In industries like automotive and aerospace, the demand for manufacturing high-precision parts is constantly increasing. To meet these needs, 3+2 axis CNC machining offers high-quality, efficient part production without the added complexity of full 5-axis simultaneous machining.

In this article, we will introduce what 3+2 axis CNC machining is and cover its fundamentals. We will also explore the significant advantages and key applications of this crucial machining method.

Table of Contents

1. Understanding CNC Machining Axes

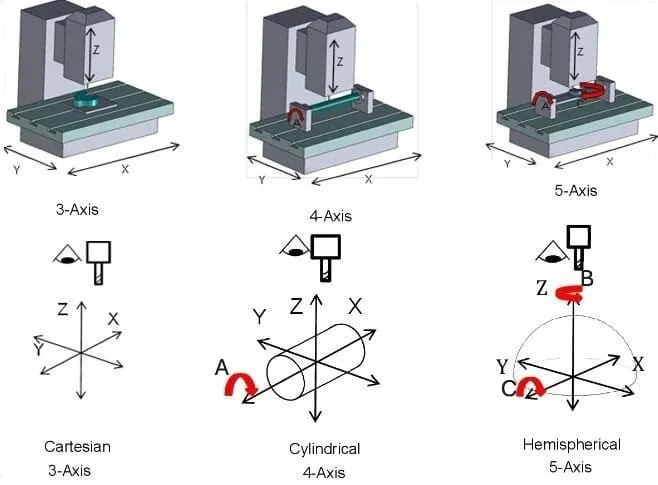

CNC machine tools are categorized based on their rotary and linear movements. There are three basic types of linear motion:

- X-axis: Left to right

- Y-axis: Front to back

- Z-axis: Up and down

To position the cutting tool at different angles, modern CNC systems also incorporate rotary axes (A, B, and C).

- The A-axis rotates around the X-axis.

- The B-axis rotates around the Y-axis.

- The C-axis rotates around the Z-axis.

Machines with only three axes (X, Y, and Z) are typically used for manufacturing simple parts on a single plane. Adding a fourth axis (A-axis) allows for multi-sided machining by rotating the workpiece. Meanwhile, five-axis machines include both B and C axes, enabling the tool to move rotationally and linearly simultaneously. This capability allows complex shapes to be machined with fewer setups.

2. 3+2 Axis CNC Machining Defined

3+2 axis CNC machining, often referred to as positional 5-axis machining or indexed 5-axis machining, combines the precision of traditional 3-axis milling with two additional rotary axes (A and B).

In this method, the workpiece is positioned and locked at a specific angle rather than continuously rotating. This setup allows for multi-sided machining with a fixed orientation.

3. How 3+2 Axis Machining Works

3+2 axis machining serves as an effective intermediate solution between basic 3-axis milling and 5-axis simultaneous machining. Here are the details of how the process operates:

3.1. Machine Configuration and Setup

- The workpiece is first secured to a tilting-rotary trunnion or a rotary table. This device provides the two additional rotational axes (typically A and B).

- Unlike a full 5-axis machine, these rotary axes do not move continuously. Instead, they are locked into fixed angles such as 30°, 45°, or 90° by hydraulic clamps or servo motors.

- The spindle then positions the cutting tool perpendicular to the surface being machined. This arrangement allows for the use of shorter, more rigid tools, which reduces tool vibration and deflection.

3.2. Machining Process

- With the axes fixed, the CNC machine executes a standard 3-axis milling operation along the X, Y, and Z axes. The angular orientation remains constant throughout the cutting process.

- To machine multiple sides of the part, the rotary axes will reposition the workpiece between machining operations. This repositioning eliminates the need for manual re-fixturing.

- Using this indexing mechanism, complex features like deep cavities or undercuts can be machined in a single setup.

4. Key Advantages of 3+2 Axis Machining

4.1. Superior Tool Accessibility

The two rotational axes are utilized to orient the cutting tool to a specific angle. This positioning allows you to use shorter, more rigid tools to reach difficult-to-machine areas like steep walls and deep cavities. The smaller tool size results in less deflection, leading to higher dimensional accuracy when processing complex geometries.

4.2. Cost-Effectiveness

Compared to 5-axis simultaneous machining, 3+2 machining requires simpler programming and involves a lower initial investment. Furthermore, this method reduces material waste and tool wear, which further lowers overall production costs.

