From common bolts and nuts to screws, studs, washers, pins, and rivets, different types of fasteners have distinct roles in structural form, load-bearing methods, and application scenarios. However, in practical use, many people still habitually use colloquial terms like “screws” and “nuts” to collectively refer to various fasteners, which can easily lead to confusion in selection and application.

Accurate understanding of each fastener’s structural characteristics and appropriate applications not only enhances assembly efficiency but also directly impacts connection reliability and equipment lifespan.

This article systematically outlines the definitions, typical uses, and selection principles for the twelve major categories of standard fasteners, helping you grasp the complete classification system in one read.

Standard fasteners are divided into twelve major categories. Selection should be based on the application environment and functional requirements of the fastener.

1. Types of Fasteners

1. Bolts

Bolts are widely used in mechanical manufacturing for detachable connections, typically paired with nuts (usually supplemented by one or two washers).

2. Nuts

3. Screws

Screws are generally used alone (sometimes with washers) for fastening or securing purposes, and should be screwed into internal threads in the body.

4. Studs

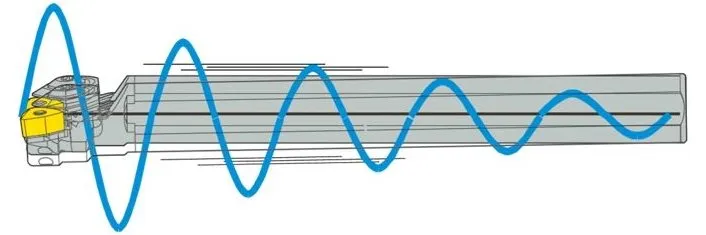

Studs are primarily used when one component is thick, requiring a compact structure, or when frequent disassembly makes bolt connections impractical. Studs are typically threaded at both ends (single-end studs have threading at one end only). One threaded end is firmly screwed into the component body, while the other end mates with a nut to provide connection and fastening. They also significantly serve as spacers.

5. Wood Screws

Wood screws are designed for driving into wood to achieve connection or fastening.

6. Self-Tapping Screws

Workpiece holes for self-tapping screws require no pre-tapping. The internal threads are formed as the screw is driven into the material.

7. Washers

Lock washers are placed between the bearing surface of bolts, screws, nuts, etc., and the workpiece bearing surface to prevent loosening and reduce bearing surface stress.

8. Retaining Rings

Retaining rings primarily position, lock, or prevent parts from moving on shafts or in holes.

9. Pins

Pins are typically used for positioning, but can also connect or lock components, or serve as overload shear elements in safety devices.

10. Rivets

Rivets feature a head at one end and a smooth, unthreaded shaft. During installation, the shaft is inserted into holes in the components being joined, then the head is riveted to secure the connection.

11. Fastener Assembly

A fastener assembly refers to the combination of a screw, bolt, or self-tapping screw with a washer. When installed on a screw, the washer must rotate freely on the screw (or bolt) without falling off. It primarily serves to secure or fasten.

12. Others

This category mainly includes items such as studs.

2. Determining Fastener Types

(1) Principles for Fastener Selection

① To enhance processing and assembly efficiency, minimize the variety of fasteners used within the same machinery or project.

② For economic considerations, prioritize commercially available fastener types.

③ Determine the selected fastener type based on anticipated usage requirements, considering factors such as configuration, mechanical properties, precision, and thread specifications.

(2) Types

① Bolts

a) General-purpose bolts: Available in numerous varieties, including hex head and square head types. Hex head bolts are the most common, categorized into product grades A, B, and C based on manufacturing precision and quality. Grades A and B are most widely used, primarily for critical applications requiring high assembly precision or subjected to significant impact, vibration, or variable loads. Hex head bolts are further categorized into standard hex head and large hex head types based on head bearing area and mounting dimensions. Variants with holes in the head or shank are available for applications requiring locking. Square-head bolts feature a larger square head with a substantial bearing surface, facilitating wrench engagement or locking against other components to prevent rotation. They are commonly used in rough structures and occasionally in T-slots, allowing for easy adjustment of the bolt position within the slot.

b) Tapped Hole Bolts: These bolts are tightly fitted into tapped holes during use to prevent workpiece misalignment.

c) Locking Bolts: These include square neck and tenon types.

d) Special-purpose bolts: Includes T-slot bolts, union bolts, and anchor bolts. T-slot bolts are primarily used in connections requiring frequent disassembly; anchor bolts secure frames or motor bases in concrete foundations.

e) High-strength bolt assemblies for steel structures: Typically employed in friction-type connections for steel structures such as buildings, bridges, towers, pipe supports, and lifting machinery.

