Aluminum Alloys

Aluminum alloys are alloys of aluminum with other elements such as copper, magnesium, zinc, silicon, etc. Aluminum alloys have properties such as light weight, high strength, good electrical conductivity and excellent corrosion resistance. Due to these properties, aluminum alloys are widely used in a variety of fields such as aerospace, automotive manufacturing, construction, electronics and packaging materials.

Table of Contents

Classification of Aluminum Alloys

Aluminum alloys are usually classified into two main categories according to their composition and production process:

Cast Aluminum Alloys: Aluminum alloys suitable for the casting process, commonly used for manufacturing complex-shaped parts.

Deformed aluminum alloys: Aluminum alloys suitable for forming by mechanical processes (e.g., calendering, extrusion).

Classified according to whether they can be enhanced by heat treatment:

Heat Treatable Aluminum Alloys: These alloys can be enhanced by solution treatment, quenching and aging. Common series include 2xxx (aluminum-copper alloys), 6xxx (aluminum-magnesium-silicon alloys), 7xxx (aluminum-zinc alloys), and others. These alloys are typically used in applications requiring high strength, such as aerospace and transportation.

Non-Heat Treatable Aluminum Alloys: The strength of these alloys is primarily enhanced by work hardening or by the addition of alloying elements such as manganese and magnesium. They include the 1xxx (pure aluminum), 3xxx (aluminum-manganese alloys), and 5xxx (aluminum-magnesium alloys) series. These materials are commonly used in packaging, construction and marine applications.

1XXX Series Aluminum Alloys

The 1xxx series of aluminum alloys, also known as the Pure Aluminum Series, is primarily characterized by a very high aluminum content, usually above 99%. These alloys have a number of specific physical and chemical properties due to their purity, making them very useful in specific applications.

Areas of application

Electrical conductors: Pure aluminum has good electrical conductivity and is widely used in the manufacture of power lines and cables.

Food and chemical packaging: Due to its excellent corrosion resistance, it is commonly used for cans and other packaging containers.

Heat exchangers and radiators: good thermal conductivity makes them suitable for use in heat sinks and cooling devices.

Decorative panels: Used for decorative panels and reflective mirrors due to their natural luster and ease of processing.

Conditions of use

1xxx series aluminum alloys are typically used in environments where exceptionally high strength is not required but good electrical and thermal conductivity or corrosion resistance is desired.

Common grades and alloy compositions

1050: Contains approximately 99.5% aluminum and is well suited for chemical and food processing equipment.

1100: The most common commercially pure grade of aluminum, containing approximately 99.0% aluminum, widely used in conductive and heat exchange equipment.

1199: Contains up to 99.99% aluminum and is primarily used for electrical applications with excellent conductivity.

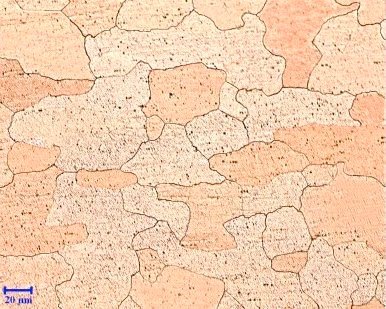

Microstructure

The microstructure of the 1xxx series of aluminum alloys consists mainly of pure aluminum crystals, which are usually larger in grain size and have less internal stress. Due to the near absence of alloying elements, there are no significant second or strengthening phases.

Mechanical Properties Range

Tensile Strength: approx. 90-130 MPa, depending on specific grade and work-hardened condition.

Ductility: 30-40%.

Common Failure Factors

Creep: At higher temperatures, pure aluminum is prone to the phenomenon of creep, resulting in a loss of performance.

Fatigue: Under repeated loading and unloading, even minor loads can lead to fatigue cracking.

Corrosion resistance issues: Although pure aluminum has good corrosion resistance on its own, it may still corrode in certain specific environments (e.g., highly saline or acidic environments).

2XXX Series Aluminum Alloys

The 2xxx series of aluminum alloys, often referred to as aluminum-copper alloys, uses copper as the primary alloying element. This alloy series is known for its high strength and good mechanical properties and is particularly suitable for the aerospace industry.

Areas of application

Aerospace industry: aircraft structural parts, fuselage frames, wing components, etc.

