# Cnc Machining On-Demand Production for

Aerospace Industry

- Tolerances up to +/- 0.003 mm

- Engineering Support, High Quality

- ISO 9001:2015 Certified

- Fast Lead Time

Aerospace Machined Parts At YP-MFG

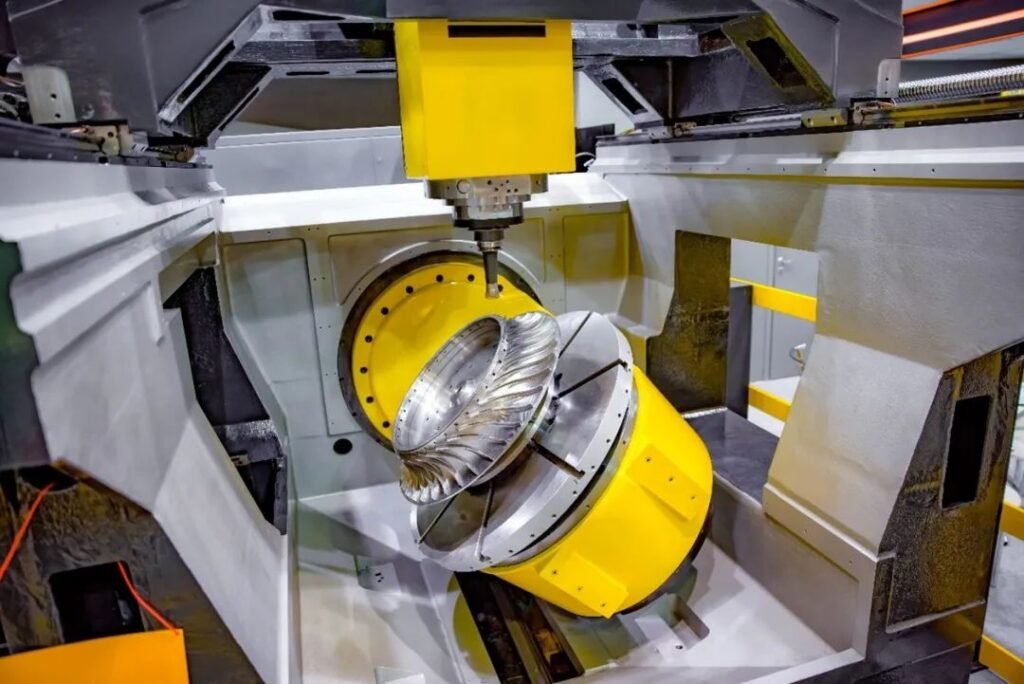

At YP-MFG, we specialize in the precision machining of complex aerospace components. With advanced multi-axis CNC equipment, aerospace-grade materials, and strict process controls, we produce high-performance parts for aircraft, satellites, drones, and other aerospace systems.

Our engineering and production teams understand the critical nature of aerospace applications and adhere to rigorous quality standards, including full dimensional inspection, material traceability, and certification. From rapid prototyping to high-volume production, YP-MFG is your trusted partner for mission-critical machined parts that meet the highest industry requirements.

