Aluminum and its alloys play a key role in many fields with their excellent properties, including low density, high strength, good conductivity, superior corrosion resistance and excellent forming performance. In addition, it maintains its performance at low temperatures, does not magnetize, does not spark on impact, and has sound absorption and nuclear radiation resistance.

Table of Contents

International Designation System for Aluminum and Aluminum Alloys

| Main Elements | System |

| Pure aluminum (aluminum content not less than 99.00%) | 1xxx |

| Cu (copper) | 2XXX Precipitation (or precipitation) heat treatment (aging) |

| Mn (manganese) | 3XXX 20% higher strength than 1xxx alloy |

| Si (silicon) | 4XXX Aluminum alloy welding material |

| Mg (magnesium) | 5XXX Good corrosion resistance, welding performance |

| Mg+Si (magnesium + silicon) | 6XXX Mg2Si is the main strengthening phase |

| Zn (zinc) | 7XXX High strength alloy |

| Li (lithium) | 8XXX |

| Spare group | 9XXX |

The 1XXX group indicates pure aluminum (with an aluminum content of not less than 99.00%), and the last two digits indicate the two decimal places after the minimum aluminum percentage. The second digit of the grade indicates the control of the alloying element or impurity limit content. If the second digit is 0, it means that there is no special control of the impurity limit content. If it is 1-9, it means that there is a special control of the limit content of one or more single impurities or alloying elements.

The last two digits in the 2XXX-8XXX grade have no special meaning and are only used to identify different alloys in the same group. The second digit indicates the modification. If the second digit is 0, it means the original alloy, and if it is 1-9, it means the modified alloy.

According to whether aluminum alloys can be strengthened by heat treatment, they can be divided into:

Non-heat-treatable alloys: pure aluminum-1000 series, aluminum-manganese alloys-3000 series, aluminum-silicon alloys-4000 series, aluminum-magnesium alloys-5000 series.

Heat-treatable alloys: aluminum-copper-magnesium alloys-2000 series, aluminum-magnesium-silicon alloys-6000 series, aluminum-zinc-magnesium alloys-7000 series.

“-“: The Hn or Tn behind indicates the chain degree symbol of the work hardening state or heat treatment state

-Hn: indicates the chain degree symbol of non-heat-treatable alloys

-Tn: indicates the chain degree symbol of heat-treatable alloys

Performance and Application of Aluminum Alloys

1. 1000 series 1050, 1070

High-purity aluminum, electrical conductivity, thermal conductivity, corrosion resistance.

Conductive materials, heat exchange devices, chemical equipment piping.

2. 2000 series 2011, 2014 2017, 2117 2024

Excellent cutting performance, high strength, weak corrosion resistance.

General term for duralumin, cutting materials: structural materials such as parts and screws, aircraft materials, forging materials, automobile and motorcycle hydraulic parts, sports equipment.

3. 3000 series 3003, 3203

Better heat resistance than pure aluminum, high strength, good corrosion resistance.

Chemical equipment piping, heat exchange devices, Photosensitive tubes for copiers.

4. 4000 series 4032

Good heat resistance and wear resistance.

VCR heads, piston components, forging.

5000 series 5052, 5056

Medium-strength alloy, corrosion resistance, good welding

Chemical industry piping, machine parts, camera lens barrels

6. 6000 series

6061 Medium-strength structural alloy with excellent corrosion resistance, weldable, good processability.

Road vehicles, ships, marine transport equipment, road materials and building materials, sports goods, etc.

6063 Corrosion resistance, good surface treatment, and excellent extrusion properties account for most of the extruded materials.

Building materials, construction materials, decorative materials, home appliance materials and other general products.

7. 7000 series

7003 Structural alloy for medium-strength welding Vehicle, automobile, locomotive parts.

7075 Known as super duralumin, the highest strength alloy, corrosion resistance, poor welding. High-strength materials: aircraft and other mechanical parts, sports equipment, etc.

8. 8000 series

8090, 8091 practical alloys are very rare

9. 9000 series

High-performance alloys, adding special elements (such as rare earth elements, etc.), have super performance or certain special properties.

