#On-demand CNC milling services

Custom CNC Milling Services

High-quality precision CNC milling services, find YP-MFG, Contact us and get your quote today!

High precision, competitive pricing and fast lead times.

Our Professional Capabilities for CNC Milling

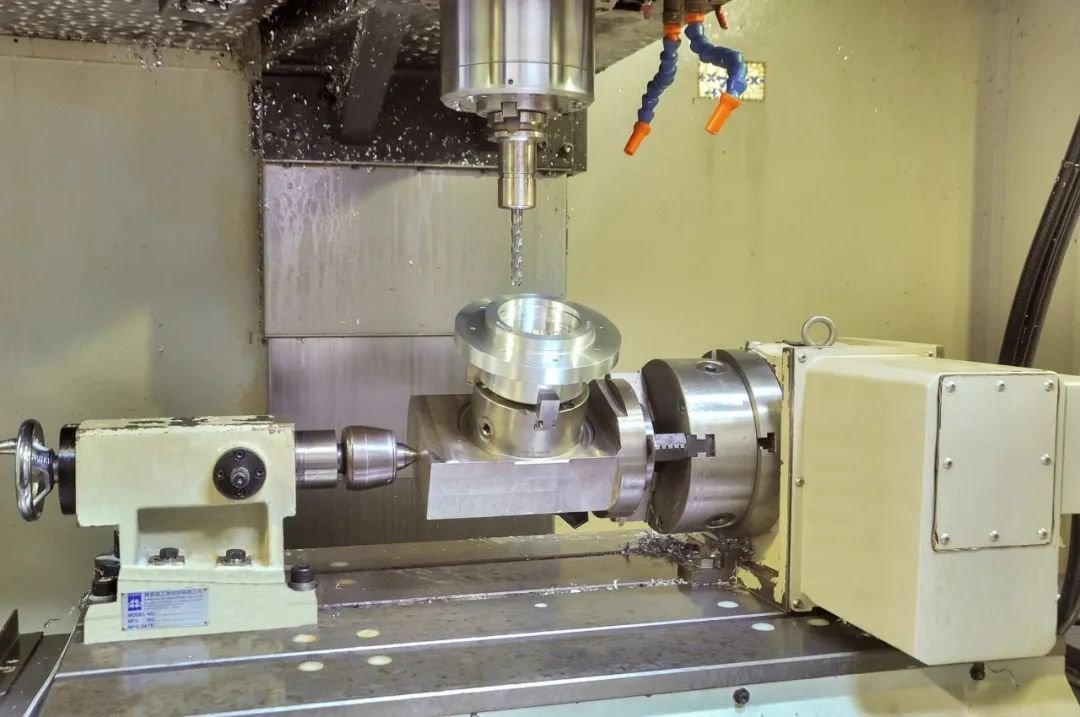

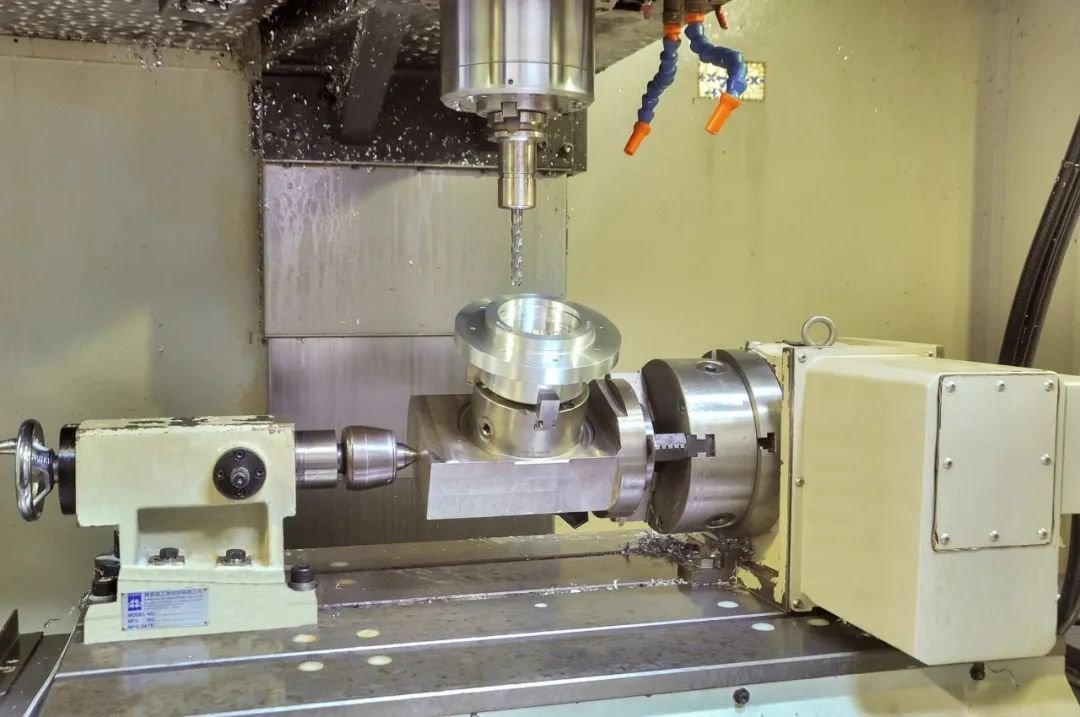

We offer comprehensive CNC milling services, including advanced 5-axis, 4-axis, and 3-axis milling. Our expertise ensures high precision and efficiency for complex parts across various industries.

3 Axis Milling

4 Axis Milling

5 Axis Milling

What we do

YP-MFG Precision CNC Milling Services Supplier

As a trusted CNC milling services supplier, YP-MFG delivers precision milling with advanced 5-axis, 4-axis, and 3-axis milling capabilities. Backed by a skilled engineering team and state-of-the-art equipment, our factory ensures tight tolerances, fast turnaround, and high quality for both prototyping and volume production. Partner with us for reliable, high-performance CNC solutions.

+(86) 137 9493 0097

sales@yp-mfg.com

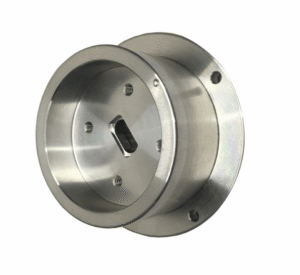

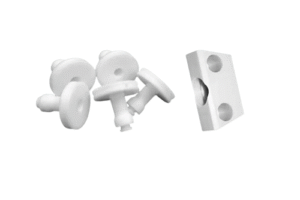

CNC Milling Products Showcase

CNC Milling Products Showcase features parts produced with 5-axis, 4-axis, and 3-axis machining. Your Reliable CNC Machining Partner.

Why Order CNC Milled Parts From YP-MFG

YP-MFG provides high-precision CNC milled parts with speed, reliability, and expert support. We’re the trusted choice for global manufacturers.

Tolerances for CNC Milling

