With the rapid development of the global economy and continuous technological progress, the aerospace industry has become an important component of national strategic emerging industries. As a modern means of transportation, aircraft demand extremely high standards of safety, reliability, and comfort. Therefore, the manufacturing accuracy and quality of aerospace components have become key factors in evaluating aircraft performance.

Table of Contents

1. Applications of High-Precision Machining in Aerospace Manufacturing

High-precision machining technology plays a crucial role in aerospace component manufacturing. Its applications can be illustrated in the following aspects:

Enhancing machining accuracy

High-precision machining technology significantly improves the dimensional accuracy of aerospace components, reducing tolerance ranges and thereby enhancing overall aircraft performance. For example, in the machining of key components such as engine blades and turbine disks, high-precision techniques ensure that the dimensions, shapes, and surface quality of the parts meet stringent design requirements.

Improving surface quality

By adopting advanced machining methods such as precision grinding and ultra-precision machining, high-precision technology effectively enhances surface quality. Components with superior surface finishes can reduce friction, minimize wear, and extend service life, ultimately improving the safety and reliability of aircraft.

Reducing production costs

High-precision machining technology reduces production costs by optimizing processes and improving efficiency. At the same time, it lowers rework rates and scrap rates, further boosting manufacturing productivity and economic benefits.

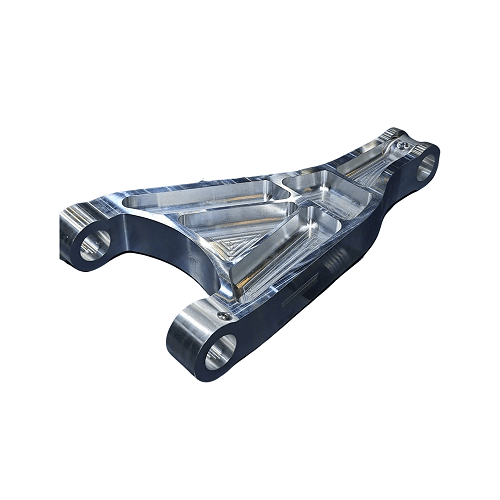

Meeting the demands of complex structures

Aerospace components often feature complex geometries. High-precision machining technology is capable of meeting these complex structural requirements. For instance, when machining difficult-to-process materials such as composites or titanium alloys, high-precision methods ensure machining quality and enhance product performance.

2. Development Trends in High-Precision Machining Technology

With ongoing technological advancement, high-precision machining technology is evolving in several directions:

Intelligent machining

Intelligent machining is a key development trend. By integrating artificial intelligence and big data, the machining process can achieve higher levels of automation and intelligence, improving both accuracy and efficiency.

Green and sustainable machining

Environmentally friendly machining represents another major trend. By optimizing processes to reduce energy consumption and waste emissions, high-precision machining contributes to sustainable development.

Interdisciplinary integration

High-precision machining technology is increasingly merging with other disciplines such as materials science, mechanics, and control theory. This interdisciplinary integration drives innovation and advances in aerospace component manufacturing.

3. Key Technologies in High-Precision Machining of Aerospace Components

Overview of Precision Machining Processes

High-precision machining processes for aerospace components refer to the use of advanced equipment and techniques, under strict quality control, to achieve high accuracy in dimensions, shapes, and surface quality. Precision machining plays a vital role in aerospace component manufacturing, as it is directly related to aircraft performance and safety, and also reflects the overall technological level of the aerospace industry.

Key Machining Technologies

Precision Grinding Technology

Precision grinding is one of the most commonly used key technologies in aerospace component machining. It removes material through the relative motion between a high-speed rotating abrasive tool and the workpiece surface. This technology achieves micrometer-level or even sub-micrometer-level accuracy and is suitable for hard-to-machine materials such as hard alloys, titanium alloys, and stainless steel.

