In the precision machining industry, quality is the foundation of customer trust, product performance, and long-term business success. Machining parts manufacturers must ensure that every component not only meets international standards such as ISO, ASME, and DIN, but also aligns with the specific requirements of their clients. To achieve this, companies implement robust quality inspection systems that span the entire production process from raw material sourcing to final delivery.

Table of Contents

1. Why Quality Inspection Matters in Machining

Machined parts are often used in demanding industries such as aerospace, automotive, medical devices, and robotics. Their reliability, accuracy, and durability depend directly on strict quality control. Effective inspection ensures:

- Compliance with international and industry-specific standards

- Precision in dimensions, tolerances, and surface finishes

- Reliable performance under operational conditions

- Reduced risk of defects, rework, and costly delays

2. Scientific Testing Methods

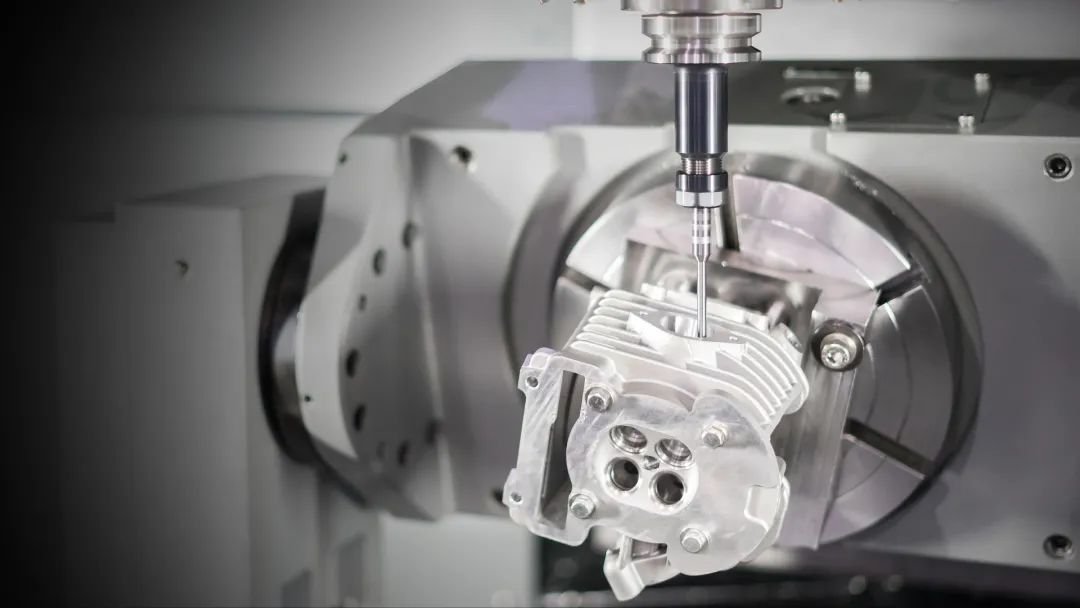

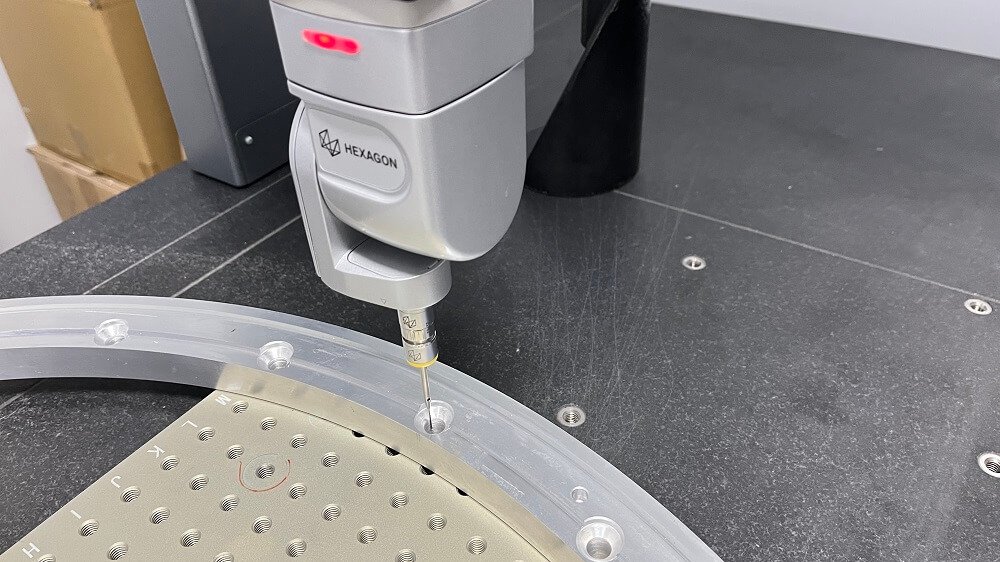

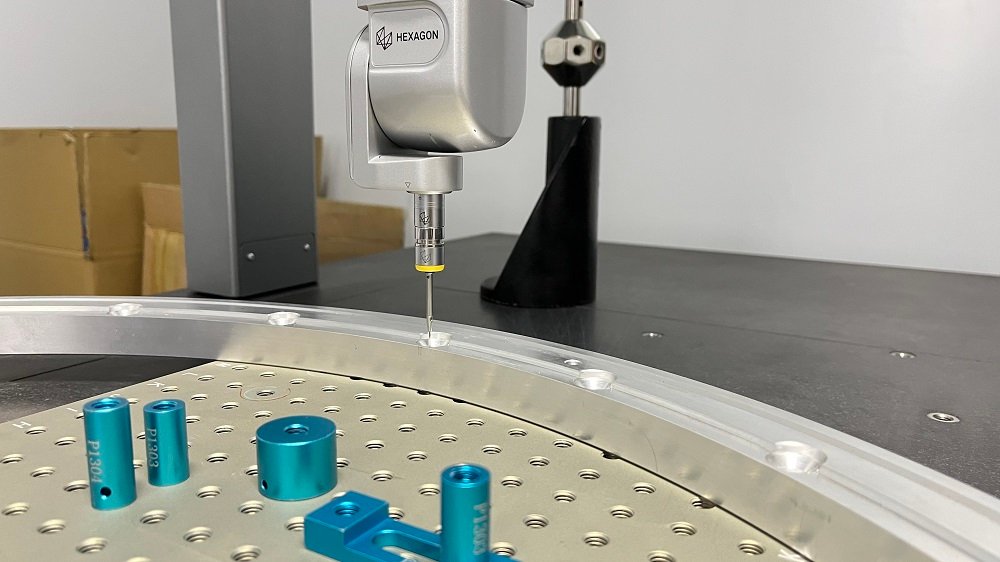

An effective inspection strategy begins with scientific testing methods. Manufacturers first design inspection plans that define parameters, tolerance levels, and inspection frequency. Advanced and calibrated equipment, including micrometers, calipers, coordinate measuring machines (CMM), roughness testers, and optical projectors, ensures accuracy and consistency.

By applying reliable measuring techniques, manufacturers can identify potential issues early and maintain full traceability throughout the production cycle.

3. Process of Inspection of Machined Parts

The inspection process for machined parts typically includes three main stages: incoming material inspection, in-process inspection, and final inspection. Each stage has different inspection focuses and methods.

1. Incoming material inspection

Incoming material inspection is the first step in the inspection process. Its primary purpose is to control the quality of raw materials and ensure that they meet design requirements. Key aspects of incoming material inspection include:

Material composition analysis: Chemical composition testing ensures that materials meet standards.

Material mechanical properties: Tensile and hardness tests are performed to confirm that the mechanical properties meet requirements.

Material appearance inspection: Observe the surface for obvious defects such as cracks and rust.

2. In-process inspection

In-process inspection is conducted during the machining process. It primarily monitors the machining process to promptly identify problems and make adjustments. Key points of in-process inspection include:

Tool monitoring: Checks tool wear to ensure stable tool performance during machining.

Machine tool accuracy inspection: Regularly inspects machine tools to ensure that their accuracy meets machining requirements and to avoid machining errors caused by machine tool problems.

Intermediate Inspection: During key machining steps, such as drilling and turning, intermediate inspections are performed to ensure that machining accuracy and surface quality meet standards.

3. Final Inspection

Final inspection is the final and most critical step in the inspection process. During this step, inspectors conduct a comprehensive inspection of the machined part to ensure that it meets all technical requirements. Final inspection includes:

Dimensional Measurement: Dimensions of machined parts are measured using measuring tools such as calipers, micrometers, and projectors to ensure they meet design requirements.

