Precision Machining Technology is an advanced form of manufacturing technology designed to achieve ultra-high accuracy in component processing, ensuring that medical devices operate with exceptional precision even in complex environments. In the field of medical device manufacturing, precision machining is primarily applied to the production of highly precise components such as optical elements, sensors, and miniature mechanical parts.

The fundamental processes of precision machining for medical devices include cutting, grinding, electrical discharge machining (EDM), and laser machining.

- Cutting involves removing excess material from the surface to achieve the desired shape and dimensions.

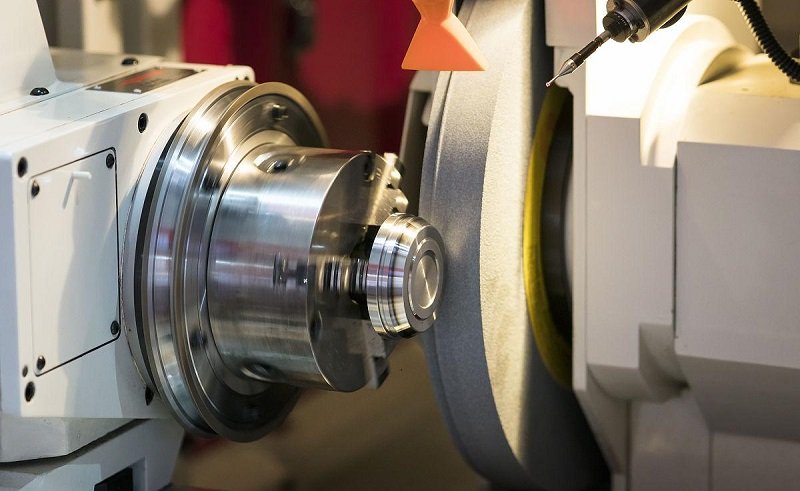

- Grinding provides further refinement to improve surface quality and dimensional accuracy.

- Electrical discharge machining is mainly used for micro-fabrication and processing of special materials.

- Laser machining, known for its high precision and efficiency, has become widely used in the manufacturing of medical equipment.

With the continuous advancement of technology, precision machining is also undergoing constant innovation. The application of new materials, the rise of intelligent manufacturing, and the integration of digital technologies have all created new opportunities for development. For example, the widespread use of carbon fiber composites and ceramic materials in medical devices requires precision machining technologies that can meet the unique processing demands of these materials. Meanwhile, the adoption of smart manufacturing technologies has significantly enhanced automation and intelligence in equipment, improving both production efficiency and product quality.

As one of the core technologies in precision medical device manufacturing, the development level of precision machining directly influences the performance and accuracy of medical equipment. With ongoing technological progress, precision machining will continue to evolve, providing strong support for the innovation and advancement of medical devices.

Table of Contents

Ⅰ. Fundamental Machining Methods for Precision Medical Devices

1. Traditional Machining Technologies

(1) Cutting Machining

Cutting machining is one of the most commonly used methods in precision medical device manufacturing, including processes such as milling, turning, and grinding. These methods remove excess material through the relative motion between the cutting tool and the workpiece, achieving the desired shape and precision. In medical device production, cutting machining is often used for finishing operations and improving surface quality.

(2) Casting and Forging

For certain large or complex medical equipment components, casting and forging are indispensable processes.

- Casting involves pouring molten metal into a mold and allowing it to cool and solidify into the desired shape.

- Forging subjects metal to thermoplastic deformation, enhancing its internal structure and mechanical properties.

(3) Welding Technology

Welding is used to join multiple components into a single structure. In medical device manufacturing, welding is widely applied to connect different metallic and non-metallic parts, such as stainless steel and titanium alloys, ensuring structural integrity and precision.

2. Modern Machining Technologies

(1) Electrical Discharge Machining (EDM)

EDM is suitable for high-precision and microstructure machining, such as the production of miniature electrodes. It removes material by utilizing the energy released from electrical discharges, enabling precise processing of complex geometries.

