Plastics come in a wide variety, and their applications in automobiles are categorized into interior components, exterior trim parts, and functional parts. Based on the distinct properties of different plastics, they are typically classified into three types: general-purpose plastics, engineering plastics, and specialty plastics.

1. General-Purpose Plastics

These are typically plastics characterized by high production volume, good formability, low cost, and widespread use. General-purpose plastics encompass five major types: polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), polystyrene (PS), and acrylonitrile-butadiene-styrene copolymer (ABS), all of which are thermoplastics.

1) PP

Polypropylene, commonly known as polypropylene plastic, resembles white wax. It is transparent, lightweight, and exhibits excellent flow during injection molding. Its moisture absorption is below 0.02%. PP has a shrinkage rate of 1.0-3.5%, with an optimal thickness range of 1.5-2.5mm.

The widespread use of PP in the automotive sector faces two primary challenges: flammability (with dripping combustion) and brittleness at low temperatures. To address these issues, appropriate additives are incorporated during industrial applications to modify PP. Flammability is mitigated by adding flame retardants. To address brittleness at low temperatures, various modifications are employed to enhance toughness by incorporating other resilient materials, rigid particles, or elastomers such as rubber (EPDM), talc (TD), or glass fiber (GF). Numerous automotive components are manufactured using PP resin, including instrument panels, door trim panels, pillar trim panels, bumpers, radiator housings, and decorative panels. The application of PP in automotive manufacturing continues to expand.

2) PE

Polyethylene, one of the lightest plastics, is a semi-translucent white waxy material with excellent water resistance, acid and alkali resistance, organic solvent resistance, and superior electrical insulation properties. Its shrinkage rate ranges from 1.5% to 4.0%, with an optimal thickness of 1.0–2.5 mm.

The primary drawback of PE as an automotive material is its flammability. The simplest and most common solution is to incorporate suitable flame retardants to enhance its combustion properties. Key automotive components manufactured from PE include fuel tanks, air ducts, front seat trim covers, air duct assemblies (HDPE), left/right ventilation duct assemblies, upper/lower airflow vane connecting rods, and left/right footwell ventilation assemblies.

3) PVC

Polyvinyl chloride, commonly known as PVC, is a multi-component plastic. Due to varying proportions of its components, PVC pellets exhibit significantly different mechanical properties and hardness levels, generally categorized into two main types: soft PVC and rigid PVC. Shrinkage rate: Rigid PVC ranges from 1-1.5%, while soft PVC ranges from 2-2.3%. The optimal thickness is 2-3.5mm.

Among automotive plastic components, polyvinyl chloride stands as the most widely used raw material. PVC-based automotive plastics are ubiquitous, including PVC dashboard skins, PVC steering wheels, PVC trim panels, and PVC automotive flooring materials. This prevalence stems not only from PVC resin’s cost-effectiveness but also its favorable processing properties and comprehensive mechanical performance.

4) PS

Polystyrene, commonly known as hard plastic, is a transparent, glass-like material with good flow properties and low water absorption. Due to its brittleness, PS is often copolymerized with other substances. For example, copolymerization with butadiene forms HIPS, where the addition of rubber significantly enhances impact strength and surface hardness. Its shrinkage rate is 0.4-0.7%, with an appropriate thickness of 2-3mm.

PS’s primary automotive applications include instrument panel housings, lamp covers, and lighting components. Expanded polystyrene is also molded into packaging and thermal insulation materials, used for headliners, and combined with other materials through graft copolymerization and modification to create numerous fixed-blend PS alloy plastics. Examples include SMA alloys used in automotive dashboard frames.

5) ABS

Acrylonitrile-Butadiene-Styrene copolymer, commonly known as ultra-impact-resistant plastic, appears white in its bulk form. It has a shrinkage rate of 0.4-0.7% and an optimal wall thickness of 1.8-3mm.

Due to its diverse varieties, excellent surface treatment results, and low cost, ABS is widely used in the automotive sector. Given its poor weather resistance, highly weather-resistant materials like AES and ASA are now extensively employed in commercial vehicles to supplement ABS. ABS is selected when surface treatment is required (e.g., water transfer printing films, spraying). ASA or AES is chosen when no surface treatment is needed. Typical automotive applications include decorative trim strips, shift knobs, interior door handles, license plate bezels, rear spoiler assemblies, mirror housings, radiator grille bodies, and armrests.

2. Engineering Plastics

Engineering plastics, renowned for their superior comprehensive mechanical properties, are extensively utilized in the automotive sector. This section primarily covers polyamide (PA), polymethyl methacrylate (PMMA), polyoxymethylene (POM), polyurethane (PU), and polycarbonate (PC).

