#On-demand sheet metal fabrication services

Custom Sheet Metal Fabrication Services

• Diverse Fabrication Methods

• ISO 9001, ISO14001 Certificated

• Material Versatility & Quality Assurance

YP-MFG Sheet Metal Fabrication Capabilities

We provide comprehensive sheet metal fabrication services, covering cutting, bending, stamping, punching, welding, and assembly. Our facility is equipped with advanced CNC laser cutting machine, stamping machines, bending machines, and press brakes to handle a wide range of materials including stainless steel, aluminum, carbon steel, and galvanized steel. With in-house design support, prototyping, and surface treatments such as powder coating, plating, and anodizing, we deliver high-quality custom sheet metal parts for industries like electronics, automotive, medical, and industrial equipment.

Play Now

Capabilities

Description

Material Types

Stainless Steel, Carbon Steel, Aluminum, Galvanized Steel, Copper, Brass and more.

Cutting Methods

CNC Laser Cutting, Plasma Cutting, Shearing

Forming Methods

CNC Bending, Press Brake Forming, Rolling

Joining Techniques

MIG/TIG Welding, Spot Welding, Riveting, Fastening

Surface Finishing

Powder Coating, Anodizing, Plating, Brushing, Polishing

Tolerances

±0.1 mm (depending on process and part geometry)

Production Volume

Prototyping to High-Volume Production

Industries Served

Automotive, Electronics, Medical, Industrial Equipment, Consumer Products, and more.

Sheet Metal Services Available at YP-MFG

As a custom parts manufacturer, our custom sheet metal fabrication shop specializes in producing complex and precision parts and components at any volume.

