# Cnc Machining for

Marine & Shipbuilding CNC Machining Services

At YPMFG, we understand the unforgiving nature of marine engineering. We don’t just machine parts, we provide manufacturing solutions designed for harsh marine environments. Our dedicated team and state-of-the-art facility are ready to work with industry leaders to provide manufacturing solutions that improve performance, safety, and longevity of critical marine applications.

Why the Marine Industry Chooses Us?

Unlike general machine shops, manufacturing for ships and offshore equipment requires a deep understanding of materials science.

Experts in Corrosion Resistance

We go beyond standard machining. We specialize in processing 316L/Duplex Stainless Steel, 5083 Marine Grade Aluminum, Aluminum Bronze, and Titanium to prevent galvanic corrosion and pitting.

Complex Surface Capabilities

Equipped with advanced 5-Axis CNC Machining Centers, we expertly handle complex hydrodynamic curves found in propellers, impellers, and fluid control valves.

Aesthetics Meets Function:

For yacht interiors and deck fittings, we offer superior finishes, including mirror polishing and Type III hard anodizing, combining visual beauty with extreme weather resistance.

Our Manufacturing Services

YP-MFG helps meet your needs more effectively, and stay competitive in your industry. Lowered manufacturing costs, increased flexibility.

CNC Machining for Marine Metal Parts

Engine & Power Components: Manifolds, flanges, heat exchanger housings, mounting brackets.

Deck & Outfitting Hardware: Custom cleats, capstan drums, heavy-duty hinges, fishing rod holders.

Plastics & Composite Machining

Critical Surface Finishing

Passivation: Essential for removing free iron from stainless steel to maximize rust resistance and prevent corrosion.

Hard Coat Anodizing (Type III): Drastically increases wear resistance and salt spray protection for aluminum parts, crucial for exposed deck components.

Mirror Polishing: High-end aesthetic finishing for luxury yacht fittings.

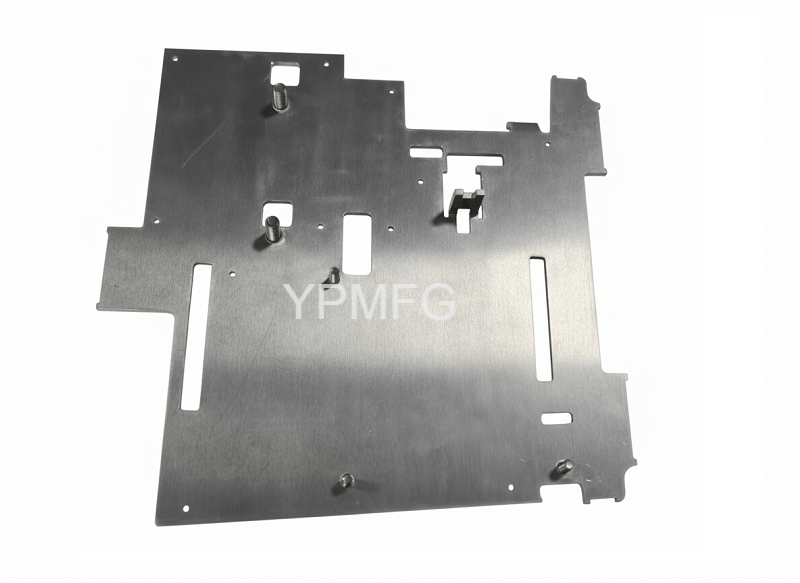

Marine & Shipbuilding Parts We Made

From high-efficiency propeller components to extreme-pressure subsea housings and specialized deck hardware, our portfolio demonstrates our mastery of maritime manufacturing challenges.We specialize in CNC machining certified corrosion-resistant materials, including 316L Stainless Steel, Aluminum Bronze, and Titanium to meet naval and offshore demands.