Customers Served

CNC Machines

Rapid Turnaround Time

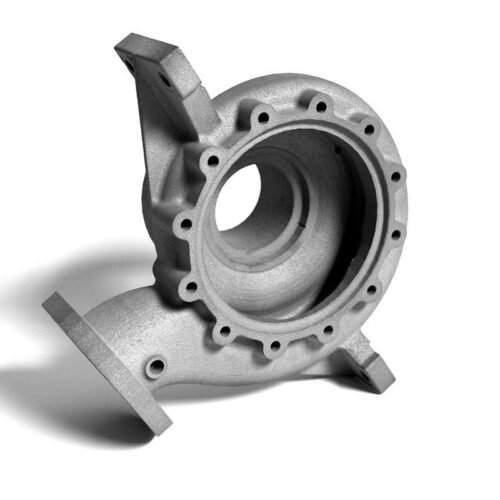

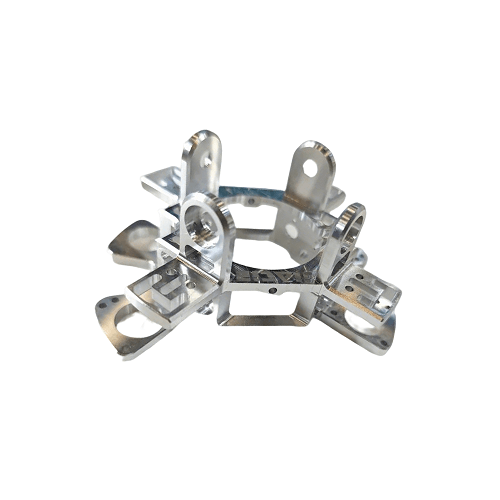

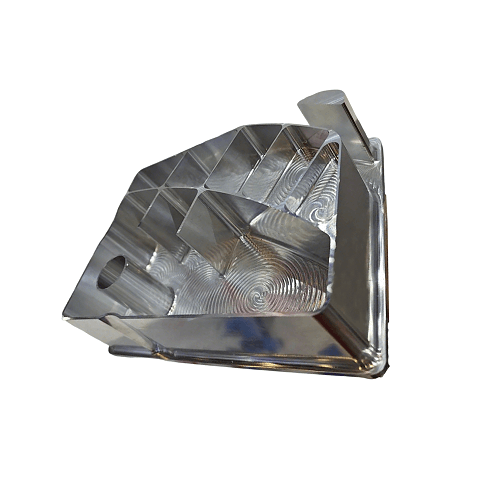

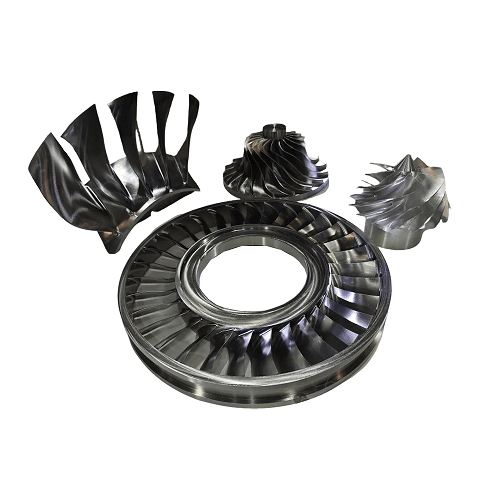

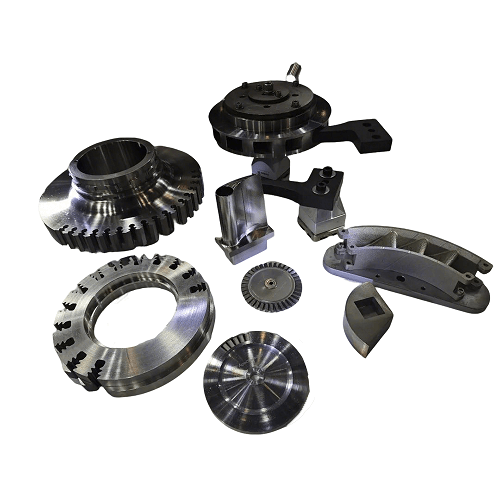

Aerospace CNC Machining Products Showcase

YP-MFG has high-precision CNC machining services for aerospace components, engineered with tight tolerances, certified materials, and full quality control.

