In product design and mechanical manufacturing, we often see designs where edges and corners are rounded, this design approach is referred to as edge chamfering and rounding.

Edge chamfering and rounding include chamfers and fillets. They play a very important role in the manufacturing, assembly, and use of products and should not be overlooked. As a result, many engineers, when seeing edges in a product design, instinctively want to add a chamfer, often insisting it must be a fillet. However, adding chamfers and fillets arbitrarily can significantly increase manufacturing costs.

This article provides a systematic analysis of chamfers and fillets from four aspects: design principles, key selection points, manufacturing processes, and cost optimization.

Table of Contents

1. What are Chamfers and Fillets

What is a Fillet?

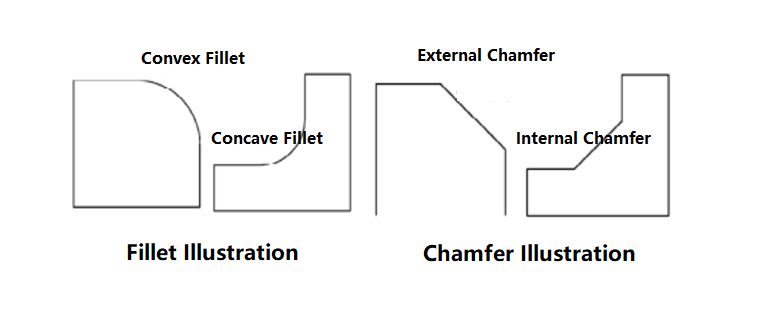

In mechanical engineering, a fillet refers to a rounded treatment applied to the internal or external edges of a part. Depending on the location in the structure, fillets can be classified as internal fillets (concave) or external fillets (convex). The primary purpose of designing fillets is to reduce stress concentration on parts by distributing stress over a larger area, preventing rapid deformation when the part is under load.

Simply put, when two surfaces intersect, if the contacting edge is rounded instead of sharp, a fillet is formed. Fillets not only improve a part’s load-bearing capacity but also extend the service life of areas subjected to tension or friction, making them especially common in technical component design.

In metalworking and the steel industry, fillets are widely used in casting, welding, and mold manufacturing to enhance the mechanical performance of load-bearing components. Fillets are also applied in construction, bridges, and heavy machinery to improve structural strength and accommodate thermal expansion.

Common types of fillets include:

- Mitered fillet: Fillet with an edge transition along a slanted line.

- Concave fillet: Edge curves inward.

- Convex fillet: Edge curves outward.

What is a Chamfer?

A chamfer is an angled or beveled treatment applied to a part’s edge, usually in a straight line rather than a curve, with angles commonly at 45° or larger. Chamfers are mainly used on edge areas that require stress concentration. Unlike fillets, chamfers cannot evenly distribute stress and are therefore not suitable for parts under high load.

Chamfers are commonly applied to internal or external edges, for example:

- Screw or bolt edges: Chamfers allow screw heads to sit flush with surfaces, facilitating installation and improving aesthetics.

- Guide lines or pilot holes: Larger chamfers (e.g., 60°) can serve as lead-ins for bolts or screws, easing assembly.

Although chamfers are often mistaken for slants, there is a difference: a slant typically forms a smooth gradient or cut, whereas a chamfer is a small cut at a specific angle dictated by the design of adjacent surfaces. Chamfers can improve the appearance of mechanical parts and reduce friction to some extent, but their stress distribution capability is inferior to fillets. Therefore, they should be used with caution on high-load components.

2. Why Are Chamfers and Fillets Needed?

The design of chamfers and fillets primarily addresses safety, manufacturing processes, and aesthetic requirements.

After milling or other machining processes, part edges are often very sharp. Chamfers and fillets are commonly used to remove these sharp corners and burrs, preventing injuries or scratches. At the same time, chamfers and fillets help eliminate stress concentrations at edges, reducing the risk of damage or failure caused by impacts, fatigue, or other mechanical stresses.

In some cases, chamfers and fillets are necessary due to functional or process requirements:

- Shafts and holes: Chamfers facilitate easier assembly of mating parts.

- Gear teeth: Fillets at the tooth top prevent deformation during heat treatment, reduce the risk of cracking, and maintain proper meshing quality.

- Powder metallurgy parts: Draft angles aid in demolding and minimize wear.

- Structural corners in molds: Chamfers or fillets ensure smooth fluid flow, even pressure distribution, and easy demolding.

Chamfers and fillets also have an aesthetic function. Slightly rounded edges make products appear more friendly, approachable, and visually appealing.

Four Common Types of Chamfers in Product Design

In product design, four main chamfer methods are commonly used: Equal-type Chamfer, Related-type Chamfer, Divergent-type Chamfer, and Plane-transition Chamfer.

1.Equal-type Chamfer

This type is characterized by parallel horizontal lines and cross-section edges that are perpendicular to each other. When the chamfer radius is small, it creates crisp and refined “lines,” highlighting the craftsmanship and overall cohesion of the product.

2. Related-type Chamfer

This chamfer creates a virtual space outside the part, making the product appear visually slimmer. It softens the rigid and cold appearance of rectangular shapes, giving the product a minimalist and cohesive design. Related-type chamfers are widely used in electronic products.

3. Divergent-type Chamfer

Divergent chamfers feature changes in polylines, curves, angles, and virtual space. Compared to equal-type chamfers, they create dynamic visual cues through rhythmic variations in edges, surfaces, and 3D space, giving a strong sense of independence in form segmentation. Typical applications include mobile phone keys, computer keyboards, and flip-cover designs in electronic devices.

4. Plane-transition Chamfer

This is the most common type of chamfer, with no obvious parting lines. Its smooth transition and versatile shapes enhance the overall aesthetics and tactile feel of the product.