Military: components for military aircraft and armored vehicles.

Sports equipment: high-performance bicycles and baseball bats.

High-performance automotive components: some structural parts for racing cars, for example.

Conditions of Use

These alloys are typically used in applications requiring high strength, good fatigue resistance and moderate corrosion resistance. Although their corrosion resistance is not as good as other aluminum alloys, it can be improved by coatings and special treatments.

Common grades and alloy compositions

2024: Aluminum-copper-magnesium with a small amount of manganese, one of the most widely used 2xxx series alloys.

2014: Aluminum-copper-silicon-magnesium alloy for high-temperature applications.

2219: Aluminum-copper-vanadium, excellent high-temperature strength and welding properties.

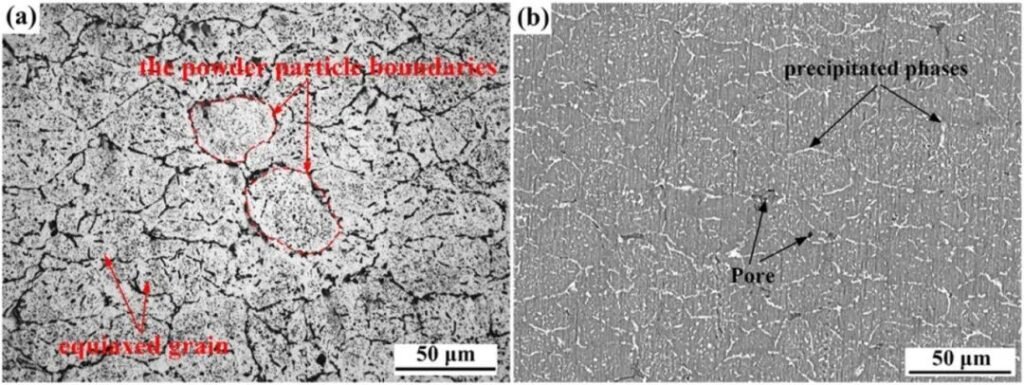

Microstructure

Matrix phase: consists mainly of aluminum with small amounts of copper and other alloying elements.

Strengthened phases: Mainly copper-aluminum compounds (e.g., Al2Cu) these second-phase particles are formed by aging treatments, resulting in significant strength enhancement.

Solid Solution Strengthening: Copper in aluminum alloys exists mainly in solid solution in the aluminum lattice. Solid solution strengthening occurs when copper atoms are dissolved in the aluminum matrix and these copper atoms take the place of some of the aluminum atoms, thereby slightly disturbing the atomic arrangement of the crystal. This minor lattice distortion makes it more difficult for dislocations to move, thereby increasing the yield and tensile strength of the material.

Precipitation Strengthening: The most important strengthening mechanism in the 2xxx series of alloys is achieved by the formation of precipitated phases, which are formed during aging treatments. The main precipitated phase is Al2Cu (known as the theta phase), an intermetallic compound that is very hard and brittle on a microscopic scale and effectively hinders the movement of dislocations.

Ageing process: The alloy is first heated to a certain temperature to solidify the alloying elements fully, then rapidly cooled (quenched), after which it is subjected to an ageing process (heated for some time at a lower temperature). This process results in the gradual precipitation of copper from the supersaturated solid solution to form the fine theta phase.

Distribution: In the early stages, the precipitates are usually dispersed in the matrix in a very fine form (known as the GP zone or θ’‘ phase), which grows and transforms into the more stable θ’’ and θ” phases as the aging time increases.

Grain Refinement: Although the strengthening of 2xxx series alloys relies primarily on solid solution and precipitation strengthening, grain refinement can also increase the strength of the alloy to some extent. Deformation during machining and subsequent annealing can be used to control grain size. Smaller grains are more effective in impeding the movement of dislocations, thus improving the yield strength and fatigue resistance of the material.

Secondary phase particles: In addition to the main theta-phase precipitation, 2xxx series alloys may contain other types of secondary phase particles such as Al2CuMg (S-phase). These particles further enhance the properties of the alloys, especially in terms of improving resistance to fatigue crack extension.

Range of Mechanical Properties

Tensile Strength: Typically between 300 and 500 MPa, higher in some heat-treated states.

