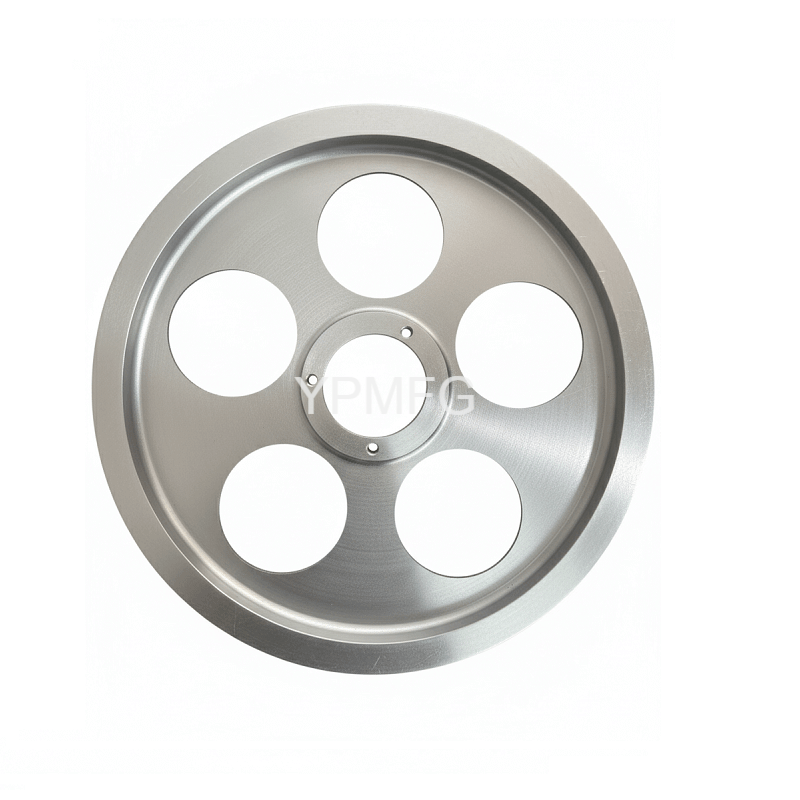

Gear is one of the most commonly used transmission parts in mechanical design, widely used in various mechanical equipment and power systems. Gears can transmit power through the cooperation of two gears: large and small gears can change the output speed and torque, and bevel gears can change the direction of power output.

Gears, as one of the most basic and critical components of mechanical transmission systems, are widely used in industrial equipment, automobiles, robots, aerospace and other fields. In order to ensure that gears have good transmission performance and service life, it is necessary to use the appropriate processing technology to manufacture their tooth shape and tooth surface quality accurately. In this article, we will introduce gear manufacturing in the common eight processing methods to help readers fully understand the characteristics of the process and applicable scenarios.

Table of Contents

I. Overview of Tooth Shape and Processing Methods

Gear tooth shape has a variety of types, of which involute tooth shape the most common. Involute tooth form has been widely used in industry due to its good meshing performance and ease of processing.

The machining methods for involute tooth forms are divided into two main categories:

- Forming method: the shape of the tool is consistent with the tooth profile of the gear and is formed by one cut.

- Spreading method: the use of the relative motion of the tool and the workpiece trajectory gradually “spread into” the tooth shape, suitable for batch or high-precision machining.

The following are several common methods of gear processing, each method has its own applicable scenarios and advantages and disadvantages of the characteristics.

Ⅱ. Common Gear Processing Methods

Gear Milling

Gear milling, a traditional gear processing method, requires the use of a disk-shaped modulus milling cutter and corresponding processing equipment. Gear milling adopts the molding method, and the cross-section shape of the milling cutter tooth corresponds to the shape of the gear tooth tip. The efficiency and precision of this processing method are low, and it is only suitable for single-piece or small-batch production.

Broaching

Broaching is commonly used in the processing of internal teeth or spline gears, using broach processing. The gear is placed on the processing equipment through the broach or broach disk on the gear processing so that the tooth surface achieves the required accuracy and quality requirements, tooth-by-tooth cutting and shaping, high precision, and good surface quality. High precision and good surface quality. Suitable for medium batch and high-precision requirements.

