From aerospace to medical devices, even the smallest deviation in component dimensions can compromise product performance, safety, and reliability. This is where Coordinate Measuring Machine (CMM) inspection comes into play.

Far beyond traditional hand tools or gauges, CMMs offer data-driven insights that help reduce waste, improve compliance, and ensure that every part meets strict design specifications.

This guide provides a comprehensive look at CMM inspection: what it is, how it works, and how to choose a service.

Table of Contents

What is CMM Inspection?

What is CMM?

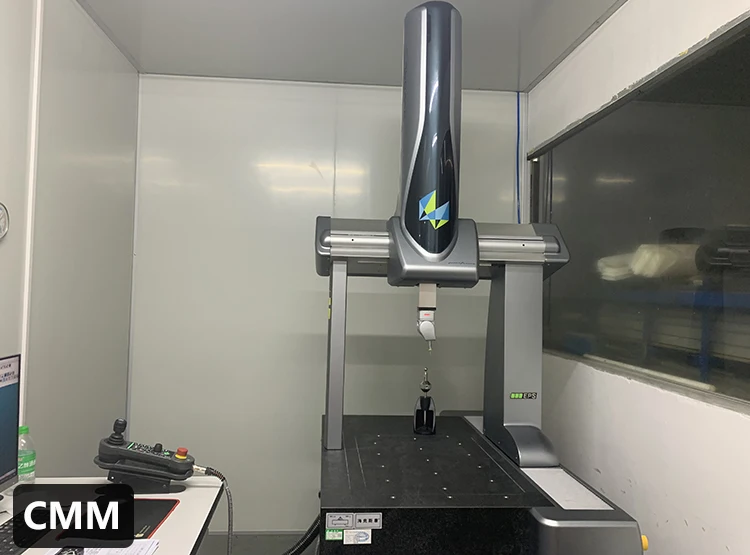

A coordinate measuring machine (CMM) refers to an instrument capable of measuring geometric shapes, lengths, and circular divisions within a six-sided spatial range. It is also known as a coordinate measuring instrument or coordinate measuring machine. A coordinate measuring machine can be defined as “an instrument equipped with a probe capable of moving in three directions along three mutually perpendicular guideways. This probe transmits signals via contact or non-contact methods. The displacement measurement systems for the three axes (such as optical scales) calculate the coordinates (X, Y, Z) of each point on the workpiece and perform various functional measurements through a data processor or computer.” The measurement capabilities of a coordinate measuring machine should encompass dimensional accuracy, positioning accuracy, geometric accuracy, and contour accuracy.