Yield strength: approximately 280 to 400 MPa.

Ductility: 3 to 18%.

Common Failure Factors

Stress Corrosion Cracking (SCC): Aluminum alloys of the 2xxx series are particularly sensitive to stress corrosion, especially in certain environments, such as chlorinated environments.

Fatigue Rupture: Fatigue rupture may occur under cyclic stress, especially in aerospace applications.

Creep: Some alloys may exhibit creep during extended service in high temperature environments.

3XXX Series Aluminum Alloys

The 3xxx series of aluminum alloys, also known as the Aluminum-Manganese series, are non-heat-treatable aluminum alloys that are strengthened by the addition of manganese. This alloy series is used in a wide variety of applications due to its good corrosion resistance, workability and moderate strength.

Areas of application

Construction industry: used for roof covering materials, side panels, and other building decorations.

Chemical and food processing equipment: Due to its excellent corrosion resistance, it is commonly used in the manufacture of chemical processing equipment and food containers.

Heat exchangers: Good thermal conductivity makes it suitable for air conditioning systems, automobile radiators and condensers.

Kitchenware: such as cooking utensils and baking pans.

Conditions of Use

3xxx series alloys are typically used in environments requiring good corrosion resistance and moderate strength. They are suitable for mild to moderate chemical and oxidizing environments and can withstand wet and variable climatic conditions.

Common grades and alloy compositions

3003: The most commonly used 3xxx series aluminum alloy, containing approximately 1.2% manganese.

3004: Contains higher manganese content and magnesium than 3003 for enhanced strength and is commonly used in can making.

3105: Contains slightly increased manganese and magnesium content and is used to make building materials and vehicle components.

Microstructure

Matrix phase: the main body is aluminum, with trace amounts of manganese and magnesium to enhance its properties through solid solution strengthening.

Strengthening phase: Unlike the 2xxx and 7xxx series, the 3xxx series does not rely on a pronounced precipitation phase for strength. Manganese is present mainly in the form of solid solution strengthening and grain refinement to improve the strength and corrosion resistance of the alloy.

Solid Solution Strengthening: In the 3xxx series of alloys, manganese acts primarily through a solid solution strengthening mechanism. Manganese atoms dissolve in the aluminum lattice, slightly perturbing the arrangement of the aluminum atoms. This perturbation, although small, is sufficient to impede the movement of dislocations, thereby enhancing the mechanical strength of the material.

Grain refinement: The addition of manganese also contributes to grain refinement. Grain refinement is achieved by controlling grain growth during solid-state deformation and subsequent heat treatment of aluminum alloys. Finer grains can more effectively impede the movement of dislocations, increasing the yield strength and fatigue resistance of the alloy. Grain refinement is achieved by controlling the cold working and annealing conditions of the alloy.

Second Phase: Although 3xxx series aluminum alloys do not rely on a complex precipitation strengthening process, the presence of manganese allows the formation of tiny second-phase particles, which are usually Al(Mn, Fe)Si phases. These second-phase particles are usually uniformly distributed in the aluminum matrix and help to prevent dislocation movement and provide additional strengthening. These particles are formed primarily during the melting and casting of the alloy and are further refined and uniformly distributed during subsequent heat treatment and processing.

Dislocation Structure: Since 3xxx series aluminum alloys typically undergo some degree of cold working, their dislocation structure is more complex. Cold working increases the density of dislocations within the material, thereby increasing its strength. However, this also reduces the ductility of the material and annealing is often required to restore ductility.

Mechanical Properties Range

Tensile Strength: typically between 145 and 290 MPa.

Yield strength: approximately 90 to 200 MPa.

Ductility: 10 to 25%.

Common Failure Factors

Corrosion: Although the 3xxx series has good corrosion resistance, prolonged exposure to extreme or more corrosive chemical environments may still result in corrosion.

Fatigue: Fatigue failure may be experienced under repeated stresses, especially where there is a concentration of stress.

Stress Corrosion Cracking (SCC): In certain environments, although uncommon, it is possible for 3xxx series to experience stress corrosion cracking.

4XXX Series Aluminum Alloys

The 4xxx series of aluminum alloys is primarily a series with silicon as the primary alloying element. This alloy series is particularly suitable for welding materials and casting bodies. The addition of silicon significantly lowers the melting point of aluminum, enhances fluidity, and also improves wear resistance.

