In the increasingly competitive manufacturing environment, controlling machining costs for mechanical parts has become a critical factor in maintaining competitiveness. Excellent mechanical design not only ensures efficient part production but also optimizes costs. This requires engineers to comprehensively consider factors such as machinability, material selection, process optimization, and resource utilization throughout the entire design and manufacturing process, striking the optimal balance between performance requirements and economic efficiency. This article systematically introduces cost control strategies throughout the entire process, from design to manufacturing, providing practical and comprehensive guidance.

Table of Contents

I. Application and Implementation of Design for Manufacturability (DFM)

1. Design Simplification Principle

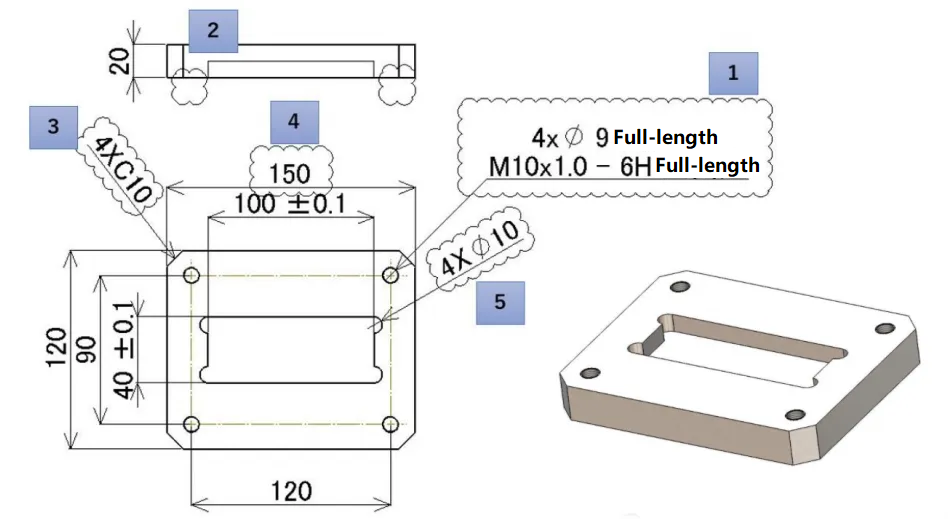

The core of Design for Manufacturability (DFM) lies in simplifying part design and reducing unnecessary complexity. Optimizing geometry can significantly reduce machining difficulty and tool wear. For example, avoid difficult-to-machine features such as deep holes and small internal fillets, which not only require specialized tools but also increase machining time and cost. During design, prioritize shapes that can be machined using standard tools to minimize the need for custom tools.

2. Process Optimization Methods

Machining process planning should be fully considered during the initial stages of product design. By analyzing and studying the structural characteristics and machining requirements of the part, the most optimal machining sequence and clamping scheme can be determined. By adopting a parallel development model and involving manufacturing engineers in design reviews early on, potential manufacturing issues can be identified and resolved during the design phase, avoiding later design modifications and rework costs.

3. Production Efficiency Improvement Strategies

Multi-tool simultaneous cutting and multi-part machining can significantly improve production efficiency. By reducing tool entry and exit times or aligning these times, the machining time for a single part can be effectively shortened. For example, when machining small parts, using a multi-station fixture to process multiple parts at once can increase efficiency by more than 30% compared to single-piece machining. The ultimate goal of implementing DFM is to achieve high yield (low scrap rate) and minimal design revisions, thereby achieving cost-effective manufacturing.

II. Cost-Benefit Analysis of Material Selection

1. Basic Principles of Material Selection

Material selection must first meet the performance requirements of the component, including mechanical, physical, and chemical properties. For example, gear transmission parts require high-strength steel to ensure wear resistance and fatigue strength, while shaft parts operating in corrosive environments require corrosion-resistant stainless steel. A material’s performance directly determines the component’s value and service life and is the primary basis for materiLal selection.

