Threads represent a crucial mechanical connection method with extensive applications in mechanical manufacturing. The precision of thread surfaces and machining efficiency significantly impact product quality and production productivity. Thread milling serves as a common machining technique capable of achieving high-precision and high-efficiency processing of thread surfaces. This article will introduce the fundamental principles, machining processes, and common methods of thread milling, along with the advantages, disadvantages, and applicable ranges of different approaches.

I. Fundamental Principles of Thread Milling

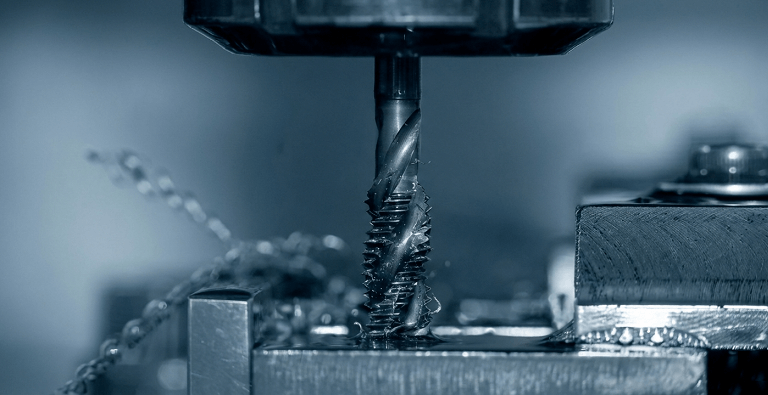

Thread milling involves cutting the workpiece material with a milling tool to form a threaded surface matching the tool’s pitch. The cutting process resembles conventional milling, primarily involving the generation of cutting forces, cutting heat, and chip formation. During thread milling, the feed rate and spindle speed of the tool must be appropriately selected based on the workpiece material and cutting conditions to ensure machining quality and efficiency.

II. Thread Milling Process Flow

The thread milling process flow includes workpiece clamping, cutting parameter setting, cutting process control, and machining inspection. When clamping the workpiece, ensure it is stable and securely fixed, aligned with the machine tool coordinate axes. Setting cutting parameters requires reasonable selection based on workpiece material, cutting tool, and cutting conditions, including feed rate, spindle speed, and cutting depth. Controlling the cutting process is crucial for ensuring machining accuracy and efficiency. This involves properly regulating the tool’s feed rate and rotational speed to prevent vibration and impact during cutting. Post-processing inspection entails conducting pr

ecision checks and surface quality assessments on the workpiece to verify that the machining results meet specifications.

III. Common Thread Milling Methods

1. Single-Tooth Milling Method:

This is one of the simplest thread milling techniques. During cutting, only one tooth contacts the workpiece, resulting in a low feed rate. Concentrated cutting forces on a single tooth can cause vibration and tool damage. However, the small cutting area enables high machining accuracy, making it suitable for threads requiring high precision.

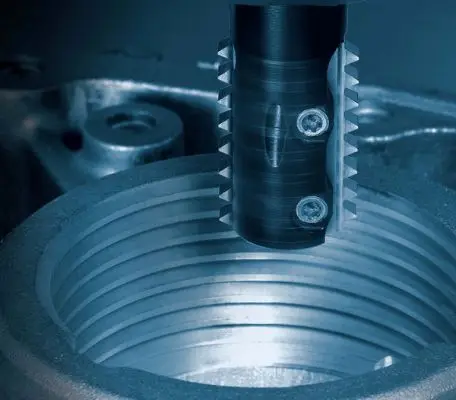

2. Multi-tooth Continuous Milling Method:

This is a commonly used thread milling technique. During cutting, multiple teeth engage the workpiece simultaneously, allowing for higher feed rates. Cutting forces are distributed across multiple teeth, reducing vibration and impact while improving efficiency. However, the larger cutting area results in relatively lower machining accuracy. It is suitable for threaded components requiring high production efficiency.

3. Chamfering Tool Continuous Milling Method:

This method employs a chamfering tool during cutting. Characterized by both cutting edges and chamfering edges, the chamfering tool simultaneously performs thread cutting and chamfering. It is suitable for workpieces requiring chamfers on threaded surfaces, reducing machining steps and labor hours.

IV. Advantages and Disadvantages of Different Machining Methods

The primary advantage of single-tooth milling is its high machining accuracy, making it suitable for threaded workpieces with stringent precision requirements. Its disadvantages include low machining efficiency and susceptibility to vibration and tool damage. The main advantage of multi-tooth continuous milling is its high machining efficiency, making it suitable for threaded workpieces requiring high production rates. Its disadvantages include relatively lower machining accuracy and a larger cutting area. The primary advantage of continuous chamfer milling is simultaneous thread and chamfer processing, reducing machining steps and labor hours. Its disadvantage is the higher cost of chamfer cutters and limited applicability.

V. Advantages of Thread Milling

Compared to traditional thread processing methods, thread milling offers the following advantages:

③ High processing efficiency: Thread milling typically employs high-speed milling machines, enabling rapid processing speeds that significantly reduce machining time.

② High machining accuracy: Thread milling completes multiple machining operations in a single process, minimizing repeat positioning errors and enhancing machining precision.