4.3. Enhanced Accuracy and Surface Finish

During 3+2 axis machining, chatter and vibration are minimized because the cutting tool is fixed in an optimal position. Consequently, machined parts exhibit tighter dimensional tolerances and a better surface finish.

4.4. Reduced Setup Time and Higher Efficiency

With 3+2 machining, you can process multiple surfaces without repeatedly repositioning the workpiece manually. This ability leads to shorter cycle times and improved production efficiency.

5. Applications of 3+2 Axis Machining

5.1. Automotive Industry

- Parts: Hydraulic components, valve bodies, transmission housings, and engine components.

- Benefit: Reduces the number of clamps and boosts production efficiency, making it valuable for high-performance automotive applications.

5.2. Medical Industry

- Parts: Surgical instruments and implants, such as knee and hip prosthetics.

- Benefit: The precision achieved through this process ensures flawless design and biocompatibility, meeting the strict standards of the medical sector.

5.3. Aerospace Industry

- Parts: Structural components, turbine blades, and engine parts.

- Benefit: Ideal for machining features like chamfers, compound angles, and steep walls. It provides superior surface finishes and tighter tolerances, essential for strict safety and aerodynamic performance requirements.

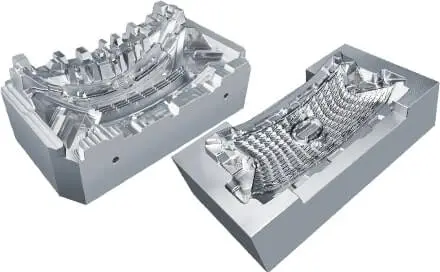

5.4. Mold Manufacturing

- Parts: Tire molds, deep cavity molds, and complex shape molds.

- Benefit: The use of small tools reduces the risk of deformation, enhancing the reliability and precision of intricate molds.

6. 3+2 Axis VS 5-Axis Simultaneous Machining

| Feature | 3+2 Axis Machining (Positional) | 5-Axis Machining (Simultaneous) |

| Tool/Workpiece Motion | Rotary axes index and lock, then 3-axis cutting occurs. Movement is fixed during cutting. | All five axes move continuously and concurrently during the cut. |

| Complexity | More economical and simpler to program. | Requires greater initial investment and advanced programming skills. |

| Efficiency | Reduces setups significantly, improving efficiency. | Often eliminates setups entirely, ideal for highly complex, contoured parts. |

| Ideal Use | Simpler parts with angled features, roughing operations, when cost is a key factor. | Highly contoured surfaces, complex 3D shapes, finishing operations requiring superior surface quality. |

| Limitation | May require additional index moves for very complex or deep features. | Higher operational and maintenance costs. |

Decision Factors: You must consider part complexity, available budget, and specific production requirements. 5-axis simultaneous machining is best suited for industries like medical or aerospace that require the highest precision and intricate contours. Conversely, 3+2 axis machining is excellent for simpler parts or when cost reduction is paramount.

7. Limitations of 3+2 Axis Machining

7.1. Machine Constraints

Unlike full 5-axis machining, 3+2 axis systems cannot perform continuous movement. This limitation reduces flexibility when producing complex parts. If a part has multiple inclined features or deep cavities, the workpiece must be repositioned multiple times. This necessary repositioning increases setup time, negatively impacting overall efficiency.

7.2. Programming Difficulty

Advanced CAM software is required to program 3+2 axis machines to efficiently handle multiple tilted work planes. While not as complex as simultaneous 5-axis machining, it still requires careful planning. Without proper planning, tool paths can overlap, which degrades surface quality and leads to longer machining times.

7.3. Maintenance and Calibration

Your 3+2 machining equipment includes additional rotary axes that require precise calibration and regular maintenance. Accurate calibration is critical to prevent misalignment of the tool or workpiece position. Misalignment leads to dimensional inaccuracies, ultimately affecting the quality of the finished product.

8. Conclusion

In summary, 3+2 axis CNC machining offers an economical and flexible method for manufacturing complex parts, delivering enhanced efficiency and precision. By reducing the number of setups and optimizing the process, it streamlines the production workflow.

If you require any type of CNC machining service, including 3-axis, 4-axis, or 5-axis machining, YP-MFG is your ideal partner. Feel free to contact us anytime.