In the field of modern manufacturing, CNC machining plays a vital role in producing high-precision components efficiently and consistently. Among the many CNC processes, turning and milling are two of the most widely used and complementary methods. While both rely on computer-controlled cutting tools, they differ significantly in working principles, motion paths, and suitable part geometries.

CNC turning excels at producing cylindrical or symmetrical parts by rotating the workpiece, whereas CNC milling uses rotating cutting tools to shape complex surfaces and features. Understanding the distinctions between these two machining processes helps engineers and manufacturers choose the optimal method for each application, balancing precision, speed, and cost efficiency.

Table of Contents

What is CNC Turning?

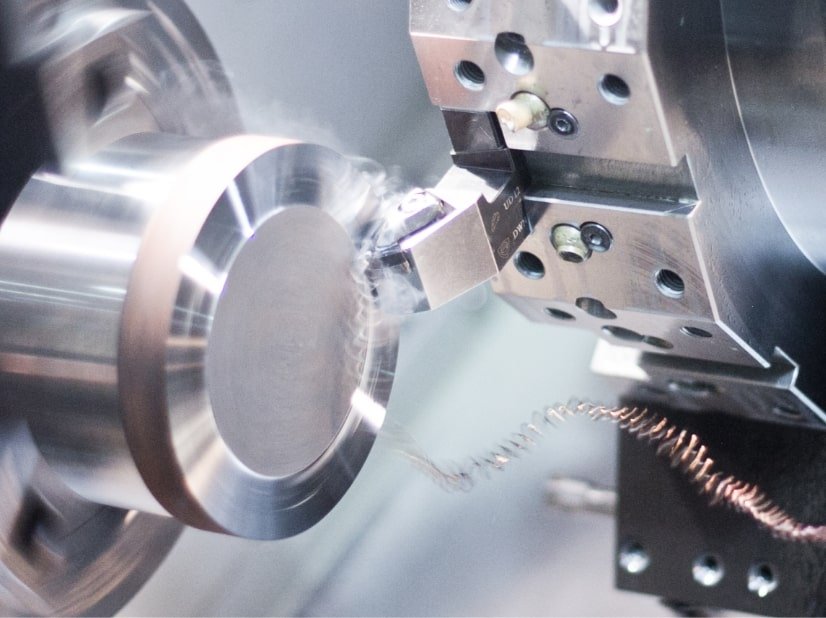

CNC turning is a type of machining process. Other machining processes include milling and drilling. In turning, a cutting tool is applied to a rotating workpiece, removing unwanted material to form the desired shape. Turning is similar to milling, another machining process, but the key difference lies in “what is rotating.” In turning, the workpiece rotates, while in milling, the workpiece remains stationary and the cutting tool rotates to perform the machining.

What is CNC Milling?

CNC milling is a machining method that removes metal in layers through motion. The cutting tool rotates, while the workpiece typically moves in a linear feed relative to the tool (most often fed by the worktable). In some cases, the workpiece remains stationary while the rotating tool performs lateral linear feed. Milling cutters possess multiple cutting edges capable of continuously removing a defined amount of material. When two or more cutting edges simultaneously engage the material, the tool cuts material to a specified depth on the workpiece.

CNC Turning Techniques and Methods

01 Face Machining

During machining, the workpiece length is slightly longer than the final part’s required dimension. Face turning is an operation that machines the end of a workpiece perpendicular to the rotational axis. During turning, the cutting tool moves along the workpiece’s radius, removing thin layers of material to achieve the desired part length and a smooth surface finish.

02 Outer Diameter Machining

OD machining involves positioning the cutting tool against the outer surface of rotating material. This remains the most common turning method, used for finishing surfaces or roughing out the target shape during initial machining stages. During OD machining, chips may wrap around the tool. Particularly in high-precision finishing operations, tool angles must be adjusted to prevent chip wrapping and accuracy degradation.

