Addressing the CNC machining requirements for typical components in the medical device industry, this study systematically analyzes the material properties, precision demands, and structural characteristics of key components such as orthopedic implants, surgical instruments, and structural parts for medical equipment. Based on this analysis, it explores the applicable scenarios for five-axis machining centers, turning-milling composite machines, and precision grinding machines. It also delves into the technical essentials of core processes like titanium alloy cutting, thin-walled part machining, and microstructure forming. By integrating industry standards with practical applications, the analysis identifies directions for process optimization and establishes a quality control system for machining medical device components using CNC machines, providing technical guidance for efficient and precise processing of medical device parts.

1. Preface

The medical device industry is an indispensable component of modern healthcare systems, with its development level directly impacting the quality and efficiency of medical services. Market demand has experienced sustained rapid growth in recent years. As the global healthcare industry advances rapidly, the medical device sector imposes increasingly stringent requirements on the precision, reliability, and biocompatibility of components. CNC machine tools, with their high precision, flexibility, and automated processing capabilities, have become core equipment for manufacturing medical device components. Particularly in high-end product areas such as orthopedic implants and minimally invasive surgical instruments, the application of CNC machine tools directly determines product performance and clinical outcomes.

The unique characteristics of medical device components—including material diversity, structural complexity, and stringent tolerance requirements—pose distinct challenges to CNC machining capabilities. For instance: Artificial hip stem surfaces require surface roughness control to Ra<0.2μm – Titanium alloy intervertebral fusion devices demand hole diameter tolerances of ±0.01mm. Orthopedic implants necessitate surface roughness control to Ra<0.4μm and porosity levels of 60%-80% to promote bone cell growth Traditional stainless steel cardiovascular stents feature wall thicknesses of just 0.12–0.15mm, while novel biodegradable magnesium alloy stents are even thinner at 0.08mm, requiring precision femtosecond laser cutting equipment with ±2μm accuracy for mesh structure fabrication. The processing requirements for such components demand machining precision far exceeding that of conventional mechanical processing.

Precision machining technology, as the foundation of medical device manufacturing, advances in tandem with the development of the industry itself. The evolution of CNC machine tools holds significant importance for driving high-quality development in medical devices and enhancing industry competitiveness. Conducting in-depth research on machine tools and processes suitable for the medical device sector provides systematic solutions for advancing precision manufacturing technologies. This work holds substantial engineering value and academic significance for improving medical device quality, accelerating domestic production, and ensuring the safety of medical equipment.

2. Current Development Status of the Medical Device Industry

(1) Industry Definition

The definition of medical devices encompasses instruments, equipment, appliances, in vitro diagnostic reagents and calibrators, materials, and other similar or related items intended for direct or indirect use in the human body, including necessary computer software. Medical devices span multiple sectors including pharmaceuticals, machinery, electronics, and materials, forming a multidisciplinary, knowledge- and capital-intensive high-tech industry. Its development level reflects a nation’s scientific and technological advancement and comprehensive strength. Product design and R&D, distribution, and brand building are key profit drivers for the industry.

(2) Industry Landscape

The United States, Japan, and Europe collectively dominate the global medical device market.

(3) Domestic Substitution

Particularly in the high-value medical consumables sector, the pace of domestic substitution is accelerating, with market share increasing annually. Concurrently, as product quality and technology advance, an increasing number of domestic medical device companies are expanding into international markets. They participate in global competition through exports or by establishing overseas branches.

3. Application of Machine Tools in Medical Device Manufacturing

In the current market environment, CNC machine tools are widely used in the medical device manufacturing industry, particularly in the processing of precision components, where they significantly enhance production efficiency and product quality. Additionally, intelligent machine tools, 3D printing machines, and multi-tasking machining centers have gained extensive application in medical device manufacturing. These new types of machine tools feature higher precision, faster processing speeds, and more intelligent control systems, better meeting the demands of medical device production.

The medical device industry is characterized by diverse product types, complex manufacturing processes, stringent quality requirements, and sterile/ultra-clean environments. This necessitates CNC machine tools with integrated capabilities for customization, flexibility, informatization, and intelligence. For instance, implantable medical devices demand exceptional surface quality and precision with zero tolerance for deviation. Simultaneously, medical devices impose stringent dimensional requirements on machine tools. Advanced imported medical device machining equipment, such as Swiss automatic lathes, multi-spindle machines, and rotary tables, features compact dimensions and integrated structures. Tool designs and coatings also require specialized engineering—compact in size while ensuring sufficient rigidity and wear resistance. The primary machine tool types applied in medical device manufacturing are as follows.