(2) Laser Machining

Laser machining technology is widely used in the manufacturing of medical devices due to its high precision and efficiency. Techniques such as laser cutting, laser drilling, and laser welding have become key processes in precision medical device production.

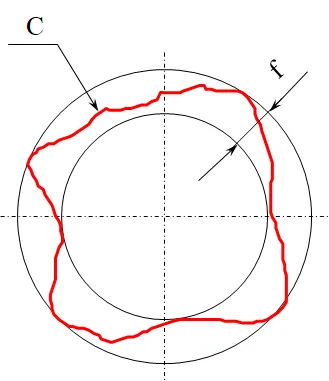

(3) Ultra-Precision Grinding and Polishing

For high-precision components such as optical lenses and sensors, ultra-precision grinding and polishing are essential steps. These processes remove microscopic surface defects, improve optical performance, and enhance overall surface quality.

(4) 3D Printing Technology

The application of 3D printing in medical device manufacturing is rapidly expanding, particularly in customized medical instruments and personalized anatomical models. By depositing materials layer by layer, 3D printing enables the rapid formation of complex structures that are difficult to achieve through traditional methods.

The fundamental processing methods for precision medical devices encompass a combination of traditional and modern technologies. In practical production, the appropriate machining method is selected based on the structural design and performance requirements of the device to ensure accuracy and functionality. With continuous technological advancements, precision medical device processing will keep evolving, providing powerful support for innovation and progress in the medical field.

Ⅱ. Material Selection in Precision Machining

In the manufacturing of precision medical devices, the choice of fundamental machining processes directly impacts the device’s performance, lifespan, and machining accuracy. Among these factors, material selection is a critical step in the precision machining process. The properties of different materials have a decisive influence on the final performance of the equipment.

1. Principles for Material Selection

When machining precision medical devices, several principles must guide material selection. First, the physical and chemical properties of the material must be considered, including the coefficient of thermal expansion, magnetism, electrical conductivity, wear resistance, corrosion resistance, and biocompatibility. These characteristics directly affect the accuracy, stability, and safety of the device. Second, factors such as material availability, ease of machining, and cost should not be overlooked.

2. Common Material Types

Commonly used materials in precision medical device manufacturing include stainless steel, titanium alloys, aluminum alloys, polymers, and specialty engineering plastics.

Stainless steel is widely used for structural components due to its excellent corrosion resistance and mechanical properties.

Titanium alloys, being lightweight, strong, and highly biocompatible, are commonly applied in surgical instruments and implants.

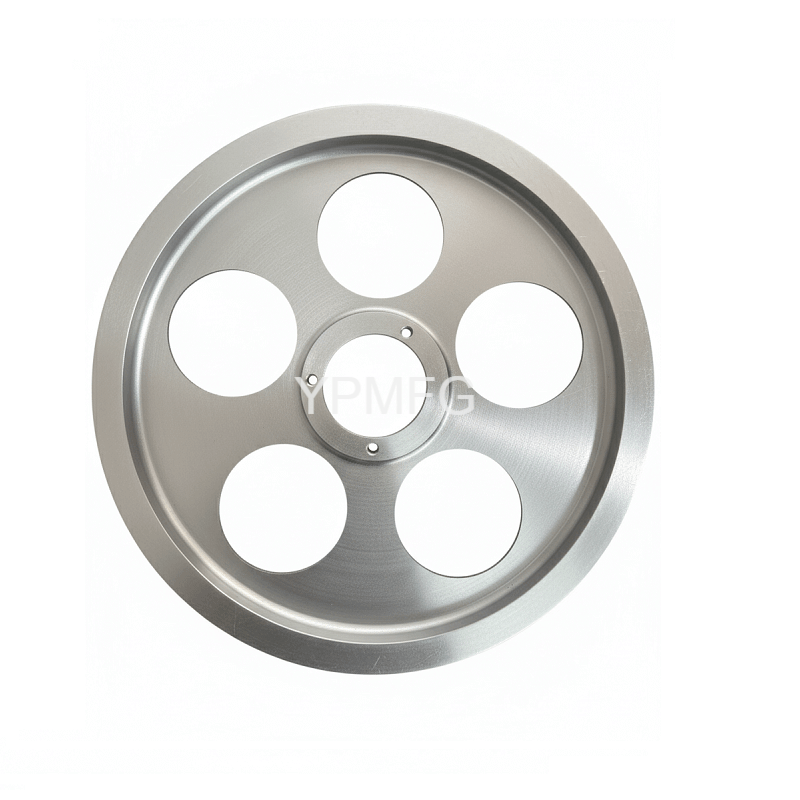

Aluminum alloys are used to manufacture components that require high rigidity but low weight.