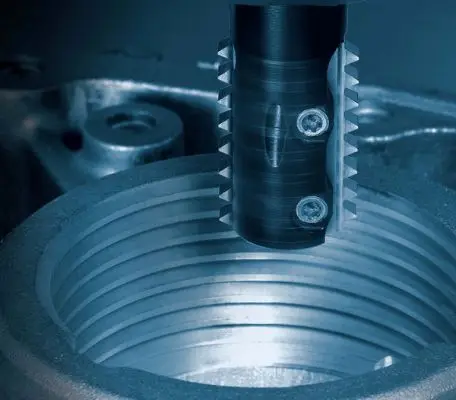

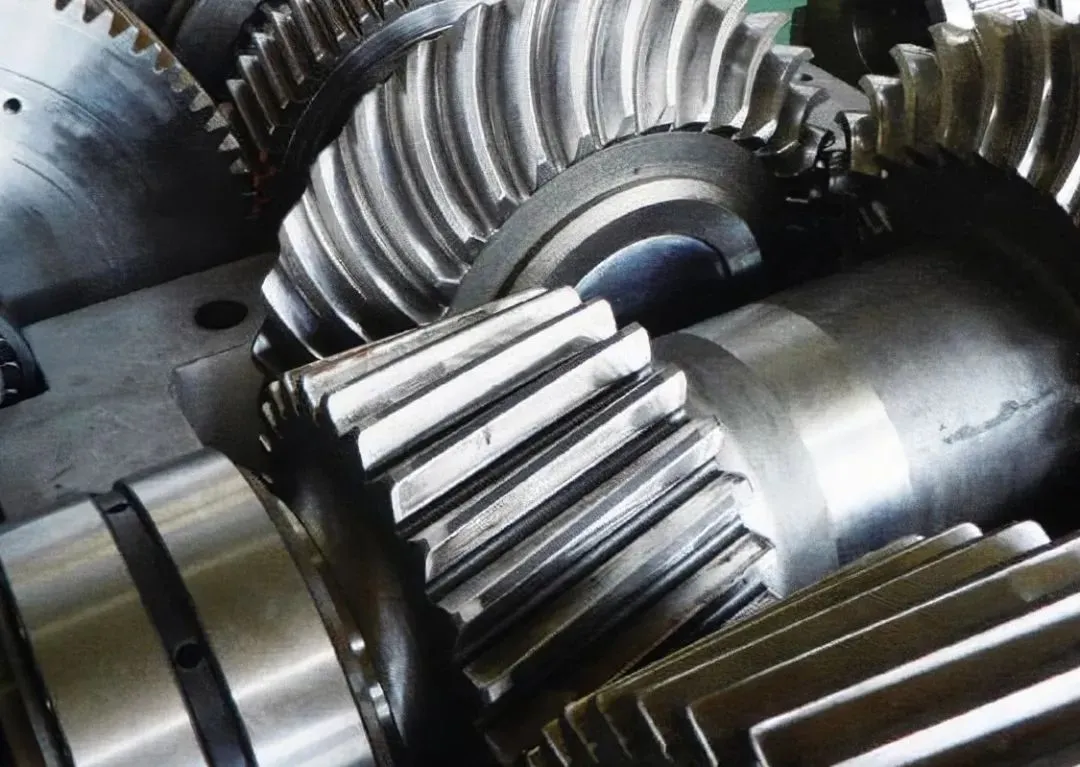

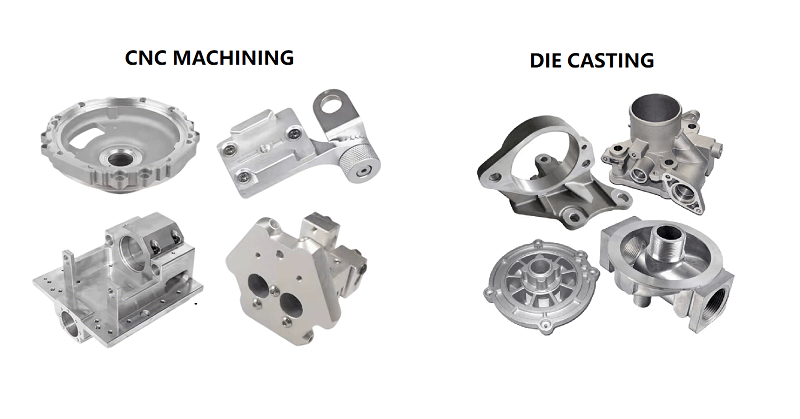

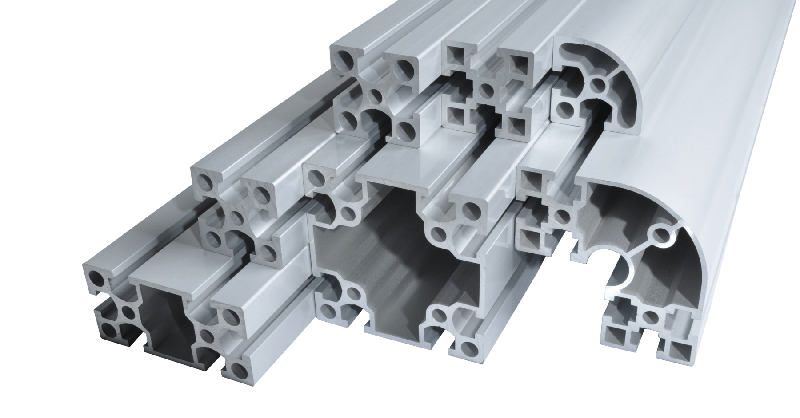

Introduction to Aluminum Extrusion Products

Aluminum extrusion products are one of the four major categories of aluminum primary processing products (the other categories are aluminum castings, aluminum forgings, and aluminum rolled products). It is still the aluminum (alloy) ingot that is heated to the plastic temperature (400~500℃), and the extruder uses the power of oil pressure to extrude the aluminum (alloy) ingot through the extrusion die to become the required profile. The shapes include profiles, tubes, bars, and wires. In terms of application, profiles and tubes account for the majority. The descriptions of various products are as follows:

1. Profiles – can be solid, hollow or semi-hollow, with angle, T-shaped, slotted and other more complex shapes.

2. Tubes – Tubes are round, square, rectangular, hexagonal, octagonal, fan-shaped or elliptical.

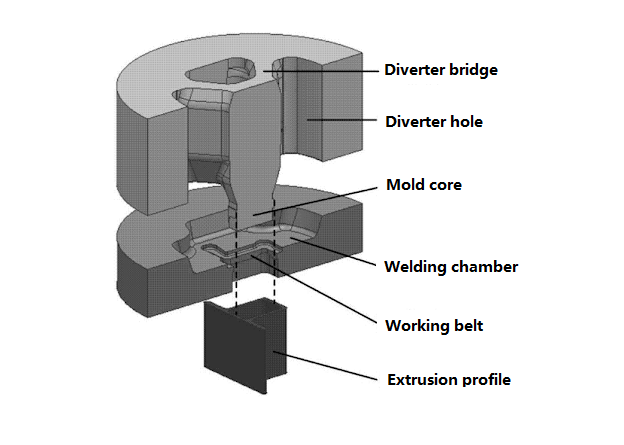

A. Seamed tube: There is a welding chamber in the middle of the extrusion die, and the solid extruded ingot is first divided into several streams, which are then fused to form a hollow shape when flowing through the welding chamber. Common extrusion dies include bridge dies, porthole dies, bracket dies, or taper-type dies.

B. Seamless tube: It can be extruded from a hollow ingot or punctured on the extruder before extrusion. However, due to the complex operation procedures and high cost of this method, and the limitation of the length of the mandrel, a larger hollow tube is often extruded first and then stretched, so the engineering cost is expensive. Unless otherwise required, seamed tubes are mostly used.

3. Rods – Aluminum rods can be formed by hot rolling or extrusion and usually need to be cold-processed to the final size. The cross-sectional area of aluminum rods is circular or nearly circular, with a diameter greater than 9.5mm (3/8 inch). The cross-sectional area of an aluminum bar can be a square, rectangular or regular polygon, where the distance between at least one set of sides is greater than 9.5 mm.

4. Wire – Aluminum wire is drawn from a bar with a diameter of less than 9.5 mm, and the cross-sectional area shapes are square, circular, rectangular, hexagonal and octagonal.

In the redesign and manufacturing of aluminum extrusion, objects with complex shapes can be directly extruded and formed, and higher strength can be obtained, so it is widely used. The main application industries are the following six categories:

1. Building material structure: such as aluminum doors and windows, curtain walls, railings, signboards, etc.

2. Transportation tool parts group: such as bicycle rims, frames, car radiators, ship cabin components, vehicle bodies and aircraft frames, seat frames, etc.

