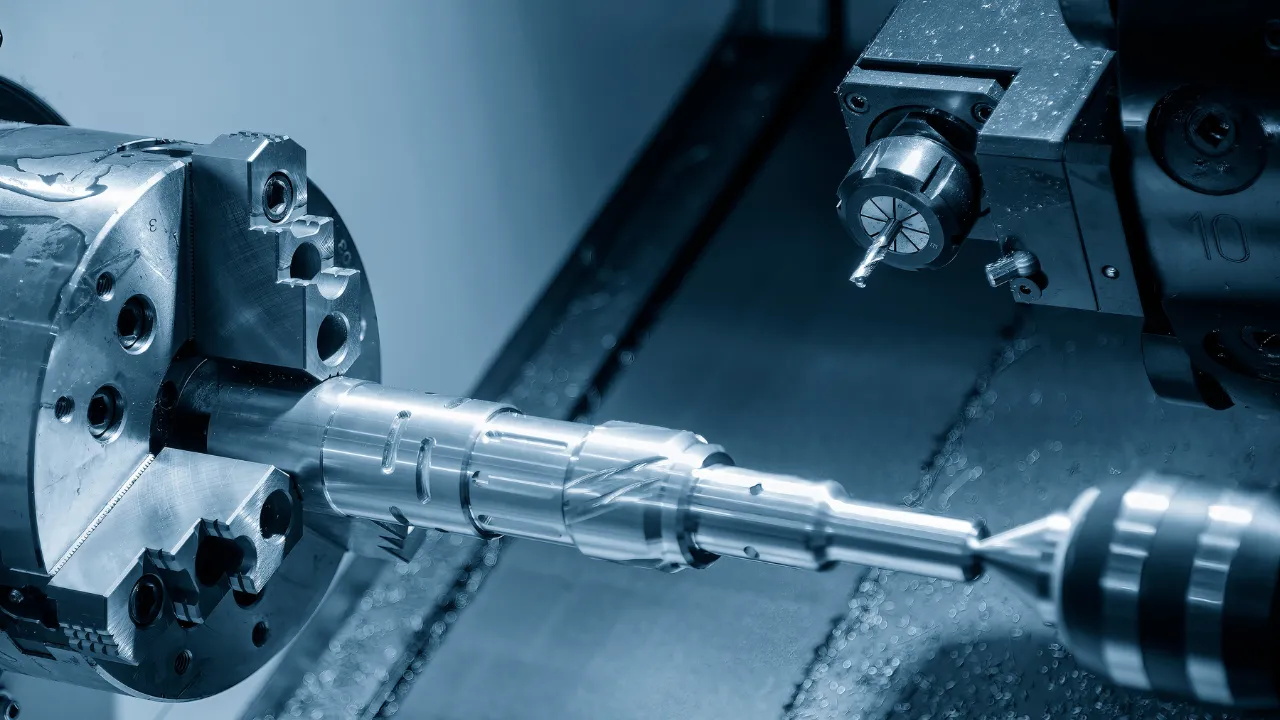

In the field of modern industrial manufacturing, titanium alloys have become the “favorite” of many high-end fields such as aerospace, medical equipment, and the automotive industry due to their high strength, low density, good corrosion resistance, and excellent biocompatibility. However, this material with excellent performance is difficult to process, the tool wears quickly, the quality is difficult to guarantee, and the cost remains high, which makes the processing and manufacturing personnel a headache. What is the reason for the difficulty in processing titanium alloys? Today, let’s find and uncover the “culprit” behind the titanium alloy processing difficulties – “heat”, and share ways to deal with it.

Table of Contents

1. Titanium is difficult to process in the face of temperature

How “heat” makes titanium alloy processing difficult. From the perspective of cutting force, the cutting force of titanium alloy processing is only slightly higher than that of steel of the same hardness, which seems to make people mistakenly believe that its processing difficulty is not too high. However, the actual situation is that the physical phenomena in the titanium alloy processing process are much more complicated than those in the processing of steel, and “heat” plays a key “disruptive” role.

Titanium alloy has a significant feature – extremely low thermal conductivity. The thermal conductivity of most titanium alloys is only 1/7 of steel and 1/16 of aluminum. This is like putting a thick “warm coat” on the cutting area. The heat generated during the cutting process cannot be quickly transferred to the workpiece or taken away by the chips and can only be accumulated in the cutting area in large quantities. As the heat continues to accumulate, the temperature of the cutting area will soar to more than 1000℃. At such a high temperature, the cutting edge of the tool is like encountering a “high-temperature furnace”, which quickly wears and cracks and also generates built-up edge. The rapidly worn blade will generate more heat in the cutting area, forming a vicious cycle and greatly shortening the service life of the tool.