2. Economic Considerations

While meeting performance requirements, materials with good machinability and low cost should be prioritized. Aluminum alloys are widely used in CNC milling, offering fast machining speeds and minimal tool wear, making them an ideal choice for mechanical and external parts. Standardized material selection can streamline procurement processes, reduce inventory variety, and lower overall costs. Statistics show that through material standardization, companies can reduce procurement costs by 15%-25%.

3. Substitution Strategy

Actively identifying and validating alternative materials is an effective way to reduce costs. For example, using SKD61 hot-work die steel instead of SKH51 high-speed steel to manufacture certain mold parts can save 50%-70% in costs without compromising performance. When selecting materials, one should not blindly pursue high performance or high price, but rather seek the most appropriate material based on the actual application and functional requirements of the part. Sometimes, through structural design optimization, it is even possible to replace expensive materials with low-cost ones.

More knowledge you could read: Comprehensive Guide to Material Properties: 11 Key Differences Between Strength, Stiffness, Hardness, and More

III. Processing Technology and Path Optimization

1. CNC Machining Path Best Practices

Using advanced CAD/CAM software for tool path planning is key to optimizing CNC machining. Modern CAM software can fully consider workpiece geometry, tool characteristics, and machining accuracy requirements to generate the most optimized tool path. Power feedback control technology adjusts feed rate or spindle speed in real time based on changes in cutting forces, keeping cutting forces within a reasonable range and improving machining efficiency and tool life.

Model predictive control technology predicts changes during machining by building models related to cutting forces and cutting temperatures, allowing it to proactively adjust machining parameters to avoid machining anomalies. Adaptive control technology dynamically adjusts parameters based on real-time machining data, ensuring machining stability and efficiency.

2. Tool Selection and Parameter Optimization

Choosing the appropriate tool type and geometry based on machining requirements is crucial. For aluminum alloy machining, end mills, ball end mills, and boring cutters are commonly used. However, specialized tools are required for difficult-to-machine materials such as high-temperature alloys. Controlling cutting parameters directly impacts machining cost and quality: excessively high cutting speeds accelerate tool wear, while excessively low feed rates reduce productivity. Optimizing cutting parameter combinations through methods such as orthogonal testing can find the optimal balance between machining efficiency and tool life. During CNC programming, tool selection and cutting parameters must be determined in real time, under human-machine interaction, ensuring both machining quality and efficiency.

3. Tool Management and Selection

The choice of tool material significantly impacts machining efficiency and quality. Diamond tools are suitable for machining non-ferrous metals and non-metallic materials. PCBN tools are suitable for machining hardened steel and cast iron. Ceramic tools are suitable for high-speed machining of cast iron and high-temperature alloys and coated tools can improve tool life and machining efficiency. It is crucial to select standard toolholders that match the machine tool system specifications to ensure quick and accurate installation of the tool into the machine spindle or return to the tool magazine, minimizing tool change time.

IV. Refined Design and Improved Material Utilization

1. Design Optimization Strategies

Reducing the forming depth of products can effectively improve material utilization. An automotive parts manufacturer achieved an 8% increase in material utilization by reducing the forming depth of the rear cross member of a roof panel. Appropriate product subdivision and assembly design can further improve material utilization. By breaking a product into smaller components and optimizing their assembly, material waste can be reduced.

Utilizing computer simulation and experimental data analysis to optimize product geometry, such as by employing non-traditional polygonal or curved designs, can achieve higher material utilization. In some cases, structural optimization can even reduce material usage while maintaining performance.

2. Methods for Improving Material Utilization Efficiency

Reducing material width and the pitch of stamped parts can reduce scrap. Multiple CAE analyses and optimizations during the die surface design phase ensure minimal blank size while maintaining product rigidity, thereby improving material utilization.

Utilizing nested design technology, the MES system selects parts to be produced based on parameters such as material type, thickness, and delivery date, and nests them together to maximize utilization of sheet or tube material. By optimizing its nesting algorithm, a manufacturing company increased its sheet material utilization rate from 70% to 85%, saving over one million yuan in annual material costs.