(1) Swiss-type automatic lathe

Featuring a compact size and structure, it is ideal for machining small medical device components. Characterized by high precision and efficiency, it can automatically perform multiple machining processes such as turning, drilling, and milling, making it suitable for batch production of small, complex medical device parts.

(2) Multi-Spindle Machines

Capable of simultaneously machining multiple parts to enhance production efficiency. Each spindle can be independently controlled, enabling concurrent execution of different machining operations. Ideal for processing small, similar-shaped medical device components such as screws and nuts for orthopedic implants.

(3) Rotary Table Machines

Achieve multi-surface machining through the rotation of a rotary table. These machines complete processing of multiple surfaces in a single setup, reducing clamping frequency and errors while improving precision and efficiency. They are suitable for medical device components requiring high-precision positioning across multiple surfaces, such as artificial joint spheres and acetabular cups.

(4) Five-axis machining centers

Capable of simultaneous movement and machining across five axes, offering greater flexibility and processing capability. Five-axis machining centers can produce complex curved surfaces and irregular structures, making them suitable for high-precision, complex-shaped medical device components like pacemaker housings and dental prostheses.

(5) 3D Printing Machines

3D printing rapidly and precisely creates three-dimensional models of human organs and bones based on patient medical imaging data. It produces orthopedic implants perfectly matched to patient skeletal structures, such as artificial joints (hip, knee, etc.) and spinal fusion devices. It also manufactures dental implants like dental implants, crowns, and bridges.

(6) Ultrasonic Machining Centers

In medical diagnostic equipment, the fabrication of micro-sensors requires ultrasonic machining centers, capable of achieving dimensions at the micrometer or even nanometer scale. As new materials emerge, ultrasonic machine tools can conduct machining trials on these materials to explore optimal processing techniques and parameters, providing technical support for their application in medical devices. For instance, in manufacturing ceramic components for artificial joints, ultrasonic tools enable high-precision cutting, drilling, and grinding of ceramics, preventing defects like cracks or fractures during processing.

(7) Laser Processing

Machines Primarily used in the medical device industry for high-precision contour cutting of instruments, fine tubing cutting, welding of metal and plastic materials, and micro-machining. Laser micro-machining technology creates microscopic structures like micro-pores and micro-grooves on the surfaces of implantable medical devices, promoting tissue cell growth and adhesion to enhance biocompatibility.

(8) Electrical Discharge Machining (EDM)

For special materials with high hardness and good electrical conductivity, such as tungsten alloys and cobalt-chromium alloys, EDM machines utilize the principle of electrical discharge erosion for processing. In medical device manufacturing, they are commonly used to produce electrodes for pacemakers and certain specialized surgical instruments. Capable of micro-machining, they can create minute holes, grooves, and irregular structures to meet the processing demands for micro-components in medical devices.

(9) Automated Machine Tool Production Lines

Comprising machine tools, robots, and conveyor systems, these lines enable multiple machines to work in coordination. After completing one process, workpieces automatically transfer to the next stage, minimizing intermediate waiting and setup times. Taking orthopedic implant connectors as an example, the entire manufacturing process from raw material to finished product can reduce processing cycles by over 30% through optimized sequence planning on automated lines. Most importantly, automated production lines enable continuous, uninterrupted manufacturing. For simple yet high-demand medical device components like surgical forceps and clamps, they achieve rapid processing, significantly boosting efficiency compared to traditional single-machine operations.

4. Analysis of Machining Characteristics for Typical Components

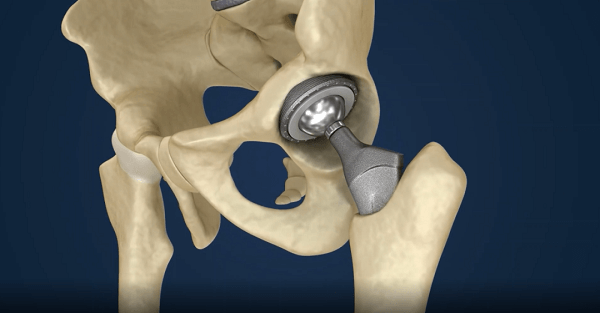

4.1 Orthopedic Implant Components

(1) Material Properties and Structural Requirements

Orthopedic implants (e.g., hip prostheses, spinal screw-rod systems) primarily utilize materials such as titanium alloys (Ti-6Al-4V), medical-grade stainless steel (316LVM), and ultra-high molecular weight polyethylene (UHMWPE). Titanium alloys offer high specific strength and excellent biocompatibility but exhibit poor machinability, generate high cutting temperatures, and cause severe tool wear. While 316LVM stainless steel has better machinability, it is prone to work hardening, which compromises surface quality. Ultra-high molecular weight polyethylene (UHMWPE) tends to undergo plastic deformation during cutting, necessitating strict control of cutting heat to prevent material melting.

