning accuracy to its absolute limits.

3.2 Micro-hole Chip Removal and Deep-to-Diameter Ratio Challenges

Despite the hole diameter being 1.50 mm, the plate thickness reaches $24.00$ mm, resulting in a high depth-to-diameter ratio of 16:1. At such depths, aluminum chips readily clog the drill, causing rapid tool softening or breakage due to heat buildup. A broken tool would render the entire expensive aluminum plate, already more than halfway machined, unusable.

3.3 Surface Protection and the “No Scratches” Commitment

The drawings explicitly note: “The part surface must be free of scratches, abrasions, or other damage.” During high-speed machining, fine aluminum chips carried by the coolant act like abrasives, wearing down the surface. Protecting the original surface before gold anodizing under such intense cutting conditions is a critical step in the process.

3.4 Impact of Anodizing on Precision Hole Diameters

While gold anodizing provides aesthetics and hardness, the oxide layer typically ranges between 5~15 micrometers thick. If poorly controlled, a φ1.50 mm hole originally meeting ± 0.05 mm tolerance may shrink post-anodizing due to excessive oxide layer thickness.

4. Manufacturing Process

To ensure on-time delivery, YPMFG has established a scientific process flow:

4.1 The Process Route

Material Preparation Stage (Day 1): Select high-quality 6061 aluminum plate and perform pre-stressing treatment.

CNC Machining and Self-Inspection (Days 2-3): Utilizing high-precision 4-axis machining centers. Single-Setup Principle: Complete top-surface milling and drilling of 300 array holes in a single setup, eliminating positioning errors from secondary setups.

Peck Drilling: Set precise retraction depth, with mandatory chip clearance after every 0.5 mm of penetration to ensure smooth hole inner walls.

Quality Intermediate Inspection: After each process, the quality inspection department must verify compliance using a Coordinate Measuring Machine (CMM) or a 2D measuring instrument. Only after passing inspection can subsequent processing proceed.

Gold Anodizing Treatment (Day 4): Employing a constant-temperature electrolyte and precise current density control ensures consistency in the gold hue, with anodic oxide film thickness fluctuations controlled within ±2 microns.

Laser Marking and Packaging (Days 5-6): Specification codes (e.g., 2.5-5/51) are laser-etched onto prominent part locations. Components undergo ultrasonic cleaning before individual soft packaging.

4.2 Quality Control Details

ISO 2768-f grade execution: For linear dimensions >120~240 mm, we control tolerances within ± 0.2 mm. Sharp Edge Deburring: Per drawing specifications, all sharp edges undergo deburring and a C0.1 mm ultra-fine chamfering to ensure assembly safety and tactile comfort. Scratch-Resistant Fixtures: Custom Teflon spacer fixtures were developed to prevent metal clamps from leaving indentations on the 6061 surface.

5. Final Results & Customer Value

Through this rigorous combination of processes, we delivered an outstanding outcome: Delivery Speed: Two sets totaling six products were shipped within just six days from order receipt to final packaging.

Hole Positioning Accuracy Achieved: All 300 holes fell within the 1.50±0.05 mm tolerance range, with 9mm pitch spacing deviations showing less than 0.015 mm in sampling inspections.

Exceptional Aesthetic Quality: The anodized gold finish exhibited rich, pure color, while laser-etched markings remained crisp and clear, imparting an artistic quality to these industrial components.

Customer Value: Upon receiving the parts, the client conducted immediate compatibility testing and reported “first-time assembly success without any secondary adjustments,” significantly boosting the shipping efficiency of their end-use cutting tools.

6. Conclusion

Manufacturing a 300-hole array plate is not merely a demonstration of CNC machining technology but also a test of supply chain management and quality system execution. At YPMFG, we understand that even a single micron of deviation can impact hours of customer assembly time.

If you have similar high-precision custom machined part requirements whether in aluminum, steel, copper, or titanium alloys our engineering team stands ready to provide end-to-end support from drawing review to surface finishing.