Galling is a major trouble with metal surfaces, and molybdenum coatings in that case are quite useful to prevent it. Galling occurs where two metal surfaces detected one another, causing injury. Molybdenum can be used to prevent galling when applied as a coating to a metal surface, thus increasing the longevity of metal parts.

Why Are Molybdenum Coatings Used for Protection of Metals?

Coatings made of molybdenum act as a protective layer between the surfaces of metals. These lubricants help minimize friction, the rubbing of things together. The molybdenum coating prevents so that the metal surfaces do not stick and hurt. In engineering, this coating comes in very handy as it holds metals sturdy especially parts that undergo maximum stress and friction.

Molybdenum Coatings vs Other Treatments

For example, molybdenum coatings outperform other methods in preventing galling, and studies consistently show that. Characteristics such as its high melting point and excellent anti-friction performance make molybdenum an ideal metal surface protector. Molybdenum coatings have proven to be more efficient and long lasting than alternative treatments.

However, according to a study conducted in the Year 2023, Molybdenum Coatings showed a lot of potential for improving manufacturing processes.

And in engineering, reducing friction and wear is essential for maintaining metal parts that work together. Because molybdenum coatings reduce friction between two metal surfaces and increase machines' lifetime, they are very useful. Designers can benefit from using molybdenum coatings in their products, as it can improve performance and durability.

Stress Testing Molybdenum Coatings

Several molybdenum coatings have been evaluated under various test conditions for their performance and durability. These tests confirm that molybdenum coatings are capable of sustaining stresses and temperature variations without compromising their protective function. That makes them a good fit for many engineering applications where metal components have to deal with extreme environments.

Enhancing Lifespan and Durability of Metallic Components

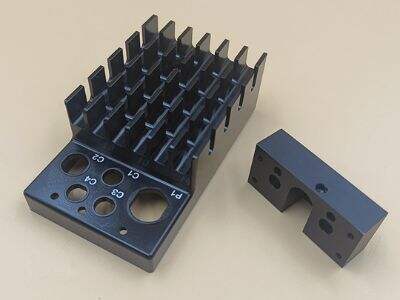

CNC Machining Service can increase longevity and performance of/for metal parts. For manufacturers and users, this is pleasant because costs can be lowered and the duration when machines are inactive is minimized. Molybdenum coatings: an intelligent choice for businesses that want their metal parts to perform better and last longer.

As a result, the molybdenum coatings are very significant to prevent galling and to reduce friction and wear on the metal surfaces. They are efficient, powerful, and can perform remarkably well in engineering. Molybdenum coatings are used both to extend the lifetime of their products and to improve performance. An industry-wide practice to enhance metal parts, we recommend molybdenum coatings. They provide reliable molybdenum coatings that will protect your metal surfaces and let your engineering work much better.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

ID

ID

LT

LT

SK

SK

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

CY

CY

IS

IS