CMM inspection

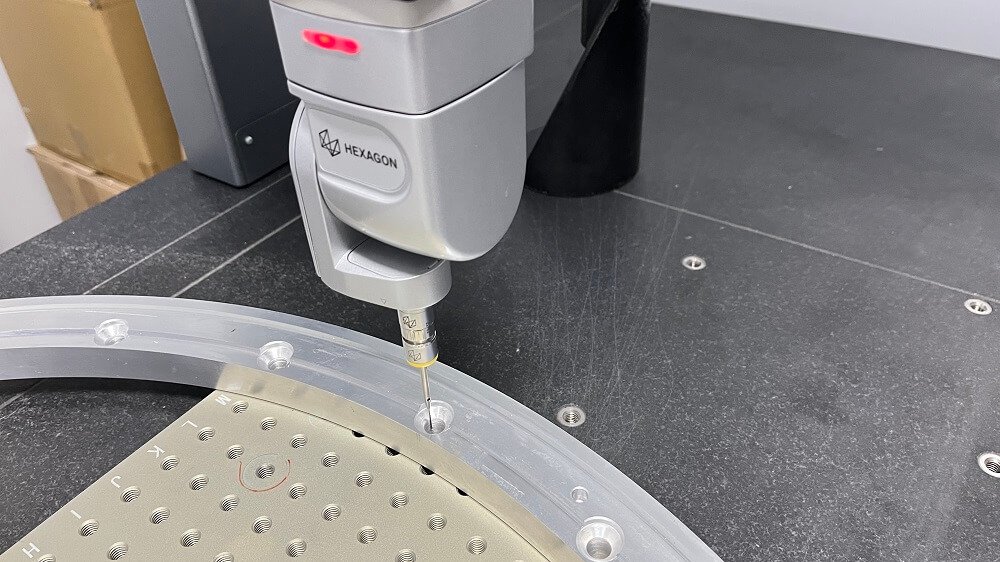

CMM inspection is a process that uses a specialized machine, the Coordinate Measuring Machine to verify the dimensions and geometrical characteristics of manufactured parts. Unlike manual measurement methods, CMM inspection delivers an automated, highly accurate assessment of whether a component conforms to its design requirements.

At its core, a CMM is equipped with probes that physically or optically interact with a part’s surface. The machine records precise data points along the X, Y, and Z axes, building a three-dimensional digital representation of the object. These measurements are then compared against the part’s CAD model or technical drawings to determine compliance.

In short, CMM inspection bridges the gap between design and production, ensuring that what is manufactured truly reflects the intended design.

The Capabilities of CMM Inspection

The primary capability of CMM inspection is to measure the dimensions of parts accurately, including length, width, height, diameter, and radius. Beyond simple measurements, CMMs excel at evaluating geometric features, such as flatness, roundness, cylindricity, parallelism, and other critical tolerances defined by GD&T (Geometric Dimensioning and Tolerancing) standards.

Modern CMMs can also perform 3D surface mapping and point cloud generation, allowing manufacturers to capture detailed representations of complex or freeform surfaces. This capability is essential for reverse engineering, quality control of intricate components, and verifying compliance with CAD models.

Additionally, CMMs offer flexible probing options, including contact, scanning, and optical sensors, which enable accurate measurement of various materials and part sizes from micro-scale medical devices to large aerospace structures. Many systems integrate automated measurement routines, real-time data analysis, and detailed reporting, supporting statistical process control (SPC) and helping manufacturers maintain consistent quality while improving efficiency.

What Are the Different Types of CMMs?

Bridge-Type CMM

Bridge-type CMMs feature a probe system that moves along X, Y, and Z axes in a Cartesian coordinate system, capturing precise surface points to form a point cloud. They come in two subtypes: moving table and moving bridge.

Advantages:

- Extremely accurate, ideal for high-tolerance machined parts

- Perfect for medium and small components

- Supports multi-sensor measurements (probing and scanning)

Disadvantages:

- Expensive

- Fixed measurement range

- Not portable, parts must be brought to the machine

- Sensitive to vibration, requires a metrology lab

- Requires careful setup and skilled operators

Gantry-Type CMM

Gantry-type CMMs are larger and designed for heavy or oversized parts. They deliver high accuracy without needing to lift parts onto a table and must be installed on a solid floor.

Advantages:

- High accuracy

- Large measurement range, suitable for heavy or large components

- Easier part loading and unloading compared to bridge-type

Disadvantages:

- Expensive

- Fixed measurement range

- Large footprint and limited portability

- Sensitive to vibration, requires a metrology lab

- Requires careful setup and skilled operators

Cantilever CMM

Cantilever CMMs differ from bridge-type CMMs because the probe is attached only on one side to a rigid base. This design provides operators with three open sides, making part handling easier.

Advantages:

- High accuracy

- Ideal for smaller components

- Three open sides allow easy manual or automated part loading/unloading

Disadvantages:

- Expensive

- Fixed measurement range

- Not portable, parts must be brought to the machine

- Sensitive to vibration, requires a metrology lab

- Requires careful setup and skilled operators

Horizontal Cantilever CMM

As the name suggests, horizontal cantilever CMMs have a probe mounted horizontally rather than vertically. They are designed to measure long, thin parts that vertical CMMs cannot reach, such as metal plates, and are often used for hard-to-reach geometries. Horizontal cantilever CMMs come in two types: plate-mounted and slide-mounted.