3. Consumer durable materials: such as sports and leisure products (aluminum baseball bats, skate frames, badminton rackets).

4. Mechanical and industrial equipment components: such as transmission frames, heat exchanger components, pneumatic tool components, air compression cylinders, forging blanks, industrial piping, and elevator room frames for electronic, food, and chemical fiber conveying machinery.

5. Electronic engineering components: such as heat sinks, disk drive read/write heads, optical rulers, photosensitive tubes for copiers, optical guide rails, and tape drums.

6. Defense weapon parts: such as missile shells, gun components, etc.

The above products are usually divided into two categories: general extrusion and industrial extrusion in the industry. The former includes categories 1 and 3, and the rest belong to the latter. General building material quality requirements: appearance life, wind pressure resistance, air tightness, water tightness, sound insulation, heat insulation, dew resistance, fire resistance, switchability (switch durability), and safety. The requirements for industrial profiles are more stringent.

Basic Elements of Extrusion

1.Die accessories: Die backing (including die holder, bolster, sub-bolster, etc.) and pressure platen often have a decisive influence on the quality of extruded products. High-strength and hard-back die backing can reduce the deflection of the die and ensure the reusability and life of the die.

Because the die itself is the first and most directly exposed to the extrusion pressure, the die designer must determine the height of the push rod (mandrel) and the die according to the cross-sectional shape of the extruded product and the length and width of the push rod. The main purpose is to avoid the die from deflection or cracking during the extrusion process because this may cause unexpected changes in the metal flow and the shape of the die. In order to minimize the deflection of the die, a set of tightly fitting die backing kits is required. The most commonly used component at present is the embedded support block. The die designer usually gives stronger support to the area with greater force in the die stress area to reduce the occurrence of deflection.

2. Basic principles of mold design:

- Although uneven wall thickness is feasible, it is ideal for all wall thicknesses to be average.

- The processing cost of solid extrusion is lower than that of hollow extrusion.

- The corners of the extrusion are designed as small radius arcs to avoid direct, sharp angles.

- Symmetrical extrusion can improve production efficiency.

- Adding grooves or ribs to the extrusion can improve strength and reduce extrusion wear.

- For complex shapes, hollow or semi-hollow sections can be considered in the design.

- Near-net shape can reduce or avoid processing.

- Screw fixation can be included in the design to improve the ease of assembly.

3. Basic principles of manufacturing tolerances:

- Linear tolerance: 0.8 of the length of the profile.

- Angular tolerance: depending on the configuration of the profile, the range is 1o~2o.

- Torsion tolerance: about 0.5o per inch.

- Wall thickness tolerance: 10% of the thickness of the part.

- Horizontal tolerance: 4/1000 of the width.

- Vertical tolerance: 1/1000 of the length of the part.

4. Extrusion manufacturing:

The mistakes that extrusion plants usually make are actually known to manufacturers. For example, if a manufacturer wants to deliver goods to a major customer in a hurry, he is in a hurry to start the extruder to produce. As a result, he did not make a complete confirmation of all the temperatures before production as usual, and then started production, making the temperature of the inner lining of the tablet barrel higher than the outside itself, becoming a heater, and it is easy to break. If it is a large tablet barrel, it should take more time to preheat it to an operable temperature. Otherwise, the tablet barrel will generate a lot of internal stress. Although this situation is not often encountered, a truly excellent extruder will not let this happen. First-class dosage form manufacturers and general manufacturers face the same market, with large price differences, and even use the same extruder. But the former can operate very efficiently. They produce very little waste, have the shortest downtime, and have much higher productivity than ordinary manufacturers so that every order can have ample time to make a reasonable profit. The most important key is that first-class manufacturers pay special attention to temperature. They often monitor, record and control temperature. Temperature and its impact are always on the minds of these manufacturers, and they fully understand the temperature changes that should occur at every production point in the process.

If there is no unexpected downtime, the level of productivity depends mainly on the extrusion speed, which is limited by four factors, three of which are certain, and one is uncertain.

The first factor is the tonnage of the extruder. Larger dosage machines can extrude aluminum ingots at lower temperatures.

The second factor is the design of the mold. During the extrusion process, the friction between the extruded aluminum alloy and the mold usually increases the extruded alloy by 38°C. The most common problem faced by the mold surface is the occurrence of wear, especially the bearing part. At high temperatures (over 450°C), the nitrided surface is prone to corrosion. Therefore, the mold manufacturer should design a higher extrusion speed before the extruded profile reaches the critical breakage temperature. This will prevent defects such as cracks or adhesion during the extrusion process. To do this, the mold must be of considerable quality. Although such molds are more expensive, this extra cost will soon be compensated by increased productivity.

The third factor is the characteristics of the extruded alloy, which is more difficult to control, especially when the profile extrusion temperature (exit temperature) reaches 538℃. The profile surface will deteriorate, such as oxides and cracks attached to the inner lining of the mold. If the extruder thrust is insufficient or the mold is too hard, the ingot temperature will increase. In this way, the extrusion speed must be reduced to prevent the profile extrusion temperature from being too high.

The last factor that limits production speed is temperature, which can be controlled. The optimal extrusion temperature of aluminum extrusion often depends on the type of extruded alloy. The following is the appropriate extrusion temperature for 6000 series aluminum alloys.

Appropriate extrusion temperature of aluminum extrusion type Metal type Extrusion temperature Extrusion temperature

6063 415-440℃ 500℃

6061 425-455℃ 525℃

6005 415-445℃ 510℃

Therefore, the temperature of the ingot barrel is very important, and the preheating work cannot be sloppy. In order to minimize the thermal stress and prevent the lining from shrinking, the ingot barrel and the lining should reach the operable temperature at the same time. This must be done gradually, and the temperature increase per hour cannot exceed 37℃.

Therefore, during the preheating process, the ideal approach is to maintain the ingot barrel at 232℃ for 8 hours and then maintain it at 427℃ for another 4 hours before starting extrusion to ensure that the overall temperature of the ingot barrel is uniform and the internal thermal stress is fully eliminated.

The best way to preheat is to use an oven. The oven can also be used to prevent the push rod (stem) from breaking due to thermal stress. The push rod should be stress-relieved every six months. The method is to heat the push rod upright in an oven from 427℃ to 428℃ for 12 hours and then slowly cool it in the oven.

In order to obtain the best extrusion effect, during the extrusion process, the ingot barrel should be 10℃-38℃ lower than the aluminum ingot. Sometimes, when the temperature of the ingot barrel is higher than the aluminum ingot due to the extrusion speed, the ingot barrel should also be cooled. Usually, when the temperature of the ingot barrel reaches 468℃, waste chips will be added.