Laser Cutting and Sheet Cutting Service

Bending Service

Welding Service

Punching

Stamping

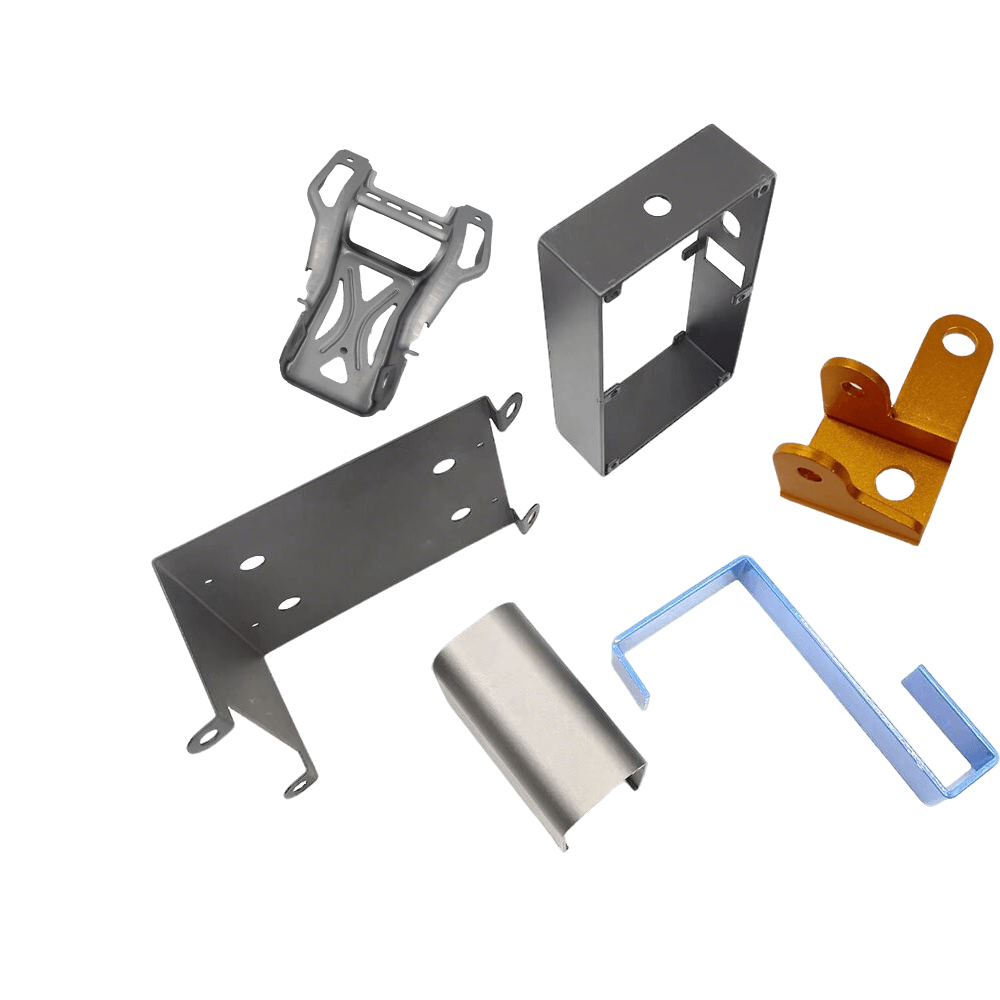

Sheet Metal Fabrication Products Showcase

Using advanced fabrication techniques such as laser cutting, CNC punching, bending, welding, and finishing, we deliver high-quality components tailored to diverse industrial needs.

YP-MFG Sheet Metal Materials

Over 300+ Material Options – high-performance materials, including metal ( aluminum, copper, stainless steel, steel, bronze, titanium) and plastics (PEEK, ABS, PC), and advanced composites.

Aluminum Advantages:

- Corrosion Resistance

- Lightweight Nature

- High Strength-to-Weight Ratio

- Recyclability

Types:

Aluminum 1100-H14

Aluminum 5052-H32

Aluminum 6061

Brass has excellent electrical, thermal, elastic and mechanical properties. It is easy to form, weld, cut and polish. It has superplasticity after heat treatment and is suitable for making electrical, thermal, elastic components and corrosion-resistant structural parts.

Types: Brass C27400, Brass C28000, Brass C36000

Copper:

- Excellent thermal and electrical conductivity

- Highly formable, making it an outstanding material for sheet metal applications.

Types:

Copper 101

Copper C110

Copper C110, H02

Stainless steel:

- Resisting corrosion,

- Strong, easy to clean, and maintains its shine.

- Good mechanical properties, and top-notch formability.

Types:

Stainless steel 301

Stainless steel 304

Stainless Steel 304 #4 brushed

Stainless Steel 304, #8 mirror polish

Stainless steel 316/316L

Stainless Steel 316, #4 brushed

Steel:

- Strong and durable, commonly used in construction and heavy industries.

- Low-cost material

- Good mechanical properties

- Excellent formability

- A wide range of surface finishes

Types:

SPCC, Galvanized Steel (SGCC / SECC), Steel 1020

Sheet Metal Fabcration Applications

YP-MFG Sheet metal fabrication capabilities support both low-volume prototypes and high-volume production.

Contact us with your application needs or drawings — we’re ready to support your project!

- Automotive - Brackets, enclosures, chassis parts, and panels

- Electronics – Housings, heat sinks, control boxes, and mounting plates

- Medical – Equipment frames, covers, instrument panels, and carts

- Telecommunications – Cabinets, server racks, and enclosures

- Industrial Machinery – Machine guards, structural frames, and housings

- Consumer Products – Kitchen appliances, furniture parts, and lighting fixtures

- Energy & Utilities – Battery enclosures, inverter housings, and electrical boxes

Sheet Metal Fabcration FAQs

We accommodate projects of all sizes, from single prototypes to large production runs. Minimum order quantities (MOQs) depend on the complexity and process but are generally flexible to suit your needs.

Typical lead times range from 3 to 25 business days depending on part complexity, quantity, and finishing requirements. We also offer expedited services for urgent orders.

In many cases, sheet metal fabrication can be more cost-effective than CNC machining for parts with simpler geometries and thinner materials. However, the best choice depends on your specific design, material, volume, and tolerance requirements.

We ensure this by:

Using high-quality raw materials

Implementing controlled forging and heat treatment processes

Performing grain refinement and inclusion control

Mechanical properties such as yield strength, tensile strength, elongation, and impact toughness can be customized to your specs. Full material and testing certifications.

Yes, we provide full assembly services including welding, fastening, and packaging to deliver complete, ready-to-use components.

Yes, we understand tight deadlines and offer rush services. Please contact us early so we can prioritize your project accordingly.

Simply send us your drawings, specifications, and quantity details via email or our inquiry form. Our team will review your requirements and provide a fast, competitive quote.

#Contact Us

Custom Sheet Metal Fabrication Parts With Easy

Upload your design files for quote pricing, free DFM analysis.

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.