Structurally, orthopedic implants often combine complex curved surfaces with porous structures. For example, the femoral condyle component of an artificial knee joint incorporates three-dimensional surfaces, intercondylar fossa grooves, and fixation holes, with surface profile tolerances ≤0.02mm and hole positional accuracy ≤0.03mm. Intervertebral fusion cages are often designed as porous biomimetic structures with pore diameters ranging from 0.3 to 1.0mm and porosity reaching 60%–80% to promote osteoblast growth.

(2) Processing Challenges for Titanium Alloy Implants

① High cutting forces and temperatures. Titanium alloys exhibit low elastic modulus, resulting in short tool-workpiece contact lengths during machining. This causes localized stress concentration, with cutting temperatures exceeding 1000°C, readily leading to tool adhesion and wear.

② High surface integrity requirements. Implant surface roughness directly impacts bone tissue integration. Traditional machining processes struggle to meet surface roughness requirements of Ra < 0.2 μm, necessitating post-processing steps like grinding and polishing.

③ Residual stress control. Cutting-induced residual stresses may cause micro-motion wear during implant service in vivo. Stress concentration must be minimized through process parameter optimization, such as reducing cutting speed and increasing feed rate.

4.2 Surgical Instrument Components

(1) Material Properties and Structural Requirements

Surgical instruments (e.g., scalpels, hemostatic forceps, endoscopic channel tubes) commonly utilize medical-grade stainless steel, titanium alloys, and medical-grade titanium alloy coatings. 440C stainless steel achieves a hardness of 58–62 HRC after heat treatment, offering excellent wear and corrosion resistance, making it suitable for cutting edges. Titanium alloys, valued for their lightweight properties and non-magnetic characteristics, are widely used in minimally invasive surgical instruments.

Structurally, surgical instruments often feature thin-walled, slender components or complex geometries with minute holes and slots. For example, the jaws of laparoscopic biopsy forceps have a thickness of only 0.5–1.0 mm and contain multiple hinge holes with diameters of 0.3–0.8 mm, requiring coaxiality ≤0.01 mm. Ultrasonic scalpel blades require micron-level serrated structures to enhance tissue cutting efficiency.

(2) Machining Challenges

① Thin-walled component deformation control. For instance, a 1.5mm-diameter endoscope channel tube with a wall thickness of only 0.15mm is prone to vibration and deformation during turning due to cutting forces. This requires high-speed (≥10,000 rpm) and shallow-depth (≤0.05mm) cutting parameters.

② Microstructure machining precision. Micron-level serrations and slot grooves demand nanometer-level positioning accuracy from machine tools, which traditional cutting processes often cannot achieve. This frequently necessitates combining with electrical discharge machining (EDM) or laser processing techniques.

③ Balance of edge sharpness and wear resistance. The radius of curvature for surgical blade edges must be ≤5μm while maintaining a hardness ≥55HRC. Conventional grinding processes often cause thermal damage to the cutting edge, necessitating low-temperature grinding or ion beam polishing techniques.