03 Chamfering

On a lathe, specialized chamfering tools can be used, with different tool angles and sizes selected as needed for turning operations. Lathe chamfering involves creating a beveled edge—typically at a 45-degree angle—on the edges of a workpiece or the inner/outer edges of a hole. This removes burrs and sharp corners, enhancing the workpiece’s safety, assembly compatibility, and aesthetic appeal.

04 Boring

Internal diameter machining involves cutting the inner surface of a material to enlarge holes created by drilling or similar processes. It is used to adjust hole size and finish the inner surface. During internal machining, tool length must be increased proportionally to the hole depth being machined. However, note that excessively long tools are prone to bending, leading to reduced precision. Additionally, chips tend to accumulate inside the hole, necessitating frequent chip removal.

05 Drilling

Drilling is a method that presses a drill bit against rotating material to create holes. When performing internal machining, a preliminary hole must be drilled to allow access for specialized tools, necessitating the use of drilling techniques. Since drilling with a drill bit does not achieve high precision, internal machining is typically employed for subsequent finishing after drilling the required hole size.

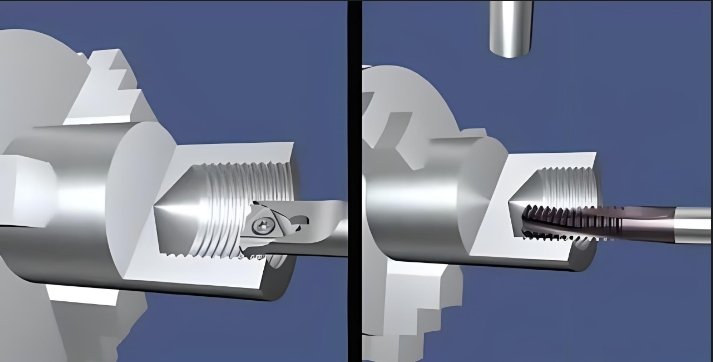

06 Thread Turning

Thread turning is a machining method for creating screw threads. Using specialized thread turning tools, both internal and external threads can be produced. While milling and machining centers are typically limited to internal threading, one key advantage of turning is its capability to create external threads. The specialized thread turning tool is positioned against the workpiece and moved at a constant speed. To ensure the thread pitch remains evenly spaced, the “automatic feed function” is typically used to maintain a constant speed.

07 Cutting

Cutting is a machining method where the tool is pressed against the material to remove unwanted sections. Examples include ring cutting on cylinders.

08 Knurling

Knurling on a lathe involves using a knurling tool to roll and press specific patterns onto the workpiece surface. This process primarily enhances surface friction or aesthetic appeal. Knurling patterns typically include straight lines and mesh designs, with varying degrees of coarseness selectable as needed.

CNC Milling Techniques and Methods

1. Face Milling: Cutting with the tool face to form flat surfaces on the workpiece.

Face Milling Explained:Definition, Applications, Tools, Process

Face milling is indispensable in the metalworking industry, which is undergoing significant transformation.

2. Peripheral Milling: Cutting with the tool’s periphery (outer edge) for machining deep slots, contours, and complex surfaces.

3. End Milling: Using end mills to create slots, grooves, holes, and intricate three-dimensional shapes.

4. Profile Milling: Machines part contours to achieve desired shapes.

5. Slot Milling: Creates slots or grooves in workpieces.

6. Plunge Milling: Cutting tool enters workpiece vertically, suitable for deep cavities.

7. Gear Cutting: Produces gear teeth using specialized milling cutters.

8. Chamfering: Creates beveled edges or chamfers on workpieces.

9. Thread Milling: Uses rotating tools that traverse along the workpiece.

Similarities Between CNC Milling and CNC Turning

While CNC milling and CNC turning differ in their machining approach, they share many core principles and technological foundations. Both processes are integral to modern precision manufacturing and contribute to the flexibility and efficiency of CNC production systems.

