This project involved the custom development of front suspension arm assemblies for a high-performance remote-controlled vehicle brand. As the core load-bearing component of the vehicle’s steering and suspension system, this part demands extreme precision in lightweight construction, rigidity, and dimensional accuracy. Through precision CNC machining and the use of polyoxymethylene copolymer engineering plastic, we successfully delivered a set of fully mirror-symmetrical left and right components. These parts meet stringent mechanical performance requirements while delivering exceptional handling responsiveness and durability.

1. Project Requirements

The client is developing a next-generation suspension component for a competition-grade remote-controlled vehicle. This component must withstand lateral impacts, landing forces from jumps, and dynamic loads during high-speed operation. Consequently, the following requirements apply to the prototype:

- The material must exhibit excellent toughness and dimensional stability.

- The part must balance lightweight construction with structural rigidity.

- Machined surfaces must be free of visible tool marks, scratches, or indentations

- Precision must be maintained for critical holes and connection points during subsequent assembly testing

- Prototype validation must be completed within a short cycle to align with product development timelines

We successfully manufactured this batch of parts for the client while upholding quality standards.

2. Core Challenges

1. Complex lightweight structure: The suspension arm features intricate internal hollow cavities and triangular reinforcement ribs to achieve ultimate weight reduction and high-strength rigidity. This design demands CNC machining capabilities for deep cavity and complex surface milling across multiple planes, while ensuring thin-walled structures maintain stability and dimensional accuracy during processing.

2. Material Specificity: The customer specified POM-H (high-strength engineering plastic, commonly known as Delrin), which offers outstanding wear resistance, low friction coefficient, and high rigidity. However, its thermal sensitivity necessitates strict control of cutting parameters and cooling methods during high-speed CNC machining to prevent heat accumulation causing material deformation or burr formation.

3. Ultra-Fine Tolerance Requirements: Critical hinge points in the suspension system demand exceptionally high mating precision. Drawings explicitly mandate adherence to ISO 2768-f (fine grade) tolerance standards, involving micron-level ultra-high precision control. Any minor deviation will cause suspension movement irregularities, directly impacting the vehicle’s racing performance.

4. Mirrored Component Sets: A complete set of perfectly symmetrical left and right mirrored parts must be delivered within a tight timeframe. This demands exceptional consistency and repeatability in CNC programming and clamping processes.

3. Manufacturing Solution

To meet clients’ time and quality requirements, we advance projects through the following approaches:

1. DFM Assessment

Prior to machining, we conduct manufacturability analysis on client designs, including:

– Whether structural reinforcement is needed in specific areas

– Identification of machining blind spots

– Optimization of toolpaths for thin-walled sections

– Benchmark planning for mirrored parts

– Feasibility assessment of surface quality requirements

This feedback helps clients finalize designs and avoid rework.

2. CNC Precision Machining

During machining, we employ strategies tailored for thin-walled components:

– Phased cutting to minimize stress concentration

– High-precision fixtures for part stability

– Repeatable finishing at critical locations

– Achieving lightweight aesthetics while maintaining structural integrity

We consistently adhere to internal quality standards, ensuring dimensional verification after each process step.

3. Surface Quality and Consistency Control

As prototypes serving both functional and display purposes, these parts meet stringent aesthetic requirements. Through optimized toolpath planning, we achieve uniformly consistent surface textures without visible tool marks or machining defects. All edges undergo deburring to ensure excellent tactile feel and seamless assembly/testing experiences.

4. Rapid Delivery

From drawing confirmation to prototype delivery, we complete production of a set of mirrored left-right parts within an extremely short cycle. This enables customers to swiftly advance to assembly and real-vehicle testing phases.

4. Final Product Showcase

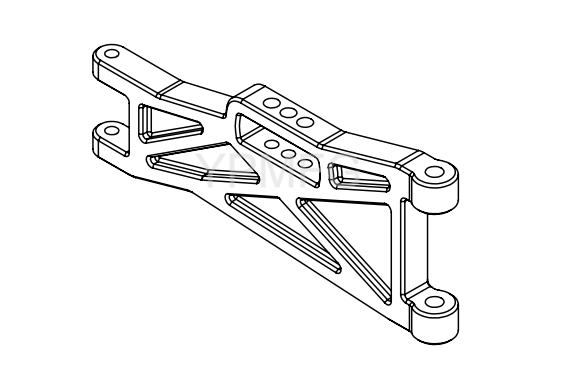

The image below displays the physical prototype of the machined structural component from this project, demonstrating our machining capabilities for the RC industry:

Visible surface characteristics include:

– Sharp, burr-free edge contours

– Clean, precise rib structures

– Uniform machining paths

– Neatly machined holes ready for direct assembly testing

5. Project Outcomes and Client Benefits

Through this collaboration, the client achieved:

- Rapid Prototype Delivery

From evaluation to delivery in just days, saving valuable time for the client’s R&D schedule.

- High Consistency and Assemblage Compatibility

Left and right structural components machined identically, meeting the client’s anticipated testing requirements.

- Reliability for Real-Vehicle Function Verification

Structural strength and visual stability satisfy RC chassis demands for impact resistance and dynamic rigidity.

- Accelerated product decision-making and mass production readiness

These prototypes enabled the client to rapidly complete validation, advance structural optimization, or conduct mass production assessments.

6. Conclusion

For the RC industry, CNC machining’s rapid response and high consistency are irreplaceable—whether for structural optimization, functional testing, or pre-production validation.

We are committed to:

- Rapid delivery of small-batch structural prototypes

- Meeting dimensional accuracy and material performance requirements for engineering testing

- Providing secure, confidential machining services that protect design intellectual property

We specialize in delivering precision component manufacturing solutions—from prototyping to small-batch production—for high-end RC models, drones, robotics, and precision medical devices. If you face challenges with lightweight, highly complex, or high-precision parts, contact us to transform exceptional designs into tangible products.