YPMFG delivers cost-effective CNC machined parts with standard tolerances, while also specializing in high-precision components for demanding applications. Every part is manufactured to your exact specifications. If 2D drawings are not available, tolerances can be defined using ISO 2768 or ASME Y14.5 standards to ensure clear and consistent manufacturing requirements.

3-AXIS

4-AXIS

5-AXIS

Maximum Part Size

4000 x 1500 x 600 mm

1000 x 500 x 500 mm

1000 × 500 × 500 mm

Minimum Part Size

5 x 5 x 5 mm

5 x 5 x 5 mm

5 x 5 x 5 mm

General Tolerances

±0.1 mm

±0.05 mm

±0.1 mm

Lead Time

Delivery of simple parts can be as fast as 1 day.

Delivery of simple parts can be as fast as 1 day.

Delivery of simple parts can be as fast as 1 day.

CNC Milling Materials

YP-MFG cnc milling works with a range of metals like aluminum, steel, titanium, brass, and copper, as well as various plastics like abs, nylon, and polycarbonate. The choice of material depends on the specific application, desired properties, and the machine's capabilities.

Aluminum offers excellent machinability, corrosion resistance, and durability, making it ideal for various applications, such as aerospace, automotive parts, and outdoor components.

Alloys:

Aluminium 7075-T651 | 3.4365 | 76528 | AlZn5.5MgCu Aluminium 6082-T651 | 3.2315 | 64430 | AlSi1MgMn Aluminium 6060 | 3.3206 | AlMgSi Aluminium 5052 | EN AW-5052 | 3.3523 | AlMg2,5 Aluminium 2017 | 3.1325 | 24530 | AlCu4MgSi

Available Finish:

As machined, Anodizing, Powder coating, Electroplating, Painting, Sand blasting, Polishing

Stainless Steel Properties: health care, corrosion resistance, fine surface treatment, high rigidity, can be formed by various processing techniques, difficult to cold process.

