This case study highlights the successful CNC precision machining of a custom gearbox component featuring complex hole patterns, multiple bolt circle diameters, and critical positional tolerances. The part plays an important role within a gearbox and motor transmission system, where machining accuracy directly affects assembly alignment, operational stability, and service life.

By applying a carefully planned CNC machining strategy and strict quality control, we delivered a high-precision component that met all drawing requirements and integrated seamlessly into the customer’s gearbox assembly.

1. Project Overview

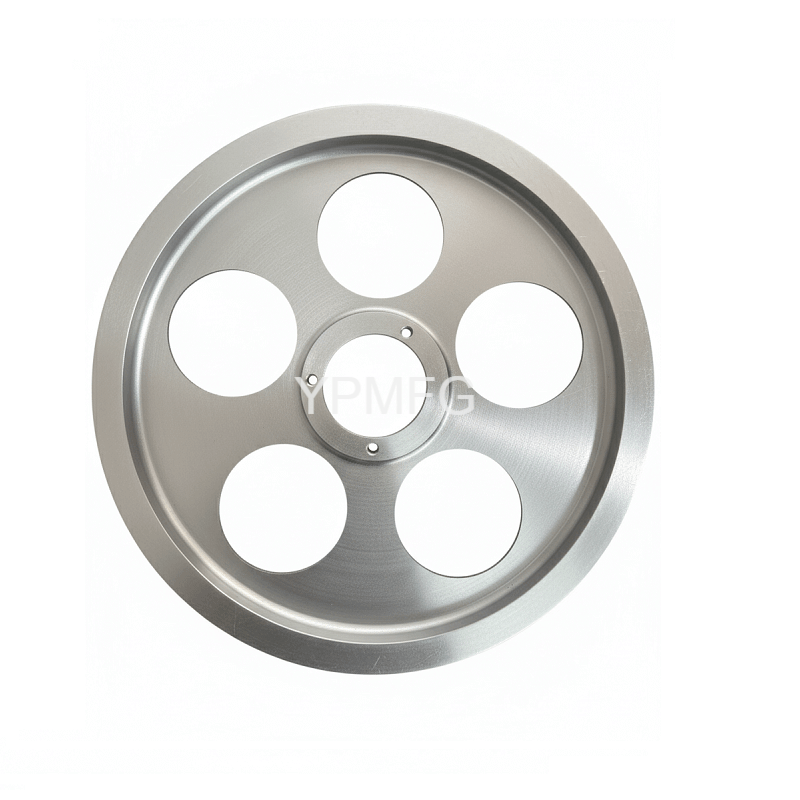

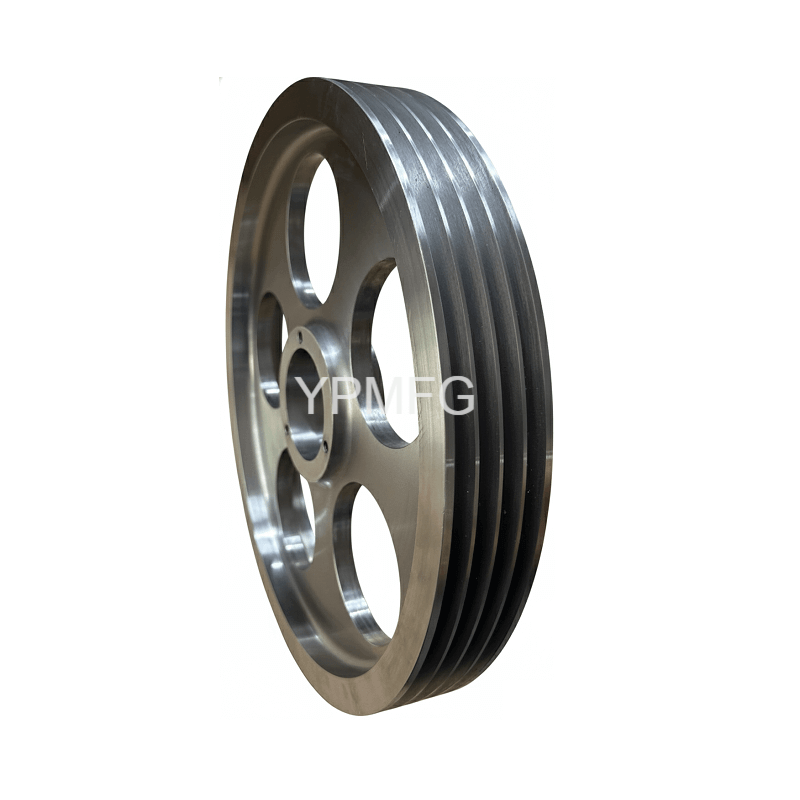

- Component Type: Gearbox / transmission system part

- Manufacturing Method: CNC precision machining

- Production Type: Custom machined part

Key Requirements:

- Accurate angular spacing of multiple hole patterns

- Consistent bolt circle diameters (BCDs)

- Reliable threaded hole quality

- High positional repeatability for assembly

The customer required a dependable machining partner capable of translating detailed engineering drawings into production-ready parts with minimal risk during assembly.