③ Superior Surface Finish: During thread milling, smaller milling cutters generate lower cutting forces, resulting in better surface quality.

④ High flexibility: Thread milling can produce various thread types as required and is applicable to machining multiple materials.

VI. Common Problems in Thread Milling

The following problems frequently occur during thread milling:

1. Poor Quality

Some parts exhibit substandard machining quality after processing due to hardness failing to meet specifications or excessive tool wear during machining.

2. Significant Deviation

Large machining deviations occur due to various factors, primarily caused by taper variations. To prevent such issues in actual production, process parameters must be thoroughly adjusted.

3. Short Tool Life

During thread machining, cutting tools are susceptible to friction, wear, and cutting forces from the workpiece material, resulting in relatively short service life. Enhancing tool material hardness and reinforcing intermediate machining processes is necessary.

4. Unreasonable Process Control

Improper process control may cause persistent deformation of the workpiece after machining, leading to dimensional inaccuracies in the finished product.

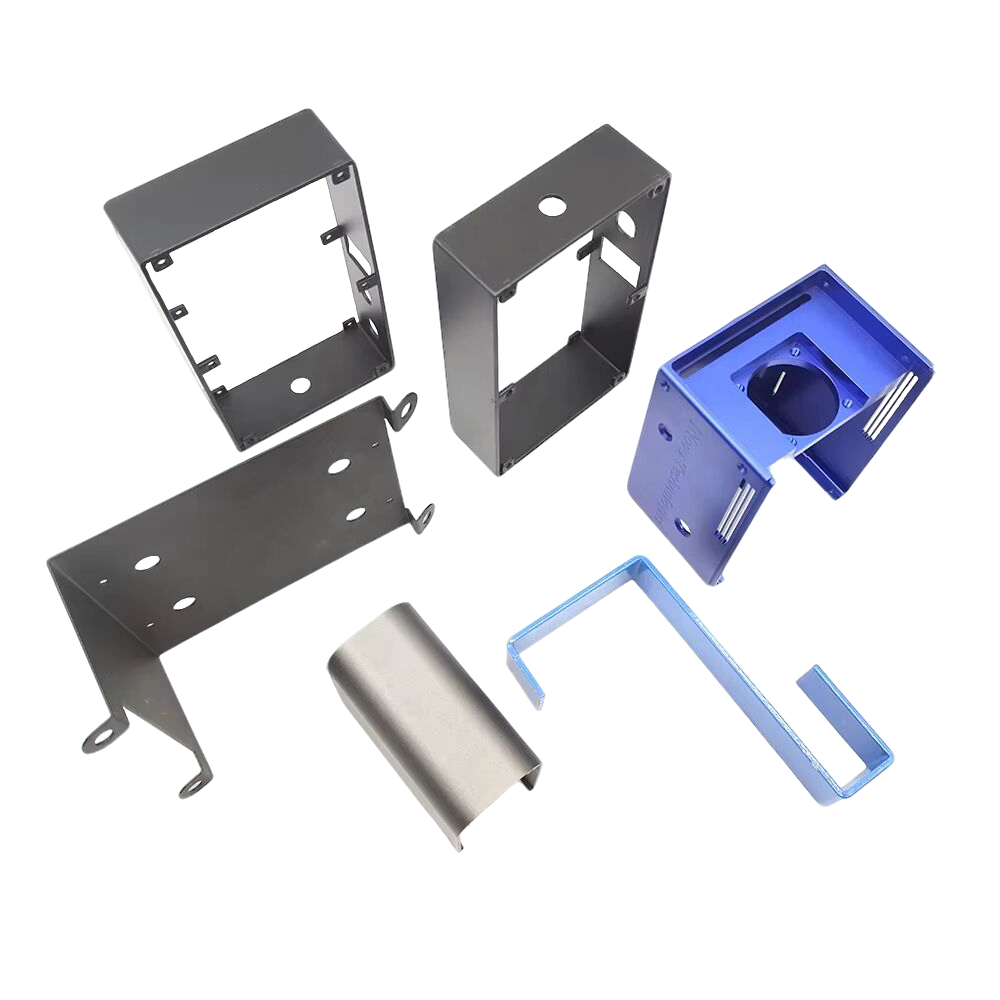

VII. Application Fields of Thread Milling

Thread milling is typically employed in processes requiring precision threads, including aerospace, automotive, marine, machinery manufacturing, and mold manufacturing industries. In recent years, with the rapid development of manufacturing and continuous technological advancements, thread milling has gradually expanded into more fields.

Significant machining deviations, primarily caused by taper variations, necessitate thorough adjustment of process parameters to prevent such issues during actual production.

VIII. Conclusion

Thread milling is a widely used machining method capable of achieving high precision and efficiency in thread surface processing. This paper outlines the fundamental principles, processing workflow, and common methods of thread milling, comparing the advantages, disadvantages, and applicability of various approaches. Selecting the appropriate thread milling method based on specific workpiece requirements and processing conditions is crucial for ensuring machining quality and enhancing production efficiency. Practical applications necessitate comprehensive consideration of factors such as machining accuracy, processing efficiency, and tooling costs to determine the most suitable processing method.