Ultra-Precision Machining Technology

Ultra-precision machining is an advanced form of precision machining that achieves processing at the nanometer scale or smaller. It mainly includes optical machining, electrical discharge machining (EDM), and laser machining. These technologies meet the demands for ultra-smooth surfaces, complex geometries, and high-precision dimensions in aerospace components.

Numerical Control (CNC) Machining Technology

CNC machining is one of the core technologies of modern manufacturing. Controlled by computer programs, it provides high machining accuracy, high efficiency, and a high level of automation, making it indispensable in aerospace component manufacturing.

Laser Machining Technology

Laser machining is a non-contact processing method characterized by high speed, minimal heat-affected zones, and high precision. In aerospace manufacturing, it is widely applied in cutting, welding, marking, and heat treatment.

Process Optimization in Machining

To enhance the quality and efficiency of aerospace component machining, optimizing process workflows is essential. Common optimization measures include:

- Reasonable sequencing of operations

Choosing the right machining sequence reduces workpiece deformation and improves accuracy. For example, when machining complex aerospace components, rough machining is performed first, followed by finish machining, and then surface treatment. - Optimization of machining parameters

Optimizing parameters such as cutting speed, feed rate, and depth of cut—determined through experiments and data analysis—can significantly improve machining quality and efficiency. - Use of advanced equipment

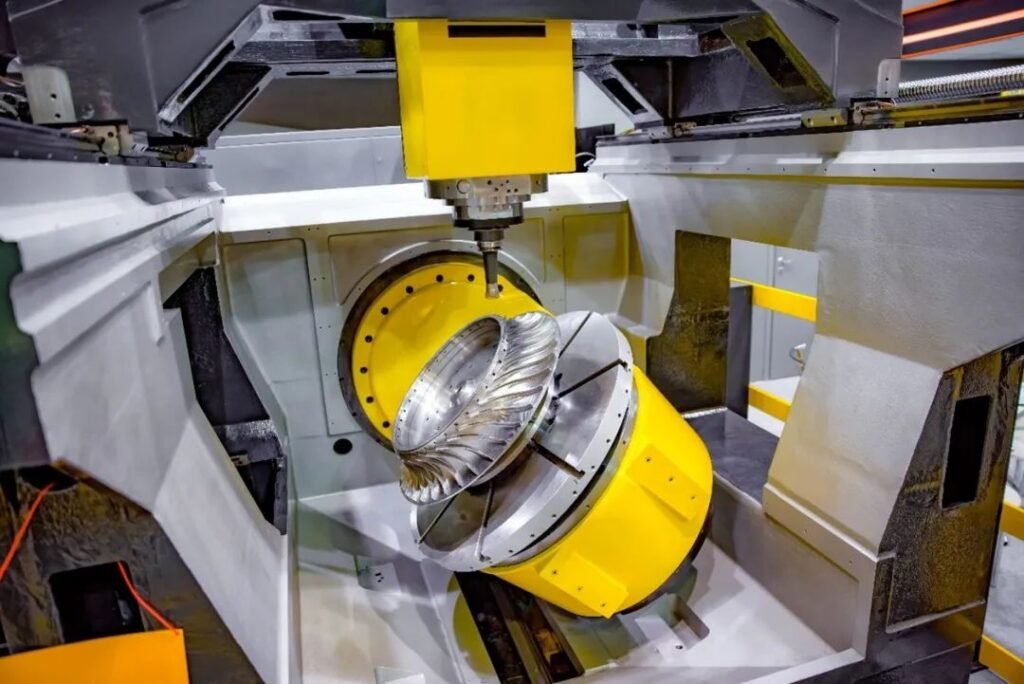

Advanced equipment is a critical guarantee for high-precision machining. For example, five-axis CNC machines and high-speed precision grinding machines can meet the complex requirements of aerospace component manufacturing.