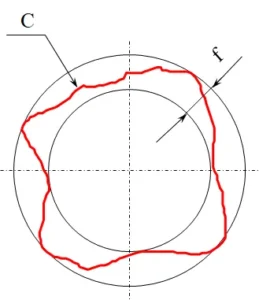

Not only that, the high temperature generated during the cutting process can also cause “fatal damage” to titanium alloy parts. It will destroy the surface integrity of the parts, resulting in a decrease in the geometric accuracy of the parts and work hardening, which will seriously reduce the fatigue strength of the parts. In addition, the elasticity of titanium alloys also “helps but does not help” during the cutting process. The elastic deformation of the workpiece is an important cause of vibration. The cutting pressure will cause the “elastic” workpiece to rebound after leaving the tool, making the friction between the tool and the workpiece greater than the cutting action. Friction generates heat, which undoubtedly aggravates the problem of poor thermal conductivity of titanium alloys. This problem is infinitely magnified when processing thin-walled or annular parts that are easy to deform. When the tool pushes away the workpiece material, the local deformation of the thin wall exceeds the elastic range and produces plastic deformation, and the material strength and hardness of the cutting point are significantly increased. At this time, if the original cutting speed is still used, the tool will wear sharply. It is almost impossible to process titanium alloy thin-walled parts to the expected dimensional accuracy.

2. Optimize the process for titanium alloy materials

Technological know-how to overcome the difficulties in titanium alloy processing Faced with the many difficulties in titanium alloy processing, researchers and engineers have summarized a series of effective technological know-how through continuous research and practice.

In terms of tool selection, the use of blades with positive angle geometry is the key. This blade can effectively reduce cutting force, cutting heat and deformation of the workpiece, laying a good foundation for the processing process. During the cutting process, it is very important to maintain a constant feed so as to avoid hardening of the workpiece. The tool should always be in the feeding state, and the radial cutting amount during milling should be 30% of the radius to ensure the stability of cutting.

The use of cutting fluid is also very particular. The use of high-pressure and high-flow cutting fluid is like installing a “powerful air conditioner” for the processing process, which can ensure the thermal stability of the processing process and prevent the surface degeneration of the workpiece and damage to the tool due to excessive temperature. At the same time, keeping the blade edge sharp should not be ignored. Blunt tools are “catalysts” for heat accumulation and wear, which can easily lead to tool failure, so the tools should be maintained and replaced in time.

In addition, it is also an important strategy to process titanium alloy in the softest state as much as possible. Because the hardened titanium alloy material will become more difficult to process, heat treatment will increase the strength of the material, thereby increasing the wear of the blade. In terms of processing methods, use a large tip arc radius or chamfer to cut in so that more blades are involved in cutting, which can reduce the cutting force and heat at each point and prevent local damage. When milling titanium alloy, the cutting speed has the greatest impact on the tool life vc among all cutting parameters, followed by the radial cutting depth ae. Reasonable adjustment of these parameters can significantly improve processing efficiency and quality.

3. Consider breakthroughs in tool selection

Breaking the dilemma from the blade and cutter body structure During titanium alloy processing, the blade wear problem cannot be ignored. Blade groove wear is a common phenomenon. It is a local wear of the back and front along the cutting depth direction. The hardened layer left by the previous processing is one of the causes of this wear. When the processing temperature exceeds 800℃, chemical reactions and diffusions will occur between the tool and the workpiece material, which is also the “accomplice” of groove wear. During the processing process, the titanium molecules of the workpiece will accumulate in front of the blade, “weld” to the blade under high pressure and high temperature to form a built-up edge, and the built-up edge will take away the carbide coating of the blade when it is peeled off. Therefore, titanium alloy processing requires special blade materials and geometries to cope with these complex situations.

In addition to the blade, the cutter body structure is also crucial. The focus of titanium alloy processing is heat. Only by spraying a large amount of high-pressure cutting fluid onto the cutting edge in a timely and accurate manner can the heat be removed quickly. The milling cutters on the market specifically for titanium alloy processing have a unique structure. They are like “secret weapons” tailored for titanium alloy processing, which can better meet the needs of heat removal and cutting during processing.

You can leave us a message about the problems you encounter with titanium alloy materials and discuss them together.