When the surface quality of the profile is extremely important, the temperature of the front pad of the push rod should also be controlled to reduce waste chips. That is, the temperature of the end of the aluminum ingot will not be too high to extrude impurities. The method is to use air to pass through the axis of the push rod directly to the front pad so that the center of the front pad is reduced by about 52℃, which can reduce the generation of waste chips and improve productivity. At the same time, this air can further reduce the temperature of the tablet barrel by 24℃, which also helps to improve productivity.

On the other hand, first-class dosage form manufacturers will not ignore the temperature of the mold. The preheating temperature of the dosage form mold is usually set at 450℃-480℃. The flat mold must be heated for at least two hours, and the hollow mold must be heated for at least four hours. In addition, although the mold has been preheated to an operational temperature, if the mold support block, which is twice the volume of the mold, is not heated, the support block will also become a heat sink for the mold, greatly reducing the preheating effect.

If the temperature of the mold is lower than 427℃, it is easy to break, and special aluminum ingots may be needed to make the required dosage form. On the other hand, if the mold is overheated, its hardness will be reduced, and oxides will be produced. Oxides usually occur in the stress area.

For mold preheating, it is recommended to use a heating furnace. If the heating furnace is too small, the molds are too close to each other, and air is not easy to circulate. At present, there is a box furnace that can heat each mold separately, which has a good effect.

The appropriate temperature of the aluminum ingot depends on the tonnage of the dosage machine, the type of alloy, the shape of the dosage form, the temperature of the mold and the extrusion speed. Aluminum ingots with lower temperatures have a larger temperature rise space during the dosage process and can also achieve a higher extrusion speed.

The extrusion temperature of the profile is also closely watched by first-class dosage form manufacturers. This temperature is controlled by the speed of the push rod and the degree of mold friction. Generally, it will increase by about 38°C during the extrusion process. This increase depends largely on the design of the mold. The design should be aimed at achieving maximum productivity. Only in this way can a higher production speed be achieved while maintaining the required dimensional accuracy and surface finish.

5. New trends in extrusion technology

Variable technology in extrusion: Use the position of the mold assembly and the mold cavity to change during the extrusion process so that the width and thickness of the output can be changed as required.

Manufacturing of large-width extruded profiles: 1. Expansion plate technology. 2. Use the angled ingot barrel to change the shape of the aluminum ingot with a large cross-section.

Recent applications of finite element analysis: using simple algebraic formulas on computers to calculate stress and strain in the aluminum extrusion process, dividing the structure into extremely small units, each unit is connected to a so-called node. When the node is stressed, the changes and effects on the entire structure are generated, which is the focus of FEA.

Basic Theory of 6000 Series Extrusion Alloys

The extrusion processing of 6000 series alloys is a composite composition of a thermal process. In order to efficiently produce high-quality extruded products, we should have a basic understanding of the metallurgical theory in the process.

1. The role of magnesium and silicon

The 6000 series alloy is a typical aluminum alloy that can be heat treated. The strength obtained by this type of alloy is easier than that caused by mechanical processing. The most critical elements in this type of alloy are magnesium and silicon. These two elements will combine into magnesium silicide grains (MgzSi). These grains will have several forms in alloy lithium, which can be roughly classified into the following three types.

● β″ (beta double primary crystal) magnesium silicide is the most delicate grain. It has a strong needle shape, and when its uniform and fine parts are inside the alloy, it is of great help to mechanical properties.

● β′ (beta primary crystal) Magnesium silicide, the larger needle-shaped grains are grown from beta double primary crystals. The help of this type of beta primary crystal is insignificant to the mechanical properties.

● β (beta crystal) magnesium silicide is the largest magnesium silicide grain in a cubic shape. Due to the coarse grain size, it is completely unhelpful to the mechanical properties.

The choice of alloys with a high silicon content is advantageous than that of alloys with a high magnesium content. The reasons are as follows:

● The high magnesium content does not enhance the final mechanical properties of the product.

● High magnesium content will increase the flow stress of the alloy and increase the difficulty of extrusion.

● The opposite silicon content is relatively high, which helps the aging treatment reaction and can improve the strength of the product.

2. The role of various alloy elements

Iron

Iron (Fe) also appears in alloys, which will combine with silicon and aluminum to form a ferro-silicon intermetallic compound. This intermetallic compound is of no help to the strength of the alloy. On the contrary, if it cannot be treated correctly, it will have a negative impact on the extrusion processability of the alloy. It is extremely important to control the iron content of the 6000 series alloys accurately, especially the surface processing requirements of the finished product, as different degrees of iron content will change in different colors when treated with electrolytic films. At the same time, it is also known that the iron content will reduce conductivity.

Manganese

Manganese (Mn) is cited in a variety of alloys in the 6000 series of alloys, including it can reduce the time of homogenization treatment because manganese can promote the conversion of beta ferroala ferrosilicon grains into alpha ferrosilicon grains. For alloys such as 6061 and 6082, the growth of coarse crystals is prevented during heat treatment after extrusion. The other benefit is that adding manganese can strengthen crack resistance because manganese can prevent silicon grains from nucleating on grain boundaries, which will make the material brittle.

Chromium

The role of chromium (Cr) is very similar in many aspects, but it is more compulsory than manganese in terms of quenching sensitivity.

Copper

The addition of copper (Cu) can improve the conductivity and mechanical processing of extruded alloys, especially high-strength alloys such as 6061. After aging treatment, the mechanical properties will have a negative impact, and copper will have a counteracting effect. However, once the copper content exceeds 0.2%, the corrosion resistance of the extruded products of the 6000 series alloy will be reduced.

Zinc

No negative impact has been found on the mechanical properties of the 6000 series alloys, but when the content exceeds 0.02%, there will be “patterns” during the oxide film treatment, which is mainly caused by differences in etching effects.

Summary of the effects of major elements and trace elements.

Alloy elements Extrusion processability Quenching sensitivity Strength/hardness Tuberculosis/toughness.

Thermal cycle of 3.6000 series alloys.

The 6000 series alloys can obtain the highest strength through the following heat treatment.

●Solid melting or solid melting heat treatment during extrusion operation.

●Quen the appropriate cooling rate adopted by different alloys.

●Then, the application of aging hardening treatment.

The lack of correct temperature control cannot achieve the highest mechanical properties of the product. The correct temperature control of the process can give regular characteristics of magnesium silicide grains.