3. How to Choose Between Chamfers and Fillets

Fillets provide a smooth transition without sharp points or edges, while chamfers create an angled surface. Regardless of the chamfer’s slope, the two edges of the chamfer form angles with the part’s contour though these angles are blunt rather than sharp. Therefore, fillets are better suited for reducing stress concentration, and their protective performance is superior to chamfers.

In assembly design, chamfers often serve as lead-ins to facilitate assembly, but interference must be avoided. For example, when pairing an external chamfer with an internal fillet, the external chamfer must be larger than the internal fillet to prevent interference. Similarly, when pairing an external fillet with an internal chamfer, the external fillet must be larger than the internal chamfer.

In machining, both fillets and chamfers can be produced using cutting, grinding, or other methods. However, chamfers are easier to machine and have a wider processing range. For instance, when machining a shaft on a conventional lathe:

- Chamfering can be completed with a standard cutting tool.

- Filleting requires a specialized forming tool.

On CNC machines, chamfering is generally more efficient than filleting.

Comparison of Chamfers and Fillets

| Comparison Item | Chamfer | Fillet |

|---|---|---|

| Purpose | Chamfers at hole openings serve as lead-ins. External features often use chamfers. | Prevents injury from sharp edges. Internal features often use fillets. |

| Cost | Slightly cheaper when parts are machined manually. | For milling operations, generally higher cost than chamfers. |

| Time | Shorter machining time. | Takes longer unless a ball-end mill is already used for complex shapes. |

| Tooling | One tool can create chamfers of various sizes. | Different tools are needed for different fillet sizes. |

| Coating | Chamfer edges still have sharp corners, coating may peel. | Fillets are preferred if coating is required. |

From an economic perspective, chamfers are more cost-effective than fillets. When there are no special requirements, it is preferable to use chamfers on external surfaces and flat areas. For internal cavity corners, fillets are recommended wherever possible. During side-edge cutting, the tool naturally leaves a radius at the corner. If internal corners are machined as chamfers or sharp angles, additional specialized equipment, such as electrical discharge machining (EDM)—may be required, resulting in relatively higher costs.

4. The Impact of Chamfers and Fillets on CNC Machining Costs

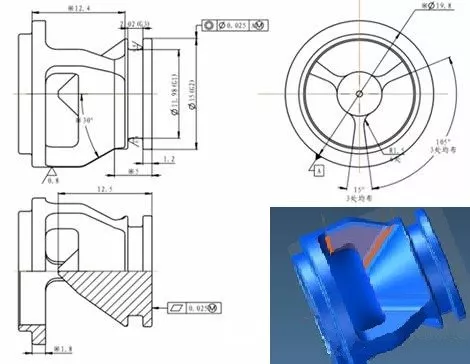

When CNC machining parts, corners—defined as the geometric edges or vertices where two surfaces meet—can be designed as either chamfers or fillets. Understanding the difference between chamfers and fillets is a fundamental consideration for designers because it directly affects the complexity, cost, and efficiency of manufacturing. Both chamfers and fillets typically incur additional CNC machining costs and can reduce production speed, so their use must be carefully evaluated.

Before adding chamfers or fillets to a design, consider the following four questions:

- What is the purpose of the chamfer or fillet?

- Is the chamfer or fillet necessary for the part’s function?

- Considering the planned production quantity, is the added design cost-effective?

- How will tolerances be checked and maintained?

Chamfers vs. Fillets:

- Chamfer: An edge or corner is angled, which removes burrs and facilitates assembly. Chamfers have sharper edges than fillets but are hidden, making them safer than raw edges. They also allow smooth movement and insertion of parts during assembly, offering higher tolerance for mating components. Chamfers can be created in various sizes with a single tool and are easier to machine.

- Fillet: An edge or corner is rounded, eliminating sharp points. Fillets enhance aesthetics, increase part longevity, reduce stress concentration by distributing stress over a larger area, and prevent injury. Fillets are ideal for sharp-edge removal and provide smooth surfaces for coatings or paint, whereas chamfers may cause coatings to peel over time. Fillets come in three types: mitered fillets, concave fillets, and convex fillets.

Factors to Consider When Choosing Chamfers or Fillets:

1.Function

Consider the part’s final purpose. Are sharp edges likely to cause damage or injury? Will the part bear a load, and if so, how much? For parts that will be painted or coated, fillets may ensure better surface finish and longevity. Consider whether the part’s function depends on the presence of a chamfer or fillet.

2.Position (Internal vs. External)

The location of the corner is crucial. External edges are more visible, exposed, and prone to wear, making them important to consider. Internal corners, such as holes for shafts, may benefit from chamfers to facilitate pin movement or screw insertion.

3.Tolerances

Optimizing dimensional tolerances is critical in CNC machining. Determine the accuracy needed and how deviations may affect assembly or functionality. Note that fillets or chamfers can impact tolerances, and strict tolerance requirements may increase machining costs.

4.Cost

Adding chamfers or fillets can increase expenses. Consider whether they are essential for part performance or mainly for aesthetics. Production volume also affects the cost-efficiency of adding these features.

5. Conclusion

Chamfers and fillets are not only decorative, they play a crucial role in part safety, functionality, and assembly. Proper selection and optimization can reduce machining costs, enhance part performance, and balance assembly and aesthetic requirements. Engineers should follow the principles of function first, reasonable positioning, appropriate tolerances, and controllable costs to achieve a balance between scientific design and efficient machining.

YPMFG Machining is committed to providing professional CNC precision machining services, offering optimized chamfer and fillet solutions to ensure long-term stability and high-quality assembly of your parts.