Areas of application

Welding materials: used as welding rods and wires for the welding process of aluminum alloys.

Castings: Used in the manufacture of automotive components, machine parts and other cast products requiring high wear resistance.

Heat sink materials: Used in the electronics industry to make heat sinks and radiators.

Service Conditions

These alloys are typically used in environments where good heat and wear resistance is required, and are often used as casting materials that require good flowability and a low coefficient of thermal expansion.

Common grades and alloy compositions

4043: Silicon content of about 5%, one of the most commonly used welding alloys.

4032: Silicon content up to 12%, often used to make high-performance pistons and other mechanical components.

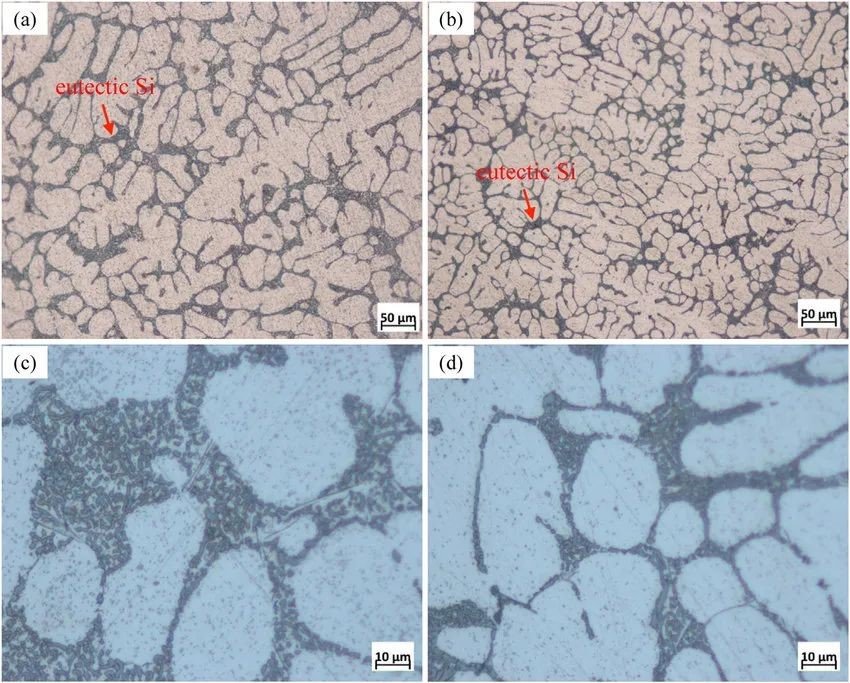

Microstructure

Matrix Phase: Aluminum alloy matrix containing a percentage of silicon.

Reinforcement phase: Silicon particles, usually in a dispersed form. These silicon particles provide some reinforcement and increase the hardness and wear resistance of the material.

Range of Mechanical Properties

Tensile Strength: approximately 100 to 350 MPa, depending on the specific alloy composition and heat-treated condition.

Yield strength: approx. 50 to 250 MPa.

Ductility: Elongation generally ranges from 5% to 25%, depending on the silicon content and heat-treated condition. Alloys with a high silicon content (e.g. 4032) have a low ductility, usually below 5%, while alloys with a low silicon content (e.g. 4043) have a better ductility, which can reach 20% or more.

Common Failure Factors

Thermal Cracking: Thermal cracking can occur during casting and welding processes due to the presence of silicon, which alters the thermal properties of the alloy.

Wear: Although silicon improves wear resistance, the alloy may still experience wear at high loads.

Corrosion: Aluminum-silicon alloys may be more susceptible to corrosion than other aluminum alloy families in certain environments, such as those containing salt water.

5XXX Series Aluminum Alloys

The 5xxx series of aluminum alloys, with magnesium as the main alloying element, are widely regarded as alloys with excellent corrosion resistance, high strength and good welding properties. These properties make 5xxx series alloys particularly suitable for use in marine environments and applications requiring high corrosion resistance.

Areas of application

Marine applications: ship structures, offshore platforms, and other equipment requiring saltwater corrosion resistance.

Transportation: car bodies, railroad cars, truck cars and trailers.