② Nuts

a) General-purpose nuts: Available in numerous varieties, including hex nuts and square nuts. Hex nuts paired with hex bolts are the most widely used. They are categorized into product grades such as A, B, and C based on manufacturing precision and quality. Hex thin nuts serve as lock nuts in anti-loosening devices to provide locking functionality, or are used in threaded connections primarily subjected to shear forces. Hex nuts with thick heads are primarily used in connections requiring frequent disassembly. Square nuts pair with square-head bolts, where the wrench grips securely without slipping, making them suitable for rough, simple structures.

b) Slotted Nuts: Primarily refers to hex slotted nuts, featuring a slot machined into the top of a hex nut. These are used with stud bolts and split pins to prevent relative rotation between the bolt and nut.

c) Locking Nuts: Nuts with locking functions, including nylon-insert hex lock nuts and all-metal hex lock nuts. Nylon-insert hex lock nuts offer highly reliable anti-loosening capabilities. They operate effectively within temperatures of -60°C to +100°C and under certain media conditions, without damaging bolts or connected components, and allow for frequent assembly/disassembly.

d) Special-purpose nuts: Examples include wing nuts, cap nuts, knurled nuts, and insert nuts. Wing nuts typically require no tools for assembly/disassembly and are commonly used in applications requiring frequent access and low stress loads. Cap nuts are used where end threads need to be covered.

③ Screws

a) Machine screws: Classified into numerous types based on head shape and slot configuration. Head types include cylindrical, pan, countersunk, and semi-countersunk. Head slots are typically slotted (slotted), cross-recessed, or hexagon socket. Phillips screws offer better alignment during tightening and have greater head strength than slotted screws, making them less prone to stripping. They are commonly used in mass production. Hex socket screws and hex socket cap screws can apply higher tightening torques, providing greater connection strength. Their heads can be countersunk into the body, making them suitable for connections requiring compact structures and smooth surfaces.

b) Set Screws: Set screws secure relative positions of components. Head types include slotted, hex socket, and square. Square heads permit higher tightening torque and greater clamping force while resisting stripping. However, their larger size prevents flush mounting within parts, posing safety risks—especially in moving components. Slotted and hex socket heads facilitate flush mounting. Set screw ends vary based on application requirements, with the most common types being tapered, flat, and cylindrical. Tapered ends are suitable for parts with low hardness. When using blunt tapered screws, a recess must be machined into the clamping surface so the tapered face rests against the recess edge. Flat-end screws offer a large contact area and do not damage surfaces when tightened. They are used for securing high-hardness flat surfaces or in applications requiring frequent position adjustments. Cylindrical-end screws do not damage surfaces and are often used to secure parts mounted on shafts (thin-walled components). The cylindrical end is driven into a shaft hole, relying on its shear resistance to transmit significant loads.

c) Hex Socket Head Cap Screws: Suitable for confined installation spaces or applications requiring a countersunk head.

d) Special-purpose screws: Includes locating screws, captive screws, and eye bolts.

④ Studs

a) Unequal-length double-ended studs: Suitable for applications where one end is screwed into a component body for connection or fastening.

b) Equal-length double-ended studs: Suitable for applications where both ends mate with nuts for connection or spacer functions.

⑤ Wood Screws

Classified into numerous varieties based on head type and slot configuration. Head types include round, countersunk, and semi-countersunk; head slots come in slotted (slotted) and Phillips (cross-recessed) varieties.

⑥ Self-Tapping Screws

a) Standard Self-Tapping Screws: Threads conform to GB5280 with coarse pitch, suitable for thin steel sheets, copper, aluminum, and plastics.

b) Self-tapping locking screws: Threads conform to standard coarse metric threads, suitable for applications requiring vibration resistance.