Advantages:

- Long measurement range, suitable for long and thin components

- Suitable for low-tolerance parts

- No need for a solid foundation

- Quick and easy installation

- Small footprint

- Lower ceiling height required compared to other CMM types

- Cost-effective

Disadvantages:

- Less precise than other CMM types

- Fixed measurement range

- Not portable, parts must be brought to the machine

- Sensitive to vibration, requires a metrology lab

- Requires careful setup and skilled operators

Portable Arm CMM

Portable arm CMMs allow direct measurement of parts on the shop floor, providing fast results and real-time analysis. Unlike traditional CMMs that require moving parts to a lab, operators use a six- or seven-axis articulated arm to measure components wherever needed. This is especially useful for parts that remain integrated in fixtures or assemblies.

Advantages:

- Lightweight and portable, bring the CMM to the part

- Expandable measurement range (step measurement)

- Supports multi-sensor measurements, including probing and scanning

- Relatively affordable

- Easy to operate, no programming required

Disadvantages:

- Slightly lower accuracy compared to traditional CMMs

- Sensitive to environmental vibrations

- Requires careful setup

Optical CMM

Optical CMMs are portable, non-contact devices that use a no-arm system and optical triangulation to scan and capture 3D data. Advanced image processing allows high-speed measurement with metrology-grade accuracy. Optical CMMs are particularly advantageous for Industry 4.0 manufacturing environments.

While their accuracy is slightly lower than traditional CMMs, it is sufficient for many applications. In fact, combining optical and traditional CMMs can improve production efficiency: high-precision parts are measured with traditional CMMs, while other components are scanned with cost-effective, flexible, and fast optical CMMs.

Advantages:

- Lightweight and portable, can be brought to the part

- Expandable measurement range (step measurement)

- Supports multi-sensor measurements, including probing and scanning

- Very fast data acquisition

- Relatively low cost

- Easy to operate, no programming required

- No strict setup needed

Disadvantages:

- Slightly lower accuracy than traditional CMMs, depending on the application

Applications of Coordinate Measuring Machines (CMMs)

- Automotive Parts Inspection: CMMs measure critical engine components such as engine blocks, cylinder heads, and crankshafts for dimensional and geometric accuracy. Cylinder roundness, flatness, and mounting hole positions can be precisely inspected to ensure engine performance and assembly quality.

- Vehicle Body Inspection: CMMs check the dimensional accuracy of car body frames, weld positions, and contours on body-in-white production lines, quickly detecting deviations and enabling timely adjustments.

2. Mold Manufacturing Industry

- Mold Design Verification: During the design phase, CMMs measure mold models to verify dimensional accuracy and ensure that molds meet product specifications.

- Mold Machining Accuracy Inspection: Machined mold parts are checked for size, shape, and surface finish, allowing prompt correction of errors to maintain high-quality production.

- Mold Repair Inspection: Worn or damaged molds can be fully inspected to provide precise repair guidance, ensuring proper restoration.

- Aircraft Component Inspection: CMMs ensure the precise dimensions and geometric tolerances of turbine blades, fuselage panels, and structural components.

- Assembly Verification: Complex assemblies like landing gear or engine mounts are measured to guarantee alignment, safety, and performance compliance.

4. Electronics and Semiconductor Industry

- PCB and Component Inspection: High-precision CMMs measure printed circuit boards (PCBs), semiconductor wafers, and delicate electronic components to ensure dimensional accuracy.

- Connector and Housing Verification: Critical connectors and casings are checked for tight tolerances, ensuring proper fit and function.

- Surgical Instruments and Implants: CMMs measure orthopedic implants, prosthetics, and surgical tools for high-precision tolerances to ensure patient safety and functionality.

- Quality Compliance: Devices are verified to meet stringent regulatory standards (e.g., ISO, FDA).