Construction: roof coverings, facade cladding and window frames.

Pressure Vessels: Used in the manufacture of pressure vessels and tanks that are required to be free of weld defects.

Conditions of Use

These alloys are typically used in environments requiring good corrosion resistance, medium to high strength and excellent weldability, especially in marine and humid climates.

Common grades and alloy compositions

5052: Contains about 2.5% magnesium and is widely used in the manufacture of ship and vehicle components.

5083: Contains 4.0% to 4.9% magnesium and is one of the strongest non-heat treatable aluminum alloys, commonly used in marine and other high-strength applications.

5754: Contains about 3% magnesium, has good weldability and is commonly used in the automotive industry.

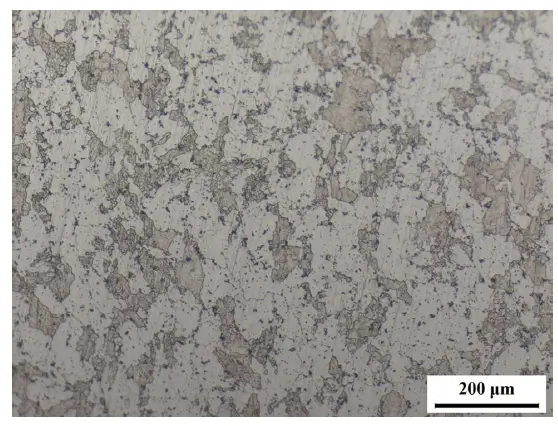

Microstructure

Matrix phase: the main body is aluminum, followed by magnesium. Solid solution strengthening is provided by the solid solution of magnesium in aluminum.

Reinforcement phase: Unlike the 2xxx or 7xxx series, the 5xxx series does not rely on a visible precipitated phase to provide reinforcement. Strengthening comes primarily from solid solution strengthening of magnesium and grain refinement.

Range of Mechanical Properties

Tensile Strength: approximately 100 to 350 MPa, depending on the specific grade and heat-treated condition of the alloy.

Yield strength: approximately 50 to 250 MPa.

Ductility: elongation typically ranges from 12% to 25%.

Common Failure Factors

Stress Corrosion Cracking (SCC): Despite the excellent corrosion resistance of the 5xxx series, stress corrosion cracking can occur in certain environments, particularly high temperatures and high stress environments.

Fatigue: Fatigue can be a problem in cyclically loaded applications such as vehicle bodies and structural components.

Corrosion: While corrosion resistance is generally very good, localized corrosion may result in extreme corrosive environments or due to improper control of alloying elements such as iron and silicon.

6XXX Series Aluminum Alloys

Series 6xxx aluminum alloys are a widely used family of aluminum alloys with magnesium and silicon as the primary alloying elements. Alloys in this series have good mechanical properties, excellent corrosion resistance and excellent extrudability, making them a popular choice for construction and industrial applications.

Areas of application

Construction industry: for building structural components, door and window frames, curtain wall systems, etc.

Automotive industry: used for car body structural parts, radiators, car frames, etc.

Aerospace: Not as commonly used as the 7xxx or 2xxx series, but used in some non-structural applications.

Industrial applications: various types of machine parts, electronic equipment housings and transportation rails.

Conditions of Use

These alloys are typically used in environments where moderate strength and high corrosion resistance are required, as well as good machinability and weldability.

Common grades and alloy compositions

6061: Contains approximately 1.0% magnesium and 0.6% silicon. It is one of the most versatile 6xxx series alloys and is widely used in structural applications.

6063: Containing about 0.45%-0.9% magnesium and 0.2%-0.6% silicon, it is widely used in building profiles and window frames, and has good surface treatment properties.

6082: Contains about 0.6%-1.2% magnesium and 0.7%-1.3% silicon. It contains slightly more magnesium and silicon than 6061 and is often used in applications requiring higher strength.

Microstructure

Matrix Phase (Aluminum Matrix): The matrix of the 6xxx series of alloys is primarily aluminum, in which magnesium and silicon are used as the primary alloying elements to enhance material properties through solid solution strengthening mechanisms. The solid solution process is usually carried out at elevated temperatures so that the magnesium and silicon are completely dissolved in the aluminum to form a homogeneous solid solution.