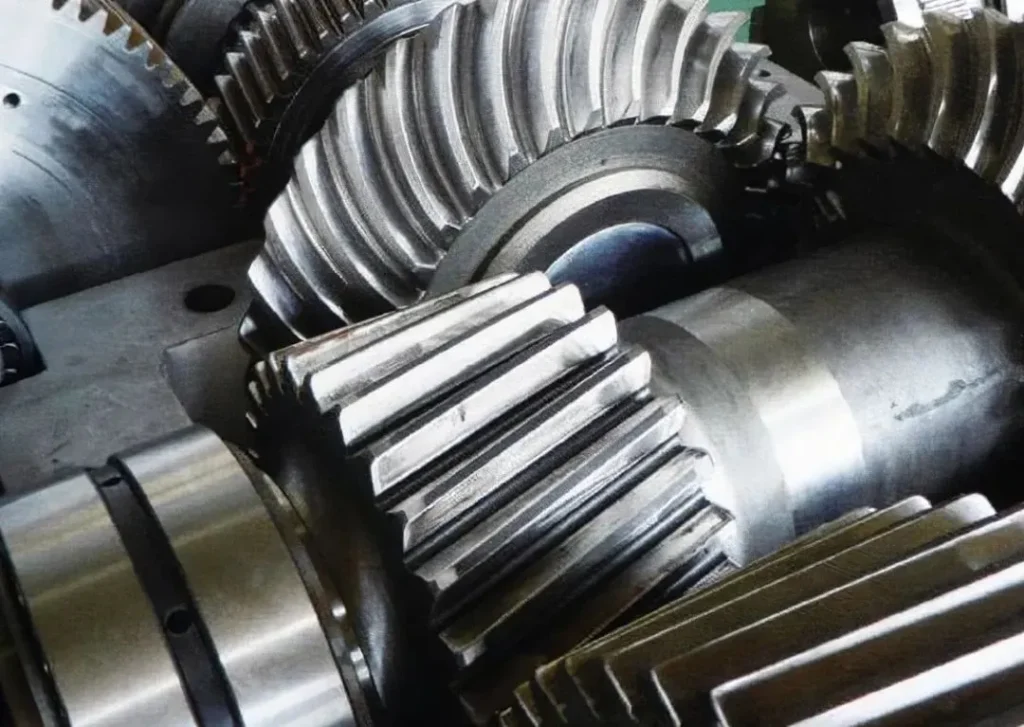

Hobbing

Hobbing, which requires hobbing cutters and corresponding equipment, belongs to the spreading method of processing. Its working principle is similar to a pair of helical gear meshing. The gear hob prototype is a helical gear with a large helix angle due to the small number of teeth, long teeth around the shaft to form a small helix angle of the worm, after grooving and shoveling the teeth into a hob with a cutting edge and back angle, used for gear processing. Hobbing is suitable for mass production of cylindrical gears, with high processing efficiency and good consistency of tooth shape.

Gear Shaping

Gear shaping, the use of shaping a knife (shaper), can process external or internal teeth, is in addition to hobbing commonly used method of spreading tooth cutting process. Shaping, shaper and workpiece are similar to a pair of cylindrical gear mesh, the reciprocating motion of the shaper is the main movement, and the shaper and the workpiece according to a certain ratio of circular motion, that is, shaping of the feed movement.

Gear Planing

Gear planing is similar to shaping but is typically used for processing bevel gears or large external gears. A planer tool performs a reciprocating motion across the gear surface to complete the cutting. The equipment used is relatively simple, making it suitable for small-batch production or maintenance work. However, due to its low efficiency, this method is gradually being replaced by more advanced machining techniques.

Shaving

Shaving, in mass production, is a common finishing method for processing non-exceptional hardened teeth. The principle of shaving is to use a shaving cutter and the gear to be processed to do free mesh movement, with the help of the relative slip from the tooth surface to pick off fine chips, in order to improve the accuracy of the tooth surface, but also the formation of drum-shaped teeth, improve the position of the tooth surface contact area. Suitable for mass production in the post-processing process.

Honing

Honing is used for hardened gear surface finishing after quenching. The surface of the gear after quenching has oxidized skin, which affects the roughness of the tooth surface, and the heat treatment deformation also affects the accuracy. In addition to grinding, it can also use honing finishing. The honing principle is similar to shaving. The honing wheel and workpiece are similar to a pair of helical gears without backlash meshing, the use of meshing at the relative sliding and applying a certain amount of pressure between the tooth surface for honing. Honing can further improve the quality of the tooth surface, which is an important high-precision post-processing means.

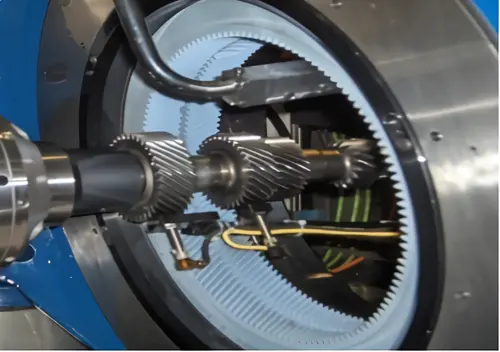

Grinding

The eighth is grinding, which also belongs to the finishing method. The use of spreading into the method, the cutting motion and hobbing similar to the gears, gears, especially hardened gears, is an important finishing method. Spread into the method of grinding can be used worm-shaped grinding wheel, conical grinding wheel or disc-shaped grinding wheel for grinding. Gear grinding can effectively ensure the accuracy of tooth shape, surface quality and consistency of tooth pitch, and is aviation, automotive, precision machinery and other fields process.

III. Other Gear Processing Methods

In addition to the traditional cutting and grinding methods mentioned above, a variety of new processes are used in modern manufacturing:

- Wire-cutting: suitable for processing of shaped gears or high-precision samples.

- Powder metallurgy: pressing and sintering molding through the mold, suitable for small modulus, high volume, cost-sensitive gear manufacturing.

- 3D printing and laser cladding: shows potential in customized, complex gear model development.

More You Want to Know

IV. Conclusion

Gears are processed in a variety of ways, and the selection of an appropriate processing method requires comprehensive consideration of gear type, material, production batch, accuracy requirements and cost factors. With the development of manufacturing technology, CNC equipment and intelligent processing means are constantly improving the efficiency and accuracy of gear manufacturing. Understanding and mastering these processing methods for mechanical designers and manufacturing engineers is critical.

For further information on the principles, equipment selection or process parameters of a particular gear machining method, please feel free to contact us.