Quality Control and Inspection

Quality control and inspection are key to ensuring product conformity in high-precision machining of aerospace components. Common methods include:

- In-process inspection (online monitoring)

Online inspection technologies allow real-time monitoring of dimensions, shapes, and surface quality during machining, enabling immediate detection and correction of errors. - Post-process inspection (offline testing)

Offline inspection is carried out after machining and includes methods such as coordinate measuring machines (CMM), optical inspection, and advanced ultrasonic non-destructive testing. - Quality management systems

Establishing comprehensive quality management systems ensures continuous monitoring of the entire machining process, guaranteeing that product quality meets relevant standards and requirements.

4. Challenges and Strategies in High-Precision Machining of Aerospace Components

Material Challenges and Solutions

In the manufacturing of aerospace components, material selection and machining are two critical factors. With the growing demand for lightweight and high-performance aircraft, the development and application of new materials have become a major challenge for high-precision machining technology.

Machining of difficult-to-cut materials

Titanium alloys, composites, and other hard-to-machine materials are increasingly used in aerospace components, but they present significant processing challenges. To address this, the following solutions can be adopted:

- Use specialized cutting tools and grinding wheels to improve cutting performance.

- Optimize machining parameters to reduce cutting force and heat generation.

- Introduce advanced machining methods such as electrical discharge machining (EDM) and laser machining.

Material deformation control

During machining, materials are prone to deformation, especially in thin-walled or complex-shaped components. To control deformation, the following measures can be taken:

- Select appropriate machining methods, such as CNC machining and precision grinding.

- Strictly control temperature variations during processing through cooling or heating techniques.

- Optimize machining paths and sequences to minimize stress concentration.

Equipment and Process Compatibility Challenges

High-precision machining of aerospace components demands extremely high equipment accuracy and stability. Equipment and process compatibility thus become critical factors influencing machining quality.

Equipment accuracy and stability

High-precision machining equipment must deliver superior accuracy and stability. Strategies include:

- Selecting high-end precision equipment from internationally renowned brands, such as five-axis CNC machines and high-speed precision grinders.

- Performing regular maintenance and calibration to ensure accuracy and stability.

- Introducing advanced inspection devices such as coordinate measuring machines (CMM) and laser interferometers for real-time process monitoring.

Process adaptability

Different materials require different machining processes, making adaptability a key to improving machining quality. Measures include:

- Developing specialized machining procedures tailored to specific materials, such as composites and titanium alloys.

- Optimizing machining parameters through experiments and data analysis to enhance adaptability.

- Strengthening training and experience accumulation for process engineers to improve technical expertise.

Challenges in Quality Control and Cost Control

In high-precision machining of aerospace components, quality control and cost control are two major challenges.

Quality control

To ensure machining quality, a strict quality control system must be established, including:

- Developing detailed quality standards and inspection procedures.

- Strengthening process monitoring to promptly identify and correct issues.

- Introducing advanced inspection methods such as in-process (online) and post-process (offline) testing.

Cost control

Cost control is a critical aspect of aerospace machining. Strategies include:

- Optimizing machining processes to reduce material waste and machining time.

- Selecting appropriate equipment to improve utilization rates.

- Enhancing cost accounting and management to keep production costs under control.

Environmental and Sustainability Challenges

With the rise of environmental awareness, sustainability in aerospace high-precision machining has become increasingly important.

Green machining technologies

Applying green machining technologies, such as water-based cutting fluids and dry machining, helps reduce environmental impact.

Waste management

Establishing a comprehensive waste management system ensures proper classification, recycling, and treatment of waste generated during machining.

5. Development Trends in High-Precision Machining Technology for Aerospace Components

Research and Application of Advanced Machining Technologies

With the rapid growth of the global aerospace industry, the research and application of advanced machining technologies have become an important trend in high-precision aerospace component manufacturing. Some notable developments include:

Multi-Axis Machining Technology

Multi-axis machining enables high-precision processing of complex-shaped components, improving both efficiency and product quality. Internationally, multi-axis machining has been widely applied in aerospace, automotive, mold manufacturing, and other fields.