Subtypes: Stainless Steel SUS201, SUS303, SUS 304, SUS316, SUS316L, SUS42, SUS430, SUS431, SUS440C, SUS630/17-4PH, AISI 304

Applications: Austenitic stainless steel is mainly used in household goods, industrial pipes and building structures. Martensitic stainless steel is mainly used to make knives and turbine blades. Ferritic stainless steel has corrosion resistance and is mainly used in durable washing machines and boiler parts. Composite stainless steel has stronger corrosion resistance, so it is often used in corrosive environments.

Steel Properties: Steel is a strong, durable, and versatile material with excellent machinability, weldability, and the ability to be heat-treated for enhanced performance.

Subtypes: Steel 1018, 1020, 1025, 1045, 1215, 4130, 4140, 4340, 5140, A36, Die steel, Alloy steel, Chisel tool steel, Spring steel, High speed steel, Cold rolled steel, Bearing steel, SPCC

Applications:Chassis, body panels, engine parts, gears, shafts, bearings, machine frames, couplers, and load-bearing structures,Cutting tools, hand tools, fasteners, and protective casings.

Brass is highly malleable and ductile, making it easy to shape and form into various products.

Alloys:

H59, H62, C260, C360

Applications: plumbing fittings, electrical connectors, musical instruments, decorative items, and machinery components.

Bronze Properties: Bronze generally has good corrosion resistance, wear resistance, castability and excellent mechanical properties.

Subtype: Tin Bronze

Applications: Suitable for casting various utensils, mechanical parts, bearings, gears, etc.

Titanium: Very high strength, good corrosion resistance to weight ratio, difficult to cold work, good weldability, about 40% lighter than steel, 60% heavier than aluminum, low conductivity, low thermal expansion, high melting point.

Titanium Alloy: TA1, Alloy TA2, Alloy TC4/Ti-6Al 4V

Applications: Golf clubs, tennis rackets, laptops, cameras, luggage, surgical implants, aircraft frames, chemical tools, and maritime equipment.

Magnesium Alloy: Low Density, High Strength-to-Weight Ratio, Good Castability, Limited Cold Workability, Susceptible to Corrosion

Magnesium Alloy: AZ31B, AZ91D

ABS alloys are created by blending ABS resin with other polymers to enhance specific properties, making them suitable for a wide range of applications where a balance of characteristics is needed.

Types: ABS Beige(Natural), ABS Blac, ABS Black Antistati, ABS Milky Whit, ABS+PC Black, ABS+PC White

Applications: It is widely used in the manufacturing industry and chemical industry, such as parts and shells in the automotive, electronic appliances, toys, construction and other industries.

Pipes, fittings, Automotive Parts and components, insulation for wires and cables, and more.

PA is a versatile and widely used material due to its excellent combination of strength, toughness, and resistance to wear and other environmental factors. Its various types and modifications allow it to be used in a wide range of applications across many industries.

Types: PA6, PA66, PA11, PA12

Applications:

PA is used in various automotive parts, including gears, bearings, and engine components, due to its high strength and resistance to wear.

CNC Milling FAQs

Our workshop is equipped with a range of advanced CNC milling machines, including MAZAK Integrex series, Japan Brother series, and high-precision multi-tasking machines. These support efficient multi-axis machining and enable complex parts to be completed in a single setup.

We offer turning of outer/inner diameters, facing, threading, face and contour milling, drilling, tapping, eccentric machining, slotting, and complex multi-axis simultaneous machining. These processes can be completed in one setup, greatly improving efficiency and consistency.

Yes. Our experienced process engineering team can offer cost-saving recommendations based on your product structure and functional requirements, including material substitutions, design for manufacturability, and optimized process flows.

Yes. We provide a full range of surface finishing services including anodizing, electroplating (nickel, chrome), sandblasting, painting, black oxide, heat treatment, and chemical plating to meet both functional and aesthetic requirements—offering true one-stop delivery.

We strictly enforce confidentiality agreements (NDAs) and manage all customer documentation through a secure internal data system.

We operate under ISO9001 quality management standards. Our quality control includes incoming material inspection, first article inspection, in-process inspections, and final product checks. We are equipped with advanced inspection tools including CMM, height gauges, surface roughness testers, and optical comparators to ensure precision and consistency.

We have provided precision machining services for clients in aerospace, automotive, medical devices, semiconductor equipment, robotics, telecommunications, and new energy sectors. Our broad experience allows us to deliver tailored solutions across various industries.

#Contact Us

Custom CNC Machined Part With Easy

Upload your design files for quote pricing, free DFM analysis.

- Quote Check List:

- 3D and 2D files if available

- Quantity of each part

- Material and grade

- Surface finish if necessary

Request a quote Now!

- All files are secure and confidential.