4. The main conditions affecting the extrusion process

4.1. Model machine capability (or instructions for use pressure)

To give the extruder the highest productivity, the extruder is controlled to operate at conditions close to the maximum operating pressure, which is usually used to correspond to the highest extrusion speed.

When softer alloys are used or high-pressure inputs are used to pursue higher production efficiency, this dividing line will move to the left, as for harder alloys, higher extrusion rates or complex production profiles, the opposite dividing curve may move to the right, which will expand the A region, reduce the extruder capacity (pressure), that is, reduce the extrusion speed (and productivity). Use higher-temperature aluminum blasts. The reduction in extrusion speed may be a supplementary effect, but other variables will also limit the increase in temperature.

4.2. Mechanical properties

The requirements of mechanical properties will also bring some degree of limitation to the extrusion process. It is based on the definition of extrusion speed and aluminum embryo temperature, which increases the correlation between mechanical properties and process variables. At the same time, the lotus and other related factors are also presented together.

In addition, a green dividing curve is added to represent the required dividing line of the mechanical properties of the extruded product. When using aluminum embryos containing large magnesium silicide grains or extruding profiles with thick sections, and when high mechanical properties are required, this dividing curve will move to the right, which means that the extrusion speed and aluminum embryo temperature must be increased. In this way, the product with high mechanical properties must be produced because when the extrusion speed and aluminum embryo temperature are increased, more thermal energy must be provided to promote the melting of magnesium silicide in the aluminum embryo.

When the extruded profiles contain magnesium silicide beta double primary crystal and beta primary crystal, the aluminum embryo contains a thin section thickness. It has low requirements for mechanical properties, then this boundary curve will move to the left, and the requirements for both the extrusion speed and the temperature of the aluminum embryo will be reduced. The mechanical properties of the finished product will be easily achieved.

5. Extruded control window frame

The shape of the intermediate area formed by the three boundary lines of the finished product’s mechanical properties is like a window frame. In this area, the conditions in this area can produce good quality products. As for the actual control conditions to be located in the frame, the surface quality requirements of the finished product (smooth degree, oxide film requirements and extrusion precision) and the limits specified by the mechanical properties must be considered. These three boundary lines also indicate the maximum extent to which extrusion productivity can be achieved. Other variables, such as alloy type, extrusion ratio/profile shape and mechanical properties of the finished product, may expand or shrink this control window frame.

6. Forced quenching (cooling)

The extruded profile must be cooled quickly, and the cooling rate must be sufficient to allow magnesium and silicon to remain in the solid solution. In this way, the mechanical properties can be maximized during subsequent aging treatment. The cooling rate depends on the cross-sectional size of the profile, which depends on the cooling method, such as natural air cooling, fan air cooling, and water mist spraying fire, which is sink cooling.

7. Aging treatment

When extruded profiles need to enhance their mechanical properties, the 6000 series alloy must adopt an aging treatment. In essence, the amount of mechanical properties can be improved depending on the alloy type and aging treatment conditions. These conditions include natural aging treatment at room temperature until various heat treatments at higher temperatures are called artificial aging treatment.

As for the strength of the 6000 series alloy, the most direct correlation is the impedance ability of the internal particles to be misaligned during the deformation process. When the material is stressed, the particles begin to move and move in a disorderly manner. When the stress increases repeatedly, the number of this particle misalignment will increase, and the intensity will also increase. It will not terminate until the material is damaged. The ability of the particle misalignment will be blocked by the magnesium silicide grains. In this way, the strength of the material can be improved, and the size and density of these magnesium silicide grains. Controlled by the conditions of aging treatment, a small amount of fine magnesium silicide beta double coarse crystals can slightly prevent the misalignment from happening in the material, but when the number increases, it is enough to suppress the misalignment and increase the strength of the material. If this type of grain grows too large (beta magnesium silicide beta primitive and beta crystals), then the total amount of magnesium silicon available will be reduced. Due to the decrease of magnesium silicide grains, the shuttle space will be increased, and the material strength will be reduced.

In order to achieve peak mechanical properties, when setting artificial aging treatment conditions, the goal is to achieve the precipitation of a large number of magnesium silicide beta double primary crystals. The typical conditions for 6000 series alloys are to be insulated at 170°C for 8 hours or 185°C for 6 hours.

Aluminum Alloy Heat Treatment

※What are the differences in the code names of common heat-treated aluminum alloys?

F: As fabricated means that no special treatment will be applied after cold processing, hot processing or casting.

O: Annealed means forged products annealed to the lowest strength level and cast products annealed to increase ductility and dimensional stability.

H: Strain Hardened represents a processed and deformed forged product.

W: Solution heat treated means that only the natural aging of solid solution is W1/2 hr after treatment.

T: Heat treated to produce stable temperatures other than F. O. or H

※What are the types of aluminum alloy heat treatment T codes?

T 1 cools down from the process of forming and casting, extrusion at higher temperatures and aging naturally.

T 2 is cold-worked from higher temperatures and is aged naturally.

T 3 After solid solution treatment, cold processing and natural aging

T 4 After solid solution treatment, direct natural aging effect

T5 Light and high temperature forming to apply artificial aging

T6 Artificial aging after solid solution treatment

T 7 Artificial aging to out-of-age condition after solid solution treatment

T 8 After solid solution treatment, cold processing and artificial aging

T 9 Artificial aging and cold processing after solid solution treatment

T 10 Higher temperature forming is cold-worked and artificial aging

TX 51 After solid solution treatment, use stretching to eliminate internal stress

TX 52 After solid solution treatment, use compression to eliminate internal stress

TX 53 Use extension and compression to eliminate internal stress

※What is the most common heat treatment strengthening mechanism for aluminum alloys?

(1) Precipitation hardening: The heat-treated aluminum alloy is 2XXX, 6XXX and 7XXX. It uses quenching treatment and aging treatment to cause a phase change in the internal structure of the material to produce a detailed precipitate, and through this precipitate, the material is strengthened. This phenomenon is called precipitation hardening or aging hardening.

(2) Solid solution treatment: No precipitation hardening of non-heat-treated alloys (but there will also be precipitates), so their strengthening effect is usually achieved by general methods, such as solid solution strengthening and grain refinement strengthening.