Polymers and specialty engineering plastics are often used for functional parts and seals.

3. Material Performance Optimization

With technological advancements, optimizing material performance has become a key focus in precision medical device machining. Techniques such as heat treatment, surface coatings, and the use of composite materials can significantly enhance hardness, wear resistance, corrosion resistance, and biocompatibility. Applying these methods not only improves device performance but also makes the devices more adaptable to complex working environments and extends their service life.

4. Exploration and Application of New Materials

The development of new material technologies has led to the introduction of novel materials in precision medical devices, such as high-performance ceramics, nano-composites, and biodegradable materials. These materials bring new possibilities for device design and manufacturing. For example, high-performance ceramics are increasingly used in medical instruments due to their hardness and biocompatibility. Biodegradable materials are applied in disposable medical products and implants, reducing the long-term impact of implants on patients.

Material selection directly affects the machining quality and final performance of precision medical devices. During the machining process, materials must be carefully chosen and optimized according to the device’s operating environment and requirements to ensure accuracy, stability, and safety. Additionally, exploring and applying new materials is an important way to enhance device performance.

Ⅲ. Development Trends in Fundamental Machining Processes

With rapid technological progress, the manufacturing of precision medical devices is undergoing unprecedented innovation. As a critical link in the manufacturing chain, the fundamental machining processes of precision medical devices are continuously evolving. The following outlines the key development trends.

1. Automation and Intelligent Manufacturing

With the proliferation of industrial robots and intelligent machining technologies, basic machining processes for precision medical devices are increasingly moving toward automation and intelligence. Automated machining improves production efficiency, reduces human error, and enhances accuracy and consistency. Intelligent machining systems can monitor processes in real-time and adaptively adjust, automatically selecting the optimal parameters for different materials and process requirements.

2. Advanced Precision Machining

To meet the high-precision and high-complexity requirements of medical devices, fine machining technologies are gaining attention. Techniques such as micro-machining and nano-machining allow precise fabrication of tiny structures in medical devices. These technologies have wide applications in biomedical imaging, minimally invasive surgical instruments, and more.

3. Integration with Materials Science

Another key trend is the integration of machining processes with materials science. The emergence of new materials, such as biocompatible materials and polymer composites, imposes higher requirements on machining processes. Advanced processing technologies are being developed for these materials, including specialized cutting techniques for polymers and precision casting for biological materials.

4. Flexible and Customized Machining

As the medical market becomes more segmented and personalized, precision medical device machining is shifting toward flexibility and customization. Machines must be highly adaptable and capable of rapidly adjusting processes to meet the manufacturing needs of different medical devices. Customized machining also requires extremely fine precision to meet the demands of personalized products.

5. Green and Sustainable Manufacturing

With increasing environmental awareness, fundamental machining processes are focusing on green and sustainable practices. The adoption of environmentally friendly machining techniques and materials is becoming mainstream, aiming to reduce energy consumption and waste during manufacturing, achieving greener medical device production.

The fundamental machining processes for precision medical devices are evolving toward automation, intelligence, fine precision, materials integration, flexibility, customization, and environmental sustainability. These trends not only enhance efficiency and accuracy but also provide strong technological support for medical device innovation and development.

YPMFG CNC Machining is dedicated to high-precision CNC machining, complex medical component manufacturing, and material innovation. We provide integrated solutions from prototype design to mass production for medical device manufacturers worldwide.

With stringent quality control, advanced manufacturing equipment, and extensive industry experience, we continuously push the limits of precision, contributing to medical technology innovation and the future of human health.