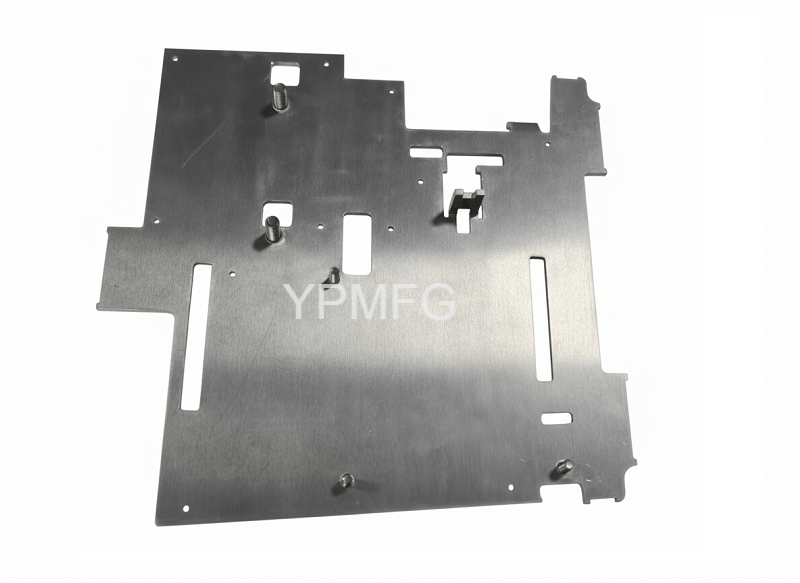

4.3 Structural Components for Medical Equipment

(1) Material Properties and Structural Requirements Structural components for medical equipment (e.g., CT scanner frames, MRI machine housings) primarily utilize aluminum alloys (6061, 7075), stainless steel, and engineering plastics (PEEK). Aluminum alloys, favored for their low weight and excellent heat dissipation, are commonly employed in large equipment frameworks. Engineering plastics, valued for their superior chemical resistance and biocompatibility, are suitable for components in contact with pharmaceutical solutions.

Structurally, these components often form large frames or enclosures with complex internal cavities. For instance, CT gantries incorporate weight-reduction holes, guide rail mounting surfaces, and cable channels—requiring guide rail mounting surface flatness ≤0.05mm/1000mm and hole system perpendicularity ≤0.02mm. MRI housings necessitate high-precision magnet mounting slots to ensure uniform magnetic fields.

(2) Machining Challenges

① Dimensional Stability Control. Aluminum alloy structural components are prone to deformation due to residual stress release. Multiple aging treatments and separating roughing and finishing operations are required to minimize distortion.

② Deep Cavity and Complex Channel Machining. For instance, the deep cavity structure of MRI housing (depth-to-diameter ratio >10) necessitates machining with long-diameter deep-hole drills or gun drills, coupled with high-pressure cooling systems for chip evacuation.

③ Multi-process coordination accuracy. Large structural components often require milling, drilling, and boring operations. High-precision fixtures and machine tools (machine tool repeat positioning accuracy ≤0.005mm) must be employed to ensure positional accuracy of all structural features.

4.4 Special Requirements

(1) Anti-Contamination Design for Cleanrooms

Medical device production must comply with cleanroom standards. Machine tool surfaces must eliminate dust accumulation dead zones, and medical-grade white oil lubricants must be used. Hydraulic system leakage rates for medical machine tools must be controlled below 0.1 mL/h, necessitating fully enclosed servo-electric drive systems, which incur higher costs.

(2) Compatibility with Medical-Grade Sterilization Processes

Implantable devices undergo ethylene oxide (EO) sterilization or gamma irradiation. This necessitates that machined parts exhibit no pores or cracks on their surfaces, as these defects could trap sterilant residues. Additionally, the machine tool’s surface treatment must withstand irradiation. This typically involves replacing conventional paint with PVD coatings such as titanium nitride (TiN) or zirconium nitride (ZrN).

5 Applicable CNC Machine Tool Types and Technical Parameters

5.1 Five-Axis Machining Centers

(1) Applicable Scenarios and Structural Features

Five-axis machining centers serve as core equipment for orthopedic implant manufacturing due to their capability to complete complex surface machining in a single setup. Typical applications include three-dimensional surface machining of hip acetabular cups and femoral stems for artificial joint prostheses, forming porous biomimetic structures for spinal fusion devices, and high-precision machining of complex cavities in surgical instruments.

Based on the relationship between rotary spindles and linear motion, five-axis machining centers primarily fall into three structural categories: dual-rotary tables, one-rotary-one-swivel, and dual-swivel heads.

(2) Key Technical Parameters

① Spindle Speed. Titanium alloy machining requires spindle speeds of 10,000–20,000 rpm while stainless steel machining requires 15,000–30,000 rpm to achieve high-speed cutting and minimize thermal damage.

② Positioning Accuracy. Linear axes: positioning accuracy ±0.005 mm, repeatability ±0.003 mm, rotary axes: positioning accuracy ±5“, repeatability ±3”.

③ Interpolation Control. Supports five-axis interpolation with predictive control functionality to ensure smooth machining of complex trajectories.

④ Cooling System. Equipped with high-pressure cooling (≥7MPa) and minimum quantity lubrication (MQL) systems to meet cutting demands for difficult-to-machine materials like titanium alloys.