2. Project Background

The component is used within a gearbox assembly connected to a main motor. In this application, even small deviations in hole position or concentricity can lead to misalignment, uneven load distribution, or premature wear of mating components.

The customer supplied a complete technical drawing package defining:

- Multiple equally spaced holes arranged at angles such as 72° and 120°

- Different bolt circle diameters, including 8.125 BCD and 3.313 BCD

- A combination of through holes and 5/16-18 UNC threaded holes

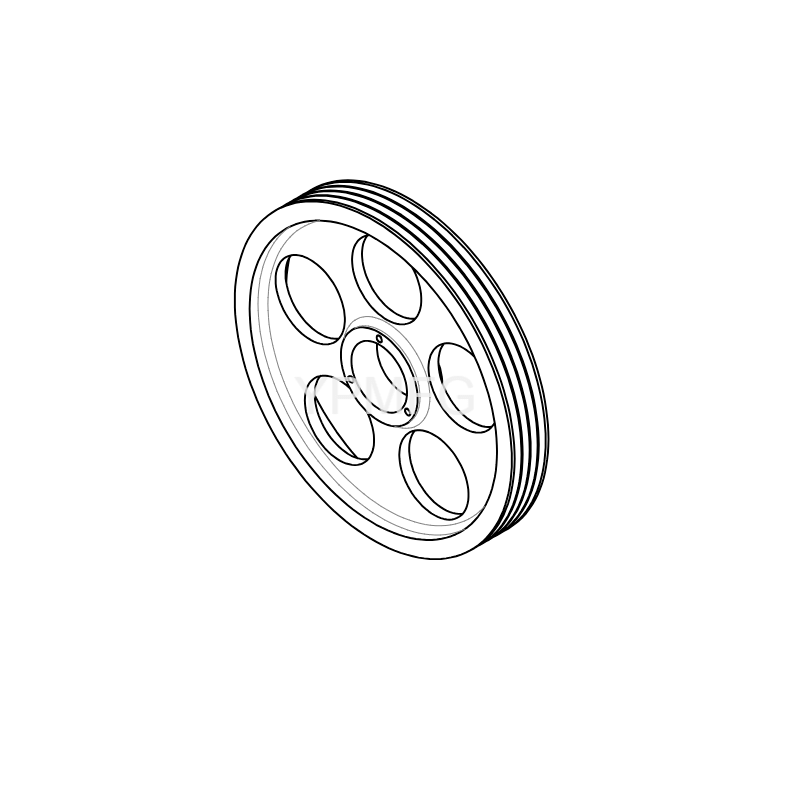

- Sectional and detailed views highlighting local geometry and feature transitions

The customer’s objective was to receive ready-to-install parts that required no secondary operations or manual fitting.

3. Part Structure Analysis

From an engineering perspective, this gearbox component presents several structural characteristics that influence machining strategy:

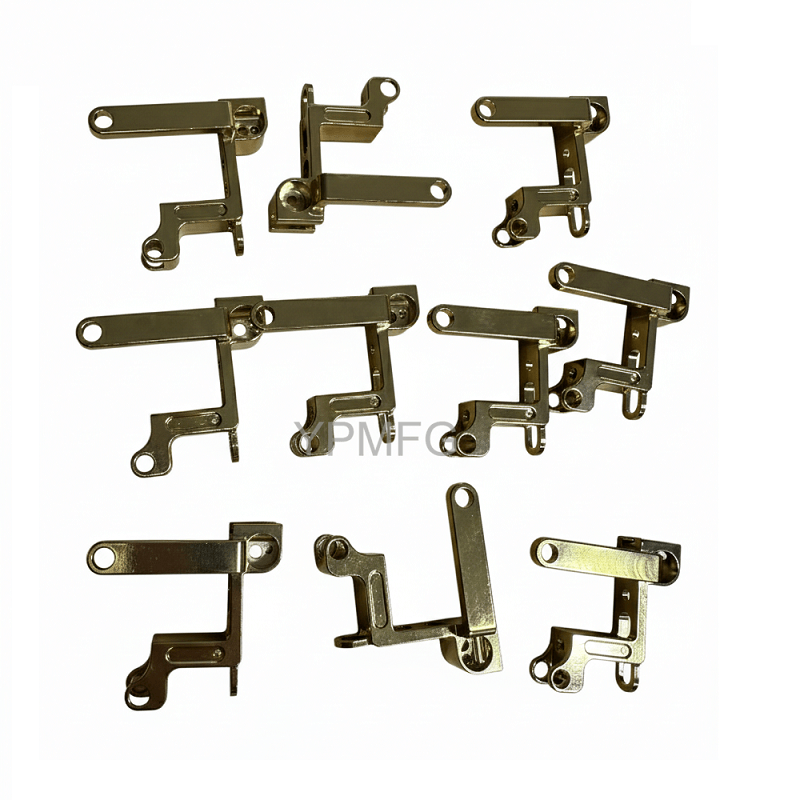

1) Multi-Hole Pattern Design

The part incorporates several groups of holes distributed evenly around the central axis. These hole patterns must maintain strict angular accuracy to ensure proper alignment with mating gearbox components.

Multiple Bolt Circle Diameters

Different BCDs are present on the same part, increasing the importance of datum consistency. Any shift in reference during machining could compromise the positional relationship between hole groups.

2) Mixed Hole Types

The design includes both through holes and threaded holes. Thread quality, depth consistency, and perpendicularity are essential to ensure secure fastening during assembly.

3) Sectioned and Detailed Features

The drawing includes sectional views and enlarged details that define localized geometry. These features require controlled tool engagement and stable cutting conditions to achieve the specified dimensions.

Overall, the part’s structure demands precision machining, careful process planning, and reliable execution.

4. Machining Challenges

- Maintaining Angular and Positional Accuracy

Equally spaced holes must align precisely with mating components. Any cumulative error can result in assembly difficulties or functional issues. - Controlling Relationships Between Multiple BCDs

The presence of more than one bolt circle increases the risk of tolerance stack-up if the datum strategy is not well defined. - Thread Integrity and Consistency

Threaded holes must meet functional requirements for fastening strength without damaging mating fasteners. - Dimensional Stability Across Detailed Features

Sectioned areas and local features require accurate toolpath transitions to prevent dimensional variation.

5. CNC Machining Solution

1) Process Planning

A CNC machining approach was selected to achieve the required accuracy and repeatability. The machining plan emphasized:

- A unified datum system based on the central axis and primary mounting surface

- Minimizing the number of setups to reduce cumulative error

- Sequencing operations to maintain structural stability throughout machining

2) Machining Operations

- Hole Machining

- Through holes produced using CNC drilling followed by precision milling or reaming as needed

- Threaded holes machined using CNC rigid tapping to ensure uniform thread depth and pitch

- Contour and Feature Machining

- CNC milling used for profiles and sectional features

- Optimized toolpaths applied to detailed areas to maintain dimensional accuracy and surface quality

3) Equipment and Tooling

- High-precision CNC machining centers suitable for tight-tolerance work

- Solid carbide drills and end mills for stable cutting performance

- Dedicated tapping tools and rigid tapping cycles for UNC threads

This machining strategy ensured consistent results across all critical features.

6. Quality Control and Inspection

Quality assurance was integrated throughout the machining process:

- First-article inspection conducted to confirm all critical dimensions

- Verification of:

- Hole positions and angular spacing

- Bolt circle diameters

- Thread depth and quality

- In-process checks used to maintain consistency during production

This systematic approach minimized variation and ensured compliance with customer drawings.

7. Delivery and Results

The finished gearbox components met all specified requirements and were delivered ready for assembly. Key outcomes included:

- Accurate and repeatable hole positioning

- Smooth assembly with mating components

- Reliable threaded features with consistent fastening performance

- Reduced assembly time and lower risk of installation issues

For the customer, this translated into improved gearbox assembly efficiency and greater confidence in long-term system reliability.

8. Conclusion

This project demonstrates our capabilities in gearbox component CNC machining, complex hole-pattern machining, and the production of high-quality custom machined parts. By combining engineering insight with precision machining processes, we help customers reduce manufacturing risk and achieve dependable results in demanding mechanical applications.