1) PA

Polyamide, commonly known as nylon, encompasses multiple industrial grades, with PA6, PA66, and PA610 being the most prevalent. Due to thermal expansion and moisture absorption, molded parts exhibit poor dimensional stability with a shrinkage rate of 1–2%. Post-molding dimensional changes caused by moisture uptake require attention. Water absorption reaches 100%, and relative humidity saturation can absorb 8%. Suitable wall thickness: 2–3.5 mm.

In the automotive sector, PA is primarily used for manufacturing hoses (brake hoses, fuel lines), fuel filters, air filters, oil filters, water pump housings, water pump impellers, fans, brake fluid reservoirs, power steering fluid reservoirs, white window shades, headlight housings, and seat belts.

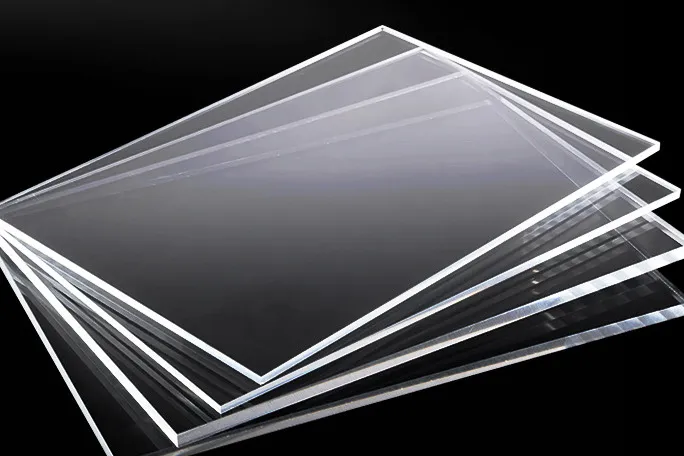

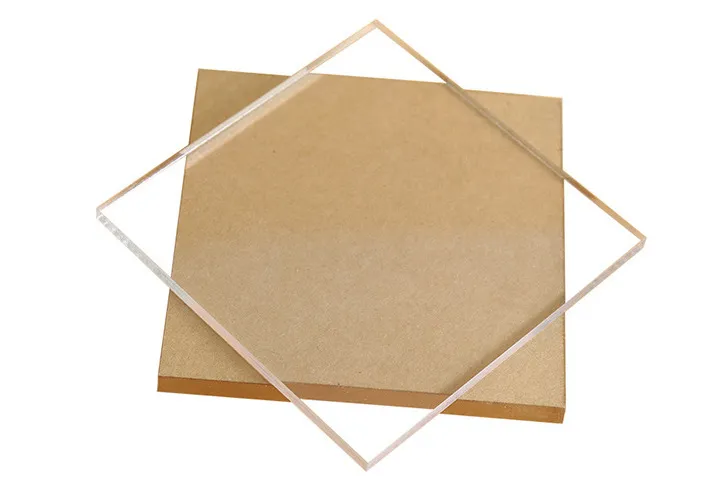

2) PMMA

Polymethyl methacrylate, commonly known as acrylic glass, exhibits excellent outdoor weather resistance and superior light transmission. Suitable plastic products: Transparent structural components requiring certain strength.

Due to its outstanding light transmission properties, PMMA is widely used in automotive lighting signs, door glass, and lamp glass covers.

3) POM

Polyoxymethylene, commonly known as plastic steel, has a shrinkage rate of 2-3.5%. Suitable wall thickness: 1.5-2.5mm.

POM is used in automotive applications for manufacturing dashboard and glove compartment accessories, various valves (drain valves, air conditioner valves, etc.), various impellers (water pump impellers, heater impellers, oil pump impellers, etc.), small gears for electrical switches and instruments, various handles, and door latches.

4) PC

Polycarbonate (PC) exhibits outstanding impact toughness and creep resistance, with excellent heat resistance and cold tolerance. Shrinkage rate: 0.5-0.7%. Suitable wall thickness: 2-3.5mm. Adding glass fiber to PC improves shrinkage rate, mechanical strength, and temperature resistance. Long-term use around 100°C increases rigidity, annealing can reduce internal stress.

Introduction to the Primary Composite PC-ABS:

PC-ABS is a blend of PC and ABS, typically supplied as pellets after compounding. Simply mixing the two materials and direct injection molding yields poor results with delamination. PC offers high rigidity and toughness but suffers from stress cracking and high viscosity. ABS offers excellent flowability but has low surface hardness. The blended PC-ABS material retains the strengths of both: high surface hardness, superior rigidity and toughness, and enhanced stress crack resistance. Its mechanical properties fall between those of the parent materials.