6. Energy and Heavy Equipment Industry

- Turbines and Pumps: CMMs inspect components such as pump casings, turbine blades, and rotors for precise dimensions and alignment.

- Large-Scale Assembly Verification: CMMs ensure the accurate assembly of large industrial machines and energy equipment.

7. Defense and Aerospace Manufacturing

- Weapon and Missile Components: Precision measurement of critical defense components ensures reliability and adherence to strict safety standards.

- Structural Integrity Verification: Aircraft, drones, and other defense platforms are inspected for dimensional and geometric consistency.

8. Consumer Goods and Appliances

- Plastic Housings and Metal Parts: CMMs verify the accuracy of parts in home appliances, consumer electronics, and other mass-produced products.

- Assembly Fit and Finish: Ensures components fit together perfectly and maintain quality standards.

How to Properly Operate a Coordinate Measuring Machine?

Power-On Warm-Up: After powering on, allow the measuring machine to warm up for a period of time, typically 30 minutes to 1 hour, to ensure all components reach a stable operating state. – Workpiece Installation: Ensure the workpiece is securely and levelly mounted. Whenever possible, align the workpiece’s measurement reference with the machine’s coordinate axes (parallel or perpendicular) to facilitate measurement and minimize errors.

Probe Calibration: Before measurement, calibrate the probe by determining its effective diameter and compensating for trigger delay. Use calibration tools like standard spheres and follow the machine’s software prompts.

Programming Measurement: Program the machine’s software based on part requirements to define measurement points and paths. Programming can be performed manually or automatically (e.g., offline programming using CAD models). After programming is complete, initiate the measurement program to execute the measurements.

Data Processing and Reporting: Upon completion of measurements, process the data to calculate dimensional deviations, form errors, etc. Generate a measurement report containing results, deviation analysis, and pass/fail status.

What Factors Affect the Measurement Accuracy of CMM?

– Machine inherent accuracy: This includes the straightness, perpendicularity, and repeatability of the coordinate axes. For example, if the X-axis exhibits poor straightness, it will introduce errors when measuring dimensions along the X-axis direction.

– Probe system: The trigger accuracy and contact force of contact probes, as well as the resolution of non-contact probes, all impact measurement accuracy. For instance, excessive contact force from a probe may deform softer workpiece surfaces, leading to measurement errors.

– Environmental factors: Temperature, humidity, and vibration are primary environmental influences. Temperature fluctuations cause thermal expansion and contraction of the machine’s structural materials; the measurement environment is typically required to be controlled at 20°C ± 2°C. Excessive humidity may damage electronic components, while vibration can interfere with normal operation and reduce measurement accuracy.

– Workpiece Factors: Surface roughness and geometric complexity also impact accuracy. Rough surfaces may cause inaccurate probe contact points, while complex shapes may create measurement blind spots.

What Does the Daily Maintenance of a Coordinate Measuring Machine Involve?

Cleaning: Regularly clean the machine’s workbench, guideways, probe, and body to prevent dust, oil, and other contaminants from affecting measurement accuracy. For guideways, use specialized cleaning tools and lubricants for cleaning and lubrication.

Inspection: Verify that all machine connections are secure, including cables and pneumatic lines. Simultaneously, check for smooth axis movement and abnormal noises. For instance, regularly inspect motors and drive belts for wear or looseness, replacing or tightening them promptly.

Software Maintenance: Regularly update the measuring machine’s operating software to ensure functionality and compatibility with new measurement tasks and data formats. Simultaneously, back up measurement programs and data within the software to prevent data loss.

Environmental Maintenance: Maintain stable environmental conditions, including temperature, humidity, and cleanliness. If feasible, install equipment such as air conditioners, dehumidifiers, and air purifiers to control environmental parameters.

How to Choose a CMM Inspection Service

Selecting the right CMM inspection partner is critical to ensuring accurate results and dependable quality control. Here are key factors to consider:

Technical Expertise: Look for providers with experienced operators and engineers who understand your industry standards.

