The demand for custom products and parts - especially within aluminum machining - is only increasing as the manufacturing sector evolves. Specially designed aluminum parts are needed by almost every industry,Organization it is required to have in order for the business processes can remain up flow. It is here that the excellent precision alloy machining proves its worth, providing specifically designed and customized solutions to fulfill these needs.

Custom aluminum machining comprises of a combination of the state-of-the-art technologies and advanced practices to develop complex, unique designs crafted according to your precise requirements. The solutions by these services typically include a broad portfolio of machining processes such as turning, milling, grinding and drilling. With the utilization of highly accurate uniform and sophisticated mechanisms, manufacturing is competent to provide more than reliable products in nature which guarantees for their next-level quality.

In the industrial market, aluminum components are highly customizable that can make all the difference when standard parts do not meet specific requirements. These personalized or custom-made aluminum parts are so necessary for the operation and effectiveness of machines, robots imboli maquiadoras in addition to automation industries. Needless to say, that industrial aluminum components are manufactured with the greatest precision and accuracy because they must comply with high standards in terms of their durability and strength while providing safety for use within an industry utilizing modern manufacturing techniques such as CNC machines etc. The parts are made to order for the seamless integration with existing systems, and thereby prolong equipment life.

Aluminum fabrication and machining processes have unique solutions that are customized to meet very specific industrial requirements. With processes like cutting, bending, welding and assembly you can design very detailed structures or components. These procedures cater to a multitude of manufacturing needs, offering an array of bespoke solutions from basic brackets and frames to complicated assemblies.

Additionally, aluminum fabrication and machining afford a wide range of material options as well as design considerations with finish alternatives. With the potential to manufacture products, in different sizes and shapes, of any specifications to cater a variety needs of customers. Additionally, these processes can include different finishes, coatings and treatments to improve the integrity of product functionality as well as aesthetics so that aesthetic sense remains intact for a longer period.

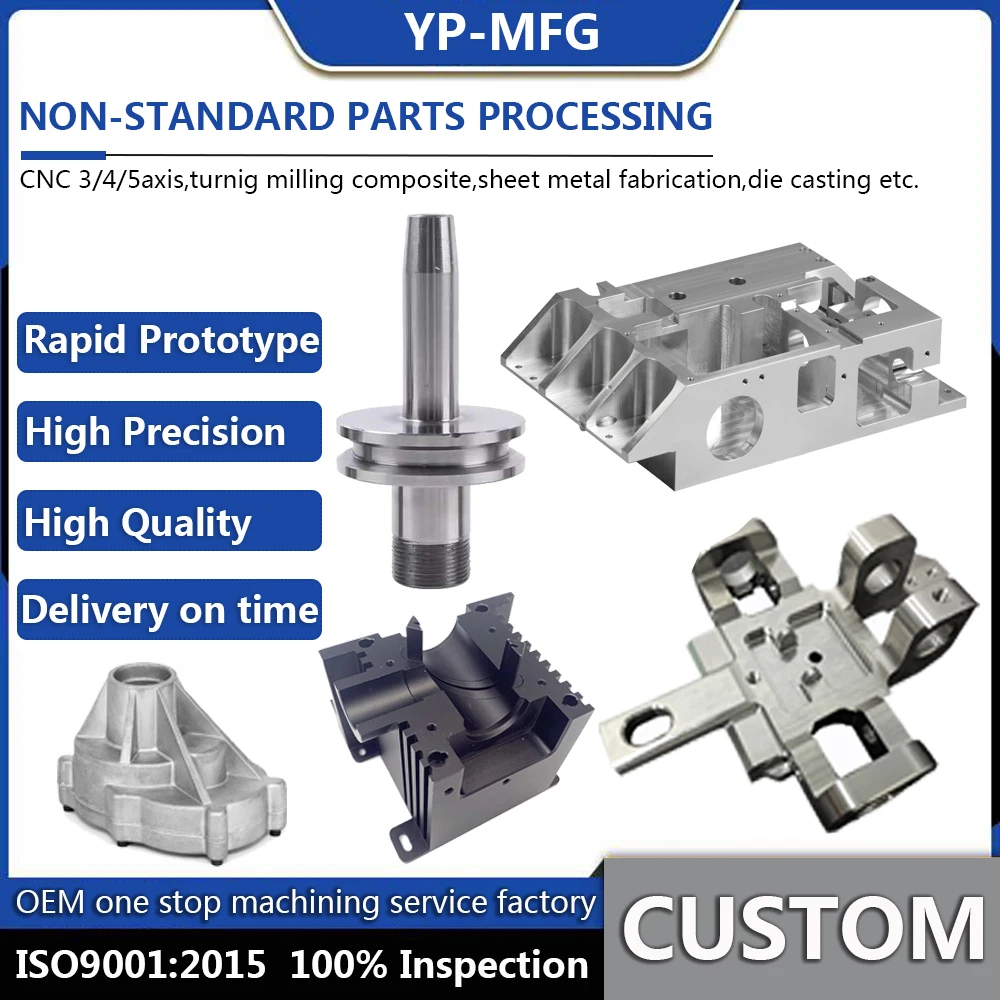

YP MFG has been in custom aluminum machining manufacturing for since the year 2000, our engineers are highly experienced.Our customer are from allover the world, EU, US, AU, Asian.More than 90 percent of our products exported all over the world.During this 20 years experience, we know different culture and request of different areas and requests that used in different areas.

YP-MFG strictly adheres to ISO 9001-2015 custom aluminum machining standards.The quality of the material is checked upon that arrives at our factory, the initial piece is inspected by CMM, and all dimension checked before surface treatment and after treatment, and surface quality checked prior to packing.We are able to meet special drawing needs as well.

YP-MFG provides a broad custom aluminum machining of services NC.service CNC machining, CNC turning, stamping, laser cutting, bending, die-casting, all kind of surface treatment, so on.

YP MFG boasts more than 70 new machines ensuring quality prompt speed delivery.equipment includes Milon from Swiss, Brother from Japan, Jingdiao China more.own 15 sets of 5 Axis custom aluminum machining machine, 39 sets of 4 axis 3 milling machines that axis-oriented, well as 16 sets turning machines.