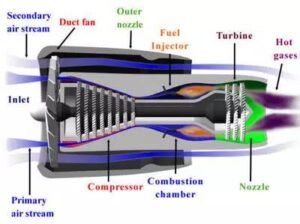

- Engines

- Housings

- Fuel Nozzles

- Turbines

- Electrical Parts

- Gears

- Impellers

- Wing Support

- Unmanned Aerial Vehicle

- Fastening Items such as Screws

- Custom Fixturing

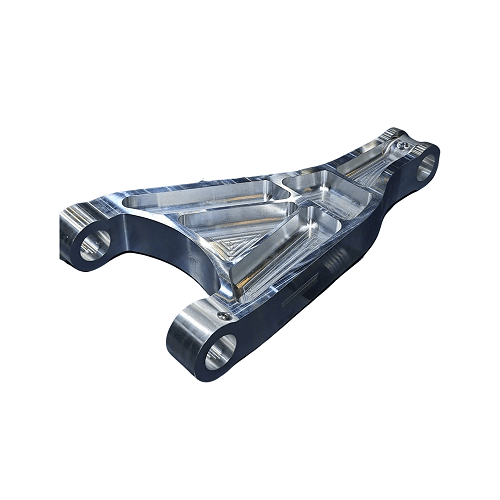

- Brackets

- Aviation Hinge

- Vacuum Pumps

- Transmission Components

- Chassis, and jigs

our services

Custom Aerospace Machining Solutions

join the success

Aerospace Machining Parts Cases

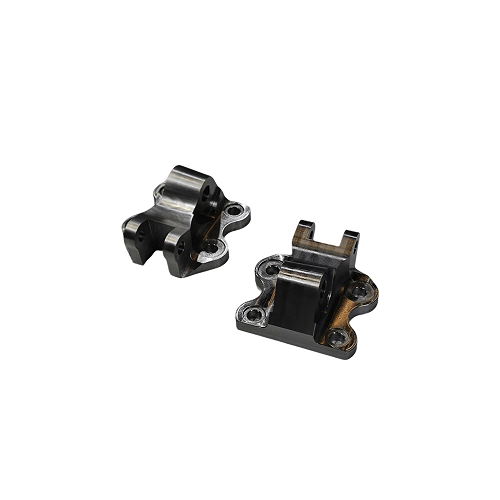

Flap Support Bracket

Material: 17-4PH Stainless Steel

Machining Time: About 50 mins

Dimension: 80*80*50mm

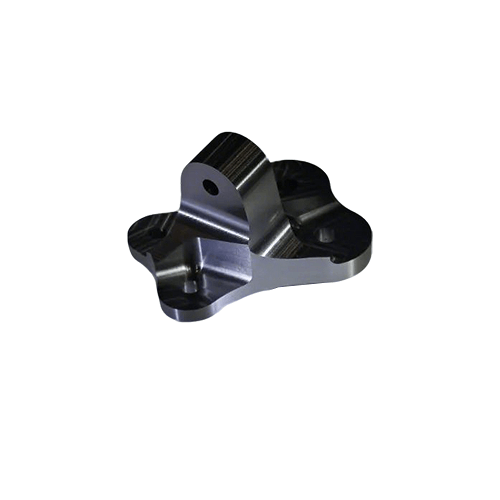

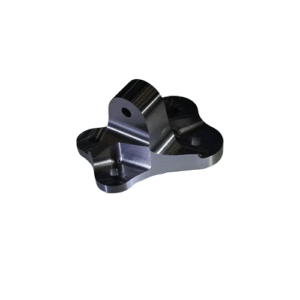

Aviation Hinge

Material: Titanium TC4

Highlights: High dynamic cycloid roughing, 5-axis simultaneous machining, good workpiece consistency.

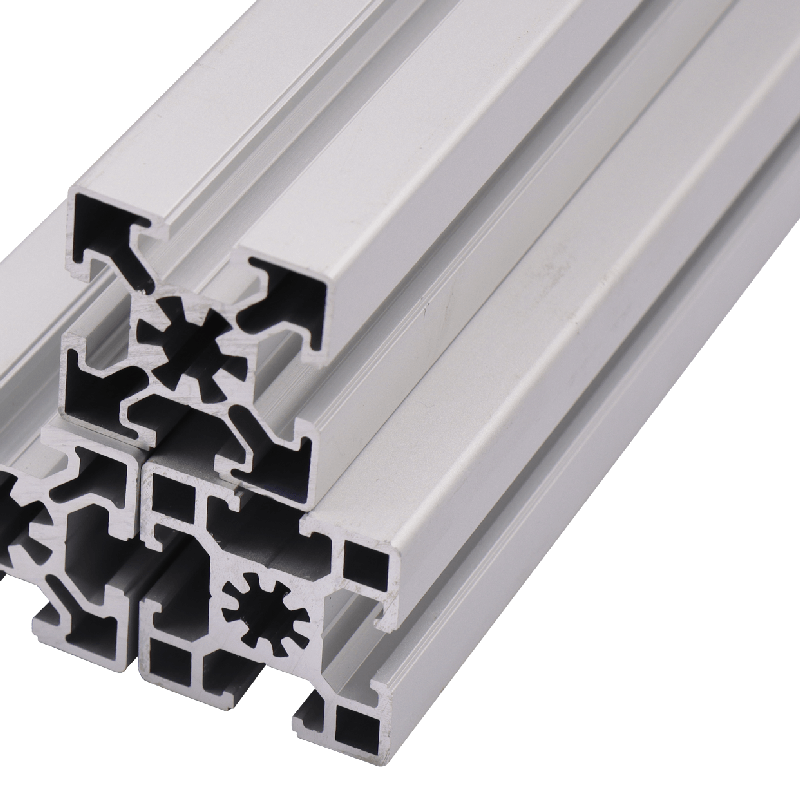

Aerospace Manufacturing Materials

Automotive manufacturing relies on a diverse range of materials, including metals like steel, aluminum, and titanium, as well as engineering plastics and composites to balance strength, weight, cost, and performance.

Compared with aluminum, magnesium, steel and other metal materials, titanium alloy has the advantages of high specific strength, good corrosion resistance, good fatigue resistance, small thermal conductivity and linear expansion coefficient, etc. It can be used for a long time below 350~450℃, and can be used at low temperatures down to -196℃.

Main applications: compressor blades, casings, engine compartments and heat shields of aircraft engines, etc.

Aluminum alloy has outstanding advantages such as high specific modulus and specific strength, good corrosion resistance, good processing performance and low cost, so it is considered to be the most important in the aerospace industry.

Main applications: engine compartment, cabin structure, load-bearing wall panels, beams, instrument installation frames, fuel tanks, etc.

Magnesium alloy is the lightest metal structural material, with the characteristics of low density, high specific strength, strong seismic resistance, and the ability to withstand large impact loads.

Main applications: aerospace engine casings, gear boxes, etc.

Ultra-high strength steel has high tensile strength and sufficient toughness, and has good weldability and formability.

Main applications: aerospace engine casings, engine nozzles, bearings and transmission gears.

The matrix materials of metal matrix composite materials include aluminum, aluminum alloy, magnesium, titanium and titanium alloy, heat-resistant alloy, cobalt alloy, etc.

Among them, composite materials based on aluminum-zirconium alloy, titanium and iron alloy are currently the main choices. For example, silicon carbide fiber reinforced titanium alloy matrix composite materials can be used to manufacture compressor blades.

Carbon fiber or alumina fiber reinforced magnesium or magnesium alloy matrix composite materials can be used to manufacture turbofan blades.

For example, nickel-chromium-aluminum-iridium fiber reinforced nickel-based alloy matrix composite materials can be used to manufacture sealing components for turbines and compressors.

Aerospace Faqs

Can I request a sample?

How fast can I get my parts?

Do you have aerospace manufacturing experience?

#Contact Us

Custom Aerospace Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.