1. CNC Automation and CAM Programming

Both milling and turning rely on Computer Numerical Control (CNC) automation, where machining instructions are generated through Computer-Aided Manufacturing (CAM) software. This allows for precise, repeatable, and fully automated operations, minimizing human error and ensuring consistent product quality across batches.

2. Wide Material Compatibility

CNC milling and turning can be applied to a vast range of materials, including metals, plastics, and composite materials. Whether machining lightweight aluminum for aerospace components or stainless steel for medical instruments, both methods provide the adaptability required for diverse industrial needs.

3. Subtractive Manufacturing Using Cutting Tools

Both processes operate on the subtractive manufacturing principle—removing material from a solid workpiece using cutting tools. Despite the difference in movement (rotating tool in milling, rotating workpiece in turning), the goal remains the same: to achieve accurate dimensions and high-quality surface finishes.

4. Multi-Axis Machining for Complex Geometries

Advanced CNC machines in both categories support multi-axis machining (3, 4, or 5 axes), enabling the creation of complex shapes and intricate features without multiple setups. This capability significantly enhances productivity and ensures geometric precision even in high-tolerance applications.

5. Broad Industrial Applications

CNC milling and turning are both widely used across key industries such as aerospace, automotive, medical device manufacturing, and electronics. Their versatility allows manufacturers to produce everything from engine housings and turbine blades to surgical implants and custom mechanical components.

Differences Between CNC Turning and CNC Milling

The distinction between turning and milling is significant. Below are their primary differences:

Processing Methods:

Turning: Primarily for machining cylindrical surfaces. The workpiece rotates while the tool performs linear or curved feed movements.

Milling: Primarily suited for flat surface machining. A rotating multi-edge milling cutter cuts the workpiece, with the tool performing the main motion while the workpiece is typically stationary.

Scope of Application:

Turning: Ideal for machining single-axis parts such as straight shafts, disc-shaped components, and sleeve-type parts. It achieves high-precision machining of rotary surfaces like inner/outer cylindrical surfaces and threads.

Milling: Suitable for producing various planar surfaces, including flat surfaces, grooves, and contour shapes. Offers broad machining capabilities and is applicable to multi-axis parts like crankshafts and eccentric wheels.

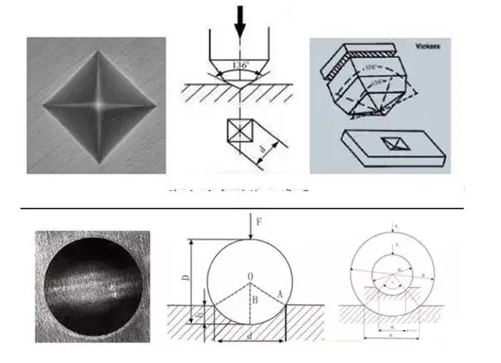

Accuracy and Surface Roughness:

Turning: Typically achieves high precision with surface roughness generally ranging from Ra 1.6 to 0.8.

Milling: Precision and surface roughness vary based on specific machining conditions and requirements, each with distinct characteristics.