Equipment Capability: Ensure the service provider has modern CMMs capable of handling the size, complexity, and precision your parts require.

Range of Probing Options: A good service should offer touch probes, scanning probes, and optical solutions for maximum flexibility.

Data and Reporting Quality: Inspection reports should be clear, comprehensive, and formatted according to your requirements.

Turnaround Time: In fast-paced industries, timely inspection is crucial to keeping production schedules on track.

Certifications and Standards: Confirm compliance with ISO, AS9100, or other relevant quality management systems.

Customer Support: Reliable communication and technical support ensure issues are resolved quickly and efficiently.

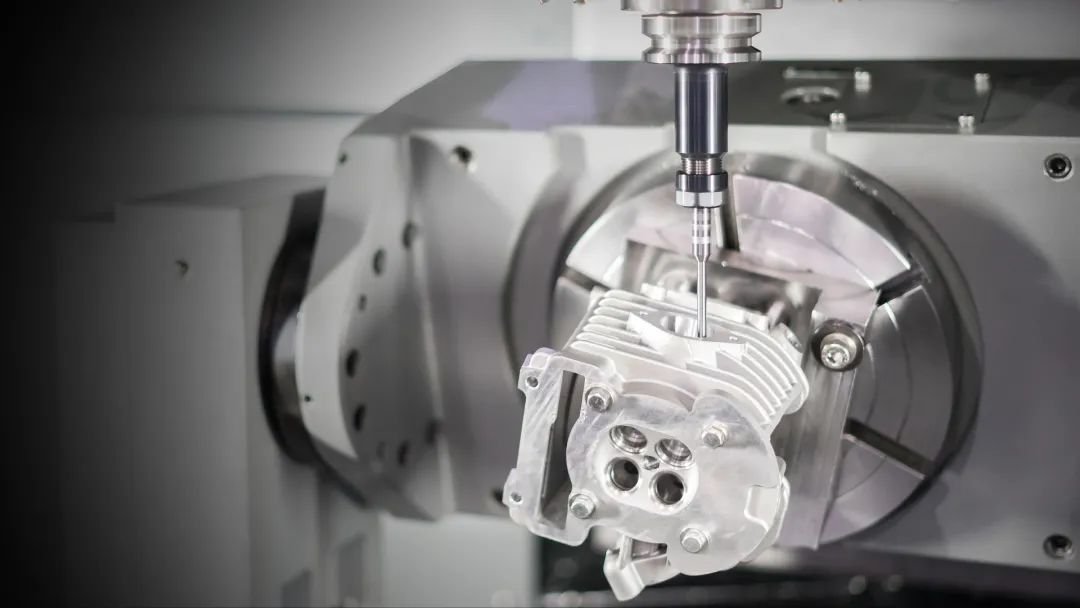

YPMFG’s Machining Services with CMM Quality Assurance

At YPMFG, precision is at the heart of every machining project. Our modern facility is equipped with advanced CNC machines as well as high-accuracy Coordinate Measuring Machines (CMM), ensuring that every part we deliver meets strict dimensional and quality standards. From prototypes to large-scale production runs, YPMFG combines skilled engineering, efficient machining processes, and rigorous CMM inspection to guarantee consistency and reliability. Whether your components are destined for aerospace, automotive, medical, or general manufacturing applications, our in-house CMM verification provides peace of mind that each part not only fits but performs as intended.

Conclusion

By providing accurate dimensional measurements, verifying complex geometries, and supporting data-driven decision-making, CMM inspection ensures that products not only meet design specifications but also exceed quality expectations. Its applications span industries as diverse as aerospace, automotive, medical devices, electronics, and rapid prototyping.

For manufacturers and engineers, investing in reliable CMM inspection, whether in-house or through an experienced service provider is essential for maintaining competitiveness, reducing waste, and delivering high-quality products. In the world of precision manufacturing, CMM inspection is not just a measurement tool, it is a cornerstone of excellence.