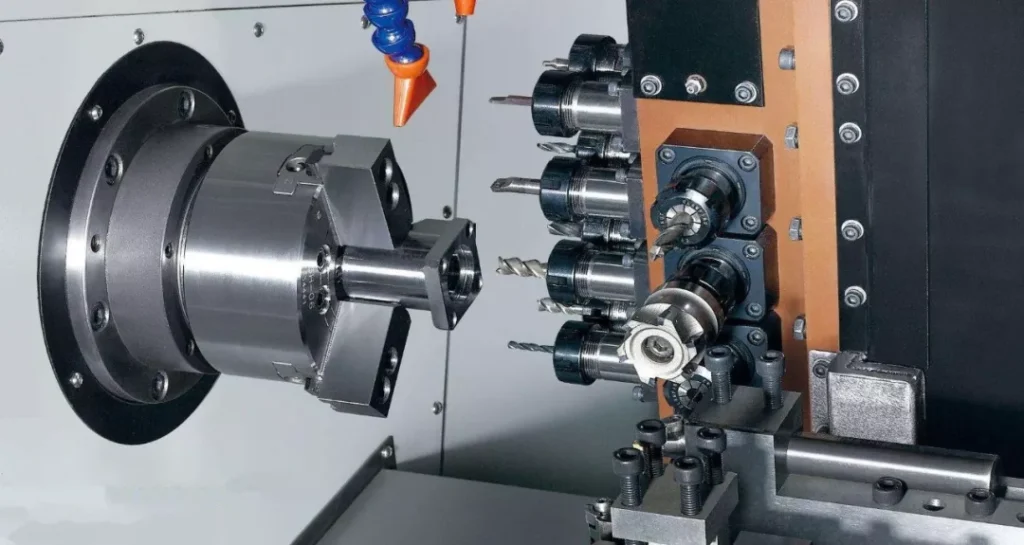

5.2 Turning-Milling Composite Machining Centers

(1) Application Scenarios and Structural Features

Turning-milling composite machining centers are suitable for full-process machining of shaft-type and disc-type medical device components. Typical applications include: integrated turning-slotting-drilling of orthopedic intramedullary nails and bone screws, threading and radial hole system machining of surgical instrument shafts, batch production of small implants (e.g., bone pins, dental implants).

These centers typically feature dual turrets and dual spindles, integrating turning, milling, and additive manufacturing (laser cladding) capabilities. They enable direct machining of complex structures on titanium alloy implant blanks, enhancing material utilization.

(2) Key Technical Parameters

① Spindle Speed

Turning spindle speed ≥ 5000 rpm milling spindle speed ≥12000 r/min to meet speed requirements for different processes.

② C-axis accuracy. Positioning accuracy ±3.6“, repeat positioning accuracy ±1.8” to ensure indexing precision for threads and radial holes.

③ Power tool holder. Equipped with servo-driven power tool heads, power ≥5kW, torque ≥30N·m, supporting high-speed milling.

④ Automation system. Integrated with loading/unloading robots and online inspection devices to enable unmanned batch production.

5.3 Precision Grinding Machines and Special-Purpose Machining Centers

(1) Applications of Precision Grinding Machines

Precision grinding machines (e.g., surface grinders, cylindrical grinders, and coordinate grinders) are used for high-precision surface machining of medical device components. Typical applications include:

Precision grinding of surgical blade edges to achieve surface roughness Ra < 0.1μm. Grinding mating surfaces of implants to ensure clearance ≤0.005mm. Planar grinding of guide surfaces on medical equipment to achieve flatness ≤0.01mm/1000mm.

Precision grinding machines typically employ linear motor drives with positioning accuracy of ±0.002mm. Combined with CBN grinding wheels, they achieve mirror-like finishes on titanium alloy surfaces, eliminating the need for subsequent polishing.

(2) Applications of Special-Purpose Machining Center

Special-purpose machining centers are indispensable for microstructure processing in medical devices, primarily including:

① Electrical Discharge Machining (EDM) centers for fabricating micro-holes (diameter ≤0.1mm) and narrow slots (width ≤0.05mm) in medical devices, such as forming the mesh structure of cardiac stents, with machining accuracy reaching ±0.003mm.

② Laser processing machines, suitable for cutting and perforating medical-grade polymer materials, such as rapid prototyping of PEEK components with a heat-affected zone ≤50μm.

③ Ultrasonic processing machines, used for machining hard and brittle materials (e.g., ceramic implants), capable of producing micro-holes below 0.1mm in diameter with a surface roughness value Ra ≤0.4μm.

5.4 Composite Special-Purpose Machines

Composite special-purpose machines demonstrate unique advantages in customized medical device production.

(1) Five-axis Interpolation + Ultrasonic Vibration Composite Machine

Positioning accuracy ±0.003mm, amplitude control within ±0.001mm. For zirconia ceramic dental prosthesis processing, surface roughness Ra ≤ 0.2μm, with processing efficiency doubled compared to traditional equipment.

(2) Femtosecond Laser + Electrolytic Composite Processing System

Features a pulse width of 350fs and adjustable electrolytic voltage from 0 to 30V. For 316LVM stainless steel microcatheter processing, it enables array machining with 100μm aperture and 150μm pitch.