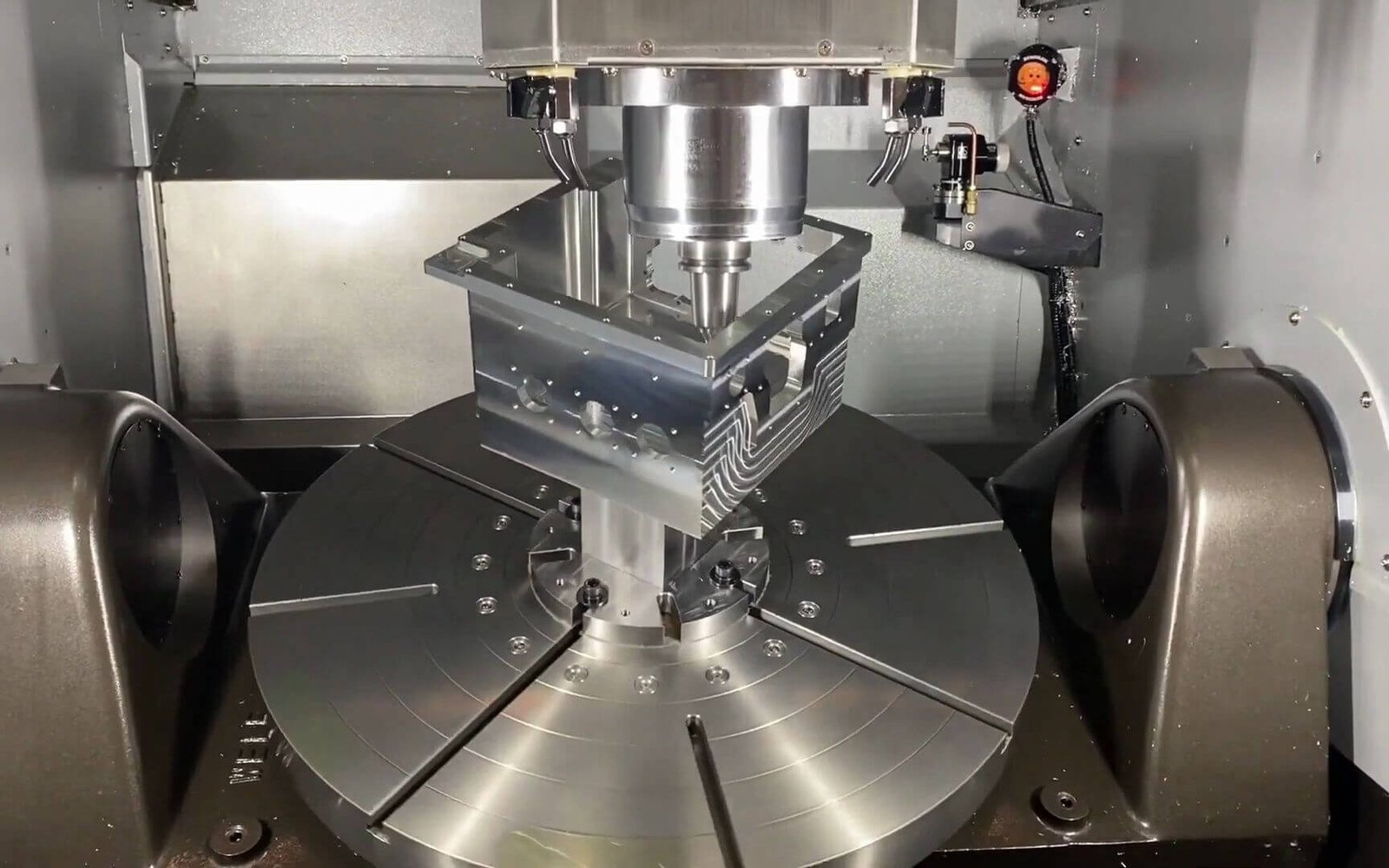

Combined CNC Turning and Milling

1. Turning-Milling Centers: These advanced machines integrate turning and milling capabilities to complete complex parts in a single setup. This integration enhances efficiency, reduces setup time, and improves precision.

2. Live Tools: On CNC lathes, live tools enable milling, drilling, and tapping operations without removing the workpiece from the lathe. This increases the flexibility and capability of turning operations.

3. Multitasking Machines: Machines capable of performing additional processes like turning, milling, grinding, or laser cutting in a single setup enhance versatility and productivity. With advancements in CNC technology, both turning and milling techniques have seen significant progress, achieving higher precision, automation, and complex operations. Each process has its unique methods and applications, integrating both into multitasking machines enables efficient production of high-precision, complex parts.

What are the Applications of CNC Turning vs Milling?