※Aluminum alloy precipitation hardening heat treatment procedure:

The practical precipitation hardening heat treatment procedure must include the following three basic steps:

Solution treatment → Quench → Aging treatment

Solid solution treatment refers to the generation of material to the single-phase zone of solid solution for a period of time so that all the solutes are dissolved into the base to form a single alpha phase, quenching refers to the rapid cooling of the material after solid solution treatment to obtain a saturated solid solution. The aging treatment will place the supersaturated solid solution at a constant temperature to gradually precipitate the precipitates and cause changes in properties. If this constant temperature is room temperature, it is called natural aging, and if it is carried out in a high-temperature furnace, it is called artificial aging.

※What is the over-age treatment of aluminum alloys?

Generally speaking, the increase in the initial aging hardness is caused by the gradual precipitation of precipitates. The volume ratio gradually increases, and the smaller the distance between precipitates, when the highest aging is reached, the precipitates show the optimal distribution state, that is, the maximum resistance to the difference row, the formation of excessive aging is caused by the coarsening of the precipitates, increasing the radius of the precipitates, the number of precipitates decreases the distance, and the distance increases. According to the aforementioned strengthening mechanism, it can be seen that the roughening reduces the resistance to the difference row and reduces the hardness.

Precipitation Hardening Treatment of Aluminum Alloy

Aluminum alloys can be divided into work-hardened (non-heat treatment) alloys and precipitation-hardened alloys. The former is suitable for 1000 series, 3000 series and 5000 series aluminum alloys, while the latter is used for high-strength aluminum alloys such as 2000 series, 6000 series and 7000 series. Among them, precipitation-hardened alloys can be combined with different heat treatment conditions to select the required mechanical properties, so their application range is relatively wide. This article briefly describes the commonly used heat treatment methods for precipitation-hardened alloys and introduces some special time-efficient precipitation technologies, hoping to be helpful to aluminum alloy heat treatment operators.

1. Solid solution treatment

This treatment is to make the solute atoms in the aluminum alloy component solid solution to the maximum extent, so it must be maintained at high temperatures for a long time. The solution treatment temperature is too high, and it is easy to cause eutectic melting. If it is too low, it is worried that the solution is incomplete. Therefore, the principle of choice is to take the temperature between the solution limit of solute atoms in the alloy and the eutectic temperature. Materials that produce eutectic melting either cause quenching or significantly reduce strength, ductility and toughness.

2. Quenching treatment

The quenching treatment is to obtain a supersaturated solid solution, so the cooling rate must be quite fast. If the cooling rate is insufficient, the solid-solution solute atoms are prone to precipitate at the grain boundaries, which will reduce the strength and ductility.

In addition, quenching does not only obtain a supersaturated solid solution but also allows high-density hollows at high temperatures to be frozen to some extent, increases the diffusion rate at subsequent low temperatures, and promotes the formation of GP zones or the precipitation of intermediate phases.

2.1 Quenching sensitivity (C curve)

Generally, the degree to which the quenching rate affects the characteristics of the material is expressed as “high quenching sensitivity” or “low quenching ability”. Figure 1 shows the T-T-P curves of several representative heat-treated aluminum alloys. This figure takes temperature and time as parameters, that is, the time required to obtain 95% of the intensity of T6 (water cooling) at different temperatures, and is called the C curve due to its shape. The more you lean to the left of the curve, the higher the quenching sensitivity. From the figure, we can see that the order of quenching sensitivity of several alloys is 7075>2017>6061>6063.

The medium for quenching is generally water, but in order to prevent the occurrence of quenching strain or residual stress, polyethylene glycol aqueous solution or warm water is often used as the quenching medium, but the cooling rate is slower. For materials with high quenching sensitivity, although strength and ductility can also be obtained, slow cooling speed will cause a decrease in toughness. Therefore, the heat treatment specifications of aluminum alloys used in aviation aircraft stipulate that the temperature of quenching water must be below 38°C.

2.2 Press quench

Materials with low quenching sensitivity can achieve a certain strength after air cooling after hot processing. Although the extrusion temperature during extrusion processing is lower than the solution limit, the heat generated by the extrusion processing will increase the blast material temperature to the solution treatment temperature and make the precipitate solid solution. Due to the short extrusion processing time, the precipitation state of the extrusion precursor material affects the final strength very significantly. In other words, the cooling of homogenization treatment before extrusion or heating to the extrusion temperature must be fast to avoid the coarseness of the precipitates so that a short-term extrusion heating can also achieve a sufficient solid solution state. Figure 2 shows the heat treatment process for 6063 alloy extrusion processing. The 6063 alloy has low quenching sensitivity, and it can be air-cooled with a fan after extrusion. However, for 6061 alloys with high quenching sensitivity, the self-extrusion die must be water-cooled immediately after extrusion. This type

Extrusion quenching has a finer fibrous structure with grains than regular heat treatment, and the resulting supersaturated solid solution has better strength.

3. Aging treatment

3.1 Room temperature aging (natural aging)

The 2000 series or 6000 series alloys have a stable strength in 4 to 14 days, but the 7000 series alloy has been continuously aged and hardened at room temperature for several years. Therefore, the 7000 series alloy is generally not processed with T4 but is tempered with W.

On the other hand, the room temperature aging of 2000 series alloys can obtain considerable strength, and the high-temperature aging can significantly increase the desolation intensity, but the increase in tensile strength is limited. Moreover, room-temperature aging has better fatigue strength and toughness than high-temperature aging, so most users use T4 or T3 treatments for 2000 series alloys.

3.2 High-temperature aging (artificial aging)

For 6000 or 7000-series alloys, high-temperature aging is required to obtain optimal strength. Sometimes, when the 2000 series alloy is to achieve higher strength, T6 is also used.

Generally speaking, the high-temperature aging treatment for a long time at low temperatures has better mechanical properties. However, industrial 2000 series alloys often use 190°C, while 6000 series alloys use 175°C. Compared with other alloys, 7000 series alloys mostly adopt a lower high-temperature aging between 120℃ and 160℃.

3.3 Second stage of time

Before high-temperature aging, the longer the room temperature aging time, the higher the strength. At the same time, for the averaging treatment of T7, the room temperature aging time is too short, or the high-temperature aging rate is too fast, which can easily cause coarse and uneven precipitation, which will greatly reduce the strength. Therefore, although room temperature aging before high-temperature aging is better, considering economic efficiency, the industry does not prefer long-term room temperature aging instead, after a first high-temperature aging of 100°C to 120°C, and then a second high-temperature aging treatment of above 150°C is used. This is called a second-stage aging treatment.