6. CNC Machining Process Optimization

6.1 Titanium Alloy Component Machining

(1) Cutting Parameter Optimization

Key parameter controls for titanium alloy (Ti-6Al-4V) machining are as follows:

① Cutting Speed: Rough machining 80–120 m/min, finish machining 120–180 m/min. Excessively high speeds cause tool overheating and wear.

② Feed Rate: Rough machining 0.1–0.3 mm/r, finish machining 0.05–0.10 mm/r. Smaller feed rates reduce surface roughness values.

③ Cutting depth: Rough machining 0.5–2 mm, finish machining 0.1–0.5 mm. For thin-walled components, control cutting depth ≤0.2 mm.

④ Cooling method: Use high-pressure internal (pressure 8–10 MPa) cooling with extreme pressure cutting fluid, or minimal quantity lubrication (MQL) + low-temperature cold air (-30°C) to reduce cutting temperature and minimize titanium alloy adhesion.

(2) Tool Selection and Wear Control

① Tool Material: Prefer CBN (cubic boron nitride) or ceramic tools with hardness ≥3000 HV and excellent high-temperature resistance. Alternatively, coated carbide (e.g., TiAlN coating) with oxidation resistance ≥1100°C.

② Tool Geometric Parameters: – Rake angle: 5°–10° – Clearance angle: 10°–15° (increasing clearance angle reduces friction between tool and workpiece) – Helix angle: 30°–45° (enhances chip evacuation capability)

③ Wear monitoring: Utilize cutting force sensors (sampling frequency ≥10kHz) for real-time tool wear tracking. Automatically change tools when cutting force increases by over 20% to prevent part scrap due to tool wear.

6.2 Thin-Walled Parts and Microstructure Machining

(1) Thin-Walled Part Deformation Control Technology

Key processing points for medical device thin-walled parts (wall thickness ≤0.5mm):

① Fixture Design. Employ vacuum-suction fixtures or multi-point support fixtures with contact area ≥60% of the part’s surface area to reduce localized stress concentration. For example, when machining a 0.3mm-thick titanium alloy biopsy forceps head, using a silicone-filled fixture reduced deformation from 0.05mm to 0.01mm.

② Cutting Strategy. Employ a “layered cutting + symmetrical machining” approach with each layer ≤0.1mm depth. Prioritize symmetrical surfaces to balance cutting forces. Maintain spindle speeds ≥15,000 rpm to reduce cutting vibration via centrifugal force.

③ Auxiliary support. For slender thin-walled components (e.g., 1mm-diameter instrument shafts), ultrasonic vibration-assisted cutting is employed at 20–40kHz frequency, reducing cutting force by 30%. Amplitude is controlled at 5–10μm to prevent resonance deformation.

(2) Microstructure Machining

Processing methods for medical device microstructures (feature size ≤1mm):

① Micro-milling. Employ micro end mills with diameters of 0.1–1 mm on high-speed machining centers (spindle speed ≥ 40,000 rpm). For example, when machining 0.5 mm diameter micro-holes in medical titanium alloys, feed rates range from 100–200 mm/min, with per-tooth feed ≤ 0.005 mm/z.

② Electrical Discharge Machining (EDM). Employing CNC EDM machines with copper or tungsten steel electrodes, processing parameters include pulse width 1–10μs, pulse interval 5–20μs, and processing voltage 60–120V. Capable of producing 0.05mm narrow slots with surface roughness Ra ≤ 0.8μm.

③ Laser micro-machining. Employing femtosecond lasers (pulse width <100fs), processing accuracy reaches ±1μm with a heat-affected zone <5μm. This method is suitable for microstructural forming of PEEK materials, such as fabricating micro-pore arrays with a diameter of 0.1mm.

6.3 Surface Treatment Processes

Surface treatment of medical device components directly impacts biocompatibility and functional performance.

(1) Titanium Alloy Surfaces

Common sandblasting + acid etching (SLA) treatment creates a 10–50μm thick rough porous surface to promote bone cell adhesion or anodizing generates a 5–10μm thick TiO₂ ceramic layer to enhance wear resistance.

(2) Stainless Steel Surfaces: Electrolytic polishing (voltage 10–20 V, temperature 50–70°C) reduces surface roughness Ra from 0.4 μm to 0.1 μm while forming a passivation film that enhances corrosion resistance.

(3) Polymer Surface Plasma treatment (power 50–100 W, gas pressure 10–100 Pa) improves surface hydrophilicity to promote cell adhesion.