CNC turning and milling are widely used across multiple industries, each excelling at producing specific types of components. Understanding which process best suits your part’s geometry and function helps optimize manufacturing efficiency and precision.

1. CNC Turning: Ideal for Rotational and Cylindrical Parts

CNC turning specializes in producing parts with rotational symmetry. The workpiece rotates while the cutting tool removes material, making it perfect for manufacturing components that require high concentricity and fine surface finishes.

Common Part Types:

Shafts: transmission shafts, motor shafts, and spindles

Bushings and Sleeves: used in machinery and automotive assemblies

Discs and Pulleys: precision rotating components

Threaded Parts: bolts, nuts, and connectors

Symmetrical Components: any part with a circular cross-section

Typical Applications:

CNC turning is essential in automotive, aerospace, and general machinery manufacturing, producing high-precision rotating parts like bearings, couplings, and valve components.

2. CNC Milling: Ideal for Complex and Multi-Surface Parts

CNC milling excels at creating parts with complex profiles, flat surfaces, and intricate features. The cutting tool moves along multiple axes, allowing for detailed machining of 3D geometries and irregular surfaces.

Common Part Types:

Flat or Planar Parts: base plates, panels, and brackets.

Groove or Slot Parts: components with channels or recesses.

Gears and Cams: precision motion-control parts.

Box-Type Components: engine blocks, gearbox housings, and enclosures.

Plate-Type Components: structural frames and equipment panels.

Mold and Die Parts: injection molds, stamping dies, and tooling inserts.

Complex Casings: phone housings, electronic enclosures, and medical device shells.

Typical Applications:

CNC milling is commonly used in aerospace, automotive, mold making, electronics, and custom manufacturing, especially for producing parts with high dimensional accuracy and complex design requirements.

Advantages of CNC Turning

1. Ensuring Positioning Accuracy of All Machined Surfaces

All surfaces share the same rotational axis (the lathe spindle axis). During a single setup, turning can process an external diameter, internal bore, end face, and grooves on the same workpiece. This ensures coaxiality requirements between external diameters and between external diameters and internal bores.

2. High Productivity

Turning processes are typically continuous, minimizing impact forces and maintaining consistent cutting forces. When tool geometry, depth of cut, and feed rate remain constant during multiple passes (where cutting edges repeatedly engage and disengage), high-speed cutting and heavy cutting can be employed. The nominal cross-sectional area remains stable, resulting in minimal variation in cutting forces. Turning is suitable for both single-piece and small-batch production with high efficiency, as well as large-scale manufacturing.

3. Lower Production Costs

Turning tools are among the simplest cutting tools, resulting in low tooling expenses. Their manufacturing, sharpening, and installation are relatively straightforward. With numerous lathe attachments and high cutting productivity, setup and adjustment times are minimized, leading to lower turning costs.

4. Wide Range of Suitable Materials

Turning can process ferrous metals (iron, manganese, chromium), non-ferrous metals, non-metals (except hard-to-machine quenched steel parts exceeding 30 HRC), and plastic materials (acrylic, rubber, etc.). It is particularly suitable for finishing non-ferrous metal components. Certain non-ferrous metal parts exhibit low hardness and high plasticity. When ground with abrasive wheels, soft grinding debris easily clogs the wheel, making it difficult to achieve a highly polished surface. Therefore, grinding is not recommended. When non-ferrous metal parts require a low surface roughness value, finishing operations such as turning or milling should be employed instead.

Disadvantages of CNC Turning

1. Limited to Rotating Parts: Primarily suitable for parts with rotational symmetry, thus restricted to cylindrical components.

2. Material Waste: Significant material removal generates substantial scrap, particularly for large workpieces.

3. Surface Finish Issues: Achieving good surface finish can be challenging for long or slender workpieces due to potential deformation or vibration.

4. Tool Wear: Single-point cutting tools wear rapidly, especially when machining hard materials, necessitating frequent replacement.