On the other hand, by adjusting the content of the main components, Mg and Si, the 6000-type alloy can achieve excellent strength immediately after room temperature aging. Figure 4 shows the effects of Mg, Si content and room temperature preparatory aging on the intensity after high-temperature aging. When the Mg2Si formed by the excess Mg and Si content is less than 0.9 mass%, the tensile strength after high-temperature aging can be improved by preparatory room temperature aging. This is called the positive effect of room temperature aging, and the 6063 alloy is just composed of this. In contrast, the room temperature aging of 6061 alloys is negative, so the direct high-temperature aging treatment after quenching of 6061 alloys has better strength. This second-stage aging treatment is a very important technology for the aluminum alloying of automobile bodies and is becoming increasingly valued.

3.4 Heat treatment to improve corrosion resistance

Different high-temperature aging conditions can continuously change the material characteristics, so appropriate high-temperature aging conditions must be selected according to the purpose of the material. Take the commonly used 7075 alloy as an example. Although the T6 treatment has the best strength, its stress corrosion resistance (SCC) and peel corrosion resistance are very poor, so it often improves corrosion resistance with an over-aging T7 treatment. The T73 treatment and T76 treatment of 7075 alloys reduced the voltage strength by about 15% and 10%, respectively, but the stress corrosion resistance was significantly improved.

In recent years, most people have adopted the so-called RRA treatment to improve stress corrosion and fracture. This method is the A286 process developed by the United States Alcoa Company and has been formatted with T77 treatment formal specifications i and g-Si7000ature. It is currently used in civil aviation aircraft B-777. This method of processing is to perform T6 treatment first and then restore the treatment at 171°C to 260°C for a short time, and finally perform the three-stage aging treatment with the same high-temperature aging as T6. In this way, not only can T6 be obtained in strength similar to T74 to T76, but it also has the same stress corrosion resistance as T74 to T76.

Aluminum alloys have the inherent advantage of being more lightweight than other metal materials. Considering the lightweight of structural parts in the future, aluminum alloys will stand out. With the choice of appropriate heat treatment conditions, not only can the required mechanical properties be obtained, but also excellent corrosion resistance can be achieved. On the other hand, if we want to expand the application scope of aluminum alloys, in addition to the development of new alloys, research on new heat treatment technologies cannot be ignored.

Anodic Treatment

1. The surface treatment of aluminum alloy can be achieved through electrochemical reactions

A dense oxide film is generated on the surface of the aluminum alloy to improve the corrosion resistance of the aluminum alloy. This oxide layer can seal the pores on the oxide layer by hydration, and this step is called a pore sealing treatment. The aluminum oxide, after the sealing treatment, has very good corrosion resistance. If dichromic acid ions are sealed in the pore, the effect will be better. In addition, the oxide film can be colored in anode treatment and provides a variety of aluminum alloy materials. Common coloring methods include (1) the dyeing method, (2) the primary coloring method, and (3) the secondary coloring method.

2. Effects of alloy composition and structure on anodizing of aluminum alloy:

The difference in anodizing properties of aluminum alloys and pure aluminum actually reflects the huge role of alloy elements and impurity elements and also reflects the huge impact of structure and surface state. Anodizing has been widely used in the past to extrude Al-Mg-Si-based 6063 deformed aluminum alloy profiles. If the same anodization process as 6063 alloys is used on Al-Cu system 2024 alloy or Al-Zn-Mg system 7075 alloys, some difficulties will be encountered, if it is used for high-silicon die-cast aluminum alloy, the problem will be even greater. If anodizing workers are not familiar with the metallization of aluminum alloys, they will often be helpless about the defects of the anodized film caused by the aluminum alloy itself.

3. Anodized characteristics of various aluminum alloys:

Aluminum alloy anodization can have different purposes: protective anodization mainly aims to improve the corrosion resistance of aluminum matrix, decorative anodization with appearance as the main purpose, hard anodization with engineering application surface wear resistance, sometimes, it also requires the colorability of the anodized film or the brightness of the original surface. An alloy cannot be suitable for all anodized types, either anodized will not be suitable for all alloys.

More About Aluminum Machining?

6 Methods to Avoid Deformation of Parts in Aluminum Machining

4. Effect of chemical composition on anodizing:

The anodizing characteristics of each aluminum alloy system are different. This is caused by the different roles of alloy elements in anodization, and this effect is often manifested by the different chemical behaviors of their intermetallic compounds in anodization. Intermetallic compounds are generally divided into three categories: Class I intermetallic compounds do not change during anodization and are doped into the oxide film. Class II intermetallic compounds are oxidized (or dissolved) into the oxide film at a slower or similar rate than aluminum in anodization. Class III intermetallic compounds are oxidized and doped (or dissolved) into the oxide film at a faster rate than aluminum in anodization. For colorless and transparent anodized films, optical transparency and structural uniformity are the most basic requirements, so it is even more important to understand the chemical behavior of intermetallic compound phases during the anodization process.

During the anodization process of aluminum alloy, the particle of the Class I intermetallic compound itself does not change and is added to the oxide film. The second phase intermetallic compound in the film becomes the center of light absorption or light reflection, which will inevitably reduce the transparency of the film and even make the film gray. Class II and Class III particles are also related to the size of the particles. If the same particle exceeds a certain size (depending on the type of particles and anodizing conditions), it is impossible to oxidize or dissolve completely, so it belongs to Class II, if the particle is extremely small, it may belong to Class III, and the dissolution rate is greater than aluminum at this time, then there may be no second phase particle in the oxide film, which is conducive to the transparency of the film. The oxide film with the highest transparency is formed on high-purity aluminum or high-purity AlMgSi alloy, that is, there is no intermetallic compound, or the second phase has been preferentially dissolved. The silicon content and thermal processing process of the alloy are relatively important factors. Taking Al-Mg-Si alloys as an example, Fe and Si first form an AlFeSi intermetallic compound with Al, the extra Si generates Mg2, and the excess Si exists as a single substance or dissolves in an aluminum matrix. The silicon content suitable for transparent oxide films is very strict. When the concentration is high, it is dominant in the form of elemental silicon, and when the concentration is low, it is dominant in the Al(Fe, Mn)Si phase, which all makes the oxide film gray.

5. Effect of tissue structure on anodizing

As for aluminum alloy itself, in addition to chemical composition, the structure that has a greater impact on the anodizing quality is the structure. The processing process determines the structure, so the entire production process, from casting to processing and forming, must take into account the quality requirements of the final product surface.