Specialized Marine Materials

We strictly control raw material procurement to ensure compliance with ASTM, AMS, and other international standards, eliminating the risk of early failure due to substandard materials.

| Material Category | Common Grades | Applications |

| Stainless Steel | 316L, 304, 17-4PH, Duplex 2205 | Fasteners, rigging, subsea connectors (Excellent corrosion resistance) |

| Aluminum | 5052, 5083 (Marine Grade), 6061-T6 | Hulls, structural frames, mast components, electronic enclosures |

| Copper Alloys | Aluminum Bronze, Phosphor Bronze | Propellers, pump valves, bearings (Superior seawater resistance) |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | Racing yacht parts, deep-sea equipment (High strength-to-weight ratio) |

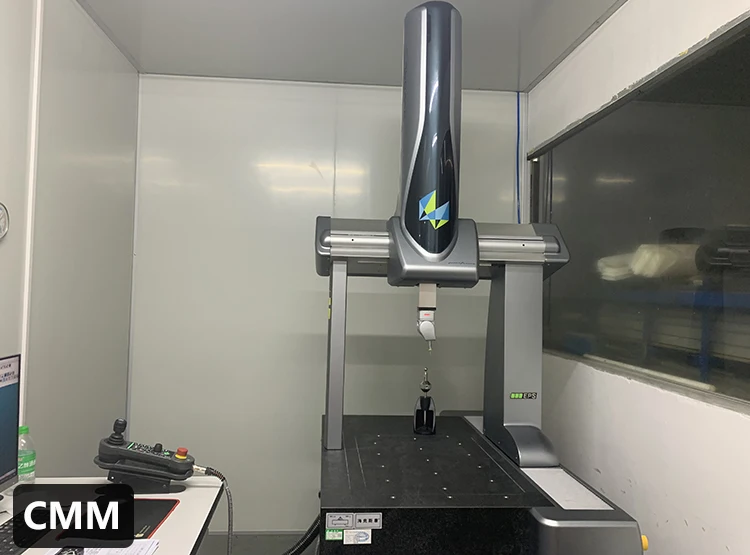

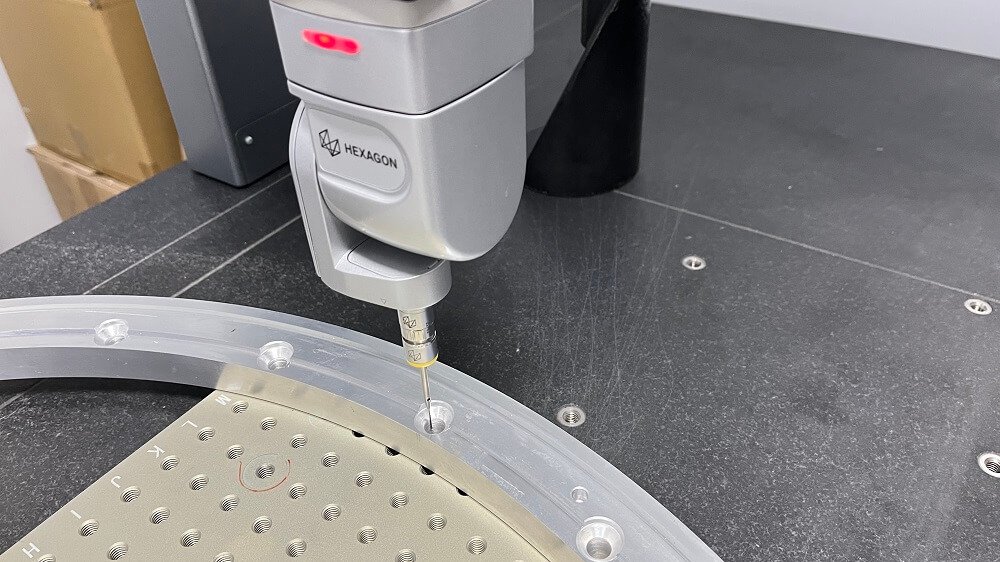

Quality Control

100% Inspection: We use CMM (Coordinate Measuring Machines) to ensure critical tolerances are held within ± 0.003mm.

Traceability: Every part comes with full Material Test Reports (MTRs) and Heat Treatment certifications.

Rapid Response: Standard lead time of 3-5 days for prototypes, 24-hour rush services available for emergency repair parts.

Frequently Asked Questions

A: Post-machining, we perform strict acid passivation processes. This removes free iron ions from the surface and restores the passive oxide layer, maximizing resistance to pitting corrosion in seawater.

A: Yes. Our Gantry CNC Machining Centers have a travel capacity, making them ideal for large engine blocks or structural hull components.

A: We can provide additional verification services, including Dye Penetrant Inspection (NDT) for cracks and surface roughness testing to ensure sealing performance under high pressure.

Absolutely. Our engineering team can provide DFM (Design for Manufacturability) feedback to improve part performance, reduce cost, and ensure machinability without compromising function.

Start Your Production Services Now!

Upload Your Files → Get Instant Quote → High-Precision Parts in Hand!