Strengthening Mechanisms

Solid Solution Strengthening: The dissolution of magnesium and silicon atoms in the aluminum lattice increases the distortion energy of the crystal structure, which prevents the movement of dislocations, thereby increasing the yield and tensile strength of the material.

Precipitation Strengthening: The primary strengthening mechanism of the 6xxx series of alloys is through the formation of Mg2Si precipitated phases. These precipitated phases are formed during the aging process of the alloy and greatly improve the mechanical properties of the alloy.

The aging process consists of rapid cooling after the dissolution treatment to form a supersaturated solid solution, followed by aging at medium temperatures to precipitate the supersaturated magnesium and silicon to form fine Mg2Si precipitates, usually in a very fine form, distributed in the aluminum matrix. These fine precipitates are uniformly distributed in the aluminum matrix and effectively impede the movement of dislocations.

Grain size: By controlling the cooling rate and heat treatment parameters of the alloy, the size and morphology of the grains can be optimized, thus further improving the mechanical properties and fatigue resistance of the material.

Range of Mechanical Properties

Tensile Strength: Approximately 240 to 320 MPa, depending on the specific alloy and heat-treated condition.

Yield strength: approximately 140 to 290 MPa.

Ductility: elongation generally ranges from 8% to 16%.

Common Failure Factors

Stress Corrosion Cracking (SCC): Under specific stress and corrosive environments, 6xxx series alloys may experience stress corrosion cracking.

Fatigue: In cyclic loading applications, 6xxx series alloys may experience fatigue problems, especially if not properly heat-treated or designed.

Corrosion: Despite good corrosion resistance, corrosion problems may occur in extreme or more corrosive environments such as marine salt spray environments.

Range of Mechanical Properties

Tensile Strength: Approximately 240 to 320 MPa, depending on the specific alloy and heat-treated condition.

Yield strength: approximately 140 to 290 MPa.

Ductility: elongation generally ranges from 8% to 16%.

Common Failure Factors

Stress Corrosion Cracking (SCC): Under specific stress and corrosive environments, 6xxx series alloys may experience stress corrosion cracking.

Fatigue: In cyclic loading applications, 6xxx series alloys may experience fatigue problems, especially if not properly heat-treated or designed.

Corrosion: Despite good corrosion resistance, corrosion problems may occur in extreme or more corrosive environments such as marine salt spray environments.

7XXX Series Aluminum Alloys

Series 7xxx aluminum alloys are a family of high-strength aluminum alloys consisting primarily of zinc as the primary alloying element, and often also containing magnesium and copper, giving these alloys excellent mechanical properties and good fatigue resistance. These properties make the 7xxx series of aluminum alloys particularly popular in the aerospace and military sectors.

Areas of application

Aerospace: for structural parts of airplanes, helicopter components, building blocks for rockets and spacecraft.

Military: Manufacture of armor plates and other structural components for military vehicles.

High-performance sports equipment: such as bicycle frames, rock climbing equipment and golf club heads.

Industrial applications: high-performance molds and machine parts.

Conditions of Use

These alloys are typically used in environments requiring extremely high strength, good fatigue resistance and moderate corrosion resistance.

Common grades and alloy compositions

7075: Containing about 5.6% zinc, 2.5% magnesium and 1.6% copper, it is the best-known alloy in the 7xxx series and is widely used for its excellent all-round properties.

7068: Considered the strongest commercial aluminum alloy, containing approximately 8.4% zinc, 2.85% magnesium, and 1.2% copper, it has higher strength and better wear resistance.

7050: Contains about 6.2% zinc, 2.3% magnesium and 2.3% copper, used in aerospace applications and has excellent resistance to stress corrosion cracking.