⑦ Washers

a) Flat washers: Used to compensate for uneven workpiece support surfaces and increase the stress-bearing area.

b) Spring (Elastic) Washers: Prevent fastener loosening through elasticity and friction from serrated edges. Widely used in frequently disassembled connections. Internal-tooth and external-tooth elastic washers feature numerous sharp, elastic teeth around their circumference that bite into the support surface to resist loosening. Internal tooth washers are used beneath screw heads with smaller dimensions; external tooth washers are predominantly used beneath bolt heads and nuts. Toothed washers are more compact than standard spring washers, provide uniform stress distribution on fasteners, and offer reliable anti-loosening properties. However, they are not suitable for frequently disassembled applications.

c) Lock washers: Includes internal tooth lock washers, external tooth lock washers, single-ear lock washers, double-ear lock washers, and lock washers for round nuts. Single-ear and double-ear lock washers allow nuts to be locked in any tightened position, but fasteners should ideally rest against the edge.

d) Tapered washers: Tapered washers are used to compensate for the inclination of working support surfaces. Square tapered washers level inclined surfaces like channel steel or I-beam flanges, ensuring the nut’s support surface remains perpendicular to the stud shaft. This prevents bending forces on the stud during nut tightening.

⑧ Retaining Rings

a) Spring Retaining Rings: Spring retaining rings for shafts and bores are snapped into shaft grooves or bore grooves to prevent rolling bearings from moving after installation. Additionally, open-end retaining rings for shafts are primarily used in shaft grooves for part positioning but cannot withstand axial forces.

b) Wire Retaining Rings: Includes bore-type (shaft-type) wire retaining rings and wire lock rings. When installed in shaft or bore grooves for component positioning, wire retaining rings can also withstand certain axial forces.

c) Locking retaining rings for shaft components: Includes rings secured with tapered pins and those secured with screws, primarily preventing axial movement of shaft-mounted components.

d) Shaft end retaining rings: Includes rings secured with screws and those secured with bolts, primarily used to lock and secure components fixed at the shaft end.

⑨ Pins

a) Cylindrical Pins: Cylindrical pins are commonly used to secure components on shafts, transmit power, or serve as locating elements. They are available with different diameter tolerances to meet various fit requirements. Typically secured in holes via interference fit, they are not suitable for frequent disassembly.

b) Tapered Pins: Featuring a 1:50 taper, tapered pins facilitate alignment and provide self-locking capability. They are commonly used as locating and connecting elements, particularly in applications requiring frequent disassembly. Internal threaded tapered pins and tapered pins with threaded shanks are employed in blind holes or holes where pin removal is difficult. Split taper pins spread at the end after insertion, preventing the pin itself from slipping out of the hole.

Holes for cylindrical pins and various taper pins usually require reaming. Repeated assembly and disassembly reduces positioning accuracy and connection tightness, limiting their load-bearing capacity. Elastic cylindrical pins possess inherent elasticity, maintaining tension within the hole to resist loosening while facilitating easy disassembly without affecting fit characteristics. Pin holes require no reaming. Both slotted pins and pin shafts are used in hinged joints.

c) Split pins: Split pins serve as anti-loosening devices for connecting components. They are inserted through the pin holes of nuts, bolts with pin holes, or other connecting parts, then spread apart.

⑩ Rivets

a) Hot-forged rivets: Typically larger in size, commonly used in locomotives, ships, boilers, etc., usually requiring hot forging to form the head.

b) Cold-headed rivets: Generally with a diameter specification of 16mm, typically forming the head through cold heading.

c) Hollow and Semi-Hollow Rivets: Hollow rivets are used in areas with low shear stress, commonly for joining non-metallic parts like plastics, leather, wood, and canvas.

3. Conclusion

In practical engineering and mechanical design, fastener selection should not merely focus on “functional fit.” Instead, it must holistically consider assembly efficiency, stress conditions, usage frequency, vibration environments, and economic factors. Adhering to the selection principle of “minimizing varieties, prioritizing standard parts, and meeting functional requirements” enhances manufacturing and assembly efficiency while reducing maintenance costs and failure risks.

Mastering the classification logic and application characteristics of standard fasteners is a fundamental competency for mechanical engineers, equipment maintenance personnel, and manufacturing professionals. This article aims to help you establish a clear cognitive framework for fasteners, enabling more accurate and efficient use of various standard fasteners in future design, selection, and practical applications.