Some Readings On Brass

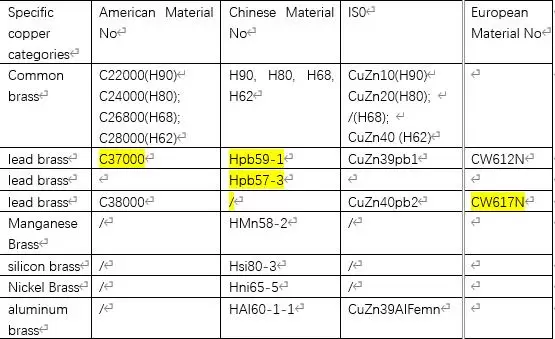

Destination: Copper-zinc alloy materials (common grades: H59, H62, H65, H68, HPb59-1 (free-cutting brass))

Characteristics: high strength, wear-resistant, water vapor corrosion-resistant

Common Uses: Architectural hardware, heat exchanger tubes, pumps, power cylinders and bushings, munitions.

H62 common brass: have good mechanical properties, good plasticity in the hot state, cold plasticity can also be, good cutting, easy brazing and welding, corrosion resistance, but easy to produce corrosion rupture. In addition the price is cheap, is the application of recidivism of a common brass varieties. Used for all kinds of deep drawing and bending manufacture of saluted parts, such as pins, rivets, washers, nuts, conduits, barometer springs, screens, radiator parts and so on.

H65 ordinary brass: performance between H68 and H62, the price is cheaper than H68, also has high strength and plasticity, can well withstand cold and hot pressure processing, corrosion rupture tendency. Used for small hardware, daily necessities, small springs, screws, rivets and mechanical parts.

H68 ordinary brass: extremely good plasticity (is the best brass) and high strength, cutting performance is good, easy to weld, the general corrosion of non-bearing stability, but easy to produce cracking. Is the most widely used in the ordinary brass a variety. Used for complex cold-drawn parts and deep-drawn parts, such as radiator shells, conduits, bellows, cartridge cases, gaskets, detonators, etc..

H70 ordinary brass: extremely good plasticity (is the best in brass) and high strength, good cutting performance, easy to weld, to general corrosion non-bearing stability, but easy to produce cracking. Used for complex cold-drawn parts and deep-drawn parts, such as radiator shells, conduits, bellows, shells, gaskets, detonators and so on.

H75 common brass: has quite good mechanical properties, process performance and corrosion resistance. Can be well in the hot and cold state pressure processing. In performance and economy between H80, H70. Used for low load corrosion resistant spring.

H80 ordinary brass: performance and H85 similar, but higher strength, plasticity is also better, in the atmosphere, freshwater and seawater has a high corrosion resistance. Used for paper mesh, thin-walled tubes, bellows and building supplies.

Recommended Products

Hot News

-

Shenzhen Yaopeng Metal Products Co., Ltd.

2023-11-21

-

Looking for Mexico Local Business Tour Guide

2023-11-21

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS