When arranging procurement using machining drawings, one occasionally receives absurdly high quotes. Despite the part’s simple geometry which could be modeled in 3D CAD and drafted in 2D within minutes—machining companies respond with statements like “This drawing is unworkable” or “We could make it if cost is no concern.” Today, we explore this issue through an engineer’s firsthand experience.

01. What Kind of Machining Drawings Drive Up Costs?

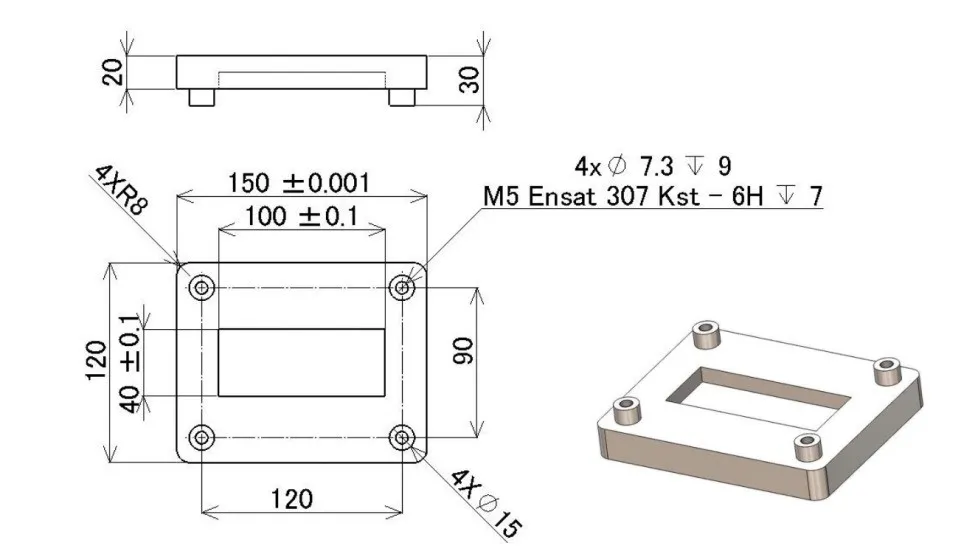

The part drawing below is one I used for procurement when I was a novice designer. Unsurprisingly, it was rejected by multiple machining companies. Even those willing to take the job quoted exorbitant prices. Where exactly did the problem lie?

02. Reasons for High Costs

① Material Forming Dimensions

When the part’s “outline dimensions” differ significantly from the “material dimensions,” the machining area increases, leading to longer processing time = higher machining costs.

② Non-standard Specifications

• Uncommon screw hole sizes in machining require purchasing new tools, increasing processing costs.

• Heat treatment processes: Quenching, tempering, annealing, normalizing, etc.

③ Right Angle Inside Groove

• Groove machining requires tools like end mills, which resemble drills. Therefore, corners must be rounded to match the end mill’s diameter.

• Creating sharp corners necessitates methods like EDM or wire cutting, increasing processing costs.

④ Pillar-Shaped Features Standing on a Flat Surface

• Since machining involves cutting operations, creating a stud requires extensive removal of material around its periphery, increasing processing time = higher processing costs.

• Milling machines excel at linear machining (during manual operation), making it difficult to process cylindrical studs. This necessitates CNC lathes, increasing follow-up time for tasks like creating CAM data and raising costs.

⑤ Other Considerations

• When parts feature radii on outer peripheries, CNC lathes become necessary, increasing machining costs.

• Excessively tight tolerances require process modifications and multiple lathes, driving up machining costs.

03. How to Control Machining Costs?

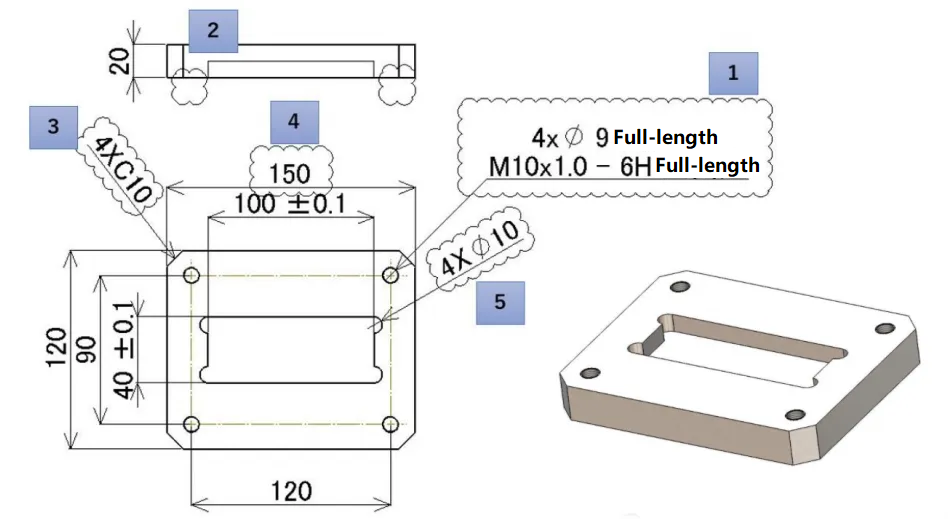

The following illustrates a machining drawing with controlled costs. What are the key points for reducing machining costs?

① Standardized Specifications

• Use standard, commonly available screw hole specifications and dimensions. Having readily available tools reduces machining costs.

② Flat-faced Bosses

Eliminate machining for bosses by using standard cylindrical parts. Although purchasing and assembling cylindrical parts is required, overall costs decrease.

③ Converting Rounds to Chamfers

Changing rounds to chamfers allows straight-line machining on milling machines, reducing processing costs.

④ Tolerance Relaxation

Relaxing tolerances simplifies machining processes, shortens processing time, and reduces manufacturing costs.

⑤ Internal Shape of Grooves

Adding circular “allowances” at sharp corners enables milling machine processing.