In the automotive sector, PC is primarily used for manufacturing lamp housings, left/right wheel arch liners, instrument panel bodies (PC+ABS), left/right air intake covers, center air intake covers (PC+ABS), and rear bumper cushion pads.

5) PU

Polyurethane is commonly classified into rigid polyurethane and flexible polyurethane based on the products of the polymerization reaction.

Polyurethane foam is extensively used in automotive interiors and vibration-absorbing components, such as coating materials, rigid polyurethane plastic sheets, polyurethane elastomers, seat cushioning foam, trim pieces, upholstery leather, and headliner trim. The most common applications involve various soft and rigid polyurethane foam materials, which provide vibration isolation, sound insulation, noise reduction, and thermal insulation. PU can also be formulated into automotive coatings, adhesives, and sealants. Key PU components in vehicles include instrument panels, rearview mirrors, bumpers, seat cushions, headrests, steering wheels, dashboard vibration dampers, pillar trim, headliner linings, window frames, roof and side headliner trim, door panels, sun visors, and rear headliner trim.

3. Specialty Plastics

Glass Fiber Reinforced Plastics

Glass fiber reinforced plastics are created by adding glass fibers and other additives to pure plastics, thereby expanding the material’s application range. Generally, most glass fiber reinforced materials are used in structural components of products, serving as structural engineering materials. Examples include: PP, ABS, PA66, PA6, PC, POM.

Advantages:

① Glass fiber reinforcement provides high-temperature resistance, significantly increasing the heat tolerance of the plastic—particularly for nylon-based plastics.

② It restricts intermolecular movement within the polymer chains, substantially reducing shrinkage and greatly enhancing rigidity.

③ Reinforced plastics resist stress cracking while substantially improving impact resistance.

④ Glass fiber’s high strength substantially increases plastic strength (tensile, compressive, and flexural strengths all improve significantly).

⑤ The addition of glass fiber and other additives substantially reduces the flammability of reinforced plastics, making most materials non-ignitable.

Disadvantages:

① Previously transparent plastics become opaque.

② Plastic toughness decreases while brittleness increases.

③ Melt viscosity increases across all materials, reducing flowability and requiring substantially higher injection pressure than unfilled plastics.

④ Poor flowability necessitates raising injection temperatures by 10°C–30°C for all reinforced plastics to achieve normal injection molding.

⑤ The moisture absorption of reinforced plastics is greatly enhanced. Even plastics that were originally non-hygroscopic become hygroscopic, necessitating drying before injection molding.

⑥ During injection molding, glass fibers can migrate to the surface of the plastic product, causing the surface to become rough and speckled (to achieve higher surface quality, it is best to use a mold temperature controller to heat the mold during injection molding, allowing the plastic polymer to migrate to the surface of the product, but this cannot achieve the appearance quality of pure plastic).

⑦ Glass fiber is a highly rigid material. When additives volatilize at high temperatures, they form highly corrosive gases that cause significant wear and corrosion to the injection molding machine screw and mold. Therefore, when producing molds and injection molding machines using such materials, attention must be paid to surface anti-corrosion treatment and surface hardness treatment of the equipment.

Common shrinkage rates for glass fiber-reinforced plastics:

PP + Glass Fiber: 0.2-0.8%

ABS + Glass Fiber: 0.1-0.2%

PA66 + Glass Fiber: 0.5%

PA6 + Glass Fiber: 0.4%

PC + Glass Fiber: 0.1-0.3%

POM + Glass Fiber: 0.9-1.2%

Representative glass fiber-reinforced materials and applications of fiberglass/composites in the automotive industry:

Body components: Including body shells, hardtops, sunroofs, doors, radiator grilles, headlight reflectors, front/rear bumpers, and interior trim parts. This represents the primary application direction for fiberglass/composites in automobiles, primarily addressing the need for streamlined body designs and high-quality appearance requirements. Significant development and application potential currently exists. These components primarily utilize glass fiber-reinforced thermosetting plastics, with typical forming processes including SMC/BMC, RTM, and hand lay-up/spray-up.

Structural Components: Including front end carriers, bumper skeletons, seat frames, and floor panels. Their purpose is to enhance design freedom, multifunctionality, and structural integrity. Primarily employs high-strength materials such as SMC, GMT, and LFT.

Functional Components: Primarily engine and engine-related parts requiring high-temperature resistance and oil corrosion resistance. Examples include: engine valve covers, intake manifolds, oil pans, air filter covers, gearbox covers, air ducts, intake pipe guards, fan blades, fan shrouds, heater covers, radiator components, outlet housings, water pump impellers, and engine soundproofing panels. Primary process materials include: SMC/BMC, RTM, GMT, and glass fiber reinforced nylon.