Advantages of CNC Milling

1) High productivity. Milling cutters are typical multi-tooth tools. During milling, multiple cutting edges sequentially engage in the cutting process, the primary motion is rotational, enabling high-speed cutting.

2) Prone to vibration during milling. Impact occurs when milling cutter teeth engage and disengage the workpiece. The cutting thickness per tooth varies with tooth movement, causing fluctuating cutting forces that destabilize the process and induce vibration, thereby compromising machining quality. This also limits further improvements in both machining quality and productivity.

3) Cutting edges benefit from relatively good heat dissipation. After disengaging from the workpiece, milling cutter teeth receive a degree of cooling, facilitating heat removal. However, during both engagement and disengagement, the teeth endure not only impact forces but also thermal shock. This accelerates tool wear and may even cause fracture of carbide tools.

Milling operations are categorized into rough milling, semi-finish milling, and finish milling. Finish milling typically achieves machining tolerances of IT8 to IT7, with surface roughness Ra values ranging from 1.6 to 2.3 μm.

Disadvantages of CNC Milling

1. Complex setup: Compared to turning, milling requires more intricate fixtures and setup procedures, increasing preparation time and costs.

2. Higher Cost: Milling machines and associated tools are generally more expensive than lathes.

3. Surface Finish: Achieving fine surface finish is more challenging than turning, especially on flat surfaces.

4. Tool Wear: Multi-point cutting tools used in milling wear rapidly, particularly when machining hard materials, necessitating frequent tool changes.

5. Part size limitations: The dimensions of milling machines impose constraints on the size of workpieces that can be machined, particularly for large components.

CNC Milling vs. Turning: How to Choose the Right Process

Selecting between CNC milling and CNC turning depends on the part’s design, material, and production goals. Each process offers unique advantages, and choosing the right one ensures better efficiency, cost control, and quality results.

1. Choose CNC Milling for Complex or Multi-Angled Parts

CNC milling is ideal when your part involves 3D surfaces, intricate contours, or features at multiple angles. With its ability to move cutting tools along several axes, milling excels at producing components such as housings, molds, brackets, and structural parts requiring detailed geometries.

2. Choose CNC Turning for Cylindrical or Rotational Components

If the part’s main geometry is round, conical, or features symmetric rotation, CNC turning is the better choice. It efficiently produces shafts, bushings, nozzles, and threaded parts with excellent dimensional accuracy and smooth surface finishes.

3. Key Factors to Consider When Choosing

Part Geometry: Determine whether your component’s design favors rotational or multi-surface cutting. Complex shapes often require milling, while simpler, round geometries suit turning.

Material Type: Both milling and turning can handle metals, plastics, and composites, but certain materials, like harder steels, may require slower feed rates or specialized tooling depending on the process.

Surface Finish Requirements: CNC turning generally provides superior surface finishes due to continuous cutting, while milling may require post-processing for highly polished surfaces.

Production Volume: Turning is often more cost-effective for high-volume production of similar parts, whereas milling offers greater flexibility for prototyping or small batches of complex components.

Budget and Lead Time: Milling setups can be more complex and time-consuming, affecting both cost and turnaround. Turning, in contrast, typically involves fewer setups and faster cycle times, reducing overall production expenses for suitable parts.

Conclusion

CNC milling and CNC turning are both essential pillars of modern precision manufacturing. While each process has its unique strengths, milling for complex, multi-angled shapes and turning for cylindrical, rotational components they share the same foundation of automation, accuracy, and efficiency.

By understanding the key differences and similarities between these two machining methods, manufacturers can make smarter decisions that align with their design complexity, material type, surface finish needs, and production goals.

In today’s competitive market, choosing the right machining process is crucial to achieving optimal performance and cost-effectiveness. Whether your project requires intricate prototypes or large-scale production, partnering with a reliable CNC machining service provider ensures consistent quality, shorter lead times, and superior results.