# Cnc Machining On-Demand Production for

Medical Devices Industry

- Tolerances up to +/- 0.003 mm

- Engineering Support, High Quality

- ISO 9001:2015, ISO 13485 Certified

- Fast Lead Time

Medical Devices Machined Parts At YP-MFG

At YP-MFG, we specialize in the precision machining of components for the medical device industry. With strict adherence to ISO certified, we deliver high-quality CNC machined parts that meet the demanding requirements of medical applications. Partner with YP-MFG for fast turnaround, competitive pricing, and dependable quality in every medical machined part we produce.

ISO Certificate

With our ISO9001, ISO 13485 certified production process, combined with expert machining experience and advanced CNC machines, we can ensure your medical devices parts are manufactured correctly and delivered on time every time.

High Quality Parts

YP-MFG specializes in high-precision CNC machining for medical devices. With advanced equipment, tight-tolerance capability, and strict quality control, our processes ensure consistent quality for demanding applications in healthcare and life sciences.

Customer Support

Senior designers provide design and processing suggestions based on processing drawings and scheme designs to optimize structures and reduce costs.

CNC machines

Clients To Work With

Plastic & metal materials

Tight Tolerance

Medical Devices Machined Products We Can Make

YP-MFG offers precision machining for a wide range of medical device components, with advanced CNC technology and experience in medical-grade materials, we ensure every product meets strict industry standards.

-

Handheld devices

-

Anatomical models

-

Surgical instruments

-

Medical carts

-

Diagnosis equipment

-

UV sanitation components

-

Medical delivery systems

-

Physiotherapy apparatuses

-

Care equipment

-

Tables and panels

-

Biotechnology components

-

Handheld devices

-

Replacement parts

-

Monitoring equipment components

Our Professional Capabilities for Medical Devices

We offer comprehensive manufacturing solutions for the medical device industry, including CNC machining, sheet metal fabrication, casting and forging, and more.

Medical Devices Materials & Finishes

We support CNC machining with a full spectrum of materials:

Metals: Aluminum (6061, 7075), Stainless Steel (304, 316), Titanium, Brass, Copper

Plastics: PEEK, PTFE, ABS, Nylon, Delrin, Acrylic

Finishes: Anodizing (Type II & III), electropolishing, nickel plating, chromate coating, black oxide, and custom surface treatments tailored to your specifications and industry requirements.

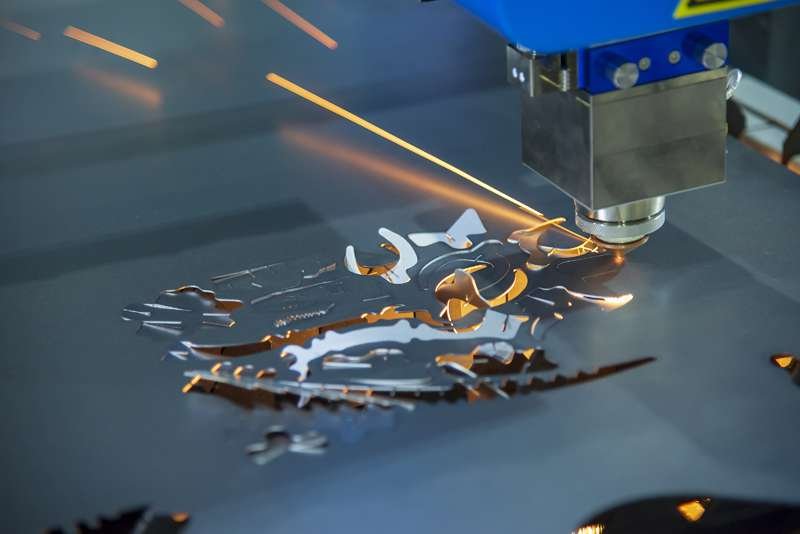

CNC Metal Machining

YP-MFG machines a variety of metals including aluminum, stainless steel, titanium, brass, and copper with tight tolerances and superior surface finishes.

CNC Plastic Machining

YP-MFG offers precision CNC machining of engineering plastics such as PEEK, ABS, PA, Nylon, and more. We produce custom plastic components with tight tolerances, smooth finishes, and excellent dimensional stability.

Medical Devices FAQs

Depending on the material and part geometry, we can achieve tolerances as tight as ±0.003 mm, ensuring high precision and repeatability.

Yes, we offer rapid prototyping services for medical components, allowing for quick validation before mass production.

Yes. We offer full traceability, including material certifications (e.g., RoHS, REACH, DFARS), inspection reports, and batch records for regulated industries like medical and pharmaceutical.

Absolutely. Our engineering team can provide DFM (Design for Manufacturability) feedback to improve part performance, reduce cost, and ensure machinability without compromising function.

#Contact Us

Custom Medical Devices Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

Email: sales@yp-mfg.com

Whatsapp: + 86 137 9493 0097

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.