Surface Quality Inspection: Surface quality is inspected using methods such as roughness testing and visual inspection.

Functional Testing: For machined parts with high functionality, functional testing such as pressure testing and strength testing is required.

4. Key Standards in Machined Part Inspection

Machining inspection standards focus on four main aspects:

- Dimensional Tolerances: Ensuring parts meet the drawing specifications

- Surface Finish: Controlling roughness for sealing, friction, and appearance

- Form Accuracy: Maintaining roundness, straightness, and flatness

- Positional Accuracy: Guaranteeing correct alignment for assembly and function

5. Common Machined Part Inspection Methods

There are various inspection methods for machined parts. The appropriate inspection tools and equipment are typically selected based on the inspection item and the required accuracy. The following are some common inspection methods:

1. Gage Measurement Method: Commonly used measuring tools include calipers, micrometers, dial indicators, and inside and outside diameter gauges. These tools are widely used for dimensional measurement. Gage measurement methods are generally applicable to general dimensional inspection.

2. Coordinate Measurement Method: Coordinate Measuring Machines (CMMs) are high-precision measuring devices commonly used in modern machined part inspection. They can perform comprehensive and accurate three-dimensional measurements of complex parts and are particularly suitable for parts with complex geometries.

3. Optical Inspection Method: Inspection is performed using optical instruments, primarily used to check surface roughness and dimensional accuracy. Optical projectors are a common tool that can be used for two-dimensional or three-dimensional dimensional measurement.

4. Functional Inspection Method: For some critical parts, specialized functional tests, such as airtightness testing and strength testing, are required to ensure their reliability in actual use.

6. Training and Continuous Improvement

To ensure effective quality testing, machining facilities also need to conduct employee training and continuous improvement. They should familiarize employees with the use of testing equipment and the requirements of testing standards. They should also encourage employees to provide suggestions for improvement and actively incorporate these suggestions to optimize the quality testing process.

Furthermore, machining facilities should regularly review and evaluate the effectiveness of their quality control plans. They should collect and analyze test data and, based on the results, adjust and improve the production process. Only through continuous optimization can machining facilities better meet international standards and customer requirements.

7. Challenges and Solutions in Machining Inspection

Even with strict processes, challenges may arise:

- Measurement Errors: Prevented through regular calibration and standard procedures

- Workpiece Deformation: Addressed with optimized machining parameters and heat treatment

- Environmental Variability: Controlled by maintaining stable temperature and humidity in inspection rooms

8. Conclusion

Quality inspection is not a single checkpoint, it is an end-to-end system that begins with material selection and extends through in-process monitoring and final verification. By applying scientific testing methods, strict inspection standards, and continuous improvement, machining parts manufacturers ensure that every product meets international standards and customer-specific requirements.

In today’s competitive global market, consistent quality is the key to building trust, maintaining long-term partnerships, and achieving sustainable growth in the machining industry.