3. Process and Standardization Optimization

Process optimization improves material utilization, reduces specialized material specifications, increases material versatility, and reduces inventory and management costs. Establishing material usage standards and specifications allows for unified planning of materials of varying thicknesses and specifications, avoiding waste and increased management costs caused by an overabundance of material specifications.

V. Cost-Benefit Analysis of Surface Treatment

1. Cost Composition Analysis

Surface treatment costs include material costs (chemicals, coating materials, etc.), labor costs, equipment depreciation, and energy consumption. When conducting a surface treatment cost-benefit analysis, these factors must be comprehensively considered and compared with the performance improvements brought about by the surface treatment. For example, electroplating can improve a part’s corrosion resistance, but it can increase manufacturing costs by 15%-25%.

2. Cost Optimization Strategies

Selecting the appropriate surface finish grade is crucial. Excessively high surface finish requirements can significantly increase processing costs, while reasonable surface quality requirements can meet functional requirements while controlling costs. Try to avoid applying multiple different surface treatments to the same part, as this adds additional processing steps and costs.

Comprehensively consider the surface treatment requirements of each part from a holistic product perspective and reduce unnecessary surface treatment steps through design and process optimization. For example, structural design can avoid machining and surface treatment of hidden internal surfaces, limiting treatment to critical functional surfaces.

3. Decision-Making Methods and Implementation

Establish a process for assessing the necessity of surface treatment to clearly define when surface treatment is necessary. For decorative surface treatments, consider more economical alternatives. For functional surface treatments, ensure that the treatment quality meets requirements. Maximize the cost-effectiveness of surface treatments through rigorous cost accounting and production management.

Optimize process scheduling to reduce preparation and turnaround time before and after surface treatment. Adopting an intensive production model to centralize processing of parts requiring the same surface treatment can reduce per-part processing costs.

More You Can Read: Types of Metal Surface Finishes That Will Boost Metal Quality

VI. Comprehensive Cost Control Implementation Framework

1. Full-Process Cost Control System

Establish a full-process cost control system from design to manufacturing, establishing cost control points at each stage. Conduct cost estimation and value engineering analysis during the design phase, optimize machining plans during the process planning phase and conduct real-time cost monitoring during the manufacturing phase. Establish a cross-departmental collaboration and information sharing mechanism to ensure the smooth flow of cost information between the design, process, and manufacturing departments.

2. Continuous Improvement and Optimization

Establish a cost monitoring and feedback system to regularly analyze machining cost structures, identify high-cost areas, and implement corrective measures. Establish a cycle of technological innovation and process optimization, encourage employees to submit cost improvement suggestions, and establish a reward mechanism. Utilize digital tools, such as MES systems and cost management software, to achieve refined cost management.

3. Case Analysis and Practical Recommendations

A precision machinery manufacturer reduced machining costs by 22% over three years by implementing comprehensive cost control measures. Key measures included: optimizing part design to reduce material usage by 15%, improving tool management and cutting parameters to increase machining efficiency by 30% and reducing machining costs by 18% through optimized surface treatment. We recommend that companies implement cost control measures gradually, starting with material selection and standardization, then moving on to process and parameter optimization, and finally implementing a full-process cost control system. It’s crucial to establish a culture of cost awareness and involve every employee in cost control.

Ⅶ. Conclusion

Optimizing machining costs for mechanical parts is a systematic process that requires comprehensive control throughout the entire process, from design and material selection to process planning, machining execution, and surface treatment. By implementing design for manufacturability, selecting appropriate materials, optimizing machining processes and parameters, increasing material utilization, and optimizing surface treatment strategies, machining costs can be significantly reduced while maintaining part quality.

By implementing these strategies, manufacturers can not only reduce component production costs but also shorten delivery times, improve quality, and ultimately deliver greater value to customers.

Contact us for customized machining solutions that can optimize your component design while maintaining quality and achieving the best price-performance ratio.