6.4 Process Integration and Automated Production Lines

(1) Multi-process Integrated Techniques

① Turning-milling-grinding composite process. For example, in dental implant manufacturing, an integrated “turning-thread milling-surface grinding” process completes all steps on a single machine, reducing production cycle time from 20 min/piece in traditional methods to 8 min/piece.

② Additive Manufacturing + Subtractive Manufacturing Composite Process. For complex porous implants, 3D-printed blanks undergo precision milling and grinding on five-axis machines, enhancing material utilization.

(2) Automated Production Line Design

① Flexible Manufacturing Cell (FMC). For example, a surgical instrument production line comprises 2 five-axis machining centers + 1 turning-milling composite machine + robotic loading/unloading system. Coordinated by an MES system, it enables rapid changeovers for multi-variety, small-batch production with changeover time ≤30 minutes.

② Intelligent Inspection Unit. Integrates vision inspection (accuracy ±0.01mm) and laser vibrometers to monitor part deformation and tool wear in real time during machining. Automatically halts operation and triggers alarms upon detecting anomalies.

7. Challenges Facing the Medical Device Industry

7.1 Technical Bottlenecks

(1) Insufficient Coordination in New Material

Processing Techniques The machining of biodegradable magnesium alloys (e.g., AZ91D) faces the challenge of coordinated control between “cutting” and “corrosion.” Experiments indicate that when using emulsion cutting fluids, magnesium ions react with fatty acids in the fluid to form saponification products. This causes the cutting fluid to deteriorate while accelerating intergranular corrosion in the magnesium alloy. Existing machine tool cooling systems are not designed for magnesium alloy characteristics. One company experienced pitting corrosion in 15% of magnesium alloy bone pins processed with traditional water-based cutting fluids after sterilization, attributed to residual cutting fluid.

The machining of ultra-high molecular weight polyethylene artificial joints faces a “machining-wear” contradiction. Chip entanglement frequently occurs during cutting. Traditional machine tool parameters (cutting speed 100 m/min, feed rate 0.1 mm/r) cause micro-cracks on the surface, which accelerate wear during joint movement. Optimizing cutting parameters requires machine tools with higher spindle speeds (over 20,000 rpm) and sufficient rigidity.

(2) Lack of Precision Retention in Micro/Nano Machining

At micro/nano machining scales (<100μm), factors like thermal deformation and vibration significantly amplify their impact on precision. Swiss-imported machine tools achieve temperature fluctuations ≤0.5℃ through liquid-cooled spindles and control thermal deformation within 0.3μm via thermally symmetric structural design—features domestic machines struggle to match. Micro/nano machining also faces process failures due to scale effects: when tool diameters <0.1mm, cutting force scale effects render traditional cutting parameters ineffective.

7.2 Industrial Ecosystem Dimension

(1) Cross-Industry Technology Mismatch

Specialized barriers exist between medical device companies and machine tool manufacturers: medical device firms prioritize medical characteristics like biocompatibility and sterilization adaptability, while machine tool makers excel in manufacturing metrics such as mechanical precision and processing efficiency. Their technical languages are fundamentally incompatible. For instance, an orthopedic implant manufacturer required a titanium alloy surface roughness value Ra < 0.2μm after machining but failed to specify the impact of surface texture (e.g., groove orientation) on bone cell adhesion. Consequently, while surfaces machined using conventional processes met dimensional tolerances, cell adhesion tests revealed lower-than-expected bone cell attachment rates.

This disconnect also manifests in differing standards systems. Medical devices adhere to the ISO 13485 quality management system, which mandates traceable process parameter records for machining equipment. Conversely, machine tool industry standards (e.g., ISO 230 series) emphasize precision measurement, lacking alignment with medical standards.

(2) Economic Contradictions in Small-Batch Production

The small-batch production (typically <50 units) of customized medical devices sharply conflicts with the high investment costs of machine tools. Imported five-axis machining centers are expensive. Calculated at 8-hour shifts with 60% utilization, equipment depreciation constitutes an excessive proportion of per-unit processing costs. Small batches result in low machine tool utilization rates.

Small-batch production also raises economic challenges for process validation. Medical device registration requires at least three batches of full-scale inspection data. However, switching batches in small-batch production necessitates re-calibration of the machine tool, with each calibration incurring significant costs that severely impact corporate profitability.