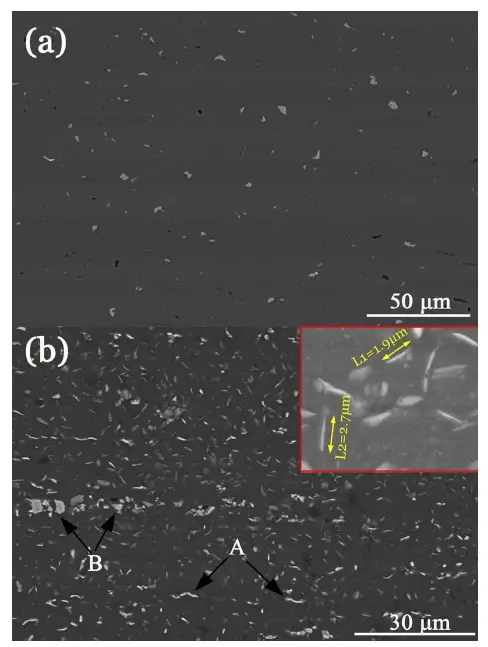

Microstructure

Matrix phase (aluminum matrix): the main structure of the alloy in which the alloying elements of zinc, magnesium and copper are dissolved in the aluminum lattice through a solid solution strengthening mechanism. Solid solution strengthening increases the lattice distortion and thus the strength of the alloy.

Strengthening Phases: The primary strengthening mechanism of the 7xxx series alloys is through precipitation strengthening, particularly precipitates containing zinc and magnesium. The most important strengthening phases include:

MgZn2 (ζ-phase): This is the main precipitate formed during the aging process. It is very fine and uniformly distributed in the aluminum matrix, effectively hindering the movement of dislocations and substantially enhancing the strength of the alloy.

Other minor precipitates, such as the sigma phase (Al2CuMg) and the η phase (MgZn2), also contribute to the properties of the alloy.

Formation of precipitated phases

Age-hardening: Involves solution treatment (heating to high temperatures to bring the alloying elements to complete solid solution, followed by rapid cooling to form a supersaturated solid solution) and aging treatment (prolonged holding time at lower temperatures to induce precipitation of elements in the supersaturated solid solution to form tiny precipitated phases).

Supersaturated solid solution: After rapid cooling, zinc and magnesium form a supersaturated state in the aluminum lattice, which is a prerequisite for the formation of precipitated phases.

Microscopic precipitated phases: During aging, the precipitated microscopic MgZn2 phases are distributed in the aluminum matrix, and these precipitates greatly increase the yield and tensile strength of the alloy.

Range of mechanical properties

Tensile strength: generally between 500 and 700 MPa.

Yield strength: about 430 to 630 MPa.

Ductility: elongation is usually between 5% and 11%.

Common Failure Factors

Stress Corrosion Cracking (SCC): Alloys of the 7xxx series are particularly sensitive to stress corrosion cracking, especially in certain corrosive environments.

Fatigue: Despite good fatigue resistance, fatigue crack generation and extension are still failure factors at high cyclic loads.

Aluminum Alloy—Summary

This article offered an in-depth look at aluminum alloys, composition, microstructure, mechanical properties and industrial applications.