5.1 Metallurgical changes in the process of melt casting and homogenization

5.1.1 Melting casting

Aluminum forms a dendrite structure during casting, and the size of the dendrite depends on the solidification rate. Cooling too quickly forms fine columnar crystals, and there is usually a layer of columnar crystal edge area near the surface of the ingot, and thick dendrites grow from the crystallizer wall to the inside of the ingot. The coarse dendrites of the ingot will leave stripes on the profile during extrusion. This means that the structural differences caused by different solidification rates cannot be eliminated in subsequent processing. Therefore, the casting process should fully consider the structural uniformity of the cross-section of the ingot. For this reason, hot-top casting and electromagnetic casting came into being.

5.1.2 Ingottenness

The eutectic phase particles are located between the dendrites. The dispersion of these second-phase particles is directly related to the grain size, and the fine grains produce fine particles. Separation of the solute elements during solidification of the melt cast causes the aggregation of the alloyed elements. The homogenization results in a more uniform and consistent tissue structure, resulting in consistent performance of the final product. During the homogenization process, we should distinguish between high-solid concentration elements and low-solid concentration elements. The former (such as Si, Cu, Mg, Zn) may dissolve in large quantities, reducing or eliminating segregation. The primary particles of low-solid concentration elements are mainly AlFeMnSi-type intermetallic compounds. The coarse particles between dendrites are spheroidized due to homogenization. In some cases, phase changes may occur to form secondary fine diffuse particles. As for the 6063 alloys, the homogenization treatment not only targets the dissolution of Mg2Si but also takes into account the conversion of the Fe-rich beta phase.

5.2 Metallurgical changes in the process of processing and forming

Larger primary phase particles are usually hard and brittle particles that are broken by cold or hot forming, and the broken particles are redistributed. In breaking, the thickness of the particles generally remains unchanged, while the length of the fragments is reduced to twice the thickness. From this, we can see that the significance of the structure of the cell is that the primary phase particles themselves are correspondingly small, and the result of processing and forming results in a more uniform distribution. The primary phase particles are located at the grain and grain boundaries and extend into lines. The higher the deformation rate, the closer the line is, and each line has fewer particles. During extrusion, the mosaic between the surface of the blank and the extrusion cylinder deforms the metal in a complex flow state. The surface of the extruder comes from the metal inside the ingot. At some locations (depending on the size and shape of the mold), the material that is obviously segregated will flow to the surface of the extruder, thus creating stripes after anodization. Taking extrusion as an example, many extrusion parameters are to be controlled during the extrusion process to obtain the best surface quality. These parameters include the residual pressure length, blank temperature, extrusion cylinder temperature, extrusion speed, mold design and cooling strength after extrusion.

6. Effect of surface state on anodizing

The appearance of the anodic film is closely related to the surface state before oxidation, and chemical pretreatment (especially alkali washing and chemical polishing) determines the surface state. Of course, the surface state after chemical pretreatment is essentially dependent on the microstructure of the matrix, the type, size and distribution of intermetallic compounds, as well as grain size and orientation. These are related to alloy composition and processing technology.

6.1 Alkaline corrosion

In the anodization of aluminum plates and aluminum profiles for construction, alkali corrosion is the most basic and important pretreatment method. Alkaline corrosion results in fine corrosive surfaces with matte satin, which is the result of high proportional diffuse reflection. Table 3 shows the electrochemical characteristics of intermetallic compound particles in aluminum alloys during alkali corrosion. Different intermetallic compounds, even the same compounds with different particle sizes, will have completely different electrochemical characteristics. There are two mechanisms for forming surface corrosion pits in aluminum alloys due to the presence of the second phase of the intermetallic compound: the second phase acts as a cathode (such as Al3Fe) so that the aluminum matrix around the particles is preferentially dissolved; the second phase intermetallic compound particles are anode (such as Mg2Si) relative to the aluminum matrix and are preferentially dissolved. The presence of the second phase intermetallic compound in the aluminum alloy, whether it is a cathode or anode relative to the aluminum matrix, will form a corrosion pit on the surface during alkali corrosion, thereby creating a dull, diffuse scattering surface. The former forms corrosion pits due to the local dissolution of aluminum around the second phase; the latter forms corrosion pits due to the direct dissolution of intermediate compounds. Therefore, we can expect that the bright effect of chemical or electrolytic polishing will be difficult to manifest after the anodization of multiphase aluminum alloys.

6.2 Brightening pretreatment

The purity of aluminum matrix for brightening surface treatment should reach more than 99.85%, so it is necessary to pay attention to the entire production process, from the mass of alumina raw materials, the metallurgical process of remelting aluminum ingots to all processes of processing and forming, such as casting, extrusion (or rolling), etc.

Although aluminum alloys with bright surfaces for industrial use have been developed, it cannot be ignored that during the chemical polishing process, the surface brightness still increases with the increase of aluminum purity. Figure 1 shows the relationship between the specular reflectivity and ferrosilicon content of the phosphoric acid brightening treatment of aluminum (99.98Al, 99.95Al, 99.90Al, 99.85A1 and 99.50Al) of different purities, indicating that the specular reflectivity decreases with the increase of ferrosilicon content. The purity of Al99.90Mg and Al99.85Mg is 0.05%, and the surface brightness is generally different from about 10-15 points (according to the 0-100 scale, 0 and 100 are the lowest and highest specular reflectivity, respectively). The main reason is that iron and silicon cannot be dissolved in the aluminum matrix.

The addition of copper to the alloy can improve the brightness in the phosphoric acid polishing process (compare rows 2 and 3 in Table 4). When the copper content is as low as 0.05%, it also has a positive effect on brightness. This is not due to changes in the microstructure of aluminum alloy but because of the dissolution of copper during the brightening process and redeposition on the surface cathode reaction. This positive effect does not occur in the polishing process of fluoride (ammonium hydrogen fluoride, hydrofluoric acid and nitric acid), so the presence of copper will not have a positive effect on the brightness of fluoride polishing.

Expert Aluminum Extrusion Solutions at YP-MFG

At YP-MFG, we specialize in delivering high-quality aluminum extrusion solutions tailored to meet diverse industry needs. With years of experience and advanced manufacturing capabilities, our expert team provides customized design support, precision extrusion, and meticulous finishing services to ensure every project meets strict performance and aesthetic standards. Whether for automotive, aerospace, electronics, or construction applications, YP-MFG combines innovation, efficiency, and cost-effectiveness to help clients achieve superior results and long-term reliability. Contact Us Today!