Additive Manufacturing Technology

Additive manufacturing, also known as 3D printing, produces complex-shaped components by building material layer by layer. Its applications in aerospace are expanding rapidly, such as in the production of engine blades and structural parts.

Innovations in Material Processing Technologies

Innovation in material processing technologies is a major driver of advancements in high-precision machining for aerospace components. Key trends include:

Ultra-Precision Machining

Ultra-precision machining achieves nanometer-level or even smaller-scale accuracy, making it suitable for hard-to-machine materials. In aerospace applications, this technology helps enhance component performance and reliability.

Application of Laser Machining

Laser machining is increasingly applied in aerospace component manufacturing, including laser cutting, welding, and heat treatment. It offers advantages such as high speed and minimal heat-affected zones.

Integration of Smart Manufacturing and Automation

The integration of smart manufacturing and automation represents another major trend in aerospace high-precision machining. Key applications include:

Industrial Robots

Industrial robots are widely used in aerospace component machining, including automated loading/unloading, assembly, and inspection. Their use improves efficiency and reduces production costs.

Intelligent Inspection Technologies

Intelligent inspection enables real-time monitoring and evaluation of dimensions, shapes, and surface quality. This improves product quality and ensures higher safety standards in aerospace component manufacturing.

Interdisciplinary Collaboration and Technological Innovation

The development of high-precision machining for aerospace components requires interdisciplinary collaboration and continuous innovation. Examples include:

Integration of Materials Science and Machining Technology

The combination of materials science and machining technology facilitates the development of new materials with superior performance and improved machinability. For instance, optimized material design can enhance the machinability of titanium alloys.

6. Conclusion

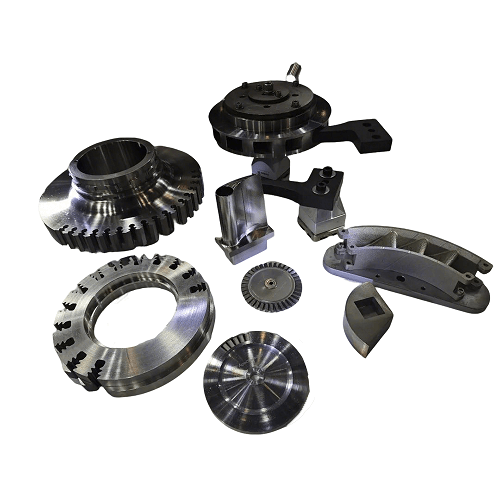

High-precision machining of aerospace components has become a core driver of progress in the aerospace industry. From precision grinding and ultra-precision machining to five-axis machining, laser processing, smart manufacturing, and green manufacturing, continuous technological advancements have improved accuracy, reliability, and performance.

At the same time, the industry is actively addressing challenges such as hard-to-machine materials, equipment precision, quality and cost control, and environmental sustainability.

Looking ahead, aerospace component machining will continue to become more intelligent, sustainable, and efficient. Interdisciplinary integration and international collaboration will further drive innovation and breakthroughs across the industry.

In this context, choosing a partner with advanced equipment, mature processes, and strict quality control systems is especially critical.

YPMFG Aerospace Component Machining Services

YPMFG has extensive experience in precision machining for aerospace components. Equipped with five-axis CNC machines, ultra-precision equipment, and comprehensive quality inspection systems, we are capable of meeting the high-precision machining needs of titanium alloys, aluminum alloys, composites, and complex structures.

We are committed to providing our clients with:

- High-precision CNC and five-axis machining

- Solutions for hard-to-machine materials such as titanium, aluminum, and composites

- Strict quality control and full-process inspection

- Customized production and rapid delivery

With a professional technical team and a complete production system, YPMFG remains customer-focused, delivering high-quality and reliable machining services for the aerospace industry.

Contact us today for customized aerospace machining solutions.