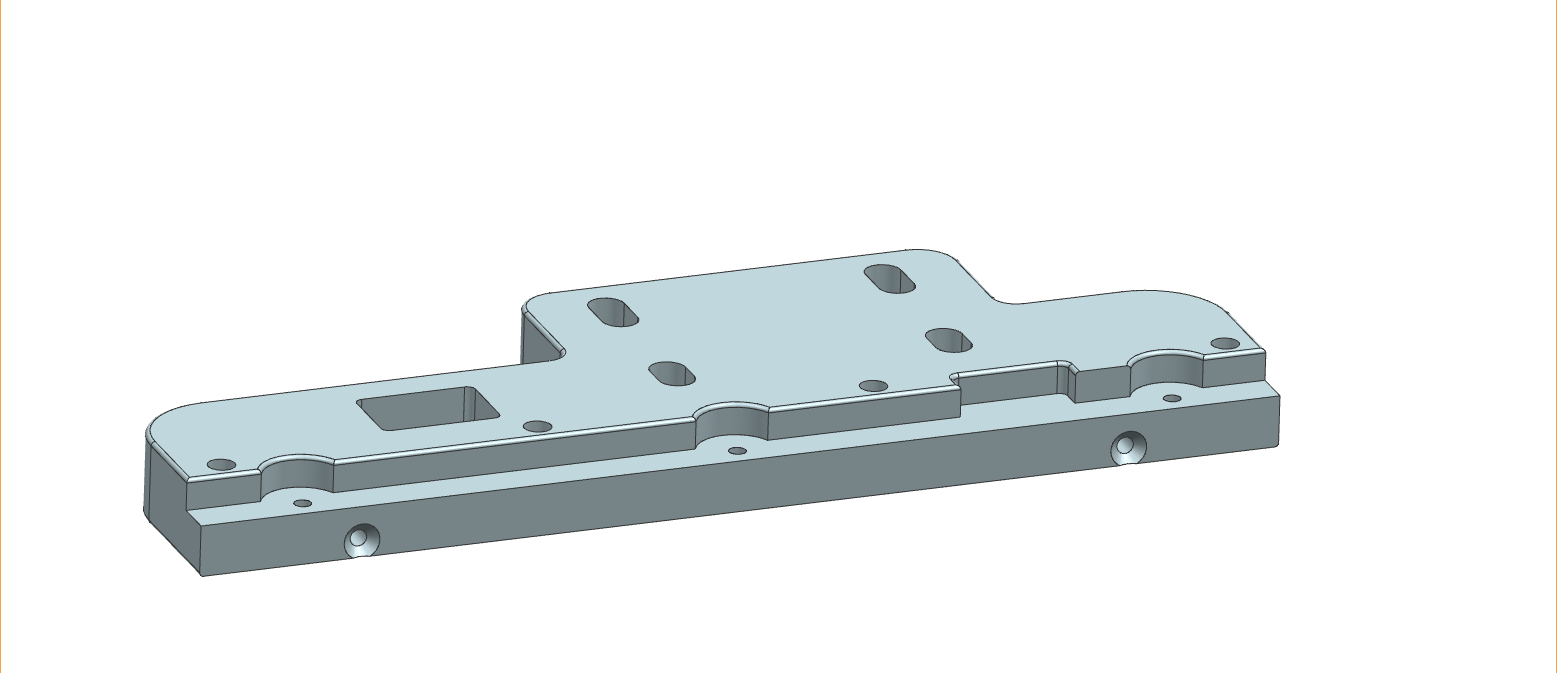

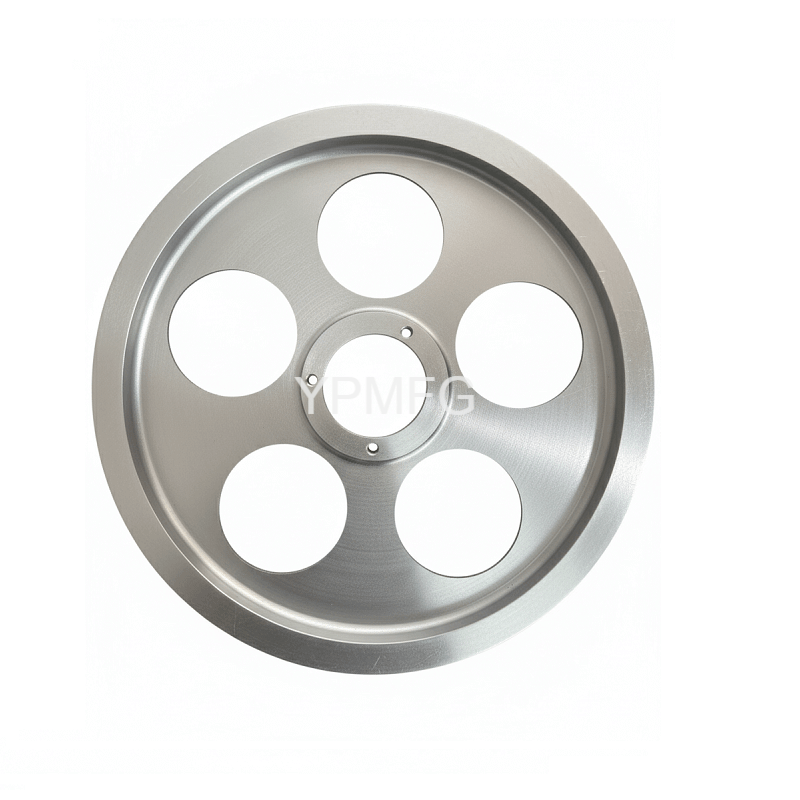

At YP-MFG, we offer a wide range of aluminum alloys, from the 1000 series up to the 7000 series. You can get an instant quote for custom parts made from these and many other alloy materials directly in the YPMFG today! Just upload your CAD to get your instant quote.