(3) Special Requirements for GMP Certification

GMP certification serves as the entry threshold for medical device companies into the pharmaceutical industry and is a prerequisite for product market launch. Major global economies maintain independent GMP standards. GMP certification imposes stringent clean design requirements on machine tools: Surface specifications mandate no right-angle corners with minimum radius of curvature ≥3mm to prevent dust accumulation. Lubrication systems must employ fully enclosed designs with leakage rates ≤0.1mL/h. Validation protocols require submission of cleaning validation plans demonstrating residual contamination control below 10ppm. This necessitates that machine tools used for medical device manufacturing adhere to GMP requirements from the design phase, incurring additional costs through the implementation of dead-angle-free welding and food-grade coatings to ensure successful certification.

8. Trends in the Medical Device Industry

8.1 High-Precision and Intelligent Machining

(1) Nanoscale Machining Technology

Machine tool spindle technology trends:

① Air-bearing spindles utilize compressed air to form micron-level air films (1–3μm thick), achieving radial runout ≤0.05μm. Suitable for nanoscale mirror-finish machining—e.g., LED lens mold polishing—with speeds up to 160,000 rpm.

② Magnetic levitation spindles: Contactless support with critical speeds up to 300,000 rpm, already employed in nanometer-level grinding of semiconductor wafers.

③ Hybrid ceramic bearing spindle: Combines silicon nitride ceramic balls with a steel inner ring, operating at 120,000 rpm. Aligning with future spindle technology applications, this enables development of ultra-high-speed machining centers with spindle speeds ≥100,000 rpm. This facilitates nanoscale texture processing on implant surfaces, promoting directed bone cell growth.

(2) Intelligent Process Optimization

Establish cutting parameter prediction models based on machine learning algorithms. AI-integrated adaptive machining systems dynamically adjust parameters in real time to achieve optimal cutting speeds and extend tool life.

(3) Digital Twin Technology

Construct virtual models of machine tools, cutting tools, and workpieces to simulate deformation and stress distribution during machining. This enables pre-optimization of process parameters and allows virtual rehearsal of machining processes.

8.2 Green Manufacturing and Efficient Processing

(1) Dry Cutting and Minimal Quantity Lubrication Promote MQL combined with low-temperature air cooling technology to eliminate coolant discharge during titanium alloy machining, reducing coolant costs.

(2) Additive and Subtractive Hybrid Manufacturing Integrate 3D printing with five-axis milling to achieve near-net-shape forming of complex implants, minimizing material waste.

(3) Automated Production Lines Deploy collaborative robots and AGV logistics systems to build smart factories and enhance production efficiency.

8.3 Integration of Micro/Nano Machining and Biomanufacturing

(1) Integrated Micro/Nano Structure Machining Develop five-axis + femtosecond laser hybrid machines to achieve single-step formation of multi-level micro/nano structures (micron-scale grooves + nanoscale pores) on implant surfaces, improving osseointegration efficiency.

(2) Bio-Manufacturing Processes Combine CNC machining with bio-3D printing, such as printing hydroxyapatite coatings on titanium alloy implant surfaces with bond strengths ≥50MPa.

(3) Flexible Electronics Manufacturing Utilize CNC micro-machining to fabricate flexible circuits for implantable medical devices with line width precision ≤10μm, meeting biocompatibility requirements.

(4) Bionic Surface Processing Technology Bionic surface processing mimics the microstructure of biological tissues to enhance the biocompatibility of medical devices.

9. Conclusion

This paper systematically analyzes CNC machining technologies for typical medical device components, drawing the following conclusions.

1) Component characteristics determine machine tool selection. Titanium alloy implants require five-axis machining + ultrasonic vibration processing, thin-walled surgical instruments rely on high-speed turning-milling composite processing, microstructure parts necessitate EDM or laser processing.

2) Process parameter optimization is critical. Titanium alloy cutting speed should be controlled at 80–180 m/min with high-pressure cooling, thin-walled parts employ high-speed, shallow-cut strategies combined with flexible fixtures, Surface treatments must align with biofunctional requirements.

3) Quality control requires end-to-end management. Based on ISO 13485 standards, online inspection and traceability systems ensure machining precision and safety.

4) Technology integration is the developmental direction. The convergence of additive/subtractive hybrid manufacturing, intelligent process optimization, and micro/nano fabrication will propel medical device processing toward high precision, high efficiency, and sustainability.

5) Intelligent equipment configuration and enhanced smart interaction are essential for the intelligent transformation and upgrading of the medical device manufacturing industry.

Currently, CNC machining of typical medical device components has evolved from single-technology applications to multidisciplinary integration. Technologies like five-axis simultaneous machining and femtosecond lasers have significantly improved machining precision and efficiency. However, challenges remain, including reliance on imported high-end CNC systems and insufficient coordination between new materials and processes. Moving forward, intelligence